2. DIGITAL BODIES¶

LASER CUTTING¶

In preparation for operating the laser-cutting machine, it was essential to comprehend its mechanism and fundamental principles, as well as become acquainted with the machine's production capabilities. We received a thorough and engaging presentation from Josep Martí, followed by hands-on instruction on how to use the equipment. As a designer who had previously only worked with the machine alongside an expert, I was excited to receive training and be able to operate the laser-cutter independently.

Presentation - Computer-controlled Cutting

BASICS OF USING A LASER CUTTER¶

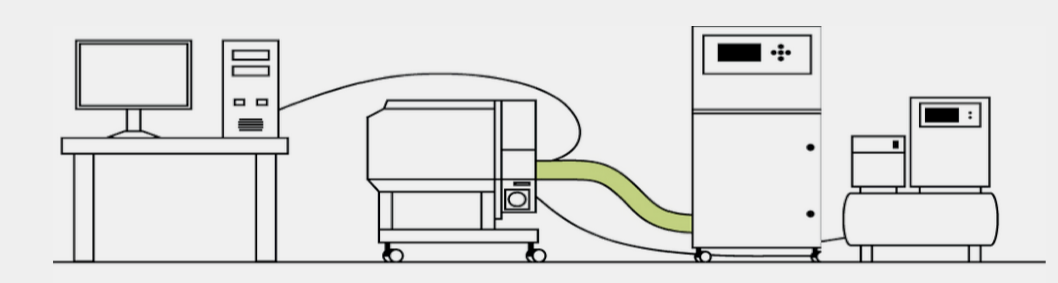

The laser cutter is connected to various other equipment. It is very important that everything is turned on and working before using the laser cutter.

- Computer is needed to set the correct cutting information.

- Fume extraction unit is required to remove fumes and small particles produced by vaporization of the materiál.

- Compressed air supply is needed to add air to the laser cutter to maintain airflow.

LASER-CUTTER ANATOMY: It consists of laser source, optics, (3) axis CNC and controller.

LASER PROCESSES: Engraving / Marking / Cutting

MY EXPERIENCE OF USING LASER-CUTTER¶

Using a machine involves multiple steps and requires familiarity with the software on the computer. When I was creating laser-cut pieces for my mannequin at FabLab BCN, I sought assistance from Petra. With her help, I successfully completed the process and felt a sense of pride after finishing the final piece on my own.

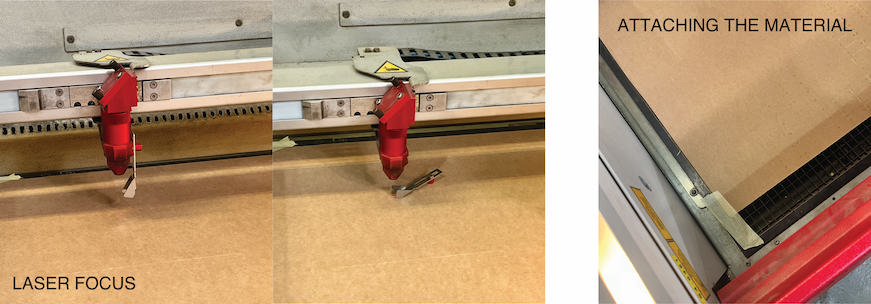

LASER FOCUS - The material must be set at the correct height for the laser lens to be in focus. The material must be moved up or down so that the laser focuses on the top surface of the material. There's a small component that falls off when the material is focused.

ATTACHING THE MATERIAL with adhesive paper tape to make it flat.

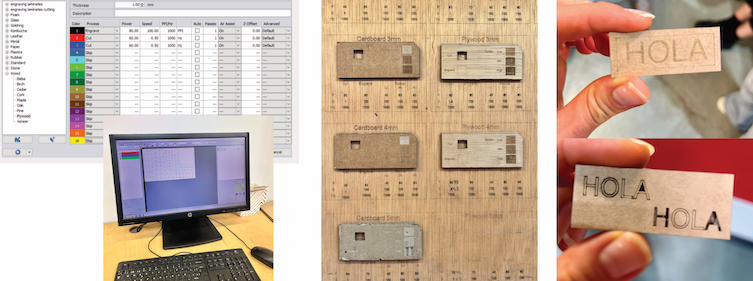

MATERIAL TESTING For laser cutting, it is necessary to select the appropriate material and then set the correct parameters. It determines the depth to which the laser will cut:

- POWER - The percentage of power used by the laser.

- SPEED - The speed at which the laser carriage moves throughout its job.

