7. Open Source hardware: from fibers to fabric¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

Assignment¶

- Research and document existing fabrication methods, machines and industries , add references and sketches of the machine and the chosen process

- Design and document the files of the machine, machine hack or tool and fabrication - assembly process

- Document the schematic and the programming code (if any)

- List the materials: electronics, materials amount other (references of the components)

- Design, create and document a final outcome, a sample project of your process

- Make a small video of the machine

- Create an interface for controling your machine

How will it be evaluated¶

- References : tutorial , links, inspiration

- Design : sketch , 3D modeling skills, Parametric modeling skills

- Fabrication : Capable of executing from file to production workflow, from 3D modelling to 3D printing , parameters, materials

- Documentation : Anyone can go through the process and understand

- Final outcome : Is the project assembled, functioning and complete

- Originality - Aesthetics : Has the design been thought through and elaborated

Files and Links¶

Workflow¶

- Research about Textile Machines for biomaterials

- Design a machine for Bio Textiles

- Get all pieces

- Assemble

- Test

- Final result

Research about Textile Machines for biomaterials¶

To find some inspiration and research about some mechanisms for machines you may visit JensDyvik GitHub repository. Jens Dyvik has been one of the main references of Maker That Make Machines.

Design a machine for Bio Textiles¶

Some months ago in FabLab ZOI we started to cook an idea of a great incubator for Bio Laboratories. And we started to design and fabricate a super nice machine. Also we have been involved in synthetic biology and we have been working with some scientists. At this point we started to develop the “Bio shake” an incubator with orbital movement.

Get all pieces and Assemble¶

Since fabricademy started we start to make the new version of Bio Shake incubator. It has passed in this month’s several tests, in some point one of those get crazy and fall to the floor. But now we know that we are on 90% of testing process.

Above you will find all mechanisms and pieces needed to build a BIO Shake. The blue components have been printed on a Form Labs printer in tough material, also you may find a white piece similar as blue ones that is printed on rigid material (same printer), and the black pieces are printed on FDM Prusa i3. The other components are rods and nuts that you can find on a harvest store.

