9. Textile as scaffold¶

Wood Textile¶

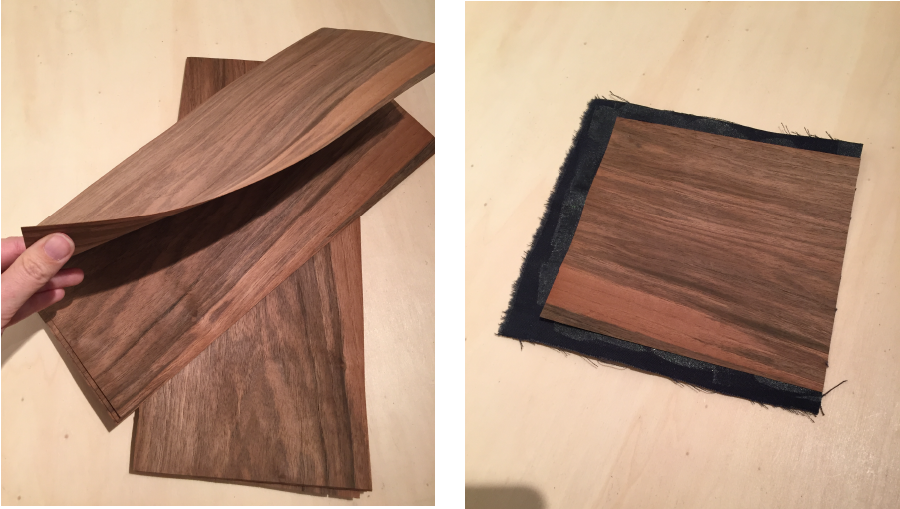

I started this week trying to reproduce Textile Wood. We see in the lecture she cut all her wood material with lasercut and rearrange it and glue on the fabric each pieces by hand, like a puzzle. First I used very fine piece of wood, less than 1mm thick, I saved form the bin a long time ago. I glue the all piece of wood onto fabric. We can see the wood well not stored the right way, it's not perfectly plane.

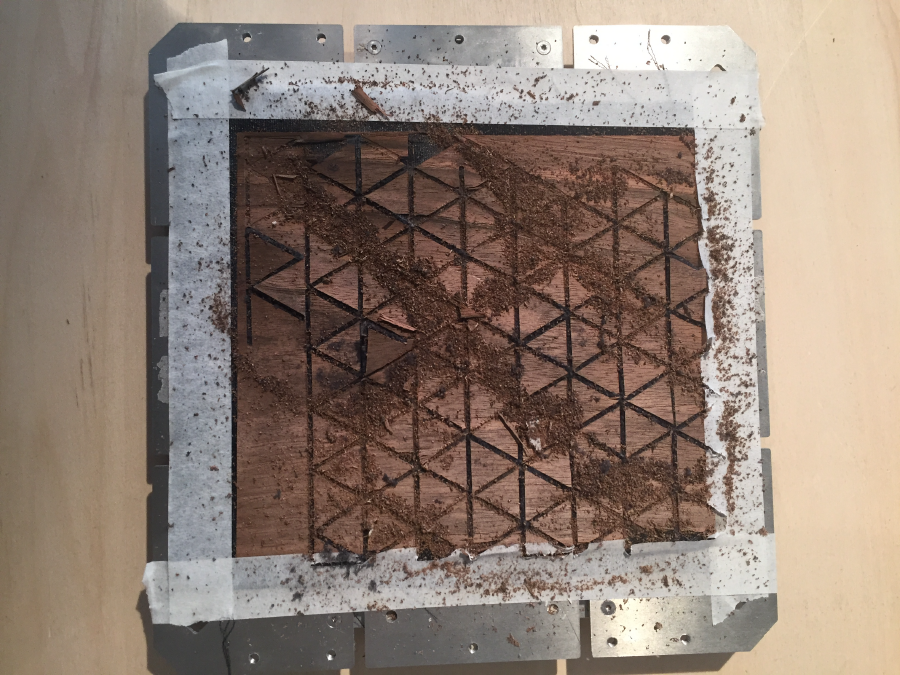

I launch a triangle pattern done in Illustrator, export in .dfx and edit a gcode in Voxeliser software.

I used a 2mm CNC flute. We can see in the next picture that the Zmorph was not calibrated, the 2 first triangles the piece of wood are barely cut and the 2 other triangles, the cut touch also the fabrics.

