Wearables

Please see research here

wearables as physical interfaces with unique characteristics

Output - Actuators

visual

- LEDs

- Neopixels

- Optical fibers

- Thermochromic ink + heated circuit/code

sound

- Fabric speakers + amplifier circuits

motion

- Shape memory alloy + high load circuit

- Flip dot

- Flapping wing

- Mini vibration motors

Sensor - analog slider (from E-textiles week)

software - Arduino code

iint sensorValue = 0;

//int value = 0;

int pinInput = 0;

int pinOutput = 9;

// the setup routine runs once when you press reset:

void setup() {

// initialize serial communication at 9600 bits per second:

pinMode(pinInput, INPUT);

pinMode(pinOutput, OUTPUT);

Serial.begin(9600);

}

// the loop routine runs over and over again forever:

void loop() {

// read the input on analog pin 0:

int sensorValue = analogRead(A0);

// print out the value you read:

// limit the values witin 150/400 range

sensorValue = constrain(sensorValue, 150, 400);

// convert the analog sensor into a switch, value under the middle of the range will turn off, value above will turn on

if (sensorValue <= 125);

{

analogWrite(pinOutput, LOW);

}

else {

analogWrite(pinOutput, HIGH);

}

Serial.print("sensorValue = "); Serial.print(sensorValue); Serial.print(" | ");

delay(6000);

