12. Soft robotics¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

Research¶

SoftRobotic Finger using silicon¶

Creating the mold¶

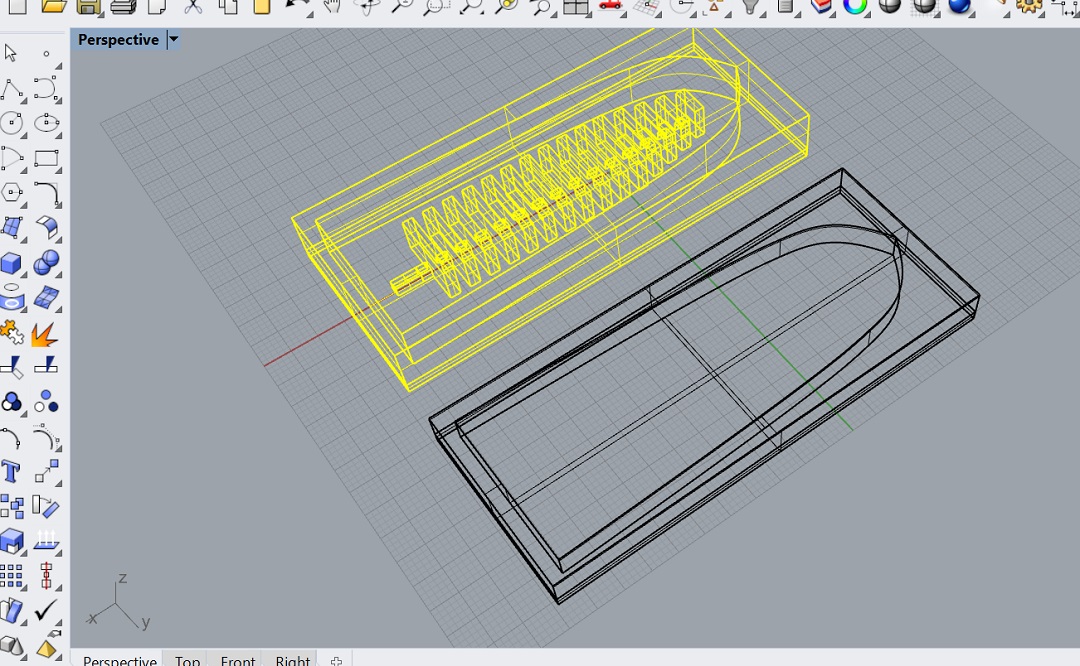

I created the mold under Rhino

You can download the Rhino file here

and visualise the STL file here

Then I 3dPrinted them on the Itopie Printer

Then I casted silicone in it, note that in flat mold I put a little bit of silicone then a piece of coton tissue and the again some silicone because I want this part to not be able to inflate in order to be the inside of the finger.

![]()

Then I put the 2 parts together with silicone as nothing except silicone will work as glue

After using a seringe I tested it

Not so bad for a very first try ;o)