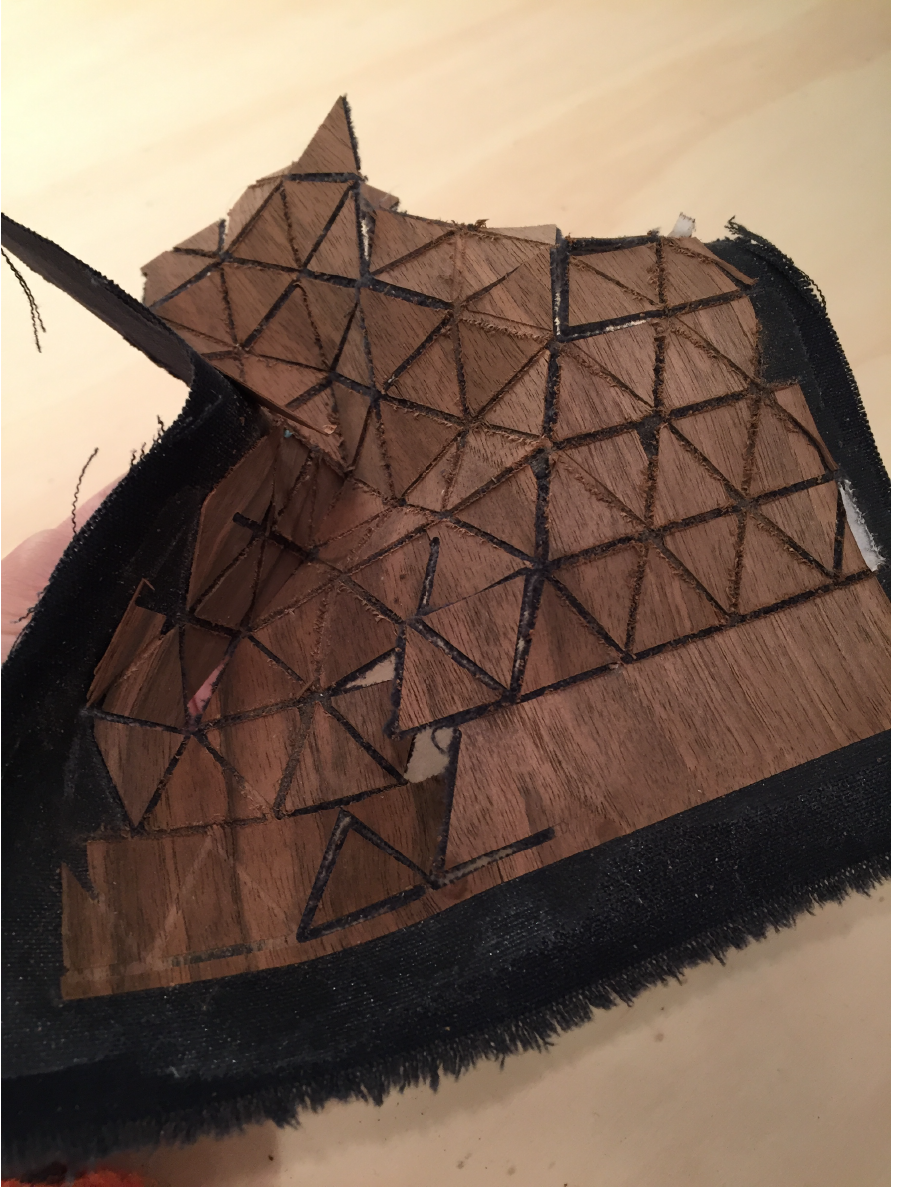

After calibration, i launch the full piece. I tape, with double face adhesive, the fabric side onto my cnc board, but the wood deformation was too strong and I couldn't get a regular cut. Also the edge of triangle shapes are really sharpy.

The result is really not up to expectations. Hole in the fabric, and sharpy edges wood.

Leather molding - Cuir Boulli¶

I saw Anastasia demonstration during the bootcamp in Iceland few month ago. She was using a DIY vacuum machine. I love the idea to make my own, and so my lab would have a new machine.

