3. CIRCULAR OPEN SOURCE FASHION¶

RESEARCH & IDEATION¶

The most sustainable clothing option is to not wear clothes, but it's our basic need. it is in our hands to explore more eco-friendly ways of producing clothing.

The textile industry is causing significant harm to our planet, being responsible for 20% of global water pollution and 10% of all CO2 emissions. Additionally, 65% of the materials used in textile production are made from fossil fuels, and a staggering 92 million tonnes of clothing end up in landfills each year. Addressing these environmental challenges, such as global warming, water scarcity, and biodiversity loss, requires a significant shift in the textile industry's practices.

AS LITTLE WASTE AS POSSIBLE¶

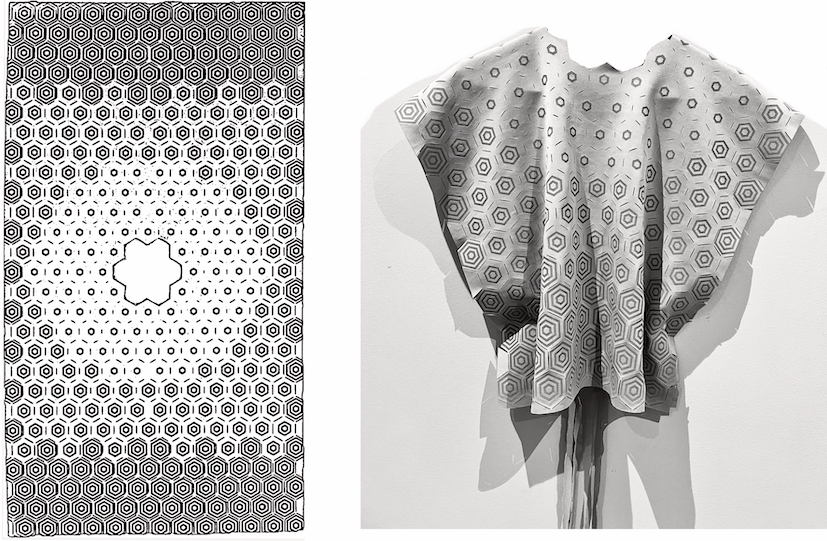

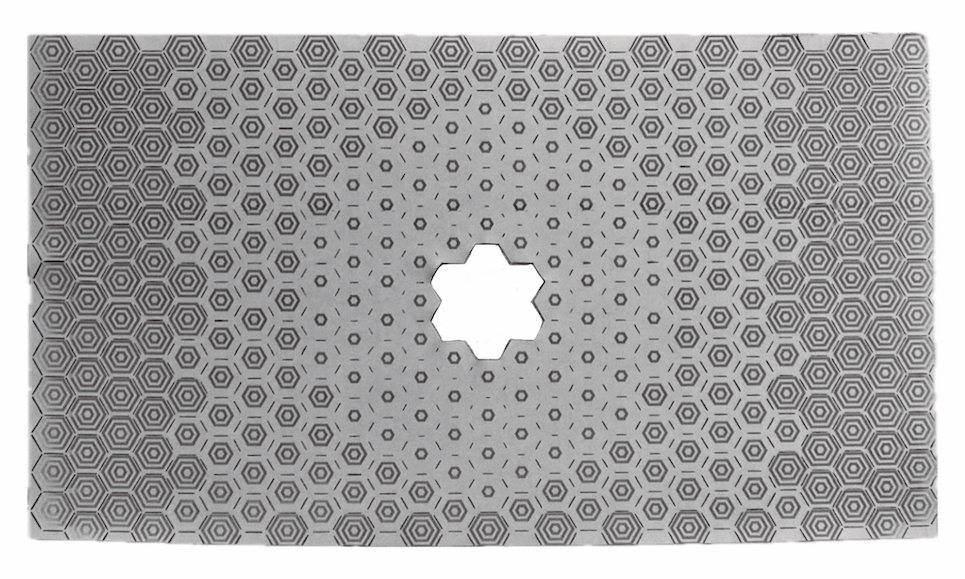

I had been pondering over how to make a garment from a single rectangular piece of fabric without any scraps left over. My plan was to utilize laser technology, which had its own limitations in terms of the maximum area of production. However, the dimensions of the fabric I had available (60 x 100 cm) were a perfect fit for my idea.

INSPIRATION¶

The hexagonal pattern found in beehives is a fascinating source of inspiration. The pattern is curious because of its incredible efficiency and economy. Bees construct honeycombs using hexagonal cells, which allow them to maximize space utilization while minimizing material waste. By utilizing hexagons, bees can create a structure that holds the largest amount of honey with the least amount of wax. This principle of space-saving and resource optimization inspired me to apply these guidelines in my design. The regularity and symmetry of hexagons also create a visually interesting and pleasing impression.

