12. Soft robotics¶

Soft Robotics is the specific subfield of robotics dealing with constructing robots from highly compliant materials, similar to those found in living organisms.[1] Soft robotics draws heavily from the way in which living organisms move and adapt to their surroundings. In contrast to robots built from rigid materials, soft robots allow for increased flexibility and adaptability for accomplishing tasks, as well as improved safety when working around humans.[2] Also, they try with this to emulete the nature: Bio-mimicry.This principle has been leveraged in the creation of pressure systems for soft robotics. These systems are composed of soft resins and contain multiple fluid sacs with semi-permeable membranes. The semi-permeability allows for fluid transport that then leads to pressure generation. This combination of fluid transport and pressure generation then leads to shape and volume change.[3] Another biologically inherent shape changing mechanism is that of hygroscopic shape change. In this mechanism, plant cells react to changes in humidity. When the surrounding atmosphere has a high humidity, the plant cells swell, but when the surrounding atmosphere has a low humidity, the plant cells shrink. This volume change has been observed in pollen grains[5] and pine cone scales.[3](From Wikipedia, the free encyclopedia)

This week we recieved the introduction for Soft Robotics by Lily Chambers and Adriana Cabrera, a new world is open for us now. And the assigment for this week is:

- Inflatables

- Molding & Casting

- Actuators

Useful links¶

About Soft Robotic¶

How to make a Soft Robotic¶

First test - Inflatabel¶

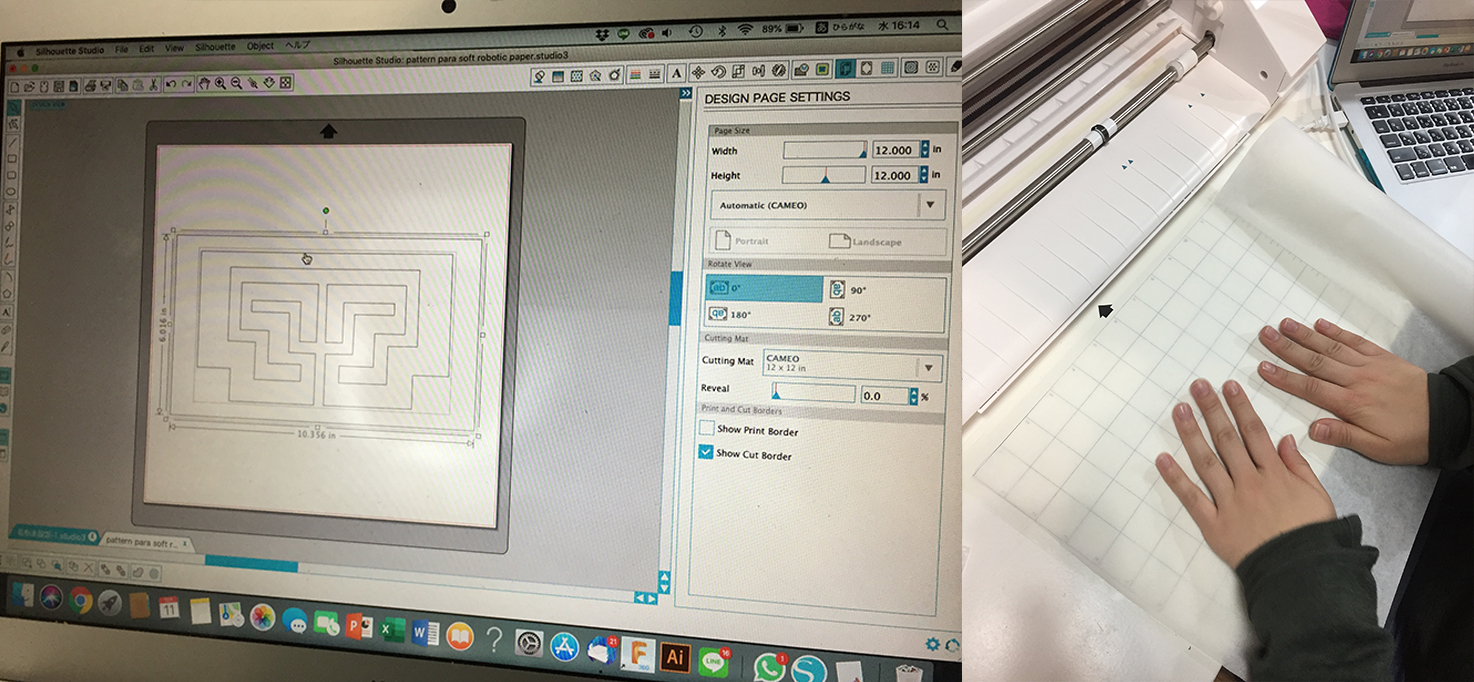

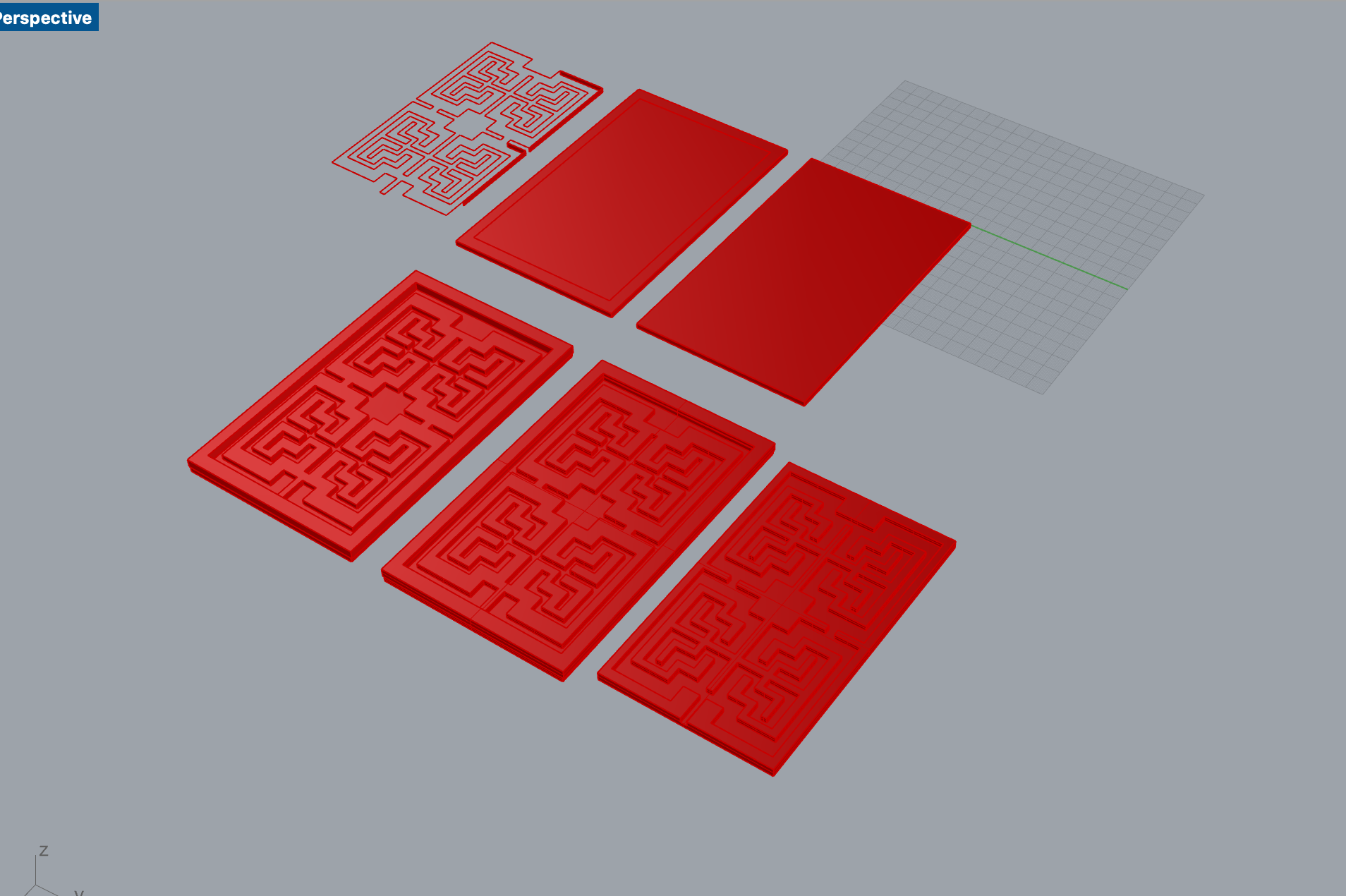

Mold for Soft Robotic - Silicone and bioplastic test¶

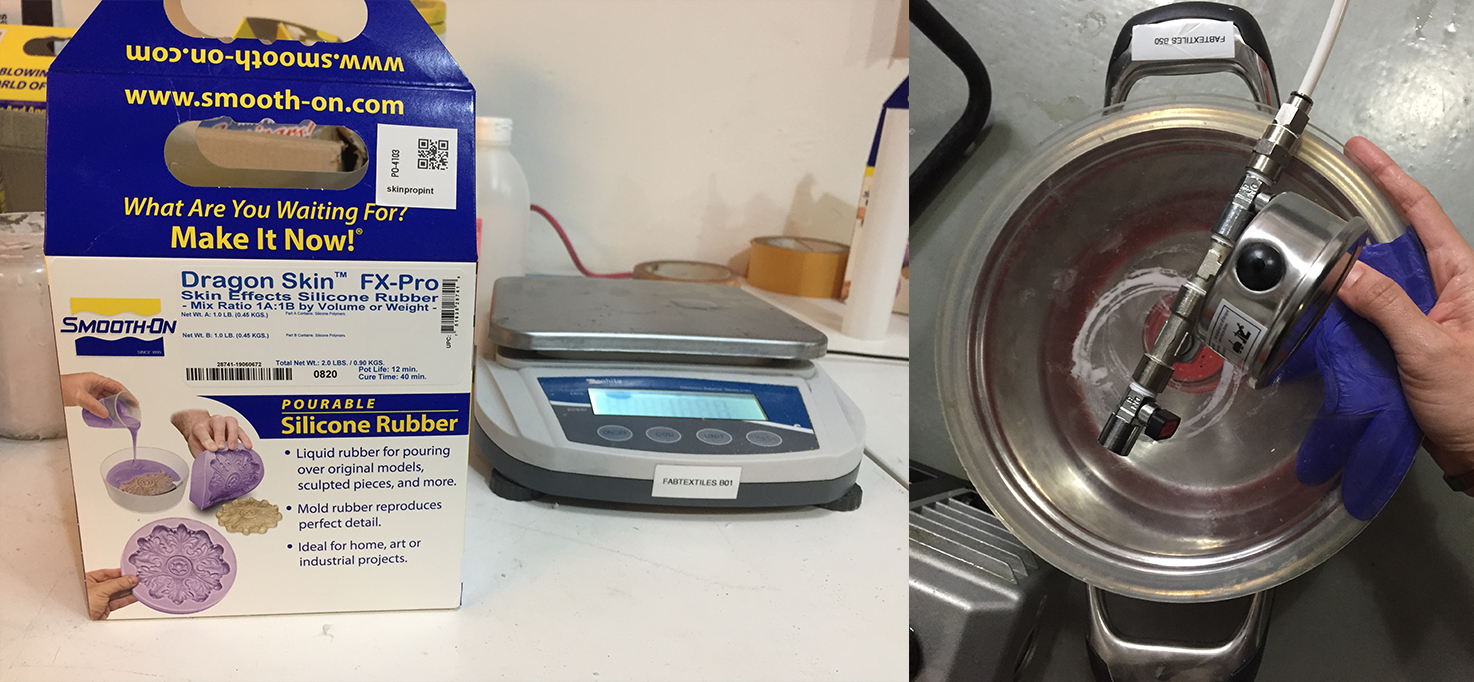