Building a Vacuum Machine¶

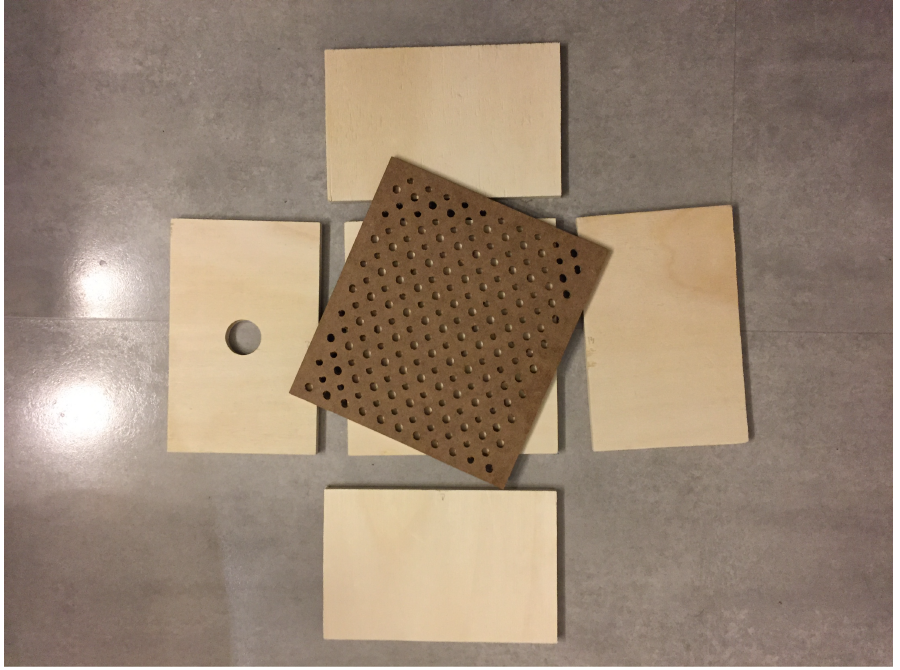

I choose to make a small one, so it would fit 3D milling the Zmorph could make. Dimensions are 20x22cm and 13,5mm height. I cut all piece in left over piece of plywood 10mm, I did the cercle with the CNC Zmorph to be at the precise size, 3mm diameter, of tube of the vacuum I have for cleaning the lab. I made a hole pattern with the CNC in chipboard 6mm.

I glue all the part to assemble it in a box, except the top. I prevent any lick by adding more glue when it schrink while dry in each join. Then I glue the perforated top.

First try, the vacuum machine works very well, we can see how the fabric stick to the box.