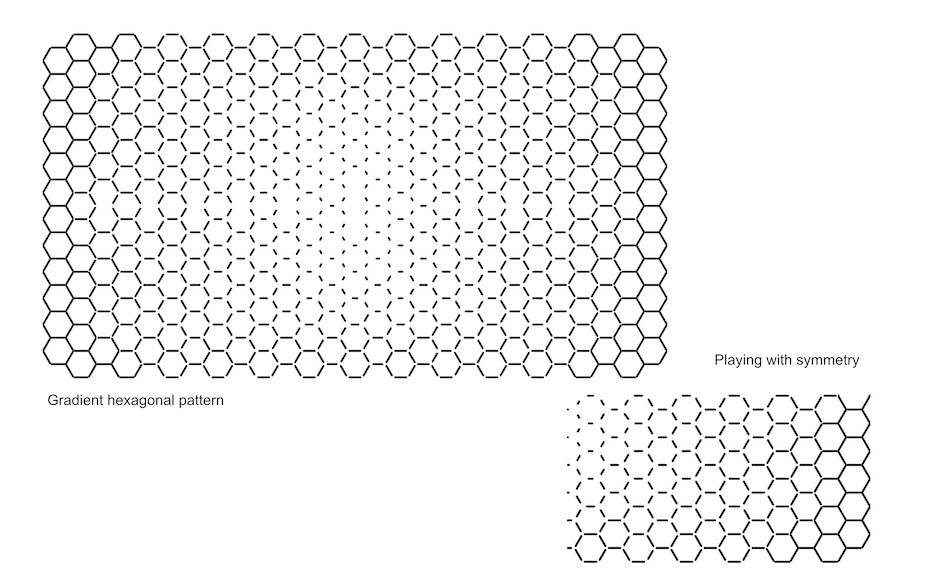

1) Indian Ponchos, 2) Iris van Herpen , 3) Dress by Alve , 4) Honeycombs , 5) Hexagonal pattern, 6) Gradient Pattern with Point Attractor

