3. Circular Open Source Fashion¶

Research & Ideation¶

The amount of waste we produce by manufacturing clothes is terrifying. There is a lot of waste created during the process, and much more when the garmet is used and ditched as unwanted piece of clothing. I have learnd that only 16.7 % of fabrics can be recycled. And about a 1/3 of produced clothes and garments are thrown away by companies, because they never get sold.

I have decided to look at the problem of Fast Fashion and waste production from a bit different angle. There are multiple reasons why we keep buying more things that we actually need. One of my personal reasons in that clothing and garmets are not multipurposeful and modular enough. That forces me to buy multiple t-shirts, jackets for different occasions, shoes, bags etc. Eventhough I am trying to be toughtful I still feel like I am fighting a battle of my comfort versus environmental issues. This week I wanted to try to see if I am able to create something, that would not force me to choose.

Inspiration¶

Contiqua Refresh¶

In Czech Republic, we have an automobile company Skoda. Skoda has a huge amount of fabrics that left from the production of seats and interior covers in the car. One of my favourite projects is Contiqua Refresh, its a project from local Q Designers studio, that gather leftover leather and produces high quality wallets and purses. The purses and wallets, are always original, since the color of the fabrics depends on the leather, they are able to gather.

Alex Monhart Backpack¶

Another very inspiring Czech designer, one of her first successful projects was a multipurposful backpack that can be folded into a hand purse. The desined the of the parts and her choice of fabric makes both od modules useful and tasteful.

Modular shoes¶

Since 2018, there has been a trend in modular shoes, that can be assembled by the customer its self. Instead of readymade shoe, you receive shoe parts and assemble it yourself. I really like the idea of bringing back the craft to people, because there is a slight corolation between we make by our own hands and our willingness to throw it away. Also there is various benefits for modular shoes:

- We can customize the shoe to fit our needs.

- Can be disassembled for easy cleaning, and fast recycling (or reuse)

- Can be interchanged with other parts.

- Reduces the need to produce mass production.

Process¶

I have decided, I want to try to design and create my own seamless modular shoe that is multipurposeful and can be used for every different season of the year. This way you have only one shoe for the whole year. Instead of buying 4 shoes, you buy only 1. I made myself a bit of a challenge to try to make is seamless, glue less and use only different interlocking techniques to connect the shoe.

Prototyping¶

This week I was determined to really do my prototyping phase properly. As adviced by Cecilia, Mesure twice and cut once. I must say it really does come into fruition. It saved me a lot of time, but also I wasn't so scared to make mistakes when using only paper and scissors.

Interlocks¶

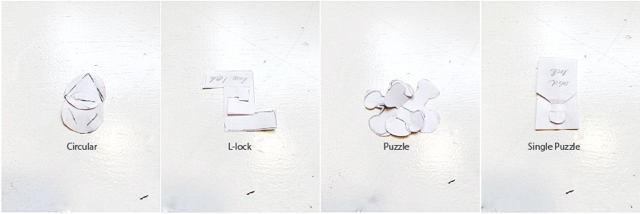

We were adviced by Bea to try first the different types on interlocks on paper. I knew I needed two different types of locks, that potentionally can be locked together if needed. I was looking for a locking pattern that is long and can hold firmly two parts, but also is not hard to lock, and other pattern that can create interesting surface structure combined together, but is difficult to unlock and lock.

We were shown a numerous number of interlocks. One of them instantly caught my eys.

I have decided to prototype four different locks and try which one would be the most suitable for me. The winner at the end was the puzzle inspired interlock.

"L" shapped lock was pretty but too loose. "Puzzle interlock" was interesting but too complex. I have made my paper prototype, tested them and the decided to create them in Adobe Illustrator. At first I have started in Rhino, bud since I was more comfortable with Illustrator and I knew this project demands quiet quick action, I turned to Adobe Illustrator instead.

Have a look at a video of how I have designed the two interlocks[2].