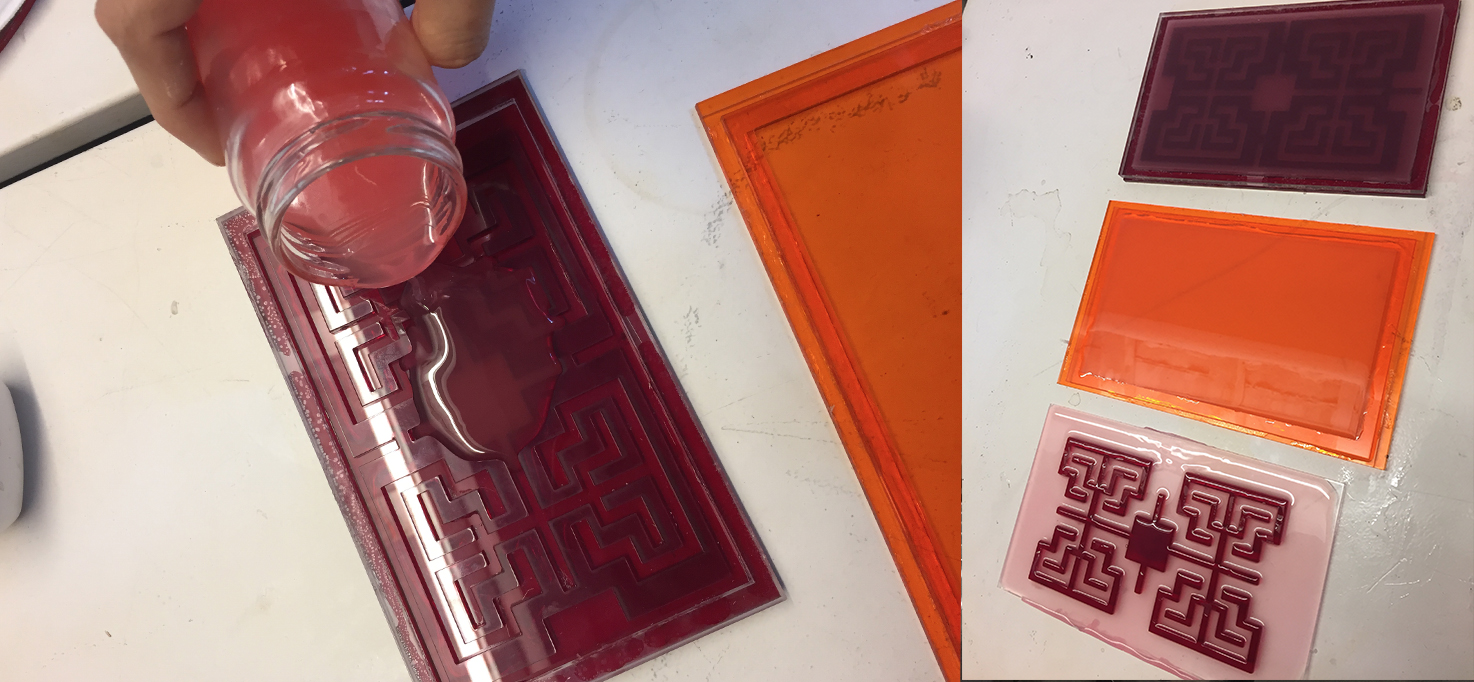

Silicone process¶

For this process we need to use Dragon Skin 10 AF Pint that is an anti-fungal silicone rubber that resists the growth of fungi. Parts A and B are mixed 1:1 by weight or volume, pot life is about 20 minutes and rubber cures in about 5 hour. We need to to the top part and the base part of our design, so is better if we make both at the same time. Then paste the two molds with a new mix 1:1, but this time 5 or 6 gr. We will put it inside and in the borders for be sure there is any hole that let the air scape. Here more information about Dragon Skin

