Open Source Hardware

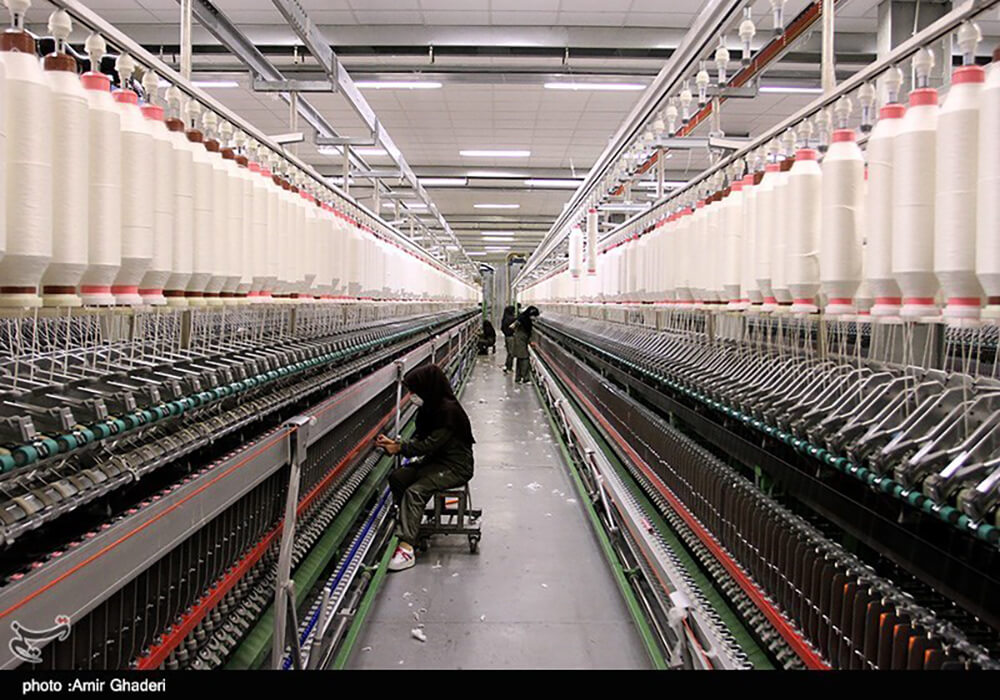

From fibers to fabrics

This week's project was a teamwork with PETRA GARAJOVÁ, make sure to check out her amazing documentation and projects!

Also, most of the documentation you can see below is done by her!

