6. Biofabricating¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

Assignment¶

Produce at least two grown and/or two crafted materials:

Grown materials - Grow a material, experimenting with at least 2 different recipes and variations thereof. Document the process, ingredients, changes, describe and compare the materials √

Craft materials - Craft a material, experimenting with at least 2 different recipes and variations thereof. Document the process, ingredients, changes, describe and compare the materials √

Document your recipes, the ingredients and process and if there have been changes, document your unexpected discoveries √

Name your materials, classify them by typology and display them in a systematic order of samples √

EXTRA POINT Submit some of your swatches to the analog material library of your lab. (20cm *20cm aprox)

How will it be evaluated¶

- Master techniques for grown and crafted materials √

- Documentation : Anyone can go through the process and use the recipes √

- Final outcome: create a material chart√

- Originality - Aesthetics : Has the design been thought through and elaborated√

Files and Links¶

Workflow¶

- Research about BioMaterials

- Crafted Materials

- Grow Materials

- Material Chart

Research about BioMaterials¶

Since I follow BioAcademy in 2016 I started to really LOVE all related to Bio Technology. Bio Materials are super interesting and at this moment, they are huge trend. My fascination around these materials is not related directly with the trend but related at technology and I like to think biomaterials as a formula. When you understand DNA as a computational program the possibilities grow exponentially because now humans are able to control nature more precisely. And Bio Materials normally are the result of a DNA program and chemical reactions.

BioMateriales Cecilia

I found super important the charter that Cecilia showed in class to defined and separated Bio Materials in three main groups because until that moment the context of BioMaterials in Fabricademy where not completely clear.

Bio-based, Bio-degradable and Bio-compostable.

Contextualizing in Fabricademy:

GrowMaterials

Are the materials produced by a living or non-living organisms (for example synthetic minimal cells) that are the result of organic chemical reactions. Mentioned materials could be Bio-based, Bio-degradable and/or Bio-compostable.

CraftedMaterials

Are the materials mixed manually by humans mixing organic and/or inorganic chemicals produce in a stable material for fashion context.

Organisms selection¶

I have select Ganoderma lucidum and Saccharomyces cerevisiae to experiment on this assignment.

Ganoderma lucidum¶

A lot of biomaterial enthusiasts are referring to Mycelium as a material but forgetting about the specie that produce the mycelium and actually that mycelium is a part of the specie.

I will use Ganoderma lucidum provided by local vendors in Ecuador. Sadly I do not have precise information about this particular specie. I will do Fabricademy experimentation first and in some month I will do a DNA sequence test of the strain used.

Because I am doing a project relate with cacao I will use two subtracts. The pure Cacao and Andre’s subtract.

Composition

carbohydrates, protein, nucleic acid, triterpenoidl, steroid, sterols, fatty acids, beta, vitamins, minerals (potassium, magnesium, calcium, sodium manganese, iron, zinc)

