Soft robotics¶

Process¶

I started off this week focusing more on materials than on a specific project. I am excited about the range of movement with soft robotics.

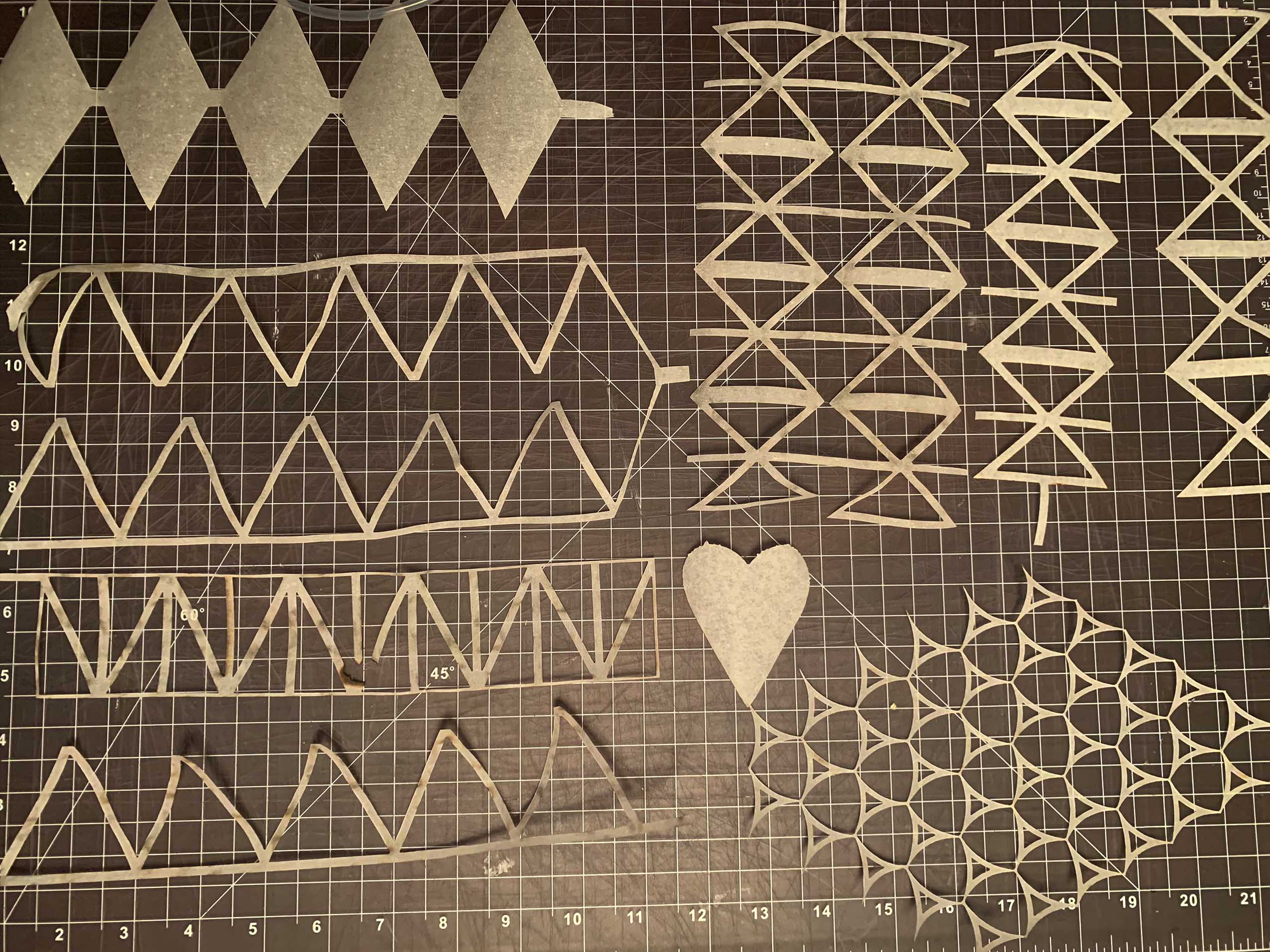

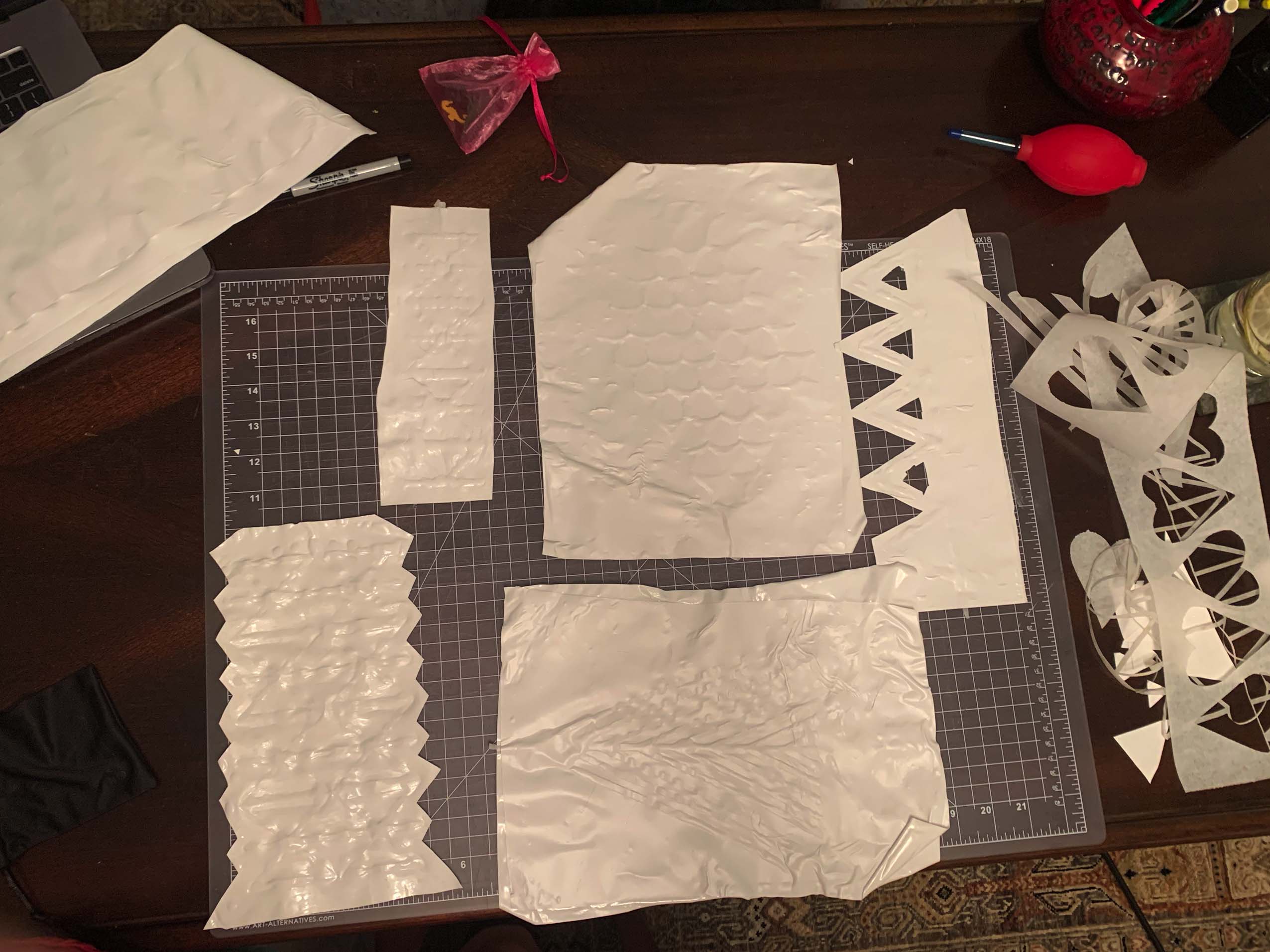

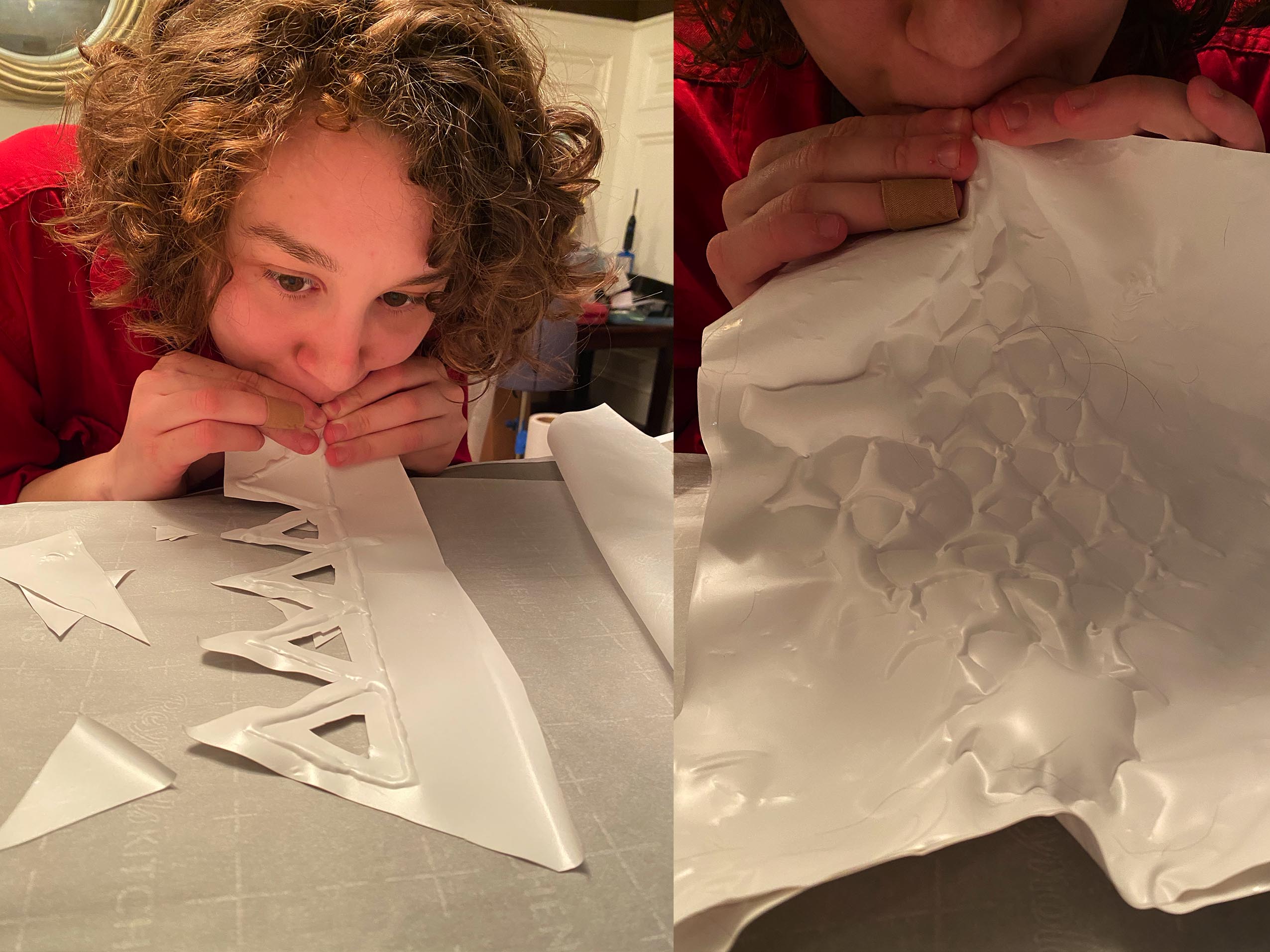

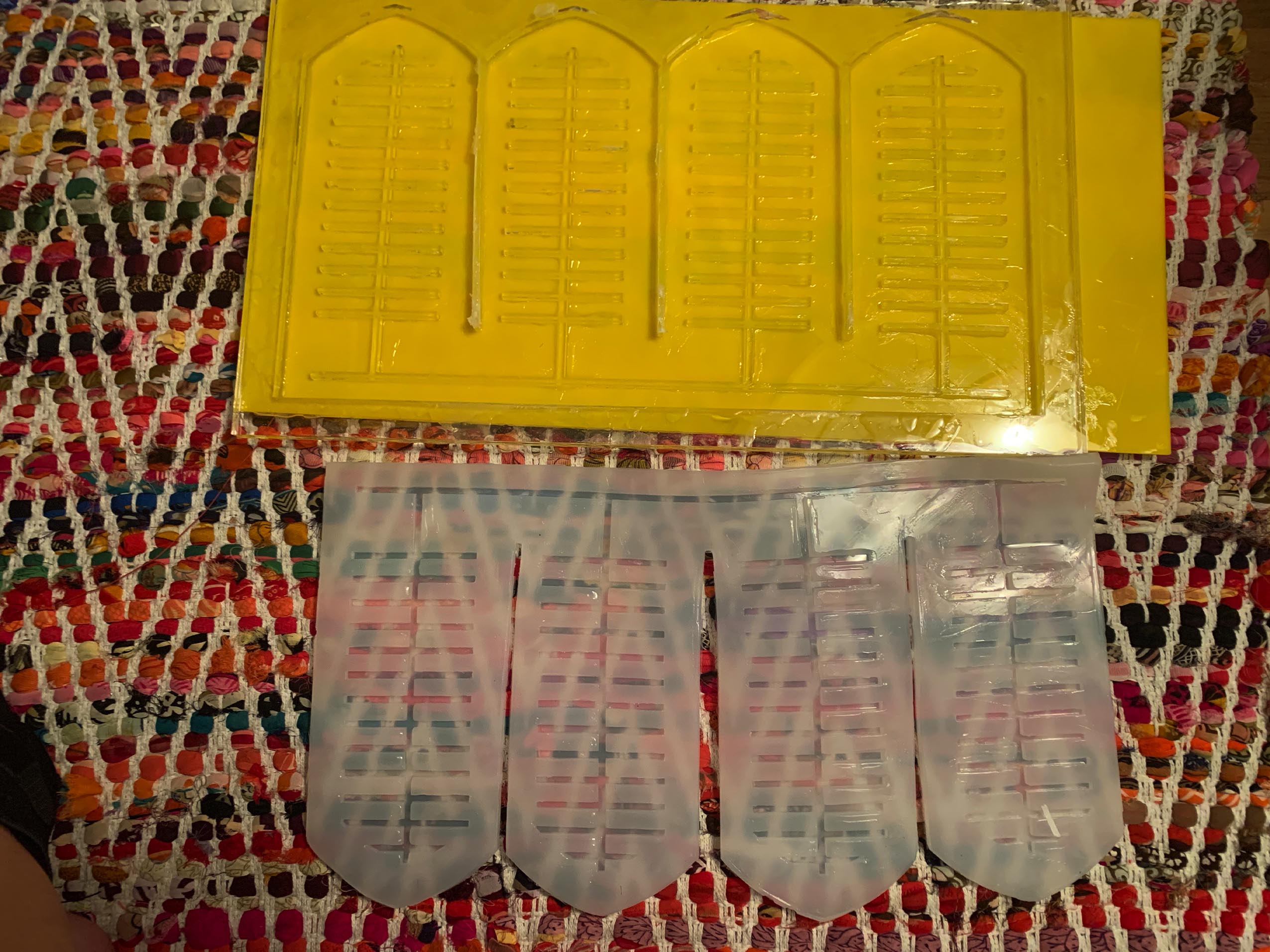

I found a great origami book at the studio and took inspiration to try and create folding structures out of vinal. I designed lots of different patterns to be laser cut out of parchment paper. I then layered the parchment paper between two layers of vinal and ironed the vinal together. The vinal sticks to itself, but not the parchment paper. My new shapes inflate as origami-inspired bubbles with the lasercut parchment paper.

I had a very tricky time getting the vinyl to stick to itself just right. At first, my iron was too hot, and then it was too cold. Through trial and error, I learned it was best to peel off the plastic coating on the vinyl beforehand, then only press the vinyl with the medium heat iron, and not necessarily rub the iron back and forth.

I was excited about my inflatables, but they didn’t blow me away. (Yes, pun intended.) I couldn’t get as much movement in them as I would have liked, and I never felt like I got the perfect recipe down for the iron and the vinyl.