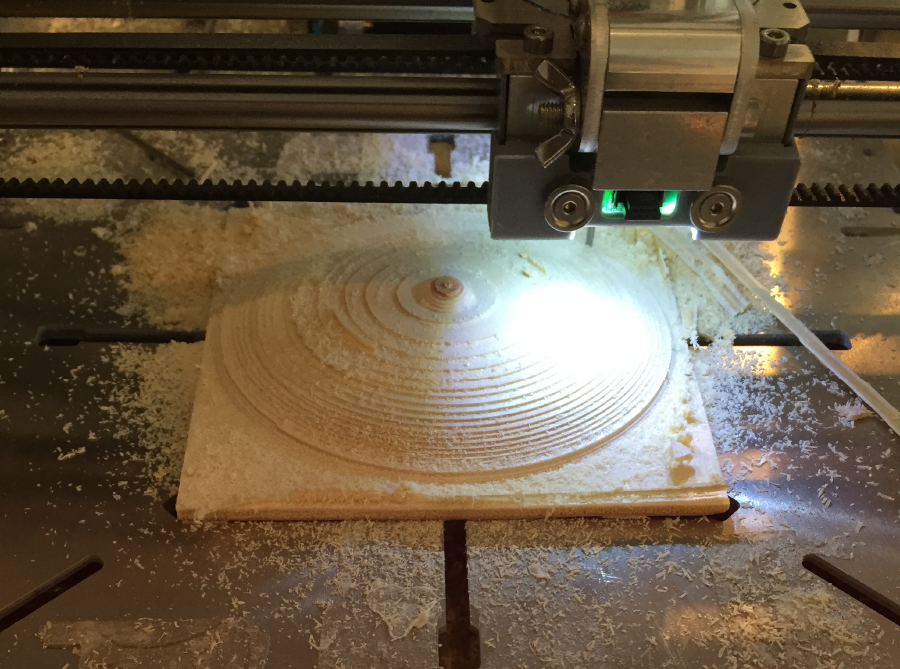

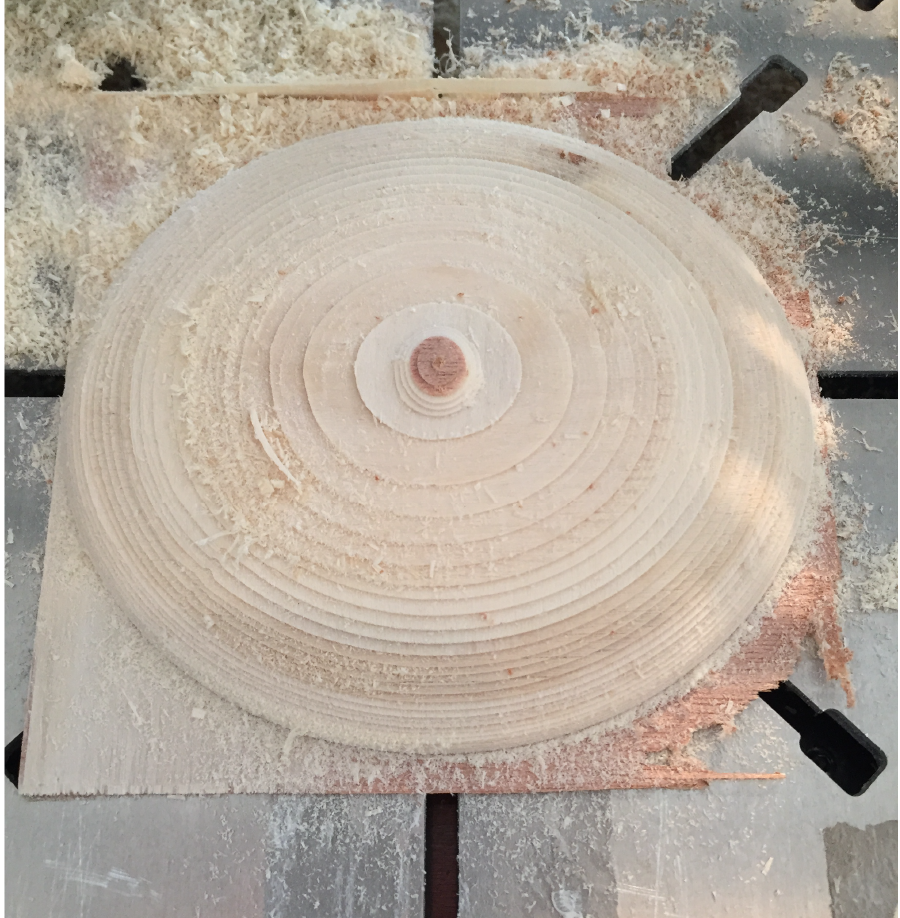

3D CNC milling on ZMorph¶

I made the 3D model using Rhino.