https://pdfs.semanticscholar.org/c3a2/7b31a4d1579baa485442aaf782f6dad61cf3.pdf

https://study.com/academy/lesson/what-is-mycelium-definition-function.html

https://exoprotein.com/blogs/blog/what-is-chitin

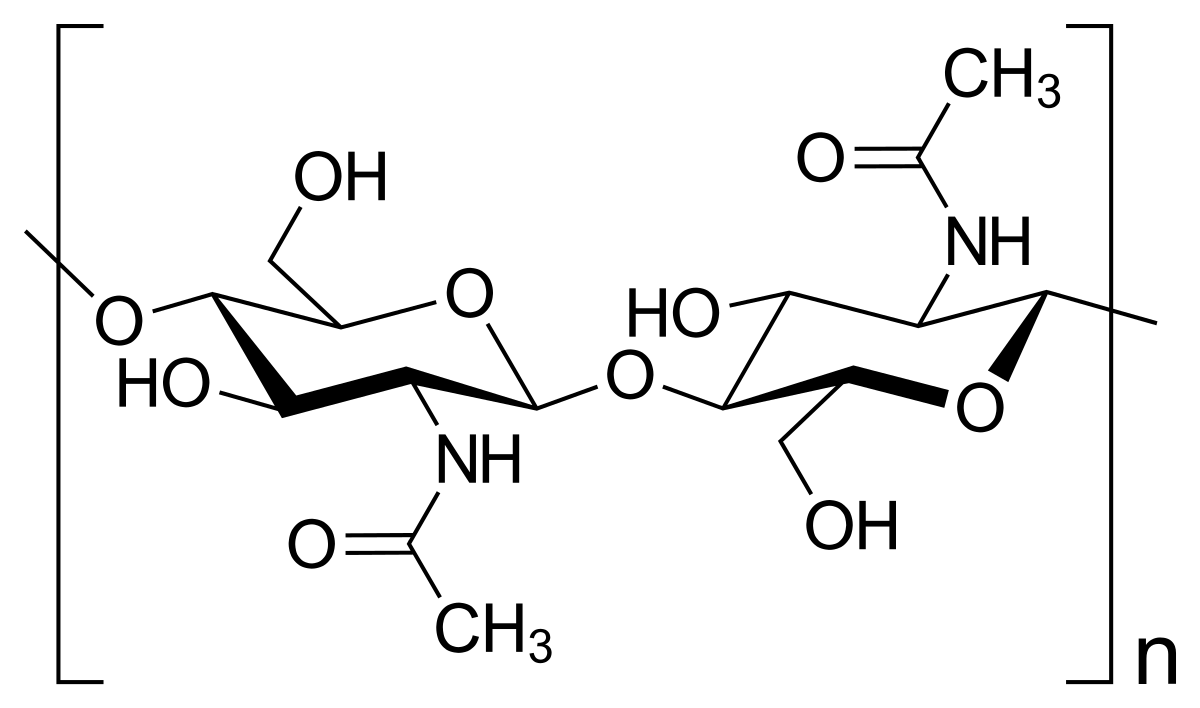

The target protein there will be chitin

Saccharomyces cerevisiae¶

It is the common yeast for breath. I will experiment with this organism to create Foam made with Gelatin.

Crafted Materials¶

I do this assignment with David Arias so probably you will find similarities on our documentation.

Yucca Flex¶

For our first crafted material we select Yucca Starch to work with:

Yucca Starch: 60 gr

Water: 60 gr

Glycerin: 100 gr

Heat a cooking pot until 60 Celsius before to put the material inside. Then put everything inside, heat until 80 Celsius and mix to obtain a uniform mix. This process helps chemical chains to connect in a new way.

Unfortunately the material that we obtain was not as good as we were imagining. But this was the first try. Too sticky