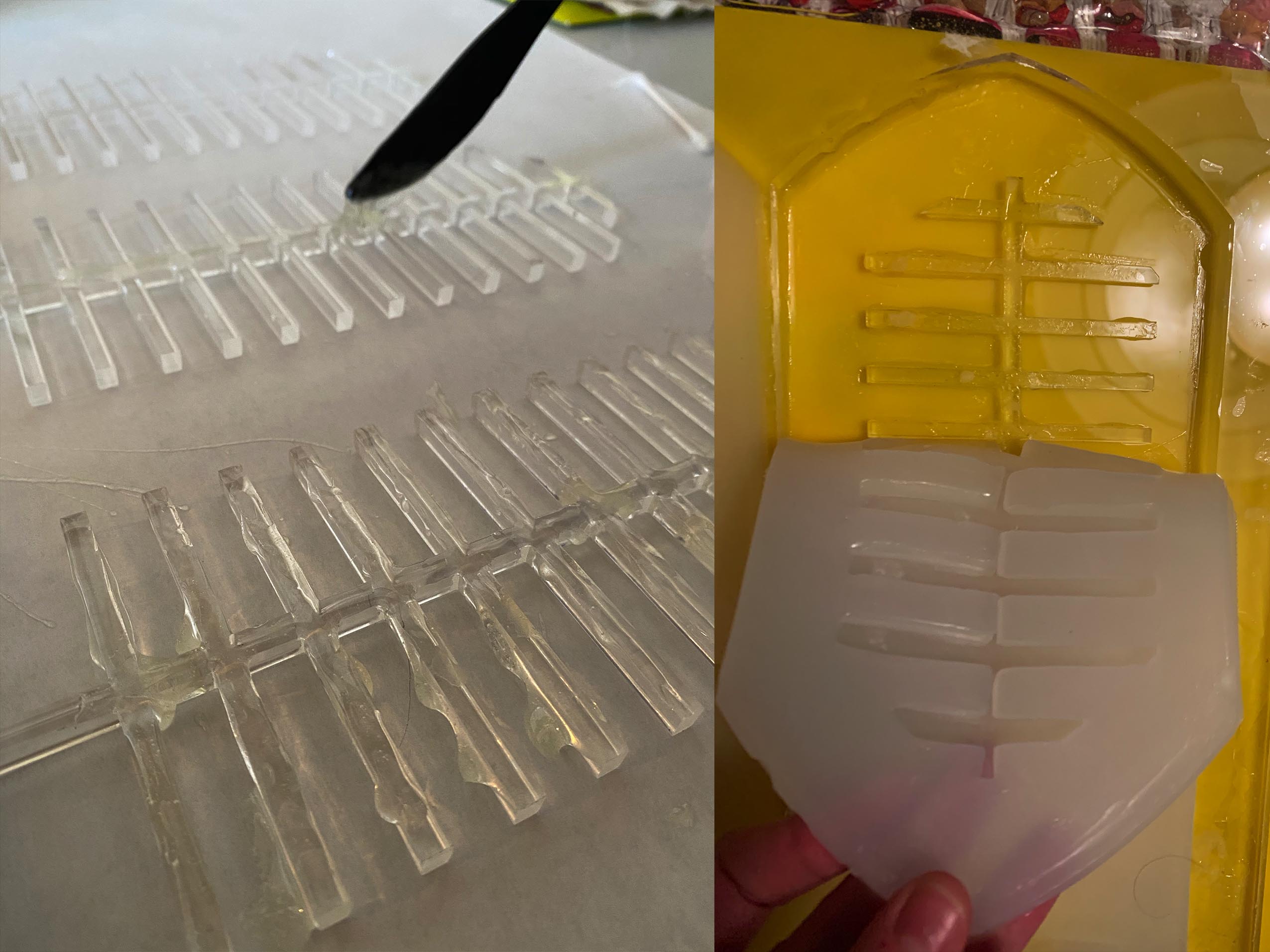

For the second half of the week, I moved onto silicone and decided to make a wearable that would allow the wearer to bloom like a flower.

After making paper models and figuring out my dimensions, I went into Rhino to create my mold. I based my mold off of a soft silicone gripper. I created layers of the mold in acrylic on the laser cutter, then epoxied each layer together. I created two molds, a top and a bottom.

Next, I poured the silicone into the molds. I really enjoy working with silicone because the texture is so fun to squish. After peeling the silicone out of the molds, I glued them together with another thin layer of silicone and then it was time to inflate!

Unfortunately when I went to inflate I had open seams and was not abe to see the sillicone in action.