6. BioFabricating Materials¶

As the week 4, this week I worked with the textilelab group on the biofabricating materials.

During this week, we explored different ways to create and fabricate biomaterials. One of aims of biomaterials is to propose alternatives biodegradable, sustainable and more ecological.

Biomaterials¶

During the presentation of the week, I discovered many biomaterials and techniques to make them.

Ressources and cook book¶

Inspirations and references¶

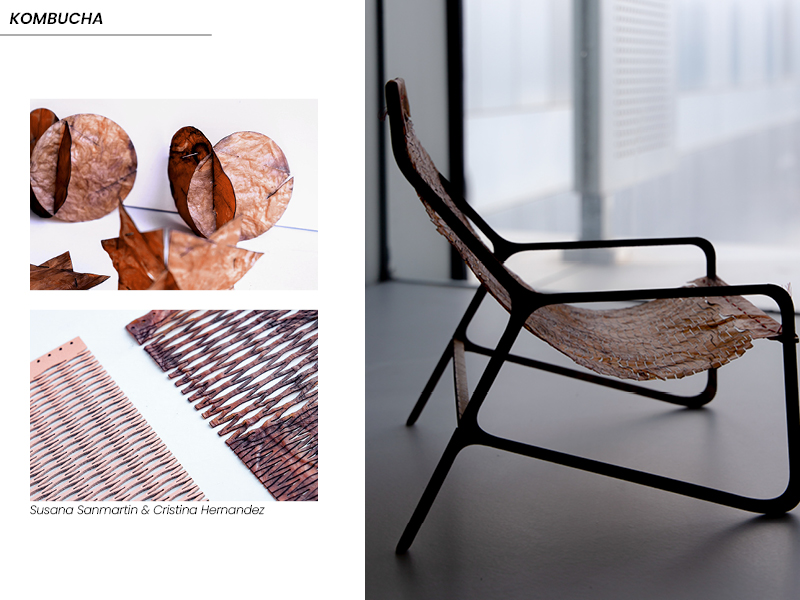

Kombucha is a fermented tea with a symbiotic colony of bacterial yeast (SCOBY) Bacteria feeding on a liquid medium of sugars and tea, start creating an acidic environment which allows them to thrive and spin cellulose layers. It grows best between 25-30 degrees Celsius, at lower temperatures the kombucha pellicle will grow, but slowly.

*Officina Corpuscoli - Website

*Officina Corpuscoli - Website

Mycelium is the vegetative part of a fungus. Mycelium looks like strings often white or cream coloured that grow in long fibres called hyphae. This structure, as a whole, is the vegetative structure of fungi. This is why mycelium is able to colonise other materials, like a substratum, think of straw or coffee for example, but also liquid nutrients. This colonisation fosters the creation of a new material.

MYCELIUM BRICK, LEATHER

Mycelium can be grown in many different ways, on a large variety of substratum. Mycelium grown materials are often fireproof, waterproof or sound isolating. They are also completely compostable and organic.

The bioplastic is an ecological alternative to plastic. There are many possibilities to create a bioplastique.

Recipes and experimentations¶

Bioplastic¶

CONDUCTIVE

| Conductive Bioplastic | Conductive Bioplastic 2 | |

|---|---|---|

| Ingredients | Quantities | Quantities |

| Agar | 2gr | 4gr |

| Glycerol | 1mL | 12gr |

| Salt | 5gr | 10gr |

| Water | 240ml | 800ml* |

Recipe 1 from Conductive Agar Ag03 by Elisabeth Lorenzi, Materiom *misread the cardboard and put 800mL instead of 200mL but it is drying well so far

The final outcome of this experience is failed. The bioplastic was rotten cause of bad drying and it didn't work.

ALGINATE

Alginate bioplastic is made by combining two separate mixtures : one containing sodium alginate, water and glycerine (as a base) and a curing agent, calcium cloride.