Gelatine Foam¶

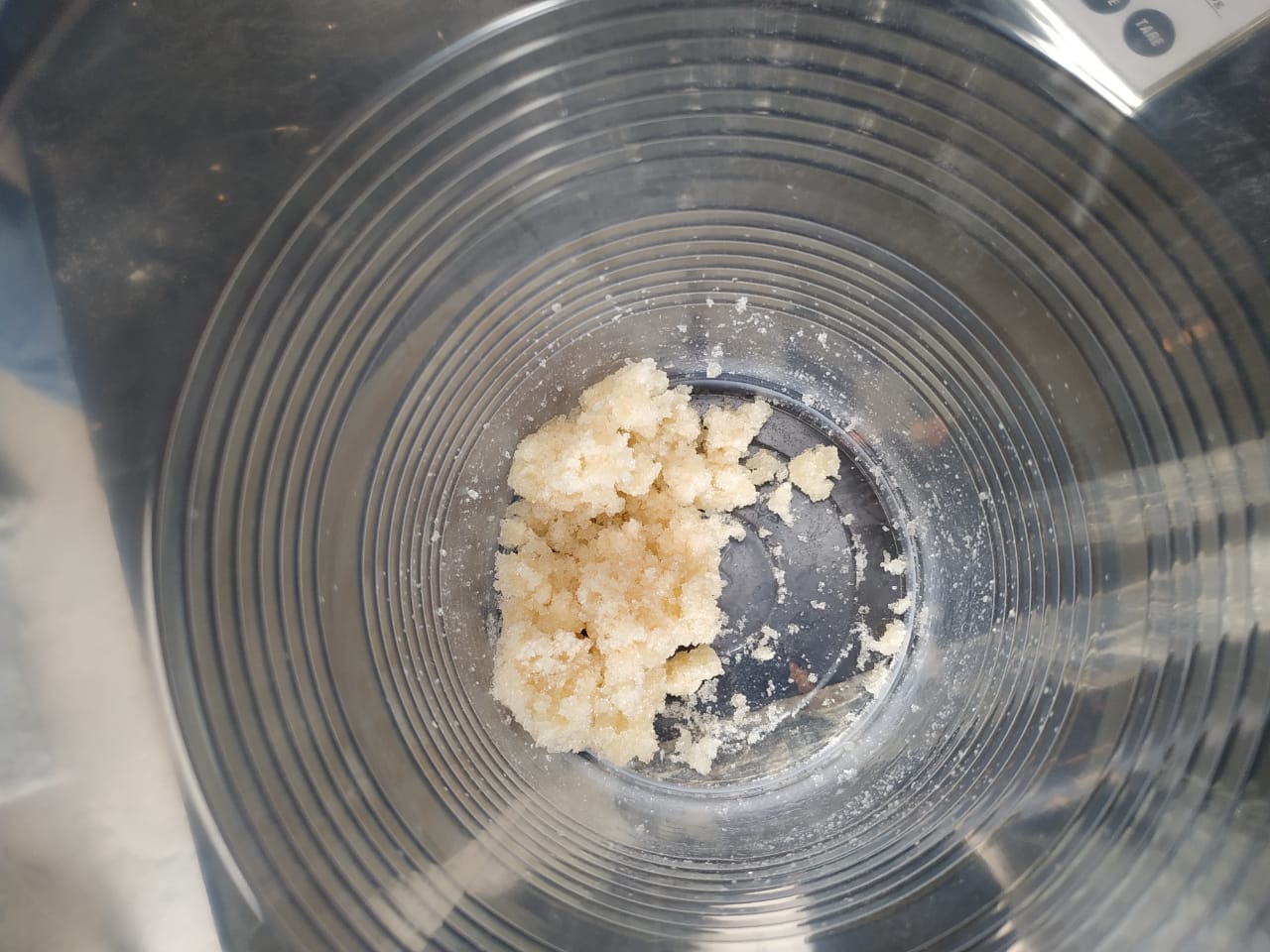

In the second round I decide to use a establish Foam recipe provided by Crafted Materials

Gelatin: 60 gr

Water: 150 gr

Glycerin: 0 gr

Soap: 20 gr

I stared to try with stand position but I got some errors that I haven’t understand at the beginning so I changed to fight position.

First dissolve Gelatin with Water and heat as you are doing a common gelatin. Then add the soup in the pot and keep mixing.

I have mixed it for 3 min and finally pour in a silicon rubber that I used before in the lab for other proposes.