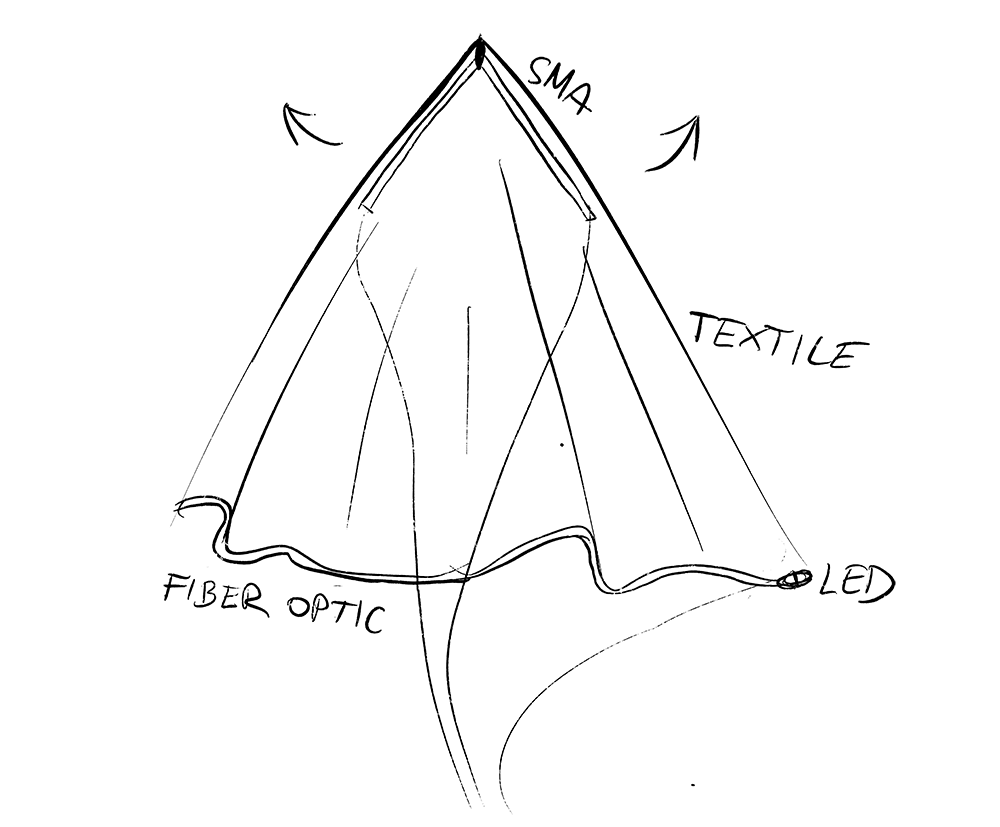

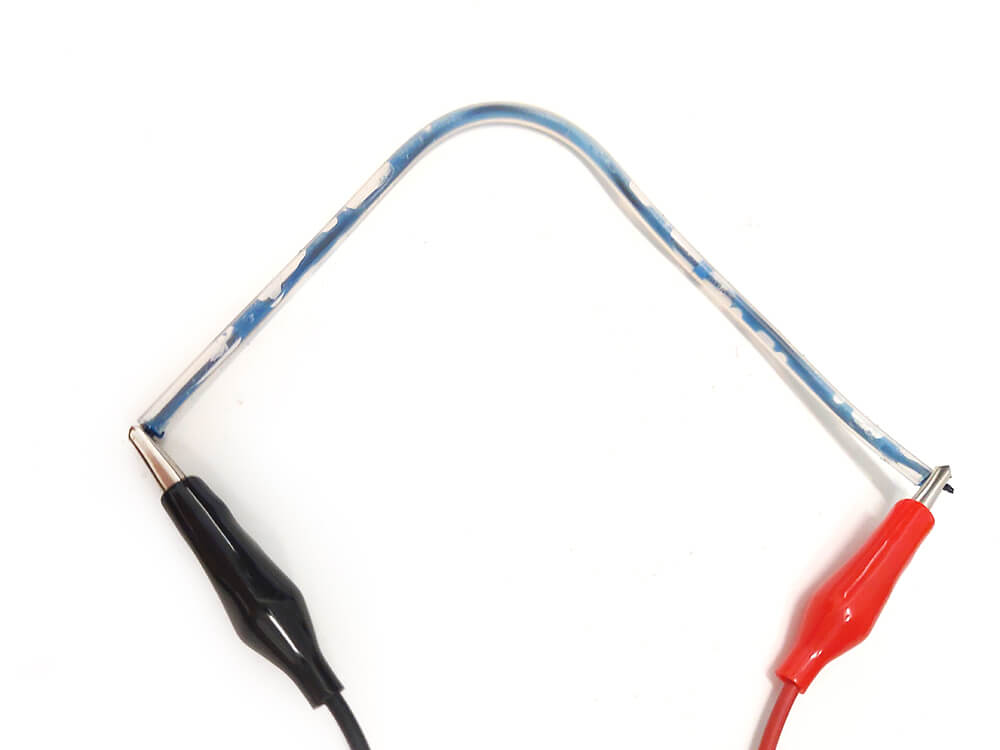

}Actuator - SMA Nitinol wire

characteristics

Shape memory alloys (SMAs) are metals that change shape when heated up. They are

wonderful actuators in that they are light, silent and can be "turned on" by simply running

current through. The shape that they change to can also be set, though this process is a bit

more tricky. Flexinol is a particular brand of nitinol, which is an SMA made of nickel and

titanium, and is pre-set to contract about 10% of its original length when heated.

The general trends are:

Actuator - optical fibre

Characteristics

The Beginners Guide to Fiber OpticsHow to Connect Optical Fibers to LEDs and Sensors