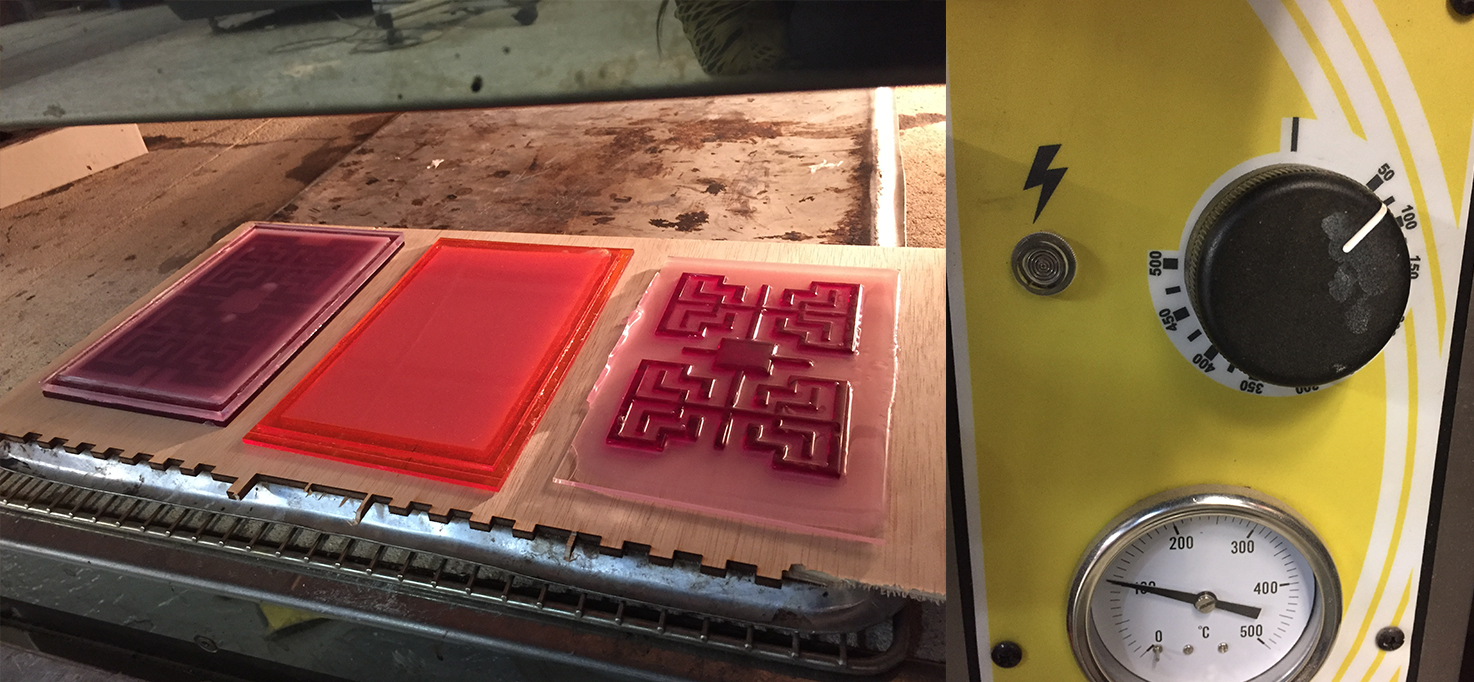

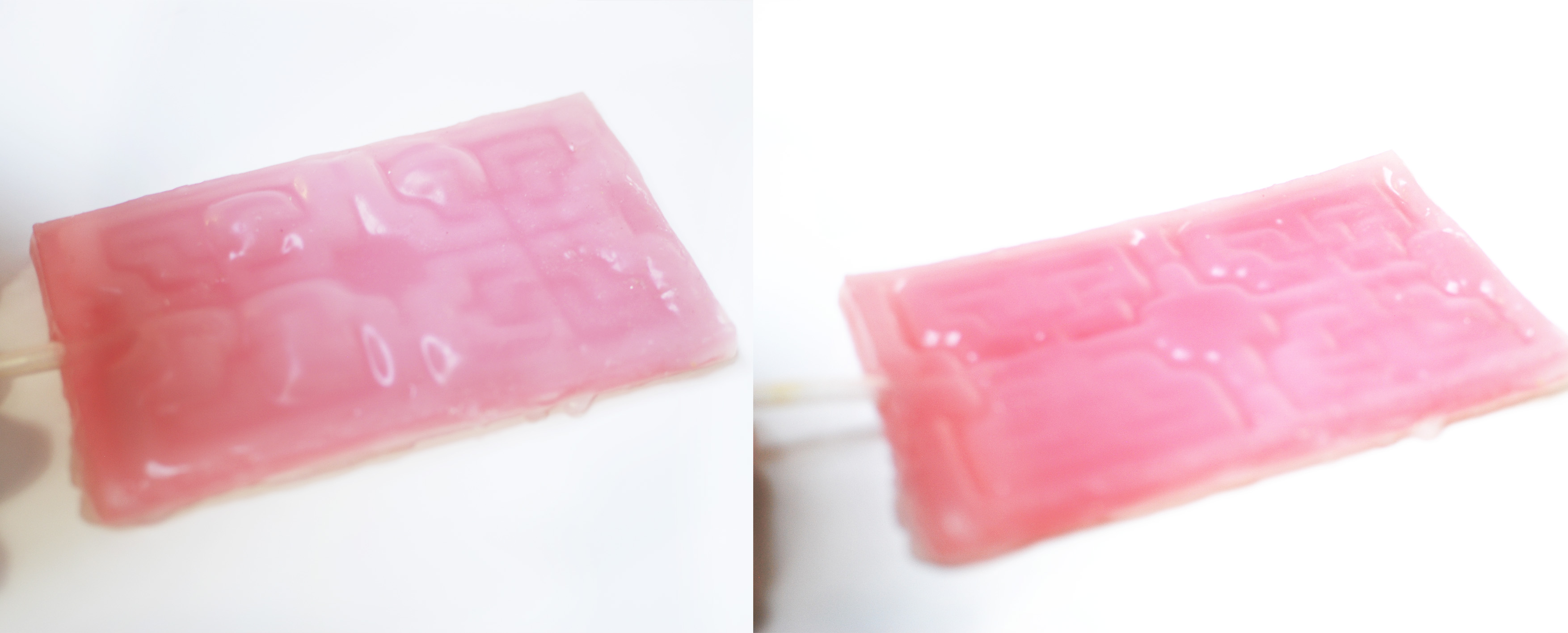

Biomaterial process¶

For the prototype with the biomaterial I chose to work with gelatine because have a fast dry. I had to do it twice because I failed in the first one when I tried to put my two molds together (base and top). What got wrong? When I tried to paste them, the gelatine dry to fast so only got stick the borders but not the inside design. So I dissolved it again and this time put the gelatine in the top mold. And it works.