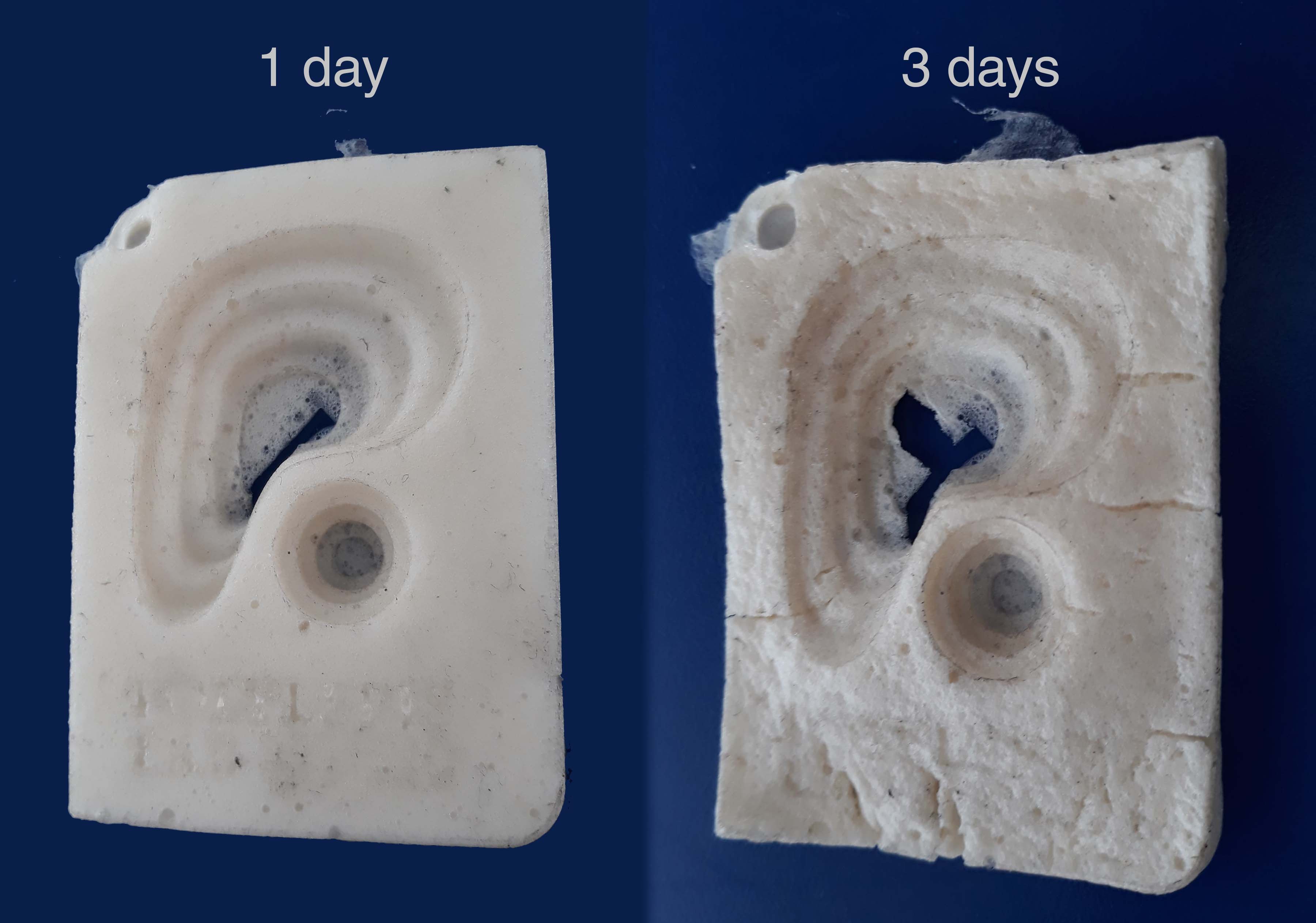

After 25 hours I have unmold my piece and it was a nice material flexible and super stable.

I have put this material in Bio Shake incubator (that you can find in Open source hardware assignment) to accelerate drying process. Three days after the foam was not flexible but hard. It is amazing how different it was before. Probably it can be used for packaging in the future.

Grow Materials¶

For Grow Materials David come up with the idea of using yeast and I have the idea of experiment with fungus.