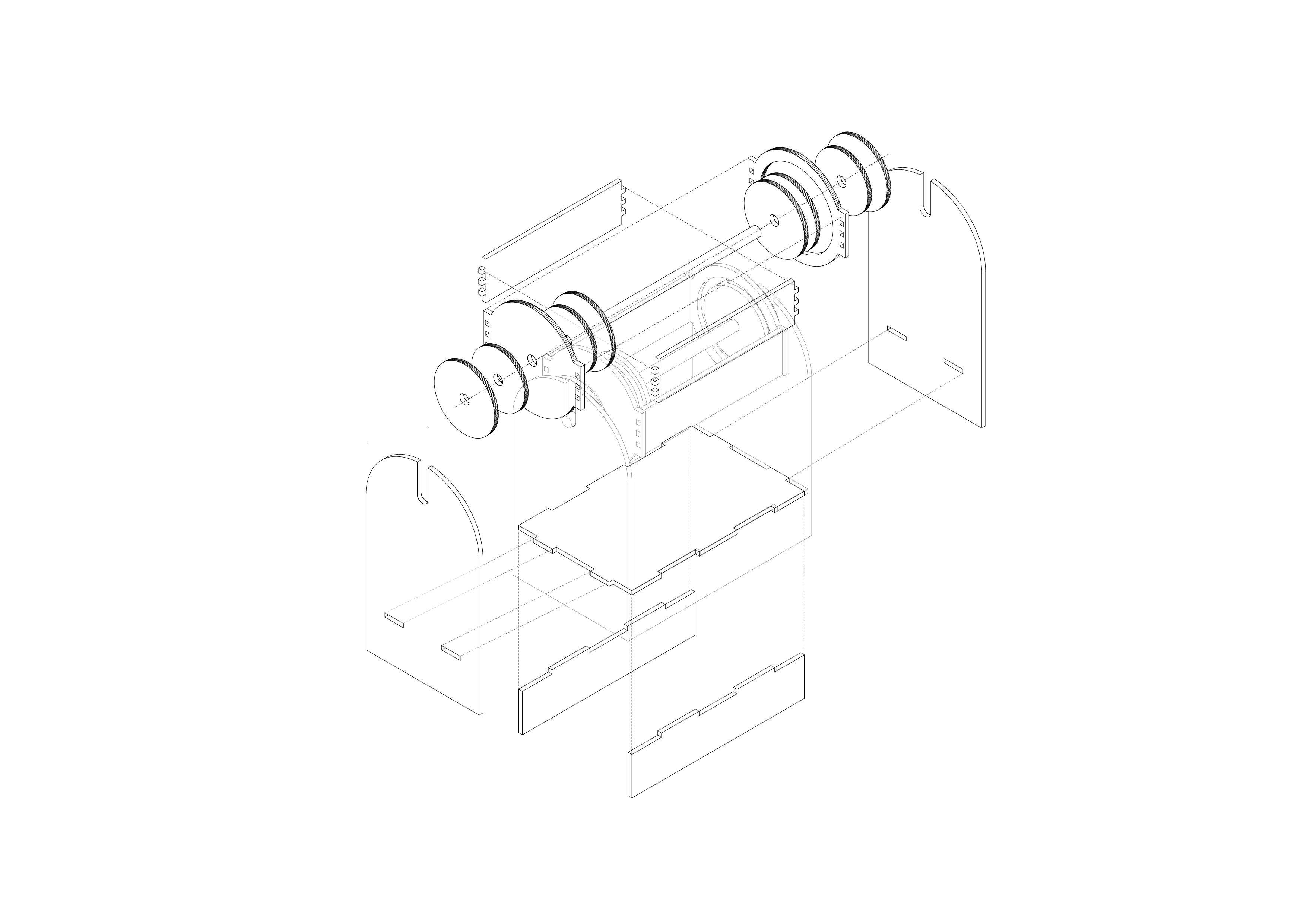

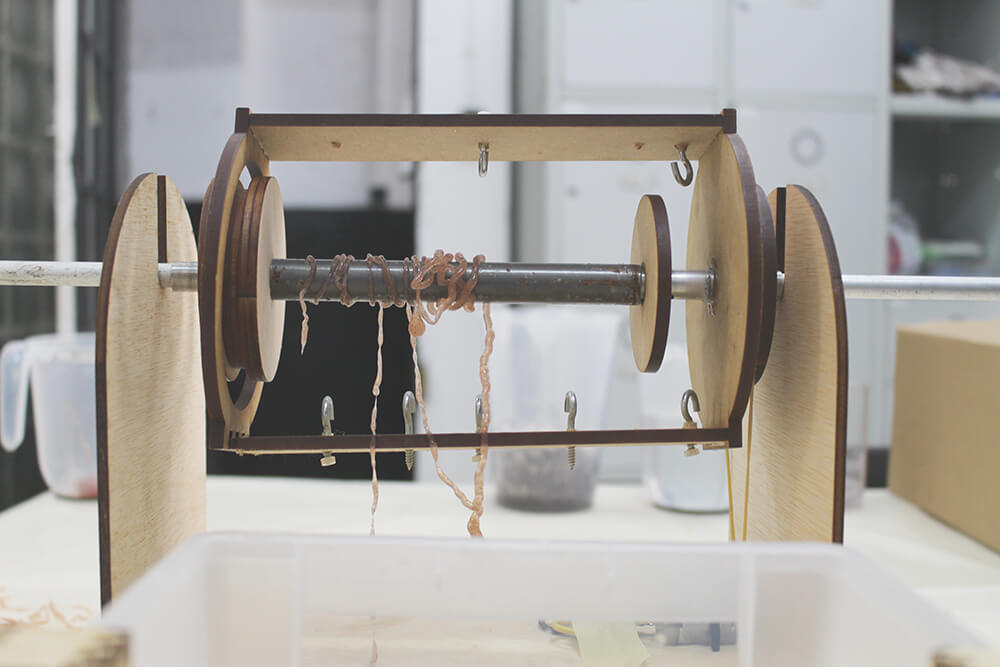

Hilo spinning machine

Spinning across centuries

- HILO Spinning Machine

- Cathrine Euale, Hilo Spinning Machine DIY

- Cathrine Euale, Alginate Bioyarn Extruder

Materials list

- Plywood 4 mm 1 board

- Hook screw 20 mm long 8 pieces

- Aluminium tube 240 mm, ∅ 15 mm 2 pieces

- Aluminium tube 165 mm, ∅ 12 mm 1 piece

- 6V DC Motor 1 piece

- 10K Potentiometer 1 piece

- C2625 Transistor 1 piece

- Alternate Current Adapter 1 piece

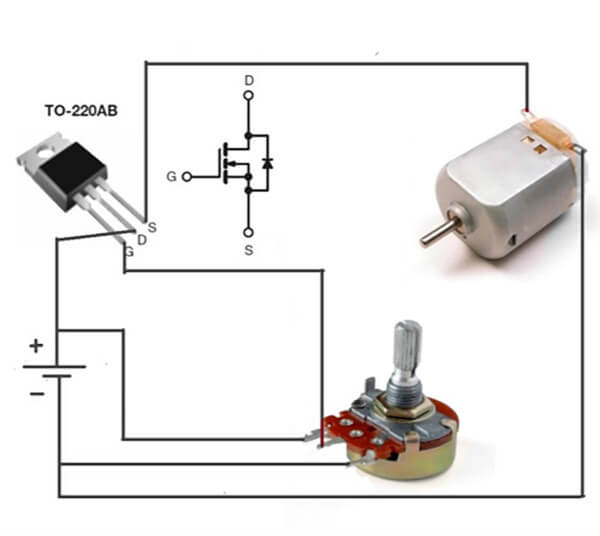

Electronics - dc motor + potentiometer

hardware

DC Motor circuit

- DC motor

- IRF540N MOSFET(N) Transistor

- Potentiometer 10kΩ

- Power supply of 5V or more, depending on the motor

Arduino + DC Motor + Potentiometer Tutorial

software

Arduino is not necessary to control DC motor with a potentiometer, it just gives more control options thank to the mapping option. DC motor + Mosfet + potentiometer could work alone though.

// code necessary only for Arduino option

int pot; //variable to which we save the potentiometer value

int motorSpeed; //variable to which we save motor speed

int motorPin=5; //pin to which we connect the gate of MOSFET

void setup() {

pinMode(motorPin,OUTPUT); //defining pin to which we connect MOSFET as an OUTPUT

digitalWrite(motorPin, LOW); //turning the motor off

Serial.begin(9600);

}

void loop() {

pot=analogRead(A0); //from the analog input A0 we read the potentiometer values

Serial.println(pot);

motorSpeed=map(pot,0,1023,0,255); //variable pot which has values from 0 to 1023 is turned into variable speed with values from 0 to 255

Serial.print("mapped value: ");

Serial.println(motorSpeed);

analogWrite(motorPin,motorSpeed); // set the value speed to motorPin to which we have connected MOSFET

delay(1000);