First test¶

Second test¶

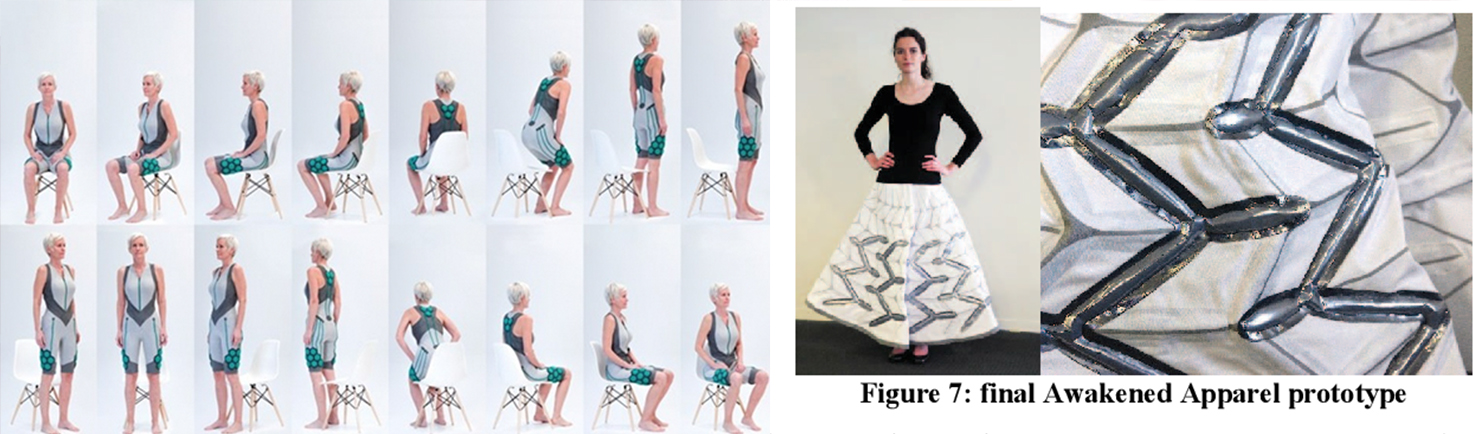

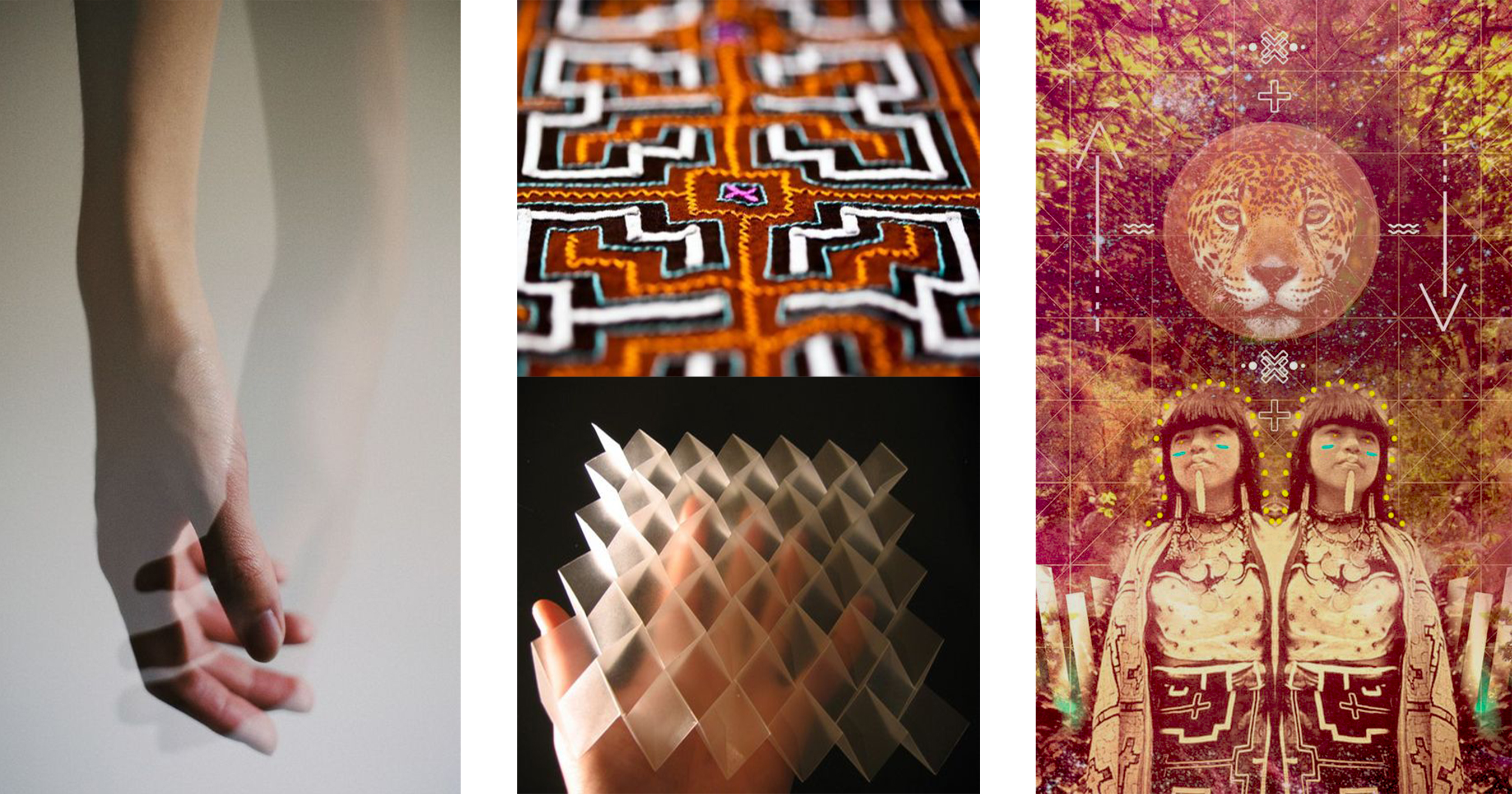

Ideas for work with soft robotics in fashion¶