Gelatine Yeast¶

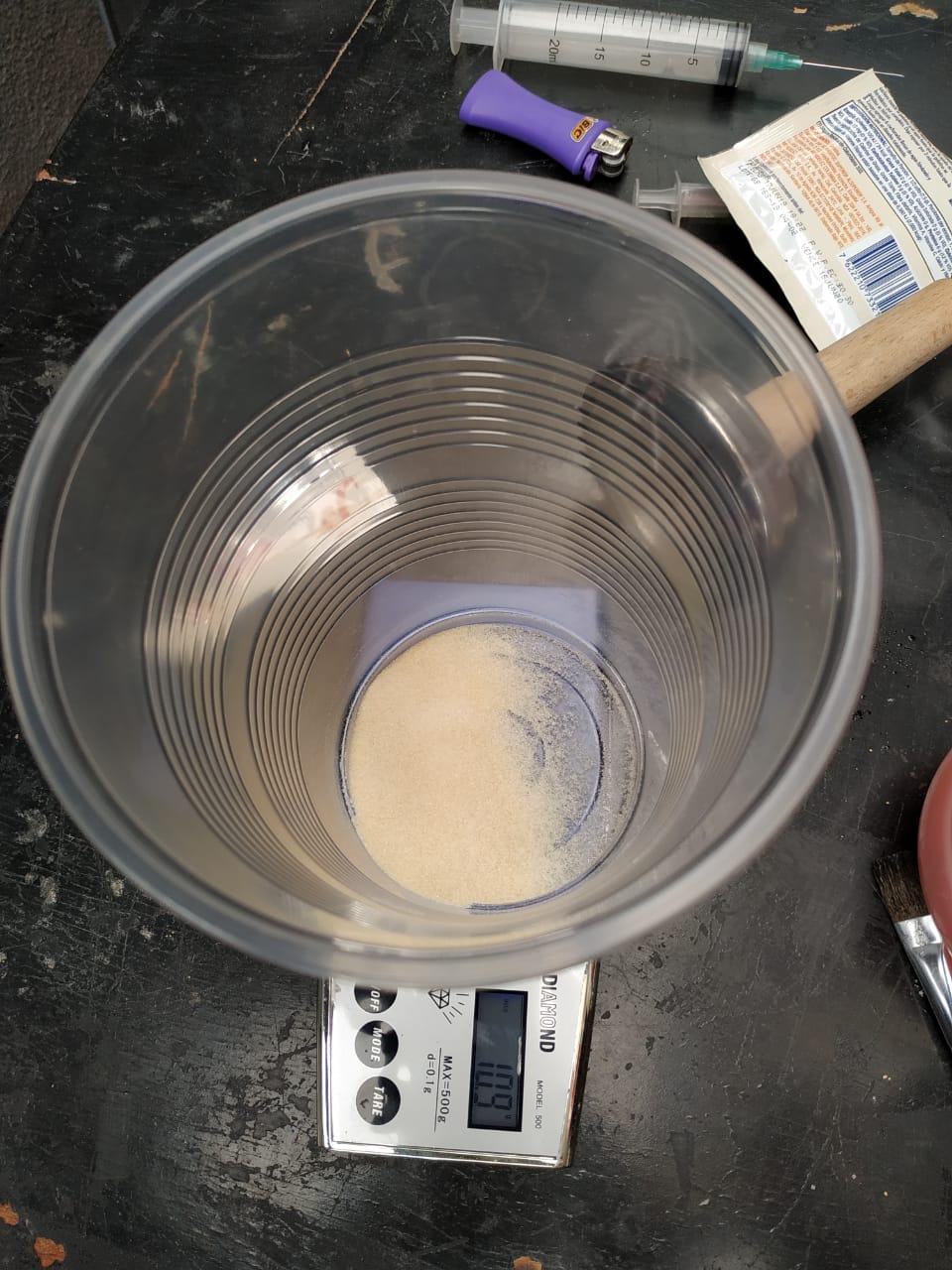

First we activate yeast with warm water (37 Celsius)