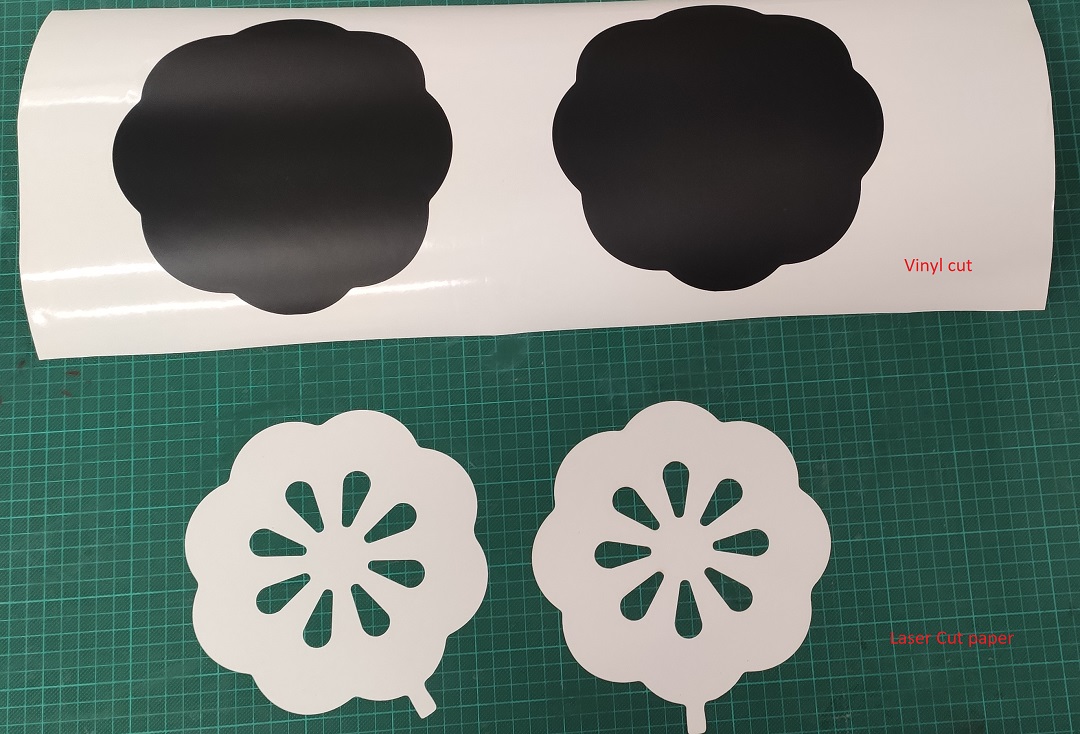

SoftRobotic using vinyl and hot press¶

I choose 2 designs which were shown during the course, I only have vinyl to try them.

You can find the design for the vinyl cutterHere and the design for the laser cutter Here

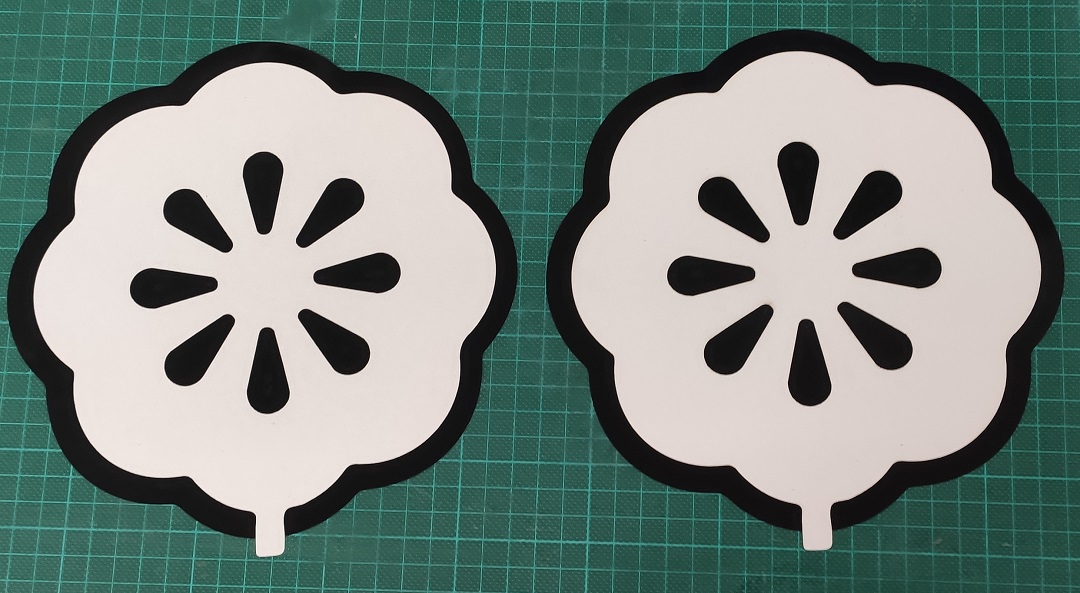

I will try to hot press them at 140° which is normally more than the melting temp, but I don't to try over this limit because as you probably know: PVC (Poly Vinyl Chloride)/vinyl/pleather/artificial leather will emit pure chlorine gas when burn.

Unfortunatly I was not working well, as you could see the two parts didn't merge properly.

I tried another material the HEXIS HFLEX100P polyurethane stretchable 90Micros, it fail also.

and a new design but resultwas the same.

So I decided to explore all kind of material around me.

and it works a little bit better with rubble bag in the sens that the 2 layers merge correctly, but the thickness is too big to permit any flexibility

I explored several material with the Hot press it was not efficient with material I found.

I also tried to use the laser cutter to ceal plastic together by adding 60mm of offset between the head and the material, it was working 2 or 3 times but even when I had the good setting and material if the layer are not really in contact the large laser beam pass over without merging them.