- PPI - The firing rate of the laser as it moves (pulses per inch).

As a demonstration, we used cardboard into which we engraved, cut and marked the word HOLA. We had to find the best adjustments for the perfect result.

CARDBOARD / PAPER: Inexpensive, recyclable, easy to paint, easy to join, x material with low durability. Parameters vary depending on the thickness of the material. You can find the reference cutting parameters at the manufacturing laboratory on the board.

I describe the workflow and an example of file preparation in more detail in the description of my work on the project.

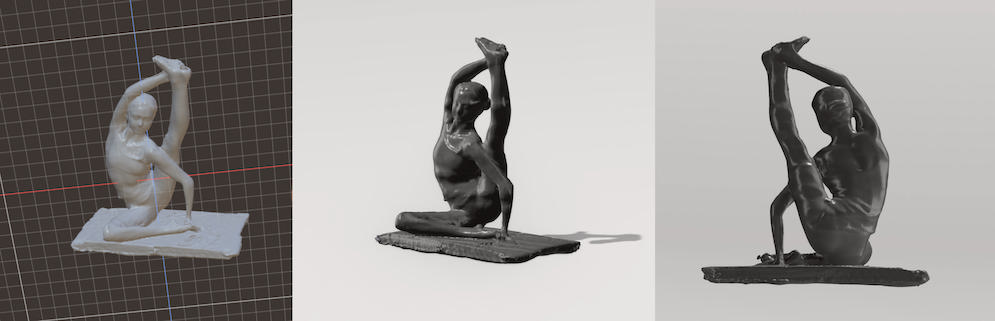

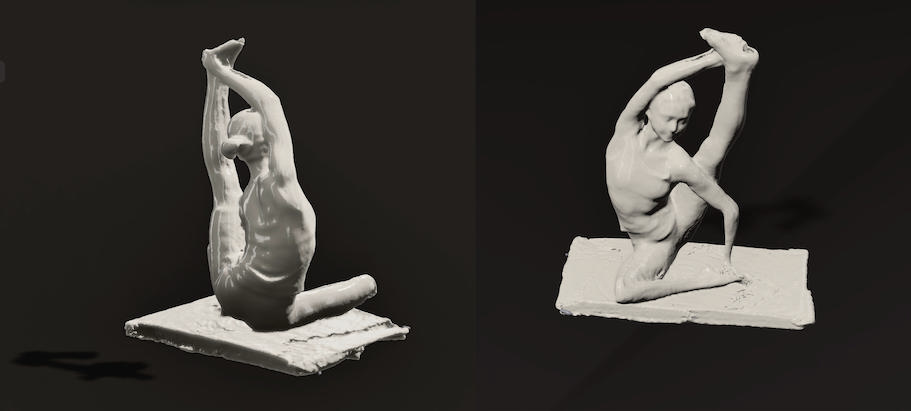

3D SCANNING¶

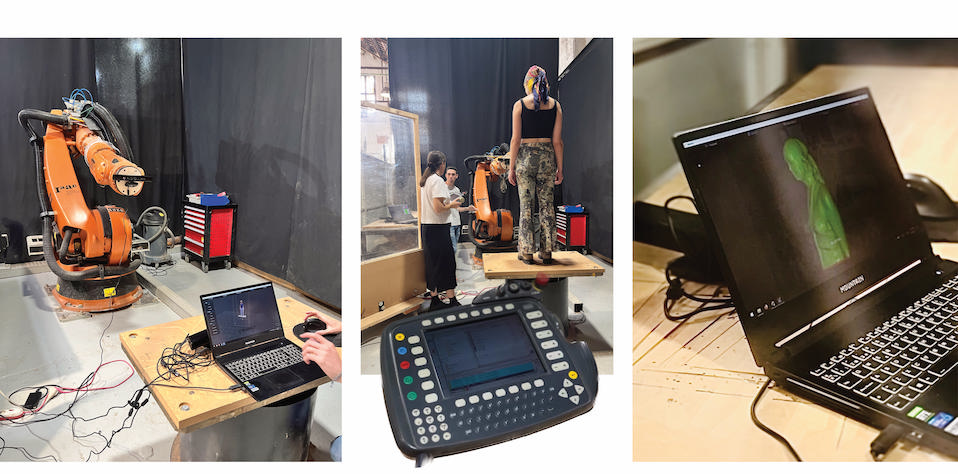

At the second workshop, we were taught how to use a KUKA robot and Kinect for 3D scanning. The KUKA robot is a versatile industrial robotic arm with six axes, to which we attached the Kinect. It was an exhilarating experience to scan an entire human body with such a large-scale robot. To operate it with ease, we used the controller or robot control panel, which had numerous buttons and display. To ensure precision in our scans, we placed the objects on a rotating board.