Recipe

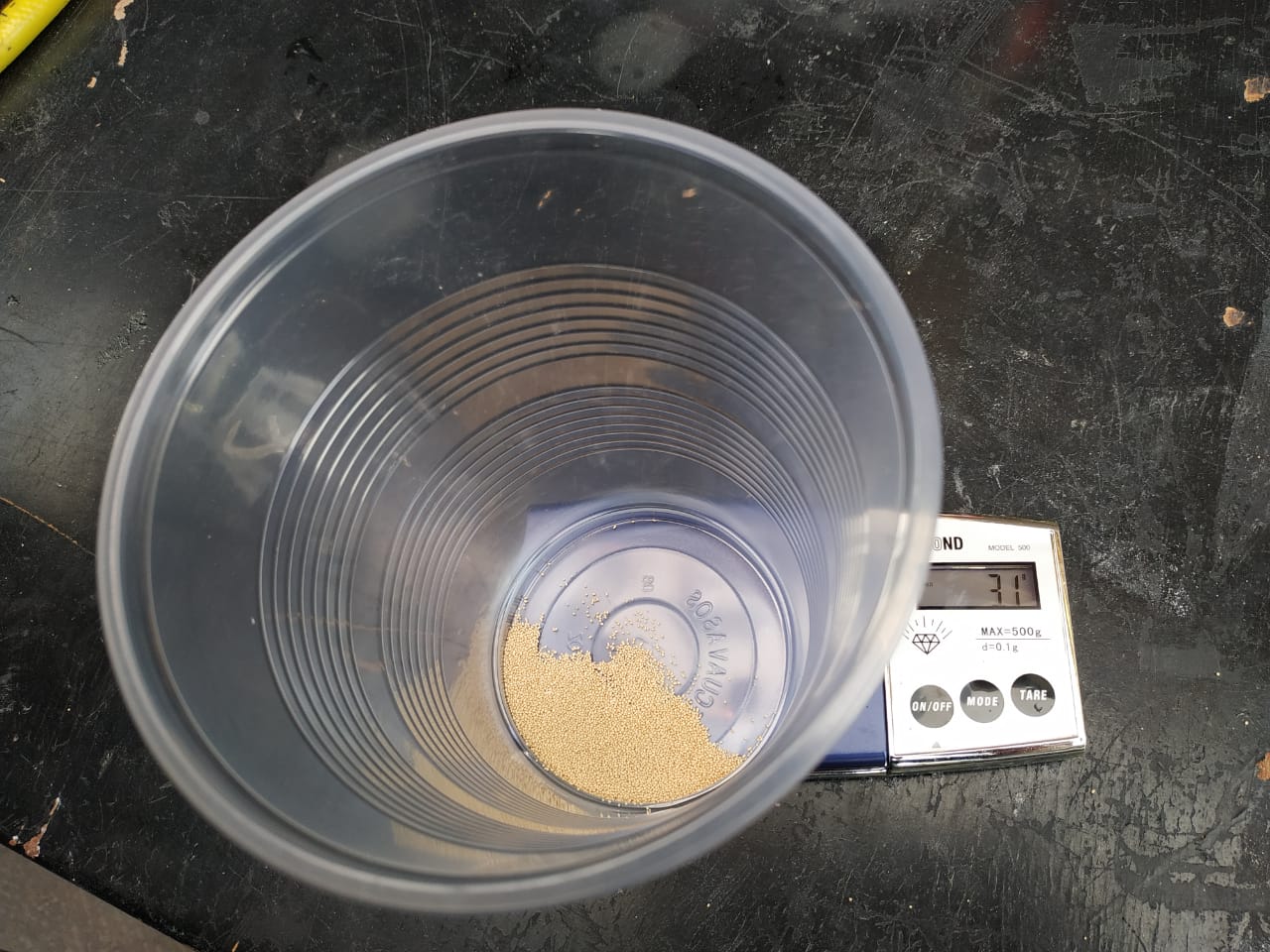

Yeast: 30 gr

Gelatin: 60 gr

Water: 150 gr

Glycerin: 60 gr

We were waiting to see if the volume of the Gelatin increase. And waiting, but probably we mistake or are wrong about this experiment.

1) Probably we had to let the gelatin in the incubator because we were in a place around 25 Celsius

2) If the experiment worked could was too minimum the volume that expands the gelatin and were not perceptible for our eyes.

It was a nice idea and probably in the future we could experiment more around it.

The characteristics of the final result are nice. More than a normal gelatin but a just little sticky because glycerin.

Cacao-My-cell¶

This was my first time working with fungus. Andres Basantes already had some experience working with mycelium so I decide to learn from him instead of try and guess how to culture Ganoderma to use mycelium.