| Flexible thin BIO-FOIL | |

|---|---|

| Ingredients | Quantities |

| Alginate | 12gr |

| Glycerol | 20gr |

| Sunflower oil | 10gr |

| Water | 200ml |

| Spread solution for curing | |

|---|---|

| Ingredients | Quantities |

| Sodium chloride hydrate/ Calcium Chlorure | 10ml |

| Water | 100mL |

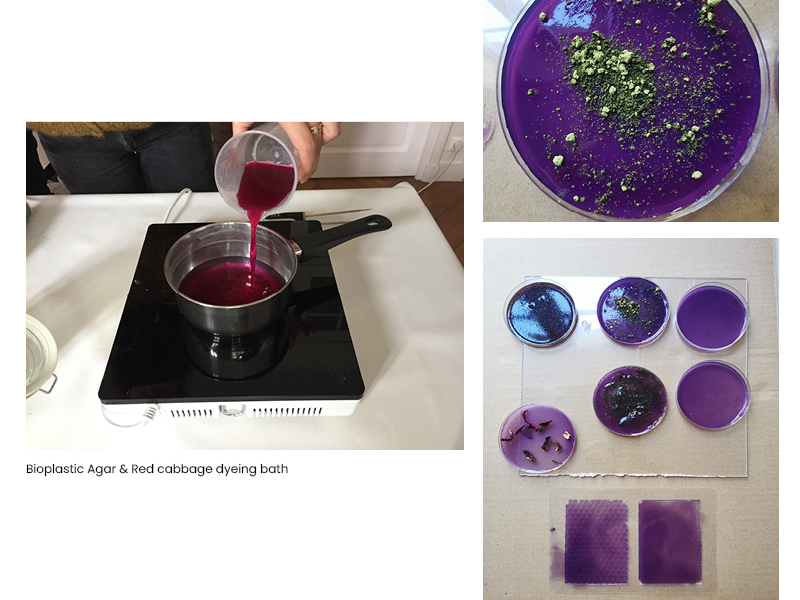

AGAR AGAR

Agar or agar-agar, is a jelly-like substance, obtained from red algae.

Agar Bioplastic is made by mixing water, glycerine and agar-agar powder. They form a plastic substitute that can be casted in very thin films, resembling plastic foils. The casted material is never elastic, but is flexible.

| Flexible Bio-Foil | Stretch Bio-Foil | |

|---|---|---|

| Ingredients | Quantities | Quantities |

| Agar | 5g | 3g |

| Glycerine | 15g | 15ml |

| Water | 250mL | |

| Gelatine | 20g | |

| Cook +/- 25 minutes at 80°C gives the best results | Cook +/- 45minutes at 80°C gives the best results |