Shoe Pattern¶

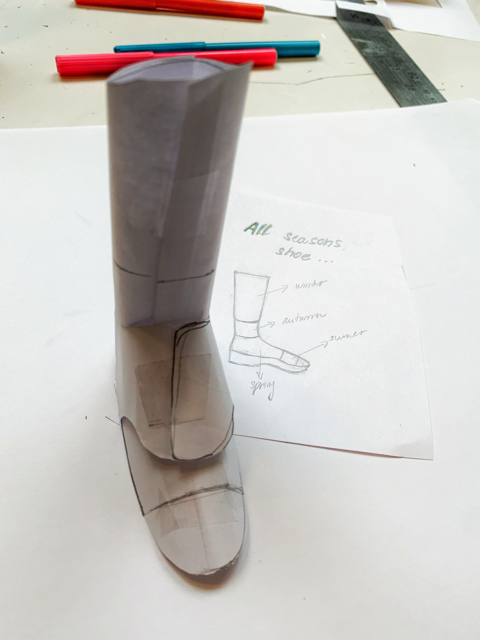

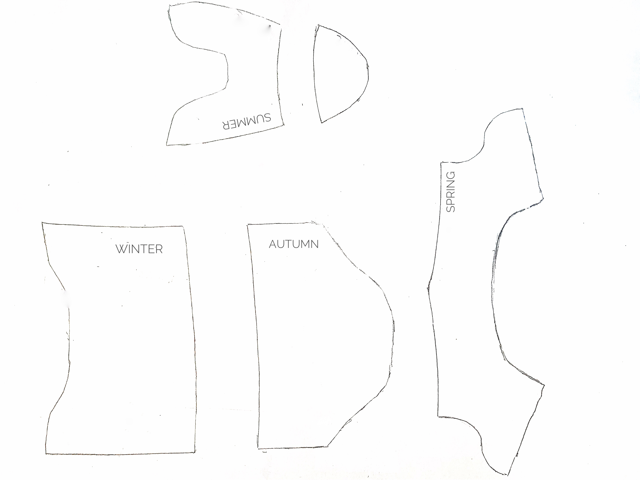

I have never made any shoe pattern or footwear design, therefore this was new to me. Fortunately I have found a great website,that has a great explanation on what importants parts you need to create the base of the shoe. From there I started drafting my shoe. Firstly I have decided draw a simple sketch, so I can think about the actual modules for different type of the shoe.

Then I proceeded with the 3D simple prototype, added highlighting tape on the conjuctions and ended up unwrapping my shoe to make a 2d pattern. I ended up tracing the pattern by hand so I have a clean base to trace on the computer.

I have uploaded the picture to my computer and traced the pattern in Adobe Illustrator, have a look at the video, to see my tracing technique.

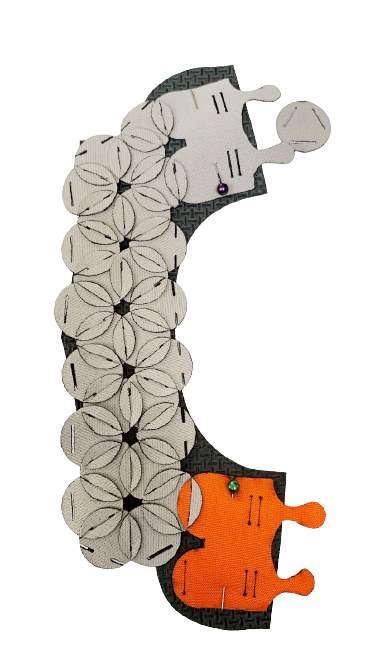

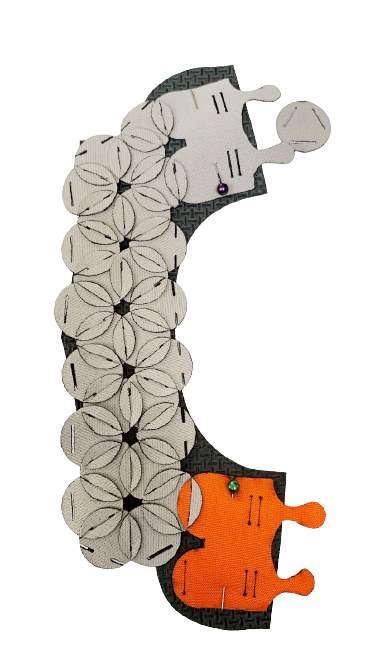

Results¶

Paper Prototype¶

I did not wanted to waste any fabrics, so I have firstly assembled my paper prototype. I have arranged my parts accordingly. It was a great think, because I have realized that my holes in interlocks are to small and were to hard to manipulate. Also some parts of my paper pattern did not sit perfectly, but that wasn't a huge problem since I knew I would use a thick fabric, that would close the gap. In addition to that I have realized I can make my intelocks easier and instead of using five locks, I joined them into one much stronger piece. I have marked the parts that were the locking parts, so I don't forget where do the connect.