}

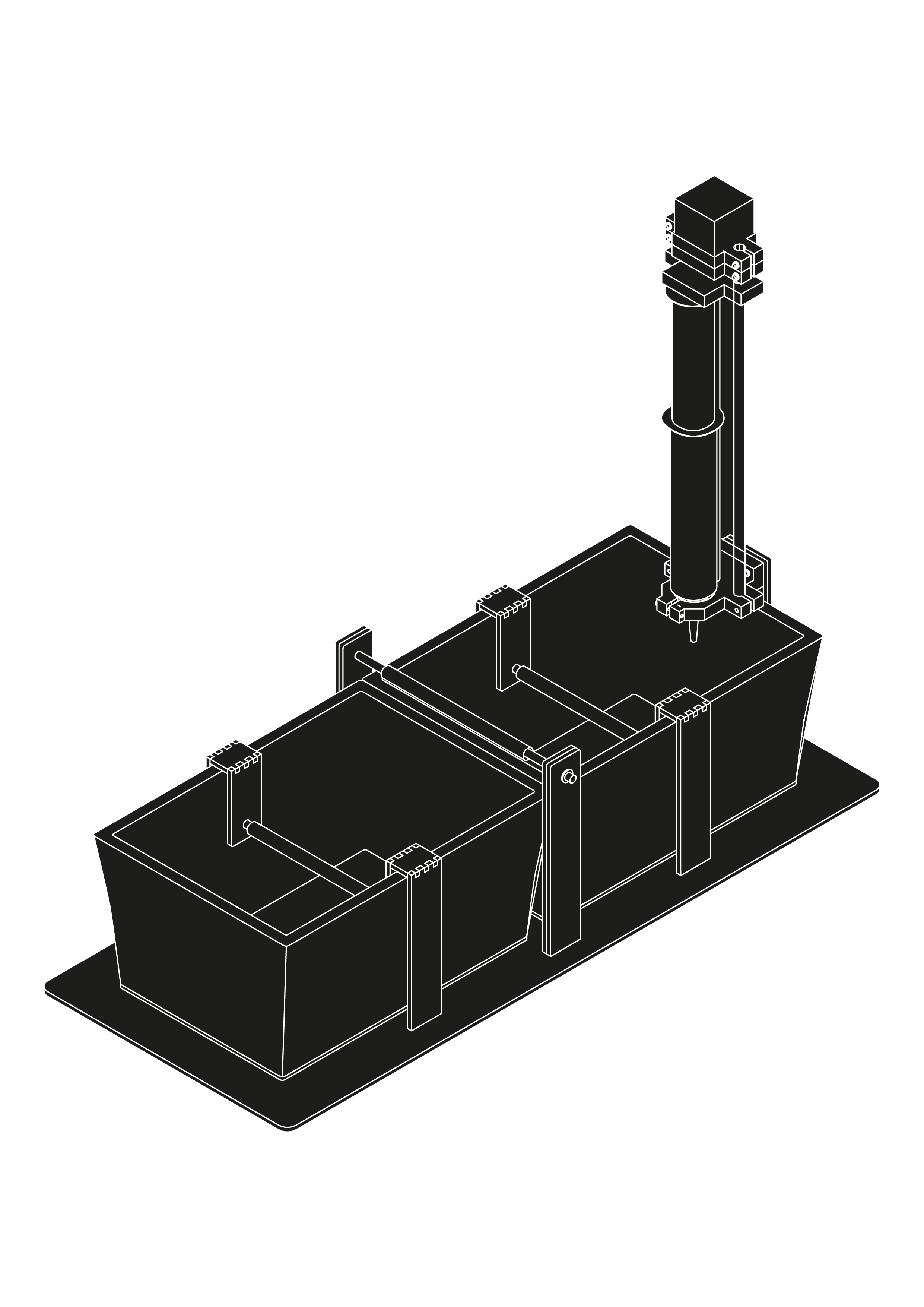

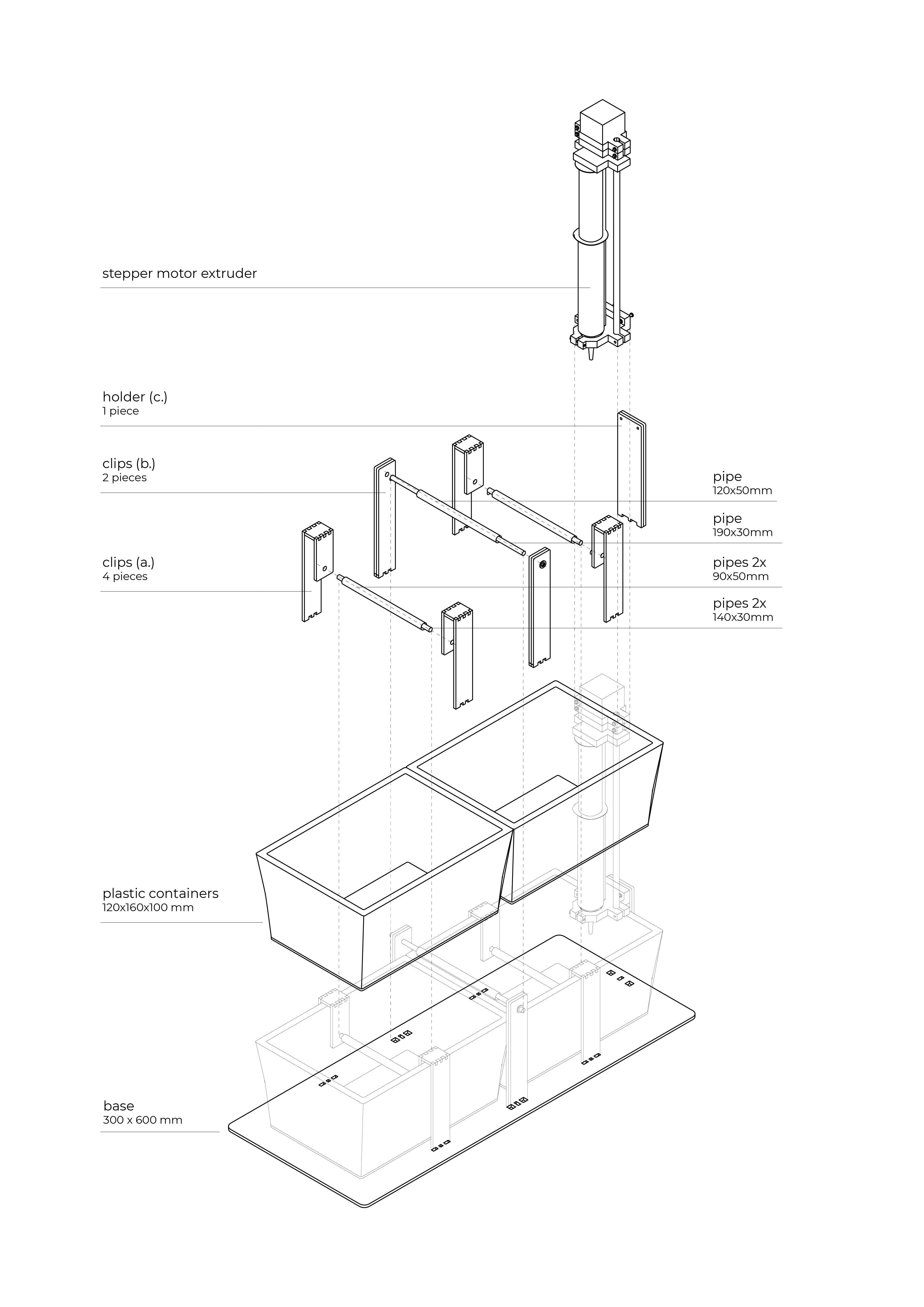

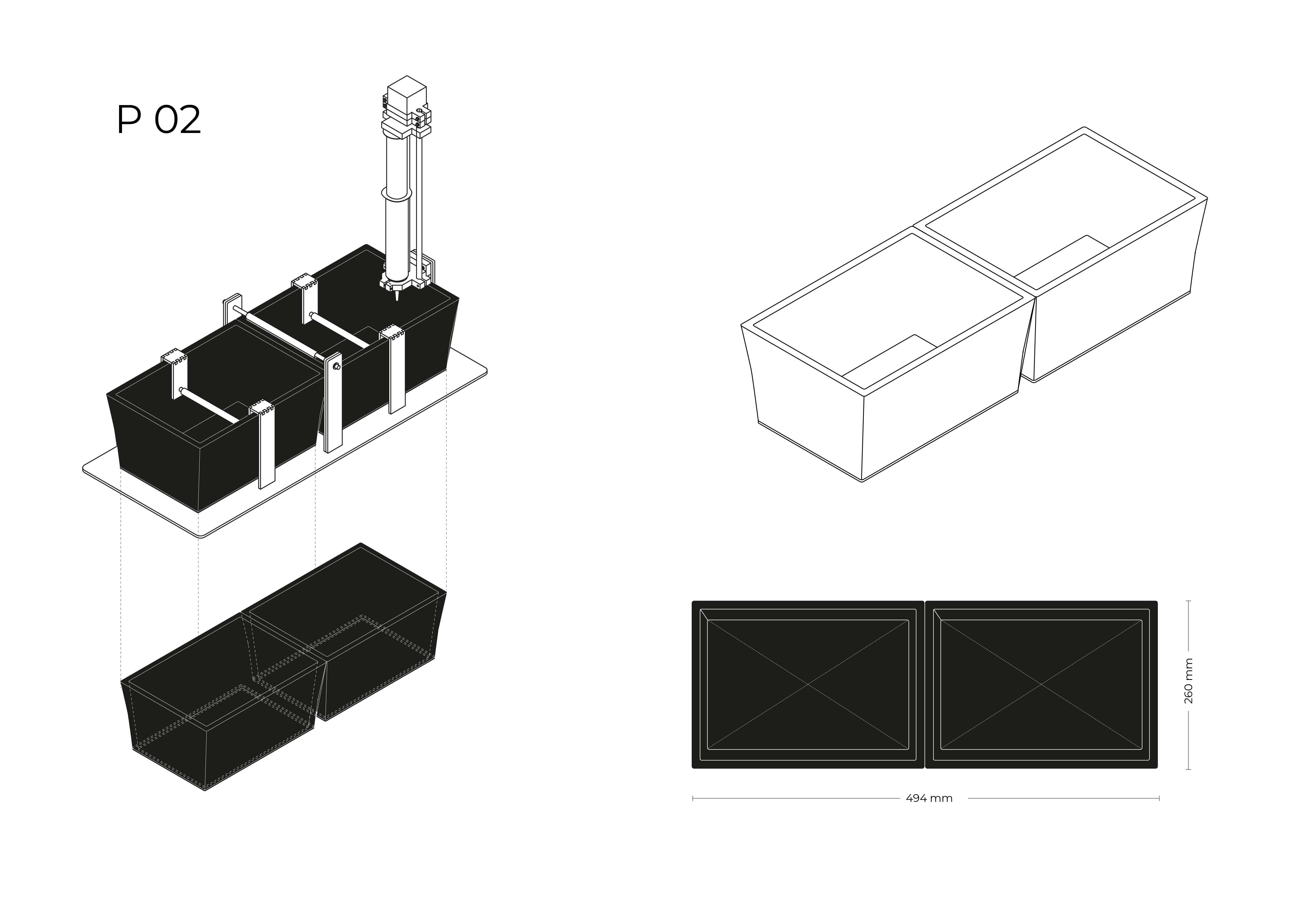

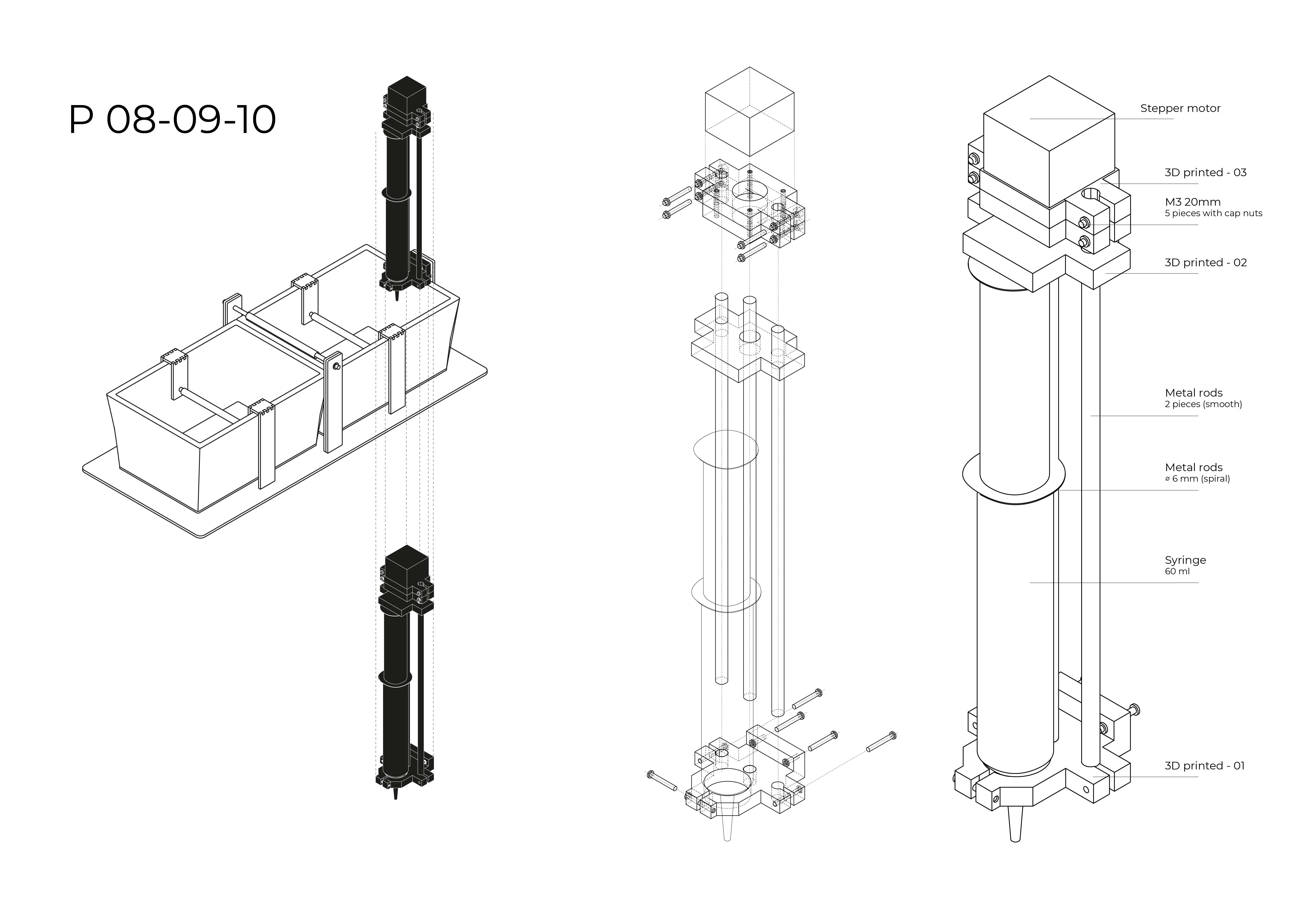

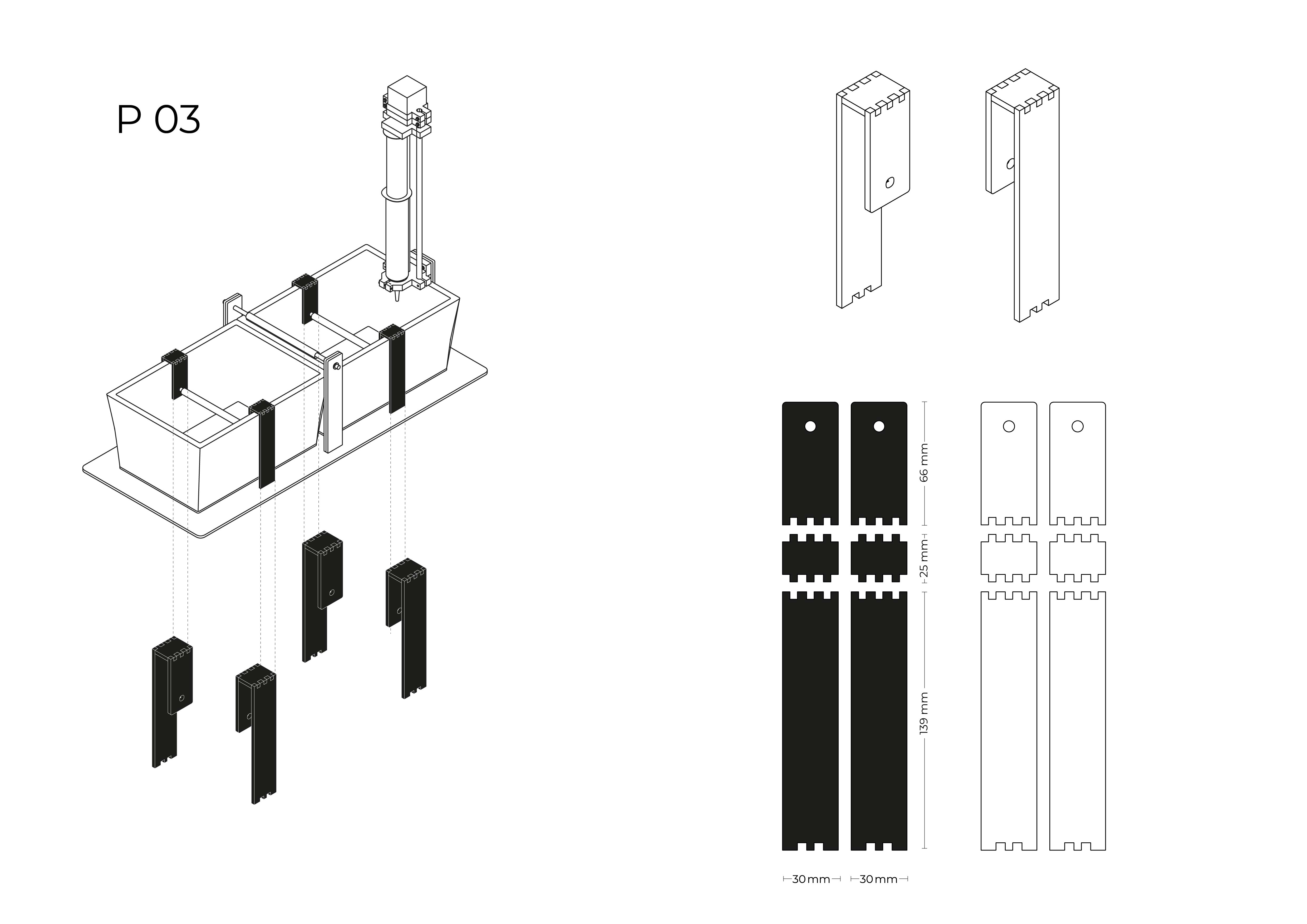

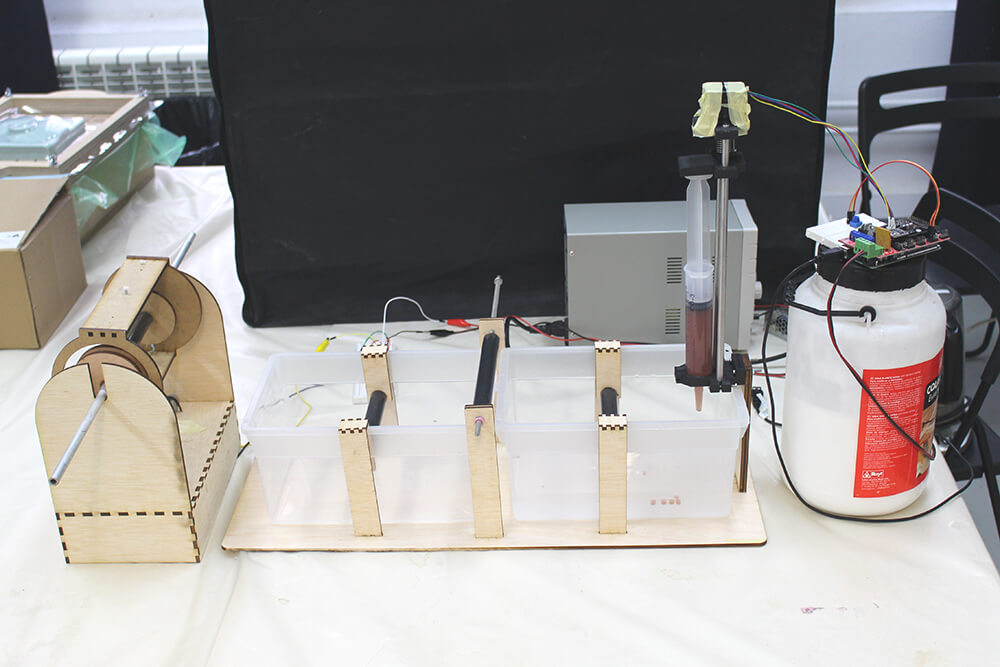

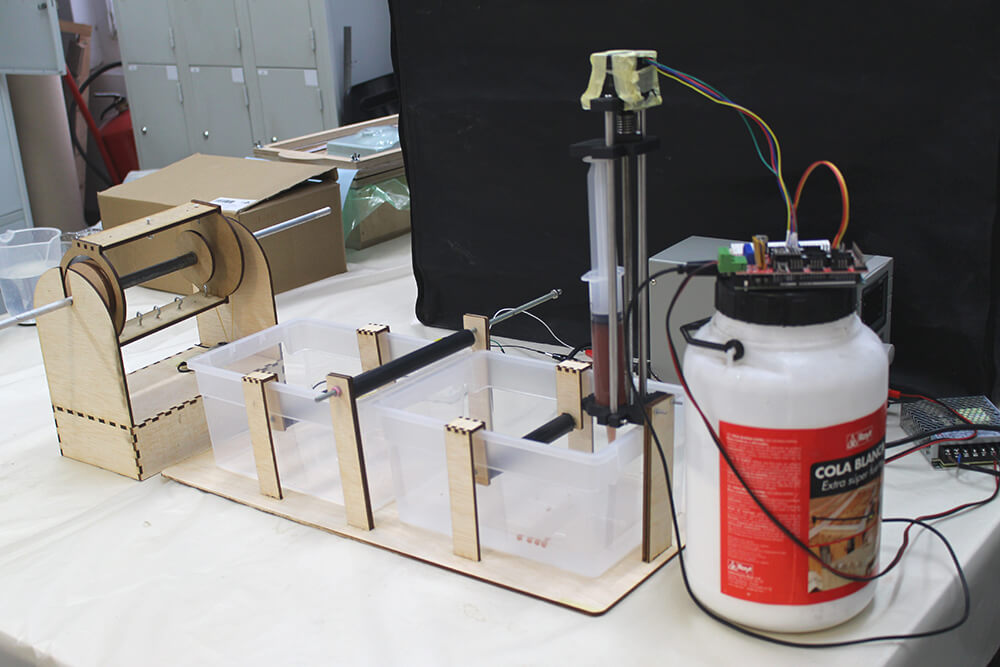

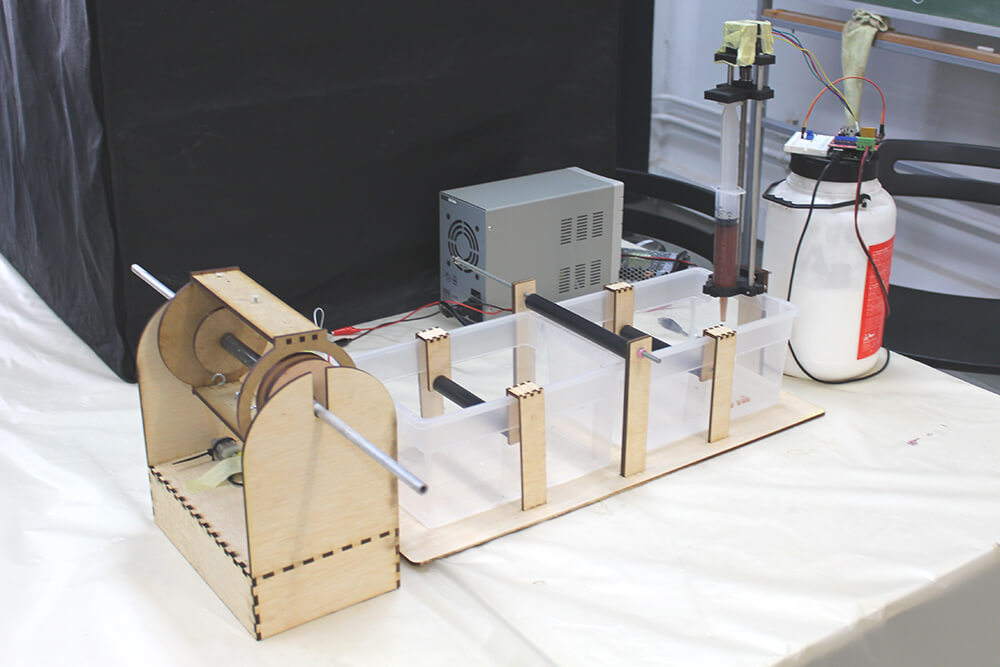

Alginate bioyarn extruder

Materials list

- Syringe 60 ml 1 board

- 3D printed parts 4 pieces

- Metal rods (smooth) 300 mm, ∅ 7 mm 2 pieces

- Metal rod (spiral) 300 mm, ∅ 7 mm 1 piece

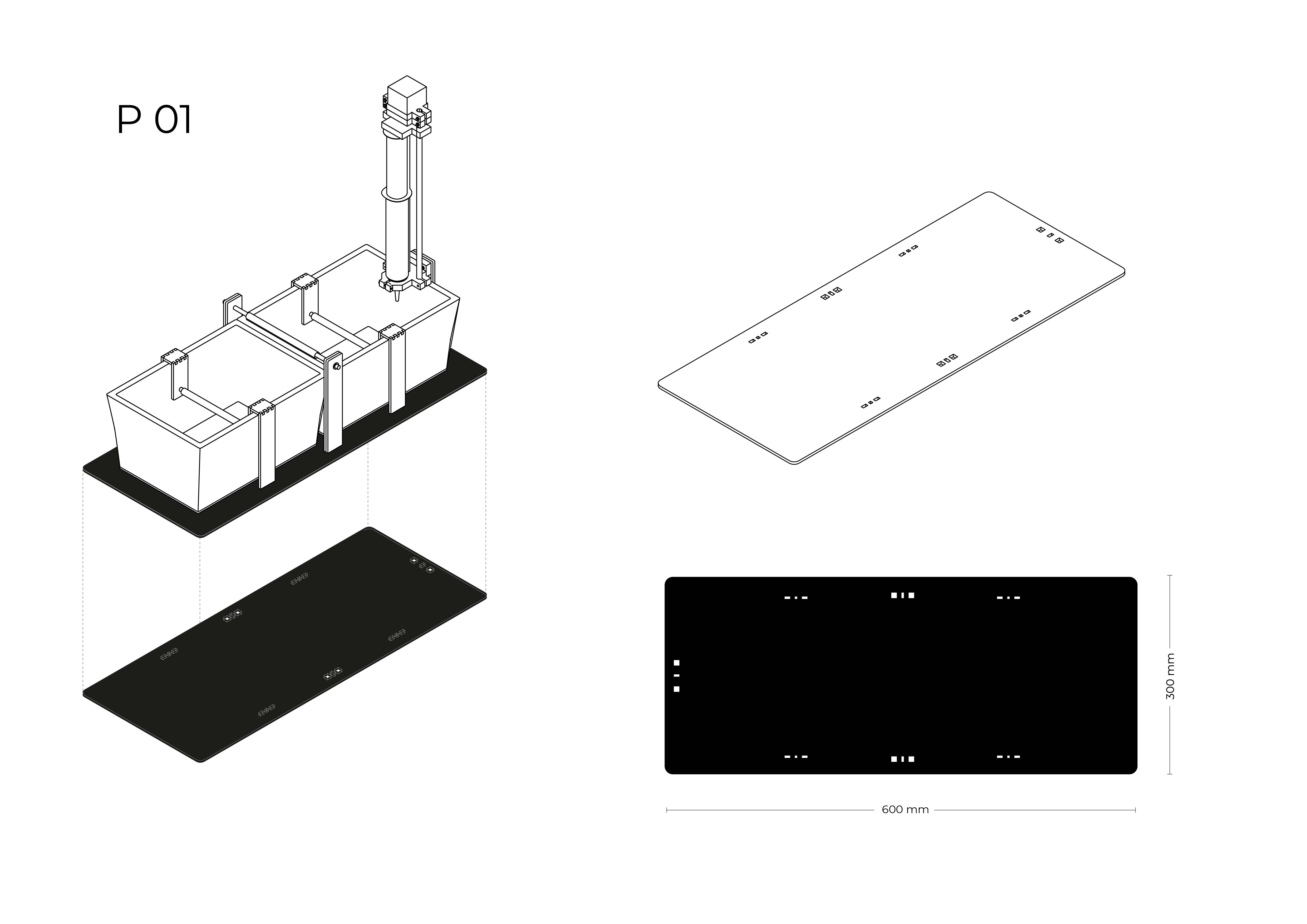

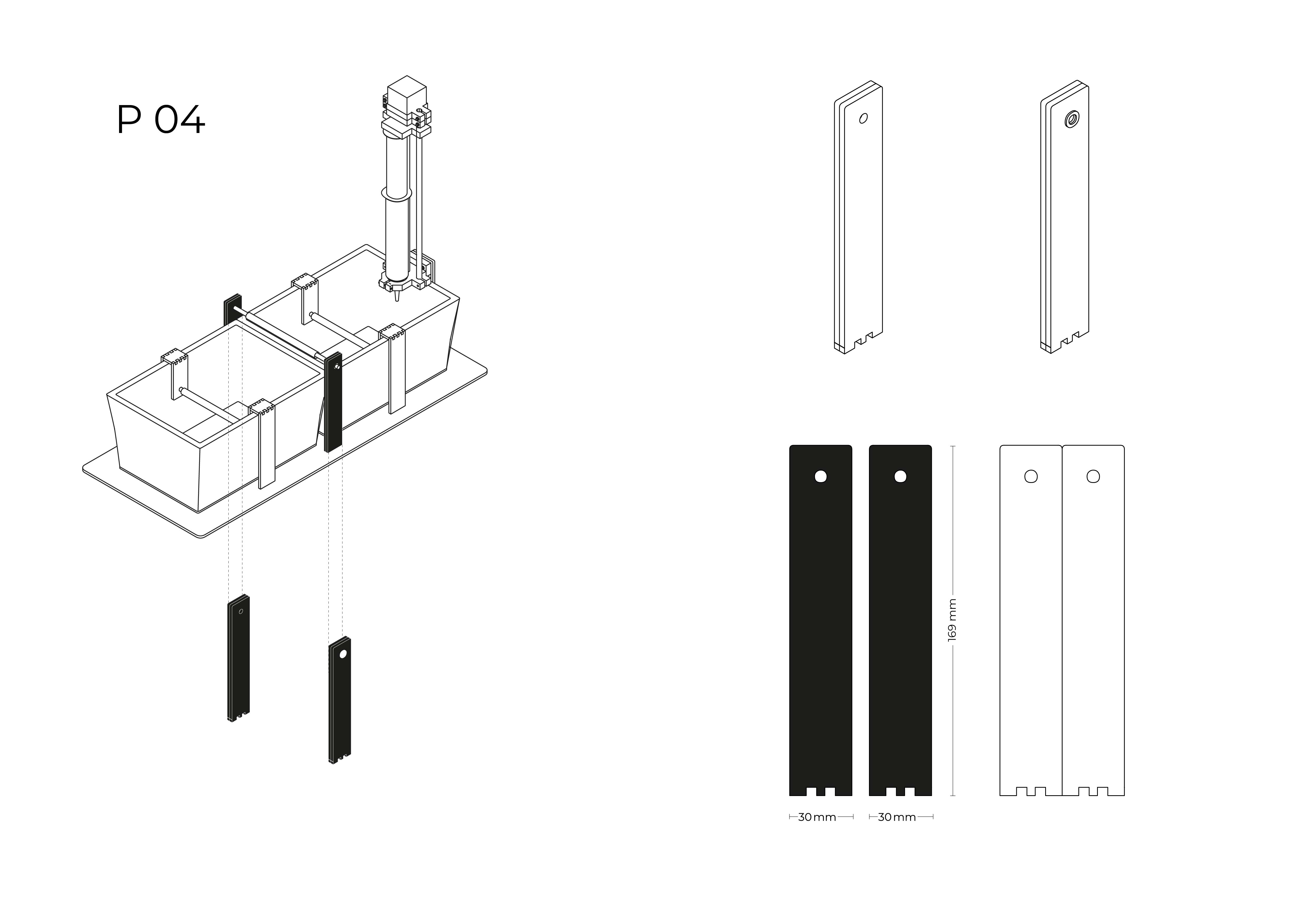