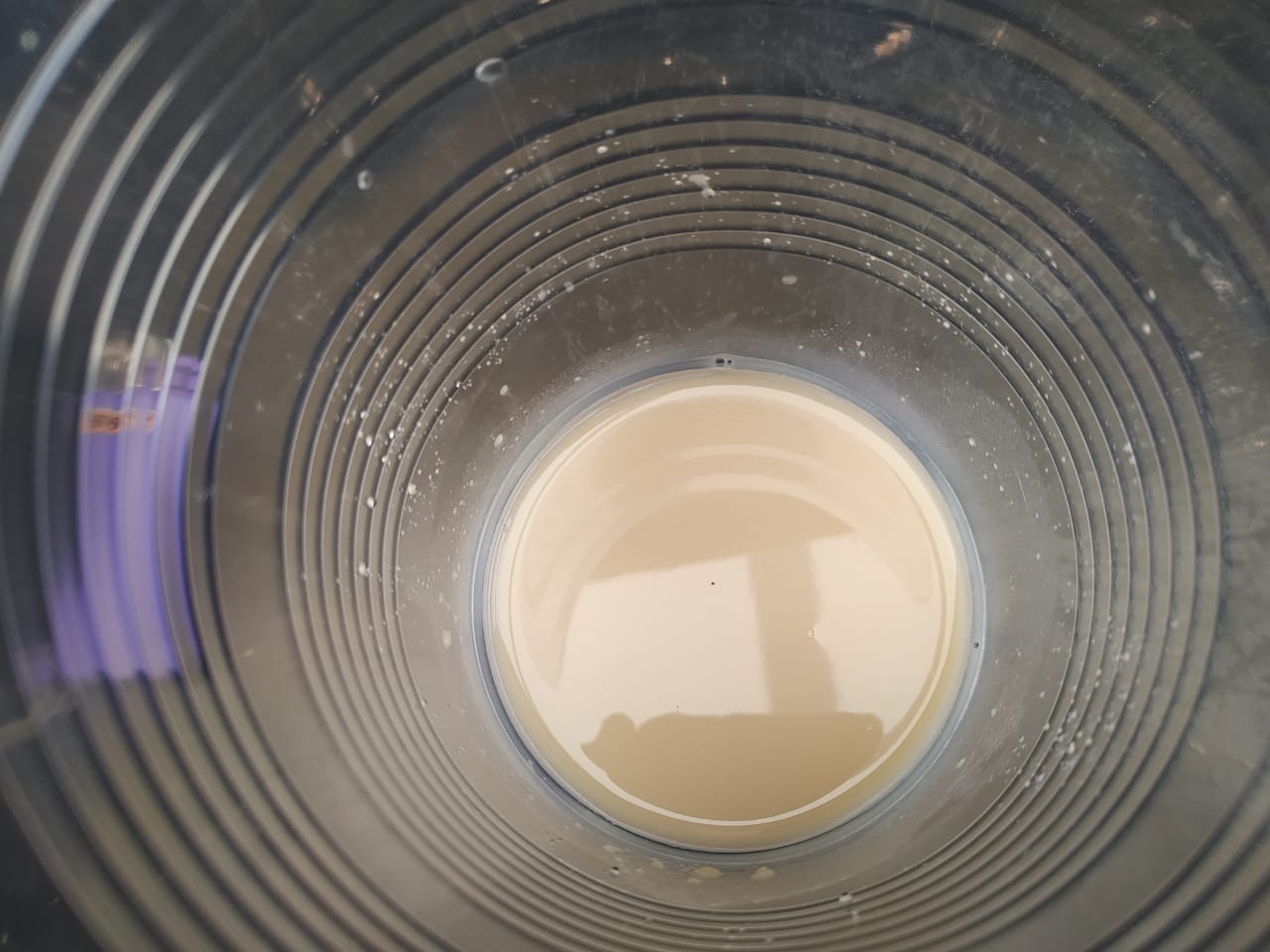

Andres knew a recipe to make s substratum (mycelium food) to start. We knew that Andre’s recipe worked so I decide to take some risk. I wanted to experiment with Cacao Waste (husk) to see if Ganoderma like or dislike it as food to colonize. in parallel we cultivate with Andres I did Cacao Raw Colonization experiment.

Cacao Raw Colonization substratum

Ganoderma Mycelium expanded on a substratum (250 gr)

Cacao husk (1 Kg)

Workflow

1.- Get Cocao Waste

2.- Put Cacao Waste in a pressure pot

3.- Empty the pot until middle with water

4.- Boil Cacao waste for 1 hour on 120 Celsius (to sterilized)

5.- Put boiled Cacao 1Kg on Polyfan bag with colonized substratum (250gr)

6.- Wait from 1 – 10 days to see if Ganoderma like Cacao husk

Problems

4.- When I was boiling Cacao my pressure pot was not working good because it was not completely closed and pressure was not going up, that means that temperature too. To contrast that problem I decided to extend time from 1 hour of boiling to 4 hours.

Result

5.- 24 hours after I collocate Cacao waste and colonized substratum I started to see how Ganoderma started to eat Cacao. 48 hours / Cacao were turning white (I did not took a pic, lol)

60 hours / Cacao were completely colonized by Ganoderma and more species and it looked as big bio battle. All was contaminated

BUT THE MOST IMPORTANT POINT WAS ACHIEVED 6.- GANODERMA DO LIKE CACAO WAISTE

Living organism¶

Ganoderma Mycelium expanded on a substratum (1kg)

Sawdust (1500 g)

Used Coffee powder(100 g)

Corn bran (400g)

Water 2lts

A big pot (over 15 lts. capacity)

Polyfan bags (3 or 4)

Portions

75% Sawdust

5% coffee

20 Corn bran

Work flow

1.- Make substratum

2.- Put it in a pressure pot

3.- Empty the pot until middle with water

4.- Boil in a normal pot for 4 hour on 90 Celsius (to sterilized)

5.- Mix new substratum with a colonized one

6.- Wait 3 weeks to have an entire new substratum colonized by Ganoderma

7.- Cover Andres cardboard mannequin with colonized substratum and attach all together with gauze

8.- Wait a month to let Ganoderma colonize Andres mannequin in darkness

9.- Fight with green fungus that fight with Ganoderma

10.- Expose part of mannequin to the sun to grow Ganoderma Fruit

Conclutions¶

1.- This was one of my favorite assignments. It is always nice to work with organisms because they are really similar to humans in some acts and different in other acts.

2.- I love the foam and the mycelium result.

3.- The more important for me was to know more about biomaterials and it is achieve.