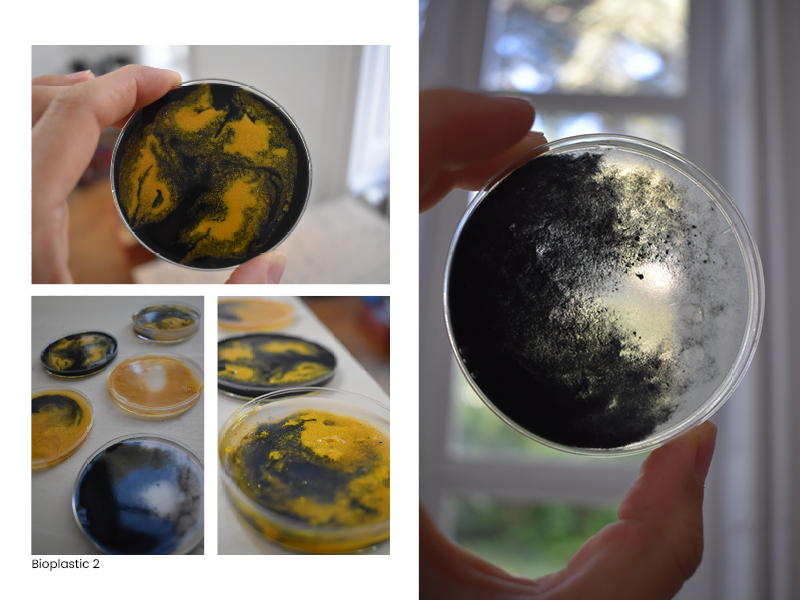

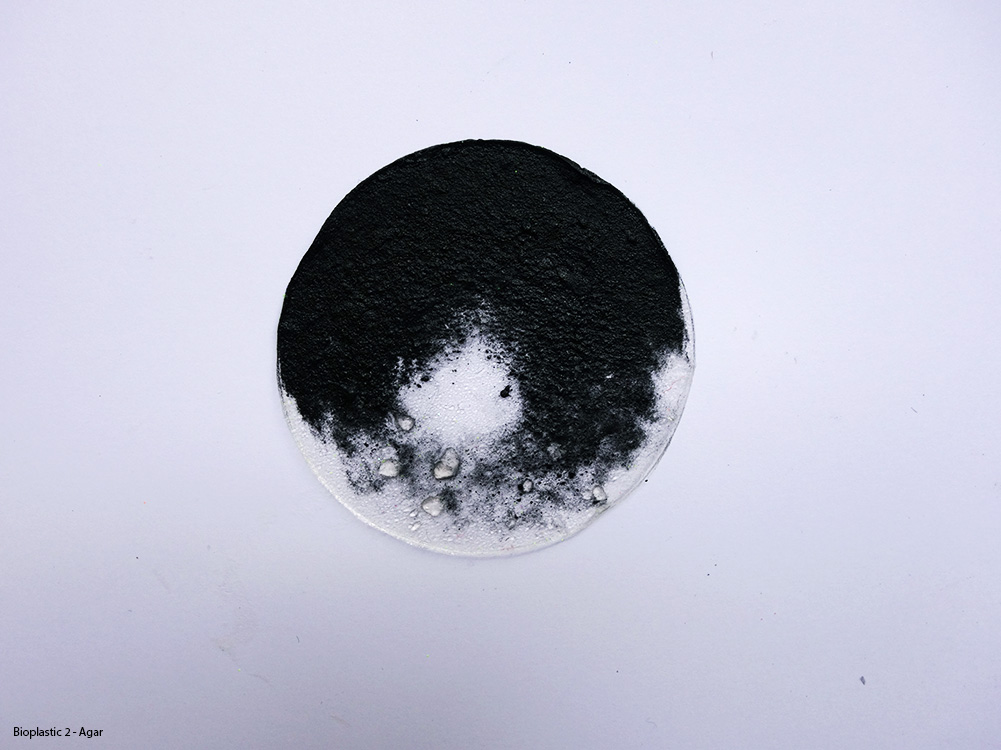

| Bioplastic 1 | Bioplastic 2 | |

|---|---|---|

| Ingredients | Quantities | Quantities |

| Agar | 4g | 4g |

| Glycerine | 25g | 17ml |

| Water | 400ml | 200ml |

KUZU

| Kuzu | |

|---|---|

| Ingredients | Quantities |

| Kuzu | 60 mg |

| Water | 120 ml |

| Glycerine | 10 mL |

| Vinegar | 10 mL |

The recipe that we followed was taken on materiom from a tapioca starch recipe

GELATINE

Gelatine is an animal derived ingredient, made from the collagen present in animal parts.

Gelatine bioplastics are crafted usually from powder, in combination with water and glycerine. Gelatine powder is sensitive to heat, and starts melting already at about 60C degrees, which makes it ideal for both cooking and recycling for new use. Recycling of both leftovers and unwanted pieces is very easy, simply by adding water and heat to the mix to re-hydrate and melt the mixture. It is then ready for casting again.

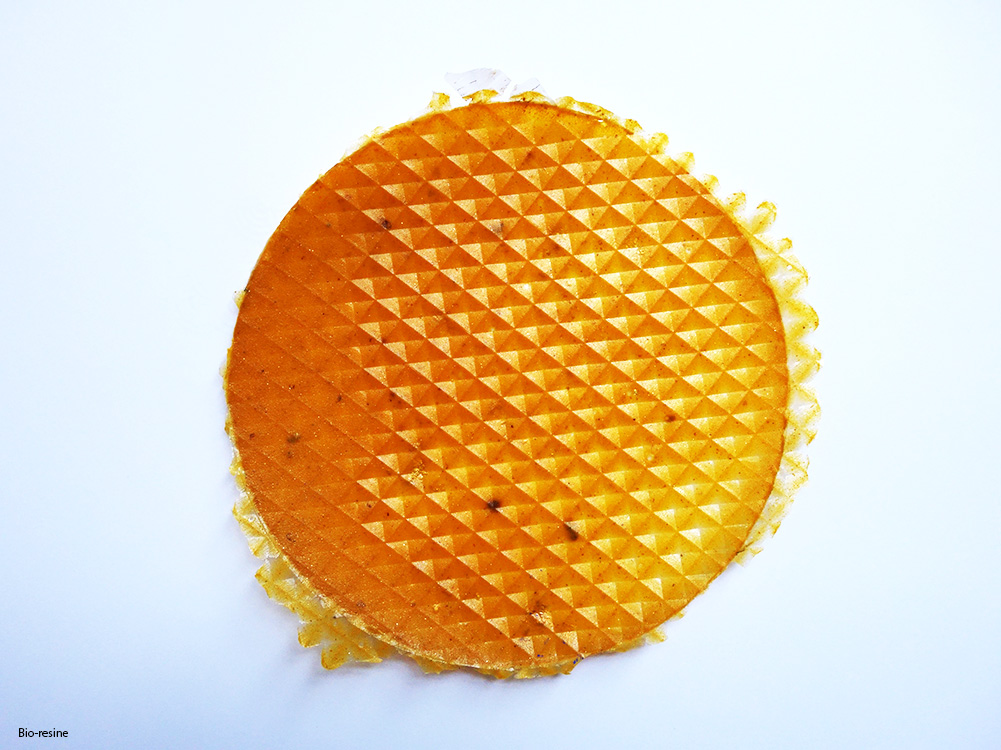

| Bio-Foam | Bio-Resin | |

|---|---|---|

| Ingredients | Quantities | Quantities |

| Gelatine | 48g | 48g |

| Glycerin | 12g | 8g |

| Water | 240mL | 240mL |

| Soap | 10mL |

Result bioplastic¶

The result of our bioplastic samples are a little bit disappointing because we haven't managed correctly the drying. The simples stayed all week end in cold space, without light and in an wet space. Sadly, many samples have molded. (but it's beautiful though)

To manage correctly the drying step, it is necessary often to check the samples, maybe to turn these sometimes and put these in a dry and temperate environment.

Fortunately, we can saved some samples.

Kombucha¶

During the week 4 we prepared the recipe of Kombucha with Surzhanna. Recipe prepareted during the week4

Below, we can see the progression of Kombucha after two weeks.

Mycelium¶

During the week, Pauline brought a mycelium growing in a bottle by accident. We tried to use this mycelium to do a myclium leather. So, we taked it, cut it and tempered it in glycerine. Then, it has been baked.

Useful links¶

Tutorials

- Bimaterials tutorials Part 1 – Beatriz

- Bimaterials tutorials Part 2 – Beatriz

- Tutorial Mycocomposite Workshop by Jessica Dias