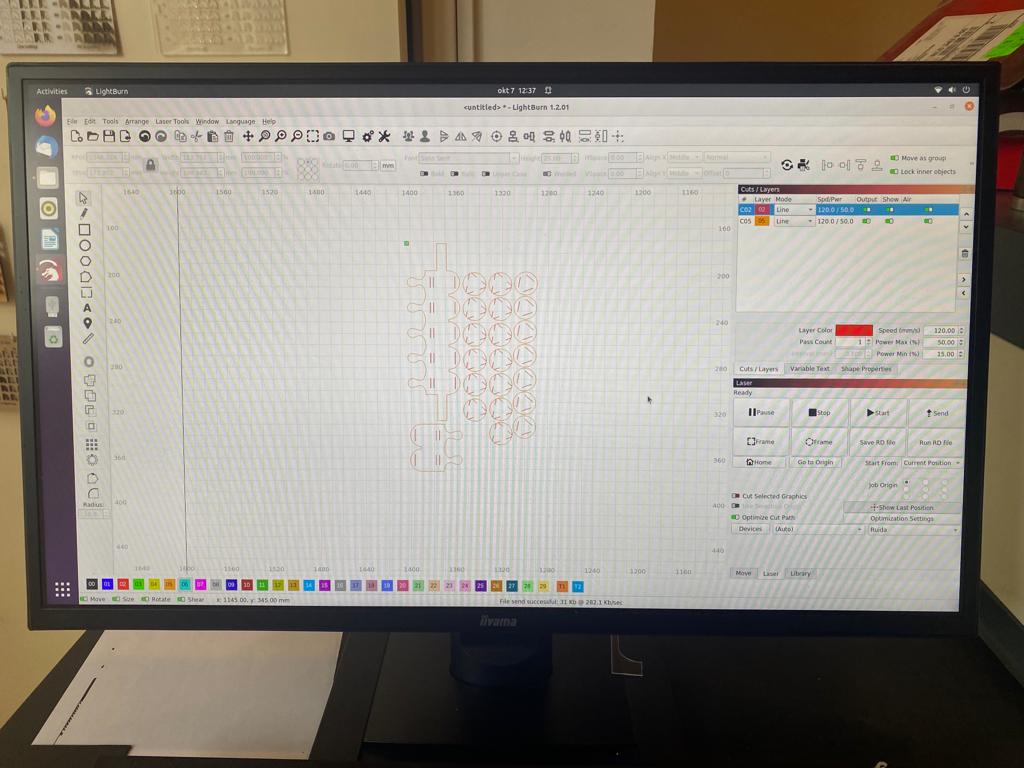

I took a lot of notes, counted the number of parts I needed for the full shoe, adjusted my laser cutting sheets and I was ready to go cutting. I have laser cutted from paper with very low settings:

- speed: 400

- max power: 15

- min power: 15

Full version¶

I wanted my shoe to be as authentic as it could be, so I have decided to use three different types of fabrics as if it was created from leftover materials.

I have laser cutted all three pieces on the same settings and it worked like a charm.

- speed: 120

- max power: 50

- min power: 15

I have assembled the shoe firstly without the sole.

Then I went to flee market a bought an old small converse pair of shoes and used the shoe sole as my base of the shoe. I named each piece base on the season you could wear the shoe on.

Conclusion¶

There are several things I would have done differently. The shoe is just a MVP of a shoe. I would love to make this shoe in real human size to wear, but it would add another dimension to the project which is reality. The shoe is still quite complex, the locking sections are way too complicated. I would like to combine this technique with 3D printing a having the intersections connect with less difficulty. I would also reconsider the round shapes of my interlocks, since they still produce some waste.

Eventhought there is a lot to improve, I have had so much fun this week. I loved the topic and all of the phases of the project at the end I am really proud of my result.

List of Tools¶

I have used sever tools finish my project. Here is the list of them:

- Adobe Illustrator - A designing software to create interlocks

- Rhino 3D - A software to create multiple objects fast

- iMovie - A free software to cut my videos (for Mac OS)

- Laser cuter - A machine to cut the pattern and interlocks from fabrics

- Snapseed - A free mobile app to edit my picturs