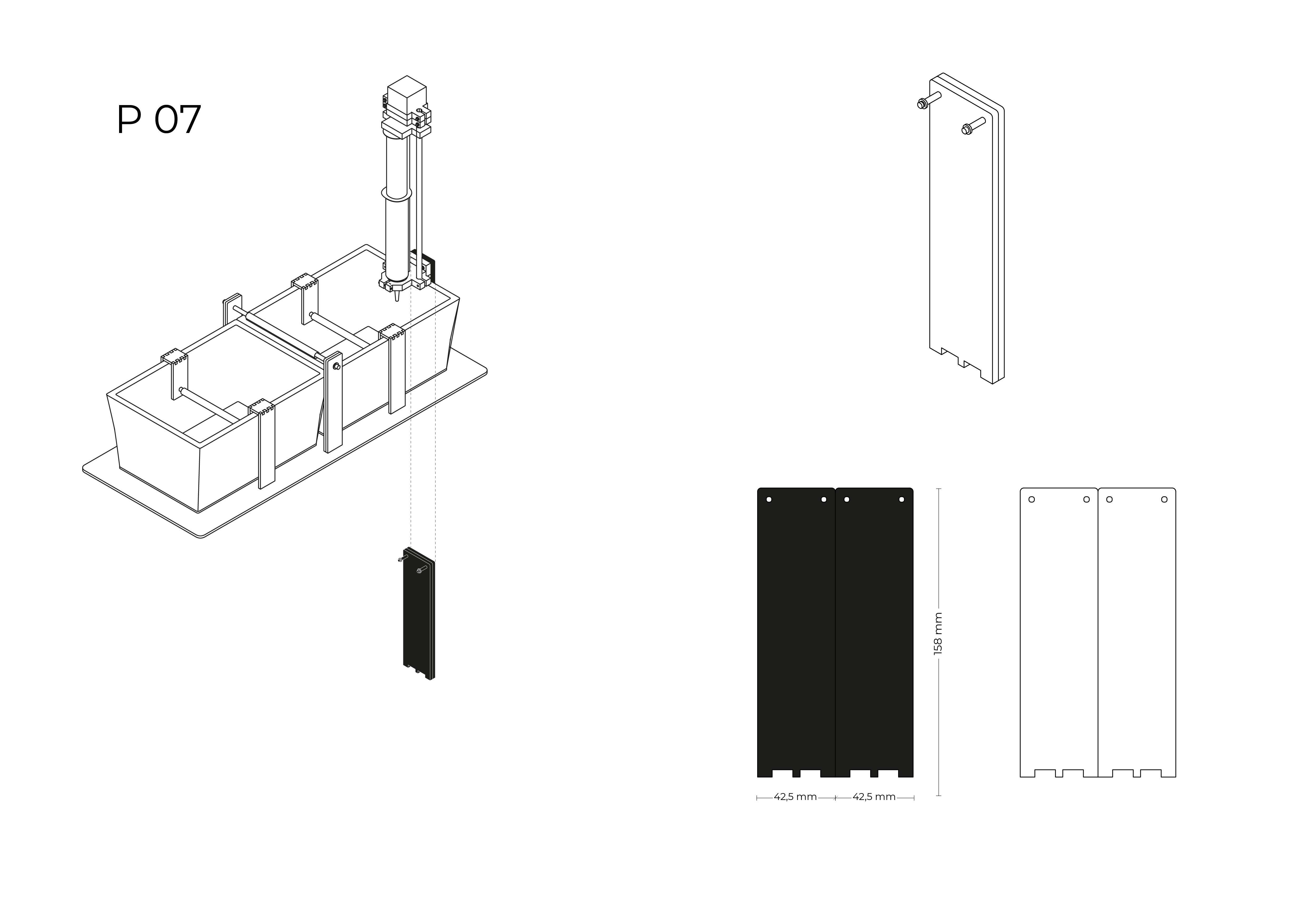

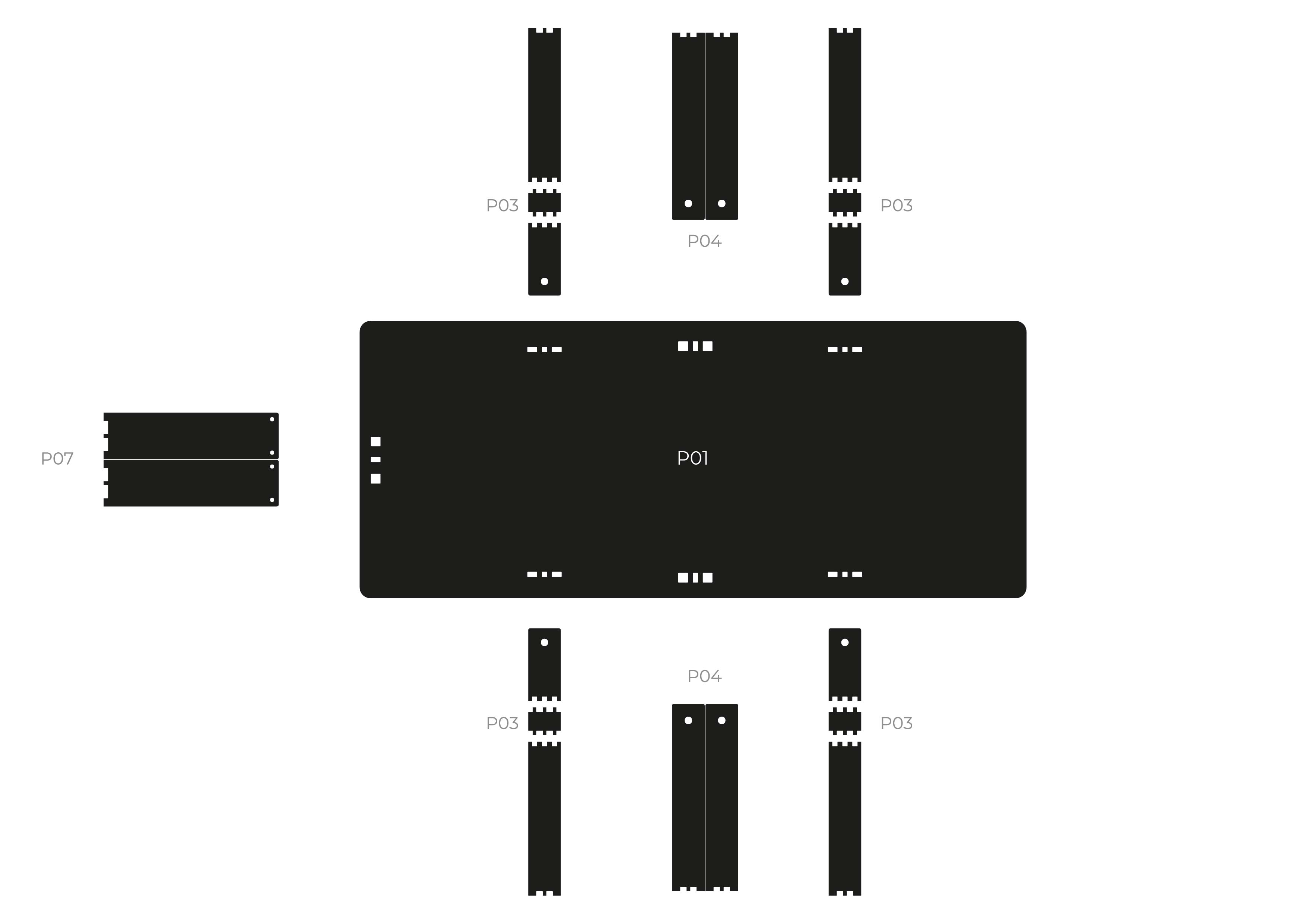

- Plywood 4 mm 1 piece

- M3 20 mm screws 5 pieces

- Cap nuts 5 pieces

- Aluminium tube 3 pieces

- Plastic tube 3 pieces

- Stepper motor 1 piece

- Arduino Microcontroller piece

- Arduino CNC Shield 1 piece

- Power supply 1 piece

- Alternate Current Adapter 1 piece

Electronics

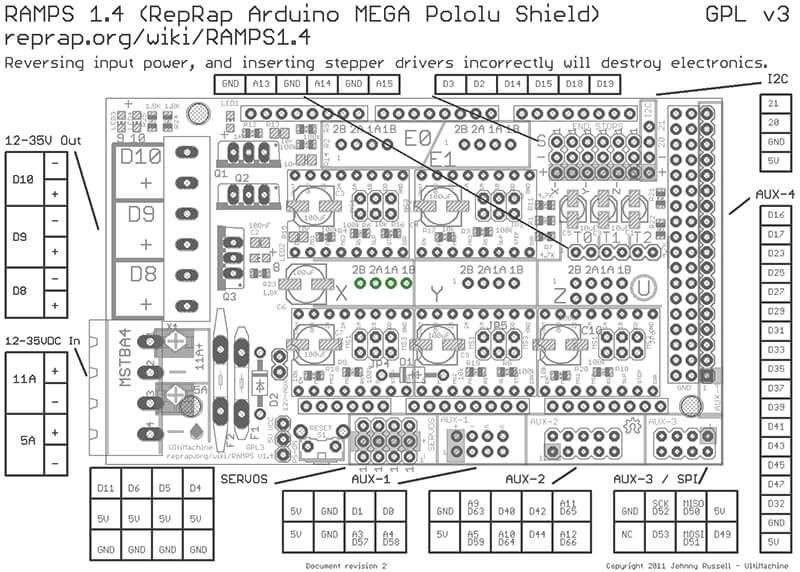

hardware - stepper motor + Arduino

Stepper Motor circuit

- Arduino Mega

- RAMPS 1.4 RepRap Shield

- Nema 17 Stepper Motor

- Stepper Motor Driver

- Potentiometer 10kΩ

- Power supply

RAMPS 1.4 configuration

