BioFabricating Materials¶

Process¶

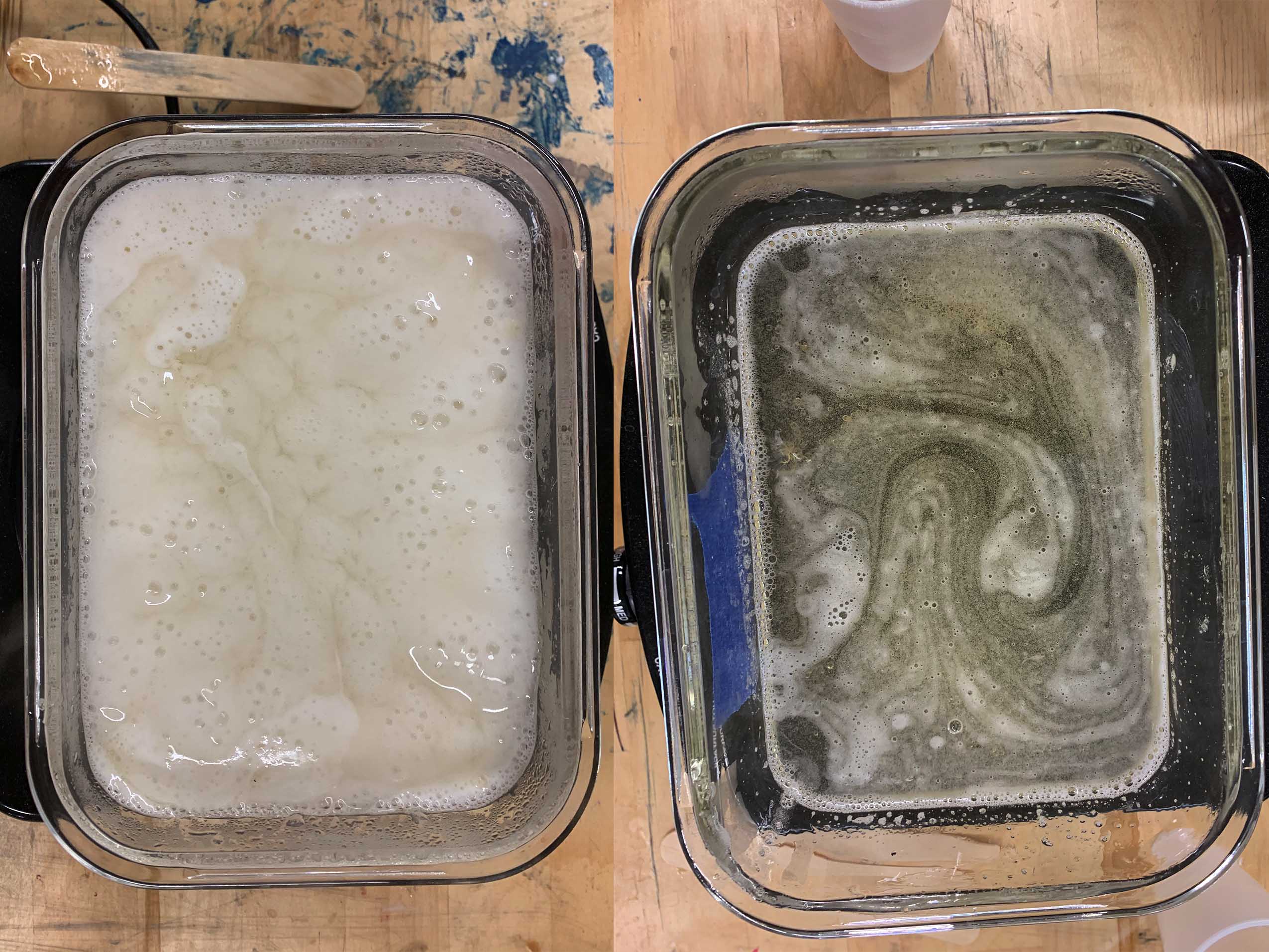

My lab cooked three different bioplastics, Bio Foil (made from 12gr Glycerin, 48gr Gelatin and 240ml Water), Bio Resin (made from 48gr Gelatin, 8gr Glycerin, and 240ml Water), and Bio Silicone (made from 48gr Gelatin, 24gr Glycerin and 240ml Water).

Each of the crafted biomaterials followed the same process. Each started with measuring and boiling the correct amount of water, then adding the ingredients one by one. Each biomaterial simmered for about 15 minutes until it was ready to poor into the molds.

I made four molds for our biomaterials. Each mold was made out of three sheets of laser cut acrylic. The base sheet was solid, the middle sheet was textured and then the top sheet was a hollow outline. I glued the sheets together with silicone glue, then poured the biomaterials into the molds with clamps on the molds to be extra cautious.

I tried to make four molds that were very different to see how the different properties of the biomaterials worked. I had two patterned molds, and two illustrative molds.

Ultimately, I only got to use two of the handmade molds, because we ran out of biomaterial to pour. I chose one texture mold that had an array of laser cut hearts, and one illustrative mold that had a sun illustrated within it.