Using the Kinect for scanning with the KUKA robotic arm offers numerous advantages. The robotic arm can navigate through space more effectively and avoid collisions, resulting in more precise movements compared to human beings. Additionally, the KUKA's scale and wide range of motion allowed us to scan the entire body.

SKANECT SOFTWARE¶

Skanect is a 3D scanning software that allows users to turn a variety of 3D sensors, such as depth cameras or structured light sensors, into 3D scanners. The software offers various scanning modes, such as object, room, and body scanning. We were using the mode for scanning the human body. Skanect provides real-time feedback during the scanning process, helping capture all necessary data for 3D models. Skanect includes basic post-processing tools for cleaning up and refining 3D scans. This can be useful for removing noise or unwanted elements from the scan. It allows to export the 3D scans in various formats, for instance, STL and PLY.

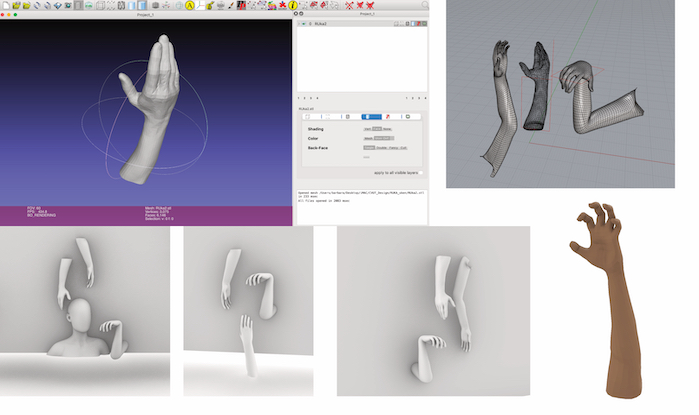

EXPERIMENTING WITH 3D SCANNING APPS¶

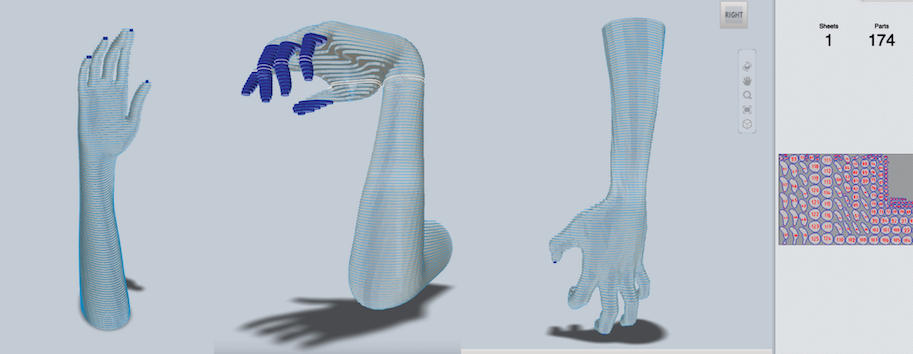

I was interested in testing the accuracy of scanning with phone apps without lidar technology. I've used the 3d Scanner App and EM3D on my iPhone and found that EM3D provided better results. However, both apps use the front-facing camera, which can be a challenge when scanning oneself. Despite this, I was able to successfully scan my hands and refine the scans using the 3D program Nomad (available on iPad) and MeshLab.

TOOLS: - 3d Scanner App - EM3D - Nomadsculpt - MeshLab

MY EXPERIENCE OF 3D SCANNING¶

We took turns in pairs, with one person controlling the KUKA robot and the other being scanned. It was a responsible task to navigate the robot and the rotating board, requiring knowledge of the controller buttons and an understanding of the robot's movement angles. The person being scanned had to remain completely still throughout the process.

I aimed to be scanned in a position that was both dynamic and static. I opted for two yoga asanas. The first one proved to be more challenging to maintain, and despite my best efforts to remain still, slight movements caused imperfections in the final scan. The second attempt was much better, and I am content with the outcome.

VIRTUAL PORCELAIN FIGURE OF YOGI¶

As I reviewed the results of my scan, I was reminded of the exquisite porcelain figures that have held great historical significance for centuries. These figures originated in ancient China and were often crafted for the imperial court, showcasing the talent of skilled Chinese artisans. In Europe, porcelain figures represented everyday people such as nobility, peasants, and even animals, and were highly valued as decorative objects for their beauty and artistic qualities. Some were even created to commemorate important events or individuals.