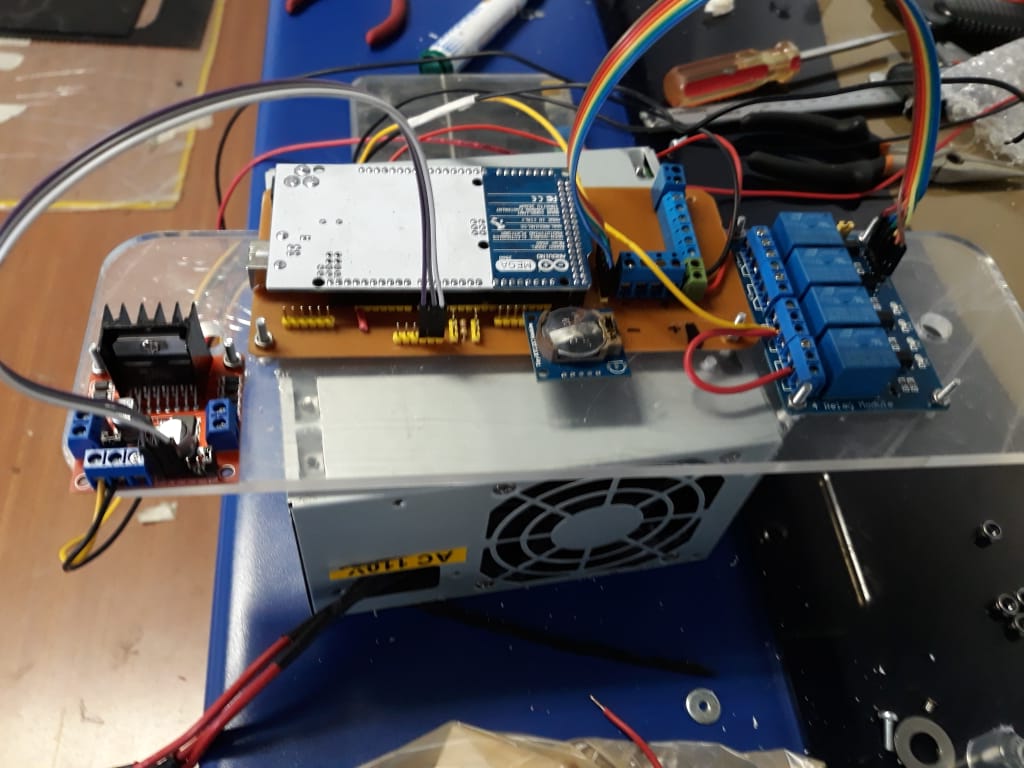

Here you may find 2 power supply, 4 relays, 3 ventilators and 3 peltier modules. We are using an arduino Mega to control everything and a time module to give the best timing for all processes

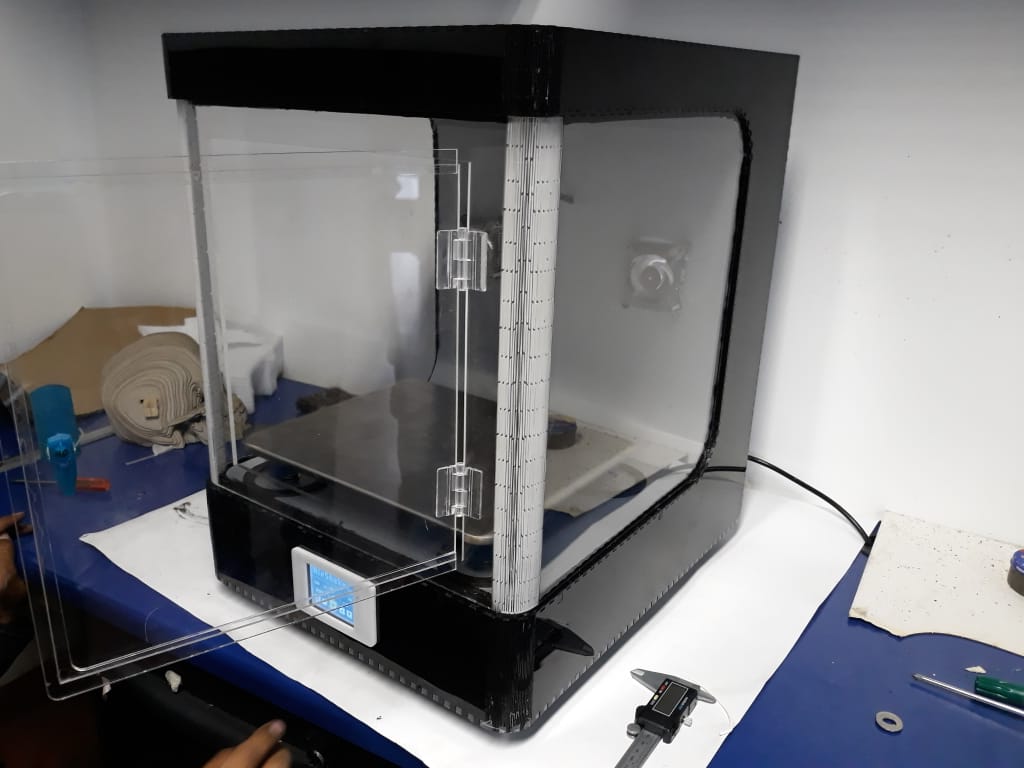

The machine chassis has been made with a laser cutter in 4mm acrylic sheet. And here you can see some of the assembling process. Until we have mechanic and electronic systems finished. Just before assembling the door to close all we do mechanical and electronic tests. Just in case we need to improve rods or mechanical movement.

Test¶

And this Fabricademy vesion is the third one we have build. Since know we have make a Bio Shake mini, a Bio Shake (The extended version) and Bio Shake mini (that we added an humidity sensor)

Once we are sure all is performing well we started to assemble the other pieces together and some of them we glue together (all of them have a press-fit system). We use Silicon to glue the transparent enclose because is good to isolate the interior and exterior of the machine.

Final Result¶

When I presented this machine to the Fabricademy class Anastasia and Cecilia ask me to add some features for BIO Shake and make a super documentation to present it as a final project. I find this idea really logic and I think that is better to concentrate my effort in this machine instead of came up with other idea that need to start from scratch (considering that I have already start this idea from scratch).