by Eduardo Chamorro Pin definition

RAMPS 1.4

//

#define X_MIN_PIN 3

#define X_MAX_PIN 2

#define Y_MAX_PIN 15

#define Z_MIN_PIN 18

#define Z_MAX_PIN 19

#define Z_MIN_PROBE_PIN 32

1:24

// Steppers

//

#define X_STEP_PIN 54

#define X_DIR_PIN 55

#define X_ENABLE_PIN 38

#define X_CS_PIN 53

#define Y_STEP_PIN 60

#define Y_DIR_PIN 61

#define Y_ENABLE_PIN 56

#define Y_CS_PIN 49

#define Z_STEP_PIN 46

#define Z_DIR_PIN 48

#define Z_ENABLE_PIN 62

#define Z_CS_PIN 40

#define E0_STEP_PIN 26

#define E0_DIR_PIN 28

#define E0_ENABLE_PIN 24

#define E0_CS_PIN 42

#define E1_STEP_PIN 36

#define E1_DIR_PIN 34

#define E1_ENABLE_PIN 30

#define E1_CS_PIN 44

Stepper Motor calibration

Stepper Current = VREF × Max RMS

The maximum settable stepper current for NEMA 17 stepper motor is 2.0A according to the datasheet

FUll Stepper Motor calibration tutorialsoftware

Marlin Firmware int enablePin = 38;

int dirPinM1 = 55;

int Pulse = 54;

int POT = A5;

//int oldstepDelay = 0;

int stepDelay = 0;

bool start = true;

bool dir = false;

bool enableMot = 1;

int maxdelay = 3000;

int mindelay = 250;

void setup() {

// put your setup code here, to run once:

//Serial.begin(115200); if uncommented the motors runs slower due to serial wait timings