Broehan museum collection, Figurine ("okimono") of a Happy Chinese Boy

It's fascinating to consider how these figures could be adapted to reflect the modern era. I decided to focus on capturing everyday scenes and activities that resonate with people today, such as a yogi figurine. This virtual figurine, which represents an increasingly popular activity in modern times, is a nod to the globalization of a world where virtual goods are becoming increasingly important. It can be easily accessed through the internet and digital platforms, allowing people to download and use it on their devices without purchasing a physical figurine. Additionally, it could attract attention and interest in new technologies and digital art.

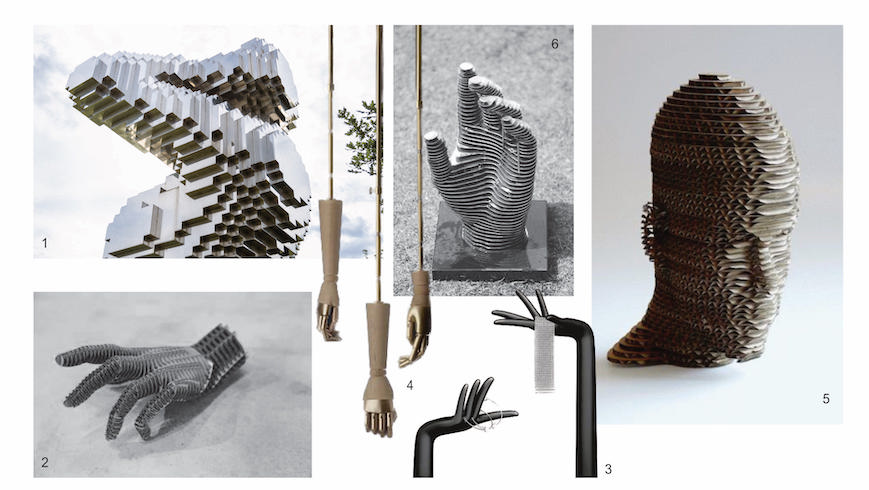

HANDS AS AN OBJECT¶

RESEARCH & IDEATION¶

Artworks and mannequins that caught my eye. 1) In Utero, (stainless steel, 6 m), David Černý, 2) Paper hand , 3) Accessories holder , 4) Hand instalation , 5) Itamar Jobani, Boy's Head, Corrugated Cardboard, 2007, 6) Korean sculptor Chan Girl Park

VISUALIZATION¶

It came to mind that I never had the right mannequin with human hand details to display small items and jewelry. I decided to try to create hands using scans of my own hands I did with my mobile phone and subsequently I edited the mesh in Nomadsculpt and MeshLab.

I was also thinking about sculpting a human head. I made many visualisations about the concept using Rhino 3D.

MODEL PREPARATION FOR LASER CUTTING¶

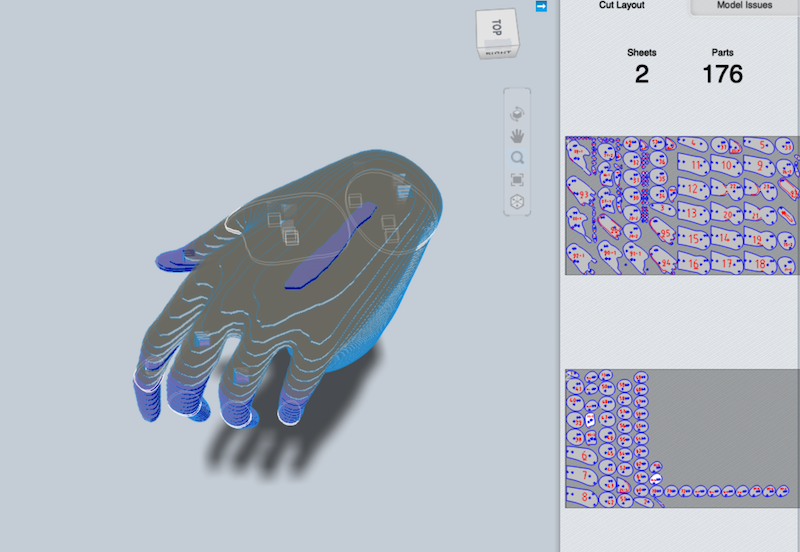

After selecting three hand shapes in different positions, I prepared 3D models for laser cutting using Slicer for Fusion 360. I decided to use the stacked slices construction technique and 3mm thick cardboard. Slicer allows me to divide a 3D model into thin layers, which is necessary for laser cutting. This way, you can prepare data for a laser cutter that works by gradually cutting through the material. Slicer enables you to adjust various parameters for laser cutting, such as material thickness and size. Slicer also provides tools for visualizing and simulating the cutting process. You can preview how the resulting cut will look and check if everything is set up correctly. The final scale is 1:1 to my hands.