Makezine tutorial: How to Connect Optical Fibers to LEDs and SensorsProject idea

re-using the analog slider from week 5

Analog slider

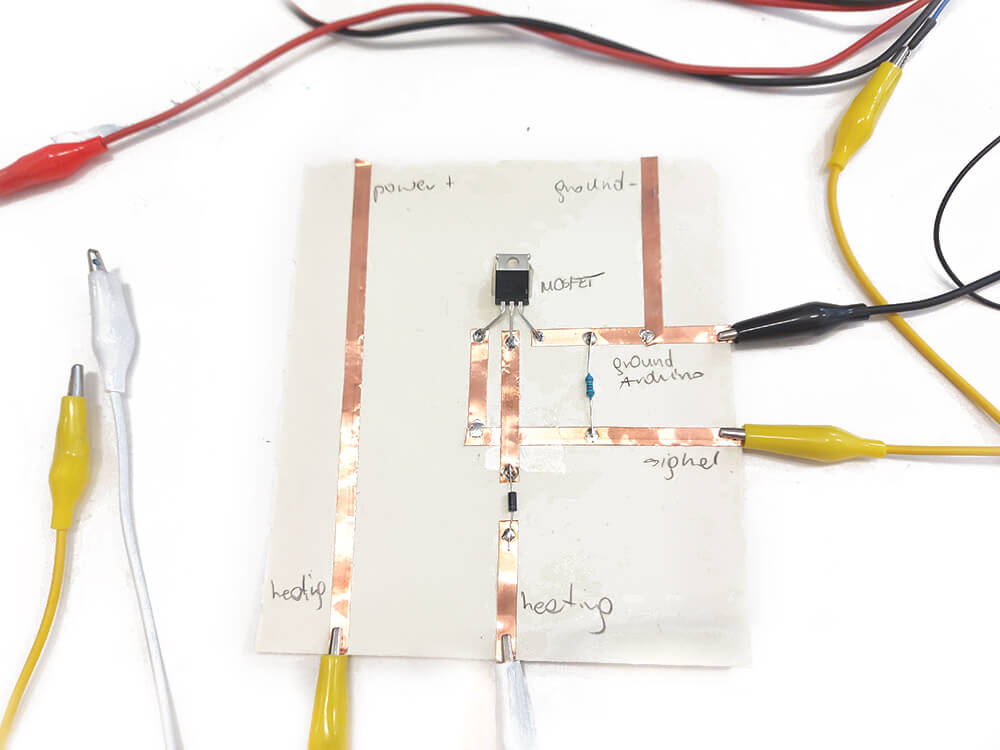

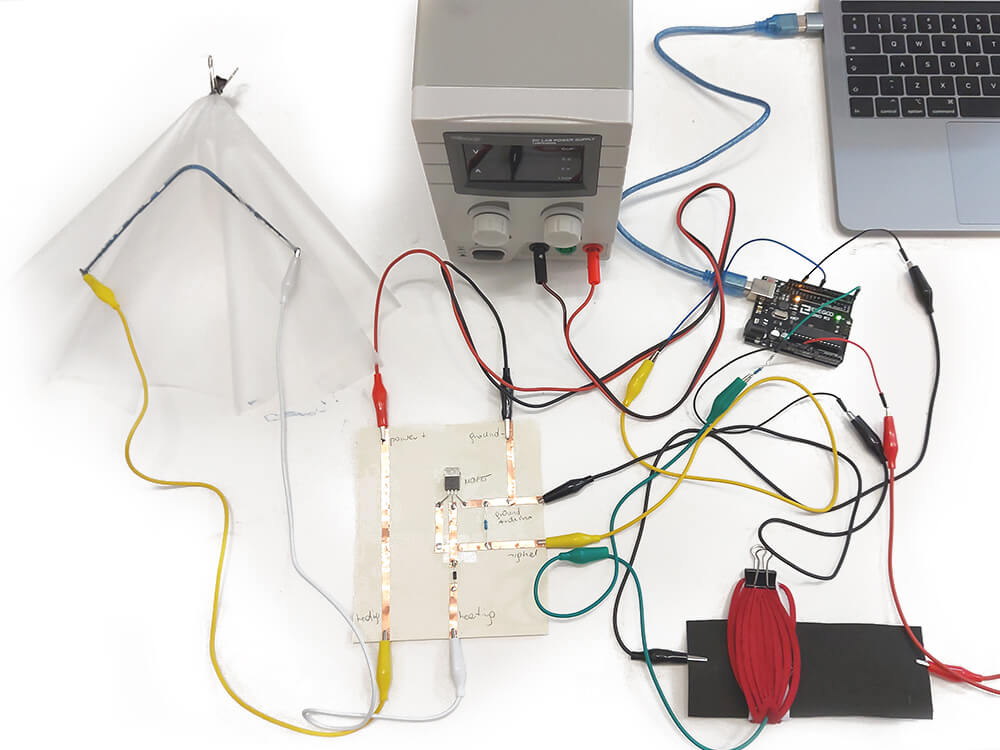

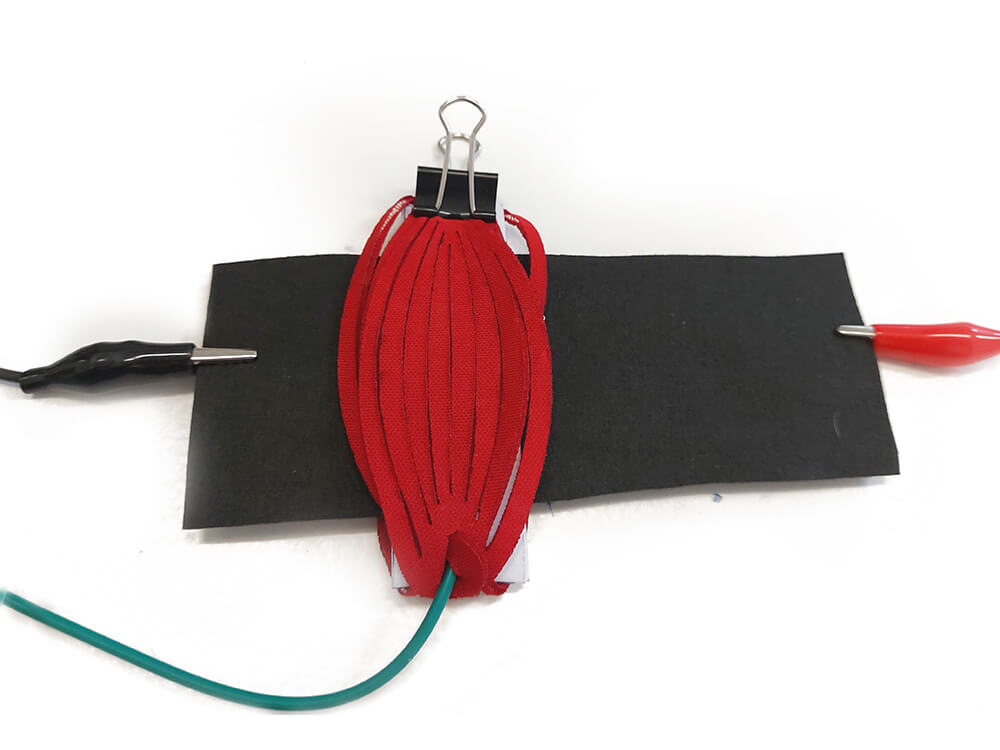

SMA test 1

SMA test 2 + termochromic ink

Thicker wire, requires much more power to move. Ink changes color fast, requires lower trigger temperature than the SMA

For further investigation

Conductive foam pressure sensor with biochar bioplastic (or graphene or graphite)

Foaming agents / processes

The Strange Physics of Foam

https://science.nasa.gov/science-news/science-at-nasa/2003/09jun_foam

Foam Making - Prof Steven Abbott

https://www.stevenabbott.co.uk/_downloads/Surfactant%20Science%20Principles%20and%20Practice.pdf

Foam Making - Prof Steven Abbott

https://www.stevenabbott.co.uk/practical-surfactants/foam-making.php

- acidic + alcaline substances

- Cellulose fibrils with foam forming surfactants

https://www.exilva.com/blog/how-to-use-cellulose-fibrils-with-foam-forming-surfactants Cellulose fibrils with foam forming surfactants - dry freezing process

- yeasts

- mechanical - foaming device for gastronomy - WHIPPING SYPHON

DIY conductive ink + termochromic ink combination

Development of a Screen-Printable Carbon Paste to Achieve Washable Conductive Textileshttps://www.mdpi.com/2673-7248/1/3/22

Self Limiting Conductive Ink 1 - Robert Murray-Smith

https://www.youtube.com/watch?v=5ccgz-4Hzwk

Self Limiting Conductive Ink 2 - Robert Murray-Smith

https://www.youtube.com/watch?v=zyGX-VyXXTQ&t=34s

Self Limiting Conductive Ink 3 - Robert Murray-Smith

https://www.youtube.com/watch?v=PnFLlWeUjPE

(fume silica + glycerol to achieve thicker paste texture)