I poured the bio silicone into the molds, because I thought that would have the best chance of coming out of the sharply angled mold smoothly.

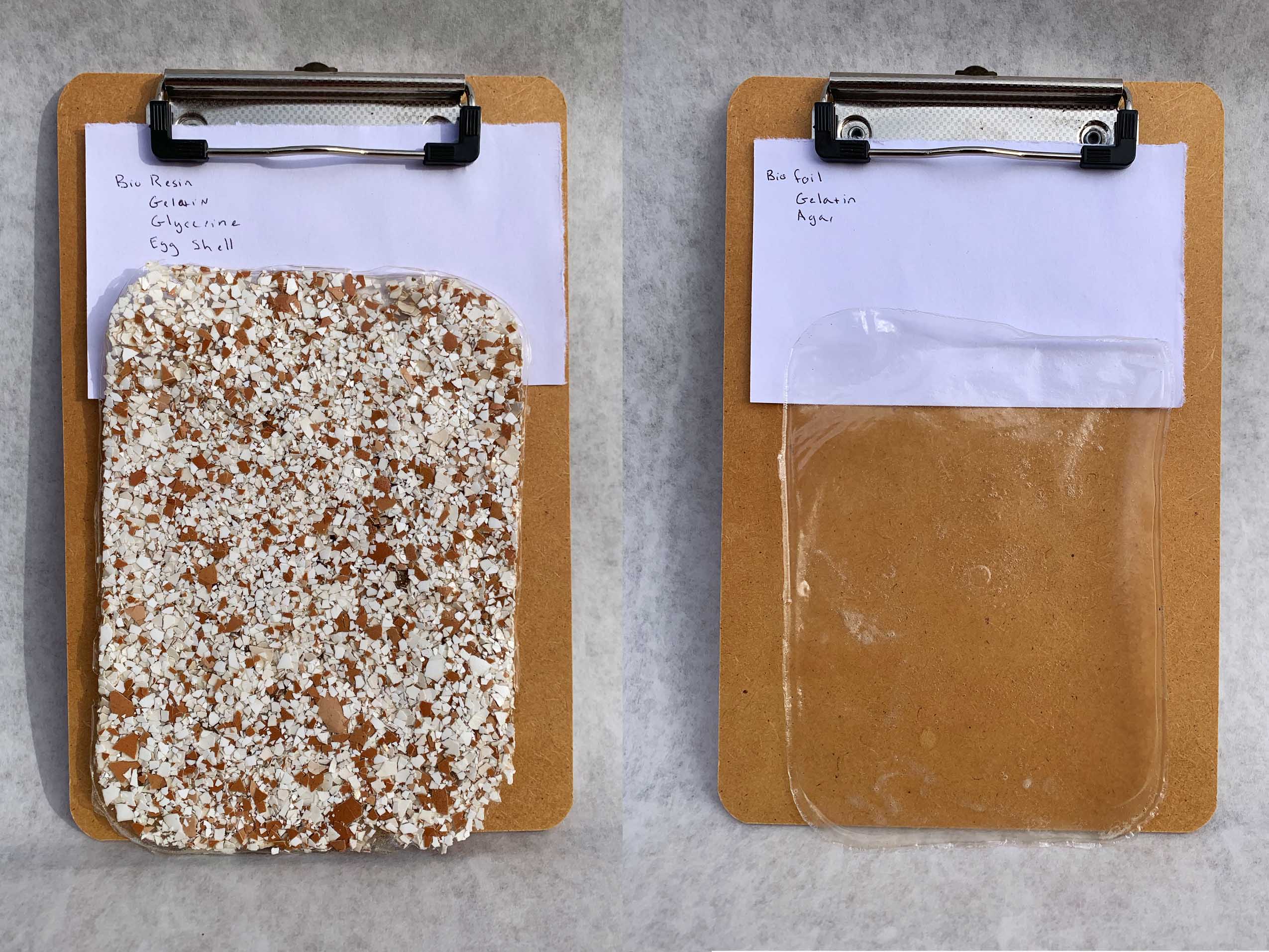

I poured the bio foil onto a Tupperware container lid, to make a smooth sheet of bio foil.

I poured the bio resin into another Tupperware container lid to try to get a thicker bio resin block. I added eggshells to the bio resin in an attempt to make it a hard and stable material.

After leaving the materials to cure for a night, I came back to the lab the next day and was very surprised with my results. When I had left the night before, everything was all gooey and seemed like it would never dry. It was a thrill to come back and be able to peel all of the bio materials right out of the molds.

The resemblance of the bio silicone to real silicone is uncanny. The only tell that the bio silicone is a biomaterial is the smell - which is hard to miss. The textures came out beautifully and I was surprised at how the bio silicone popped right out of the nooks and crannies, no matter the size.

The bio foil feels like a stiff plastic wrap, like the top of a sauce container that you would get at a fast food restaurant. It feels sturdy, but also like a single use plastic. We created a very thin sheet of the bio foil, and I would be curious to experiment with different thicknesses.

The bio resin is certainly beautiful with the eggshells, but I can’t imagine a use for it. It is quite bendable but not hard like resin. I could see using it to create a cover for a book, or maybe a one-time use cutting board.

Final¶