TOOLS: - Slicer for Fusion 360 - Rhino 3D - Nomadsculpt - MeshLab

I was also introduced to new software this week - MakeHuman. Makehuman is a 3D computer graphics application for prototyping photorealistic humanoids for use in computer graphics.

SLICER FOR FUSION 360¶

Slicer For Fusion 360 includes features for nesting. These features analyze the 2D shapes and automatically arrange them on the material sheet. It uses optimization algorithms to determine the best arrangement of shapes on the material sheet. These algorithms aim to find the most efficient use of space and automatically number the parts so that they can be assembled. I also took advantage of the dowel option in the program, which enabled me to stack the pieces precisely. Below are the exact program settings that I used.

| Material Size | Width | Length | Thickness | Slot Offset |

|---|---|---|---|---|

| units - mm | 600 | 1000 | 3 | 0,25 |

- I used Stacked Slices construction technique.

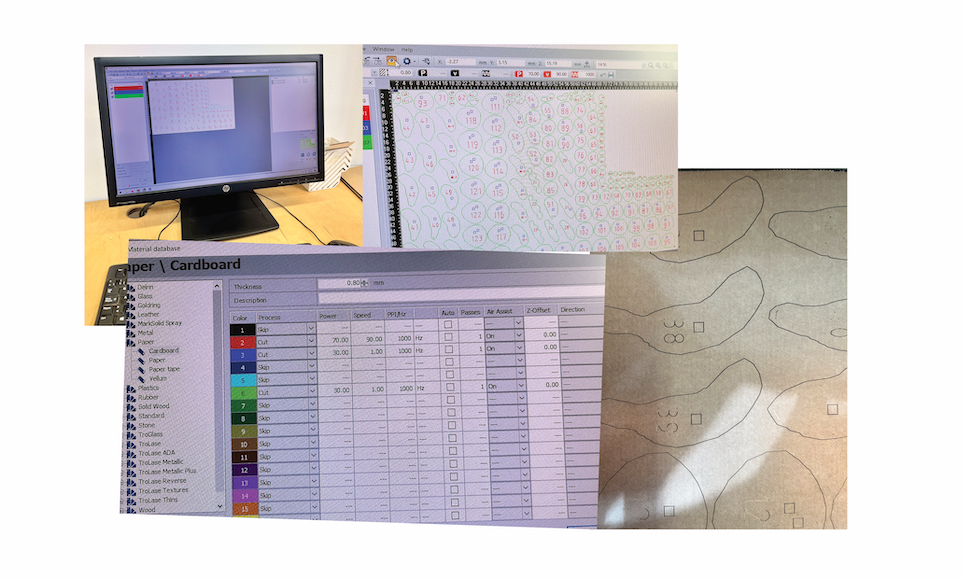

LASER CUTTING¶

Preparing the file in Rhino 3D and setting the right parameters for laser-cutting cardboard.

| Material | Thickness | Power | Speed |

|---|---|---|---|

| CARDBOARD - engraving | 3 mm | 60 | 100 |

| CARDBOARD - cutting | 3 mm | 30 | 1 |

- Total leser-cutting time was about 15 minutes for each hand.

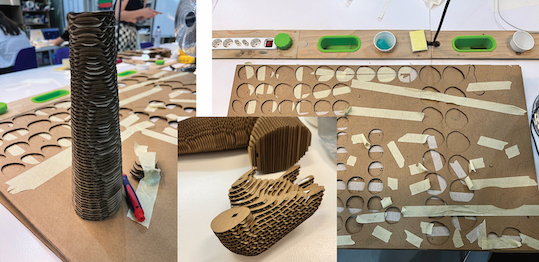

ASSEMBLING¶

I have created three versions of hands, each in a different position and with different dimensions. in the future, I intend to use them to present a wearable project.

The carving of the pieces was followed by sorting by marked digits, which the program automatically created and then I glue the pieces together. Cardboard is a relatively inexpensive material, making it a cost-effective option for creating mannequins compared to traditional materials like plastic or fiberglass. By designing the mannequin to be made with a laser cutter, it becomes accessible to a wider range of people who have access to this technology.Cardboard is a recyclable and biodegradable material; it might be a more environmentally friendly option compared to traditional mannequins.

FINAL MODEL¶

Fabrication files¶

-

File: Laser cut HANDS ↩