pinMode(POT, INPUT);

pinMode(enablePin, OUTPUT);

pinMode(dirPinM1, OUTPUT);

pinMode(Pulse, OUTPUT);

start = 0;

// Serial.println("Starting");

}

void loop() {

if (start == 1) {

digitalWrite(enablePin, LOW);

digitalWrite(dirPinM1, dir);

}

if (start == 0) {

digitalWrite(enablePin, HIGH);

}

int potPos = analogRead(POT);

// Serial.println(potPos);

//stepdelayMicroseconds = map(analogRead(POT),0,1024,1,maxdelayMicroseconds);

// make the motors move both irections depending on pots position

if (potPos < 500) {

start = 1;

digitalWrite(dirPinM1, HIGH);

stepDelay = map(potPos, 0, 500, mindelay, maxdelay);

//Serial.println("clockwise");

//Serial.println(stepDelay);

}

else if (potPos > 600) {

start = 1;

digitalWrite(dirPinM1, LOW);

stepDelay = map(potPos, 600, 1023, maxdelay, mindelay);

//Serial.println("counterclockwise");

//Serial.println(stepDelay);

}

else {

start = 0;

}

motorStep();

}

void motorStep() {

//if(start == 1){

digitalWrite(Pulse, HIGH);

delayMicroseconds(stepDelay);

digitalWrite(Pulse, LOW);

// }

} Biomaterial yarn by Petra

Petra Garajova preapred the biomaterial for extrusion with the machine. Check out more here - CELLULOSE EXTRACTION FROM AVOCADO WASTE

Assembly

Back