** Miss the screenshot form Voxelizer stl to gcode, parameters

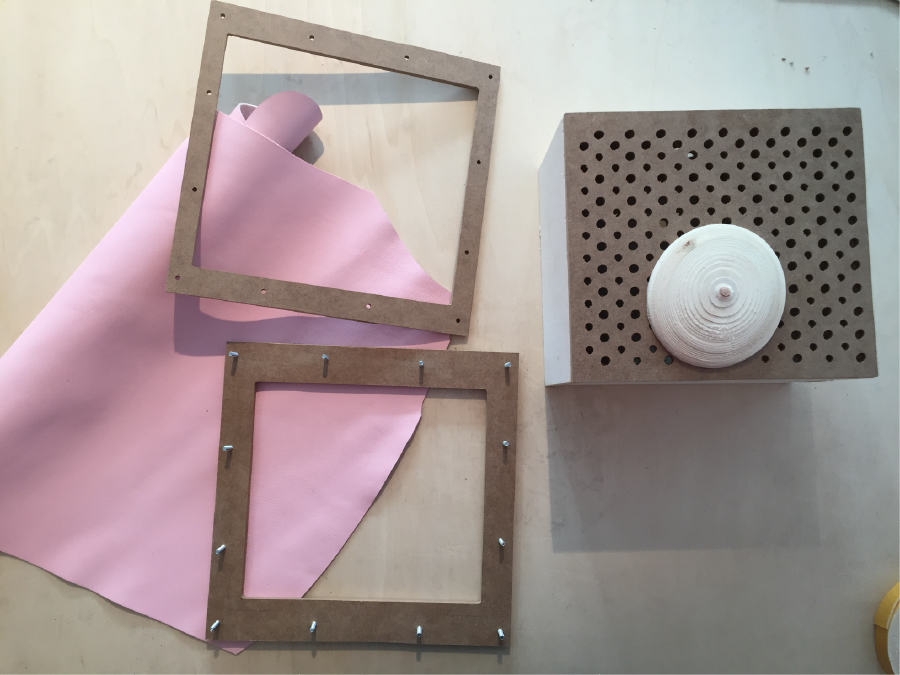

Making a frame to hold the leather¶

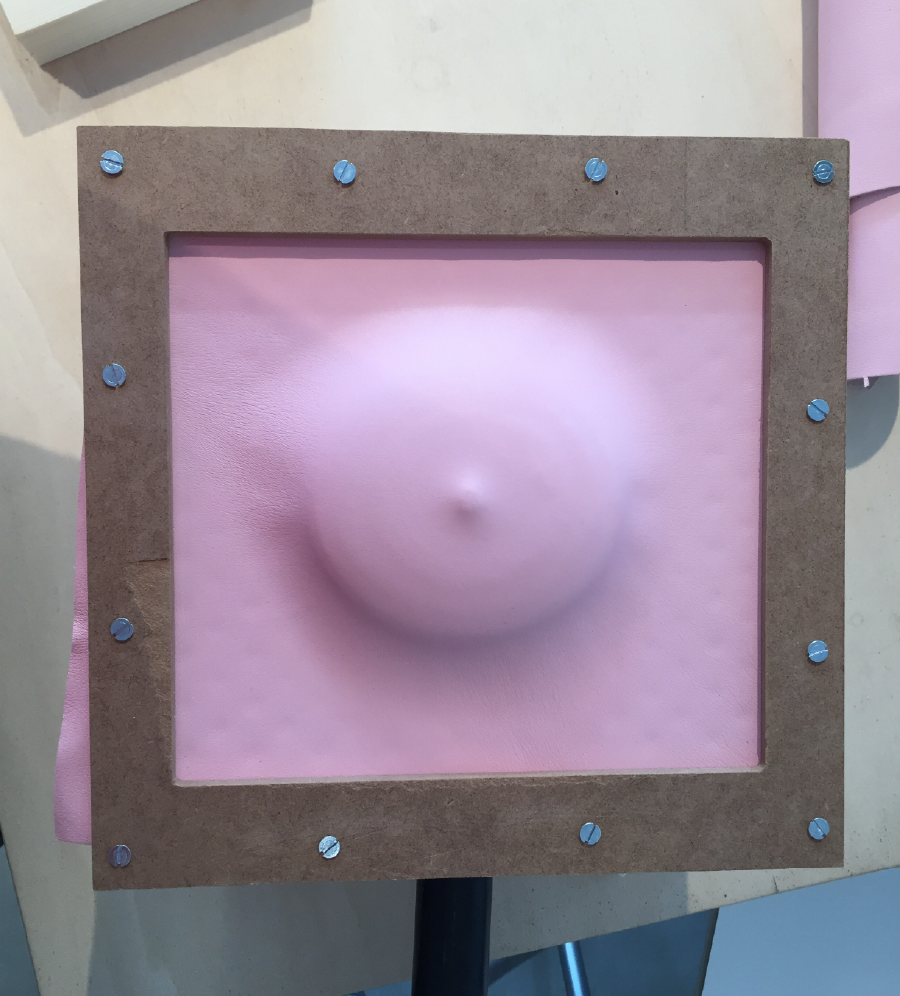

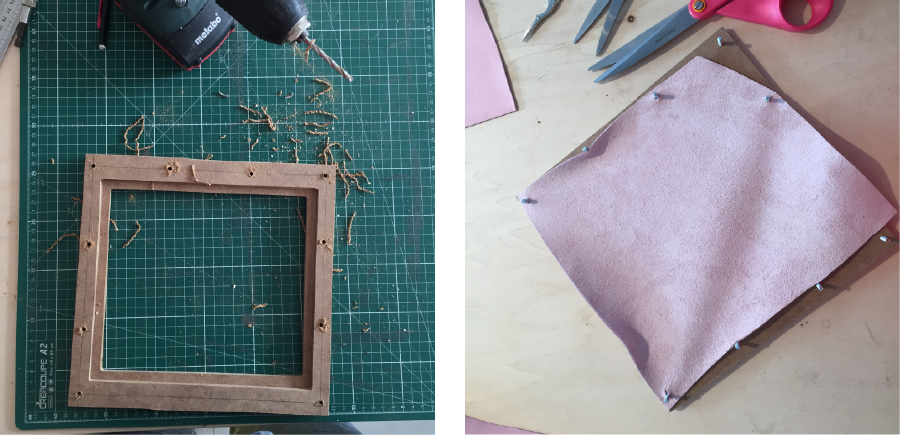

I make a frame with two part, one fit prefectly the outside of the vacuum box, it's the down side part. This other part come on top of the box so the leather is pressed against the perforated top of the box. When the frame is assemble with the box, there is no lick of air the succion is optimum. I seal the frame with screw and "écrou à ailette".

Looks to work pretty well. Ready to be "boulli"