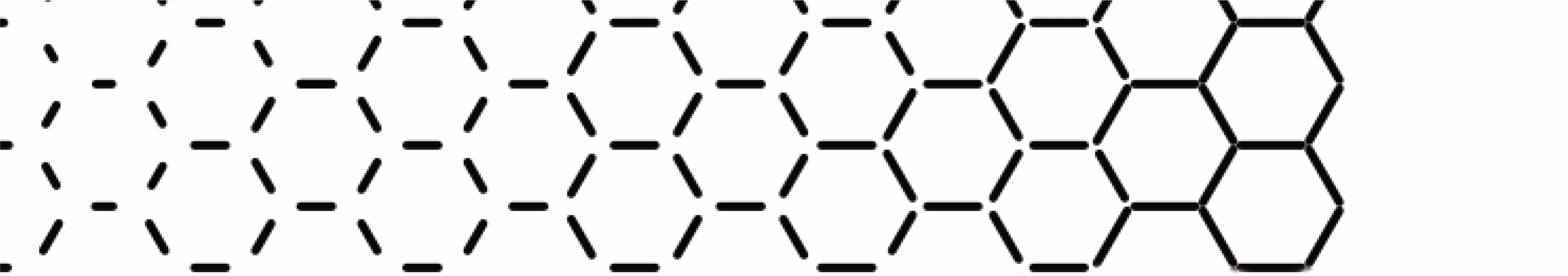

PATTERN SEARCH¶

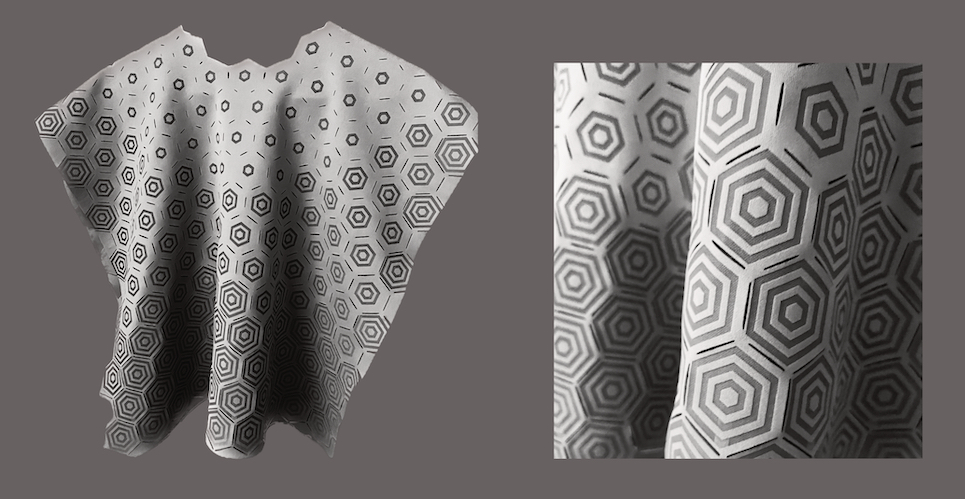

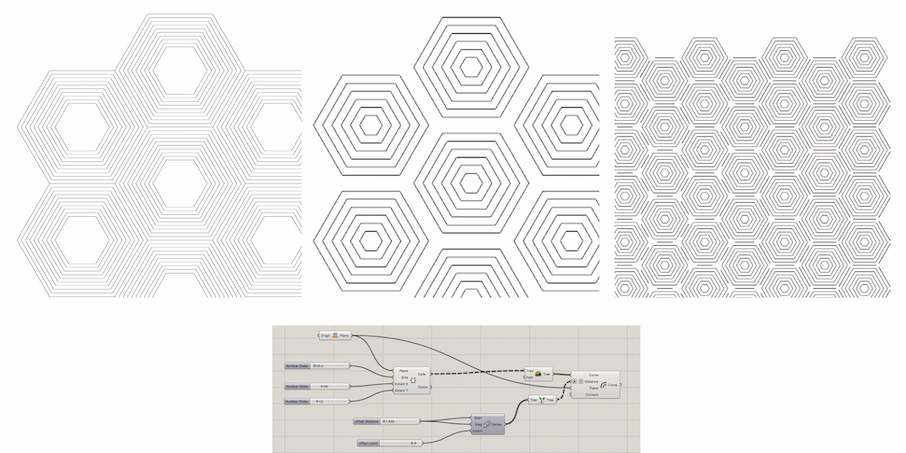

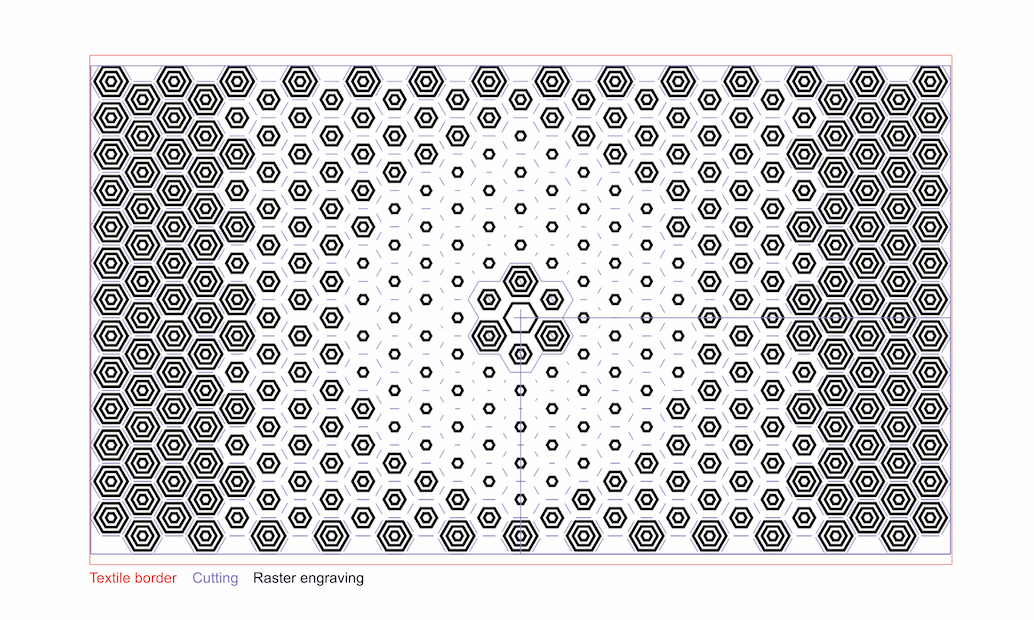

GRASSHOPPER - I used the hexagonal component to make 2D grids composed of hexagons. Hexagonal grid with Offsets - The definition offsets each hexagon a specified number of times towards its center point and the Series component generates the list of offset values. I use the Flatten and Graft components to offset each hexagon by all the offset values.

| TOOLS: |

|---|

| - Rhino 3D |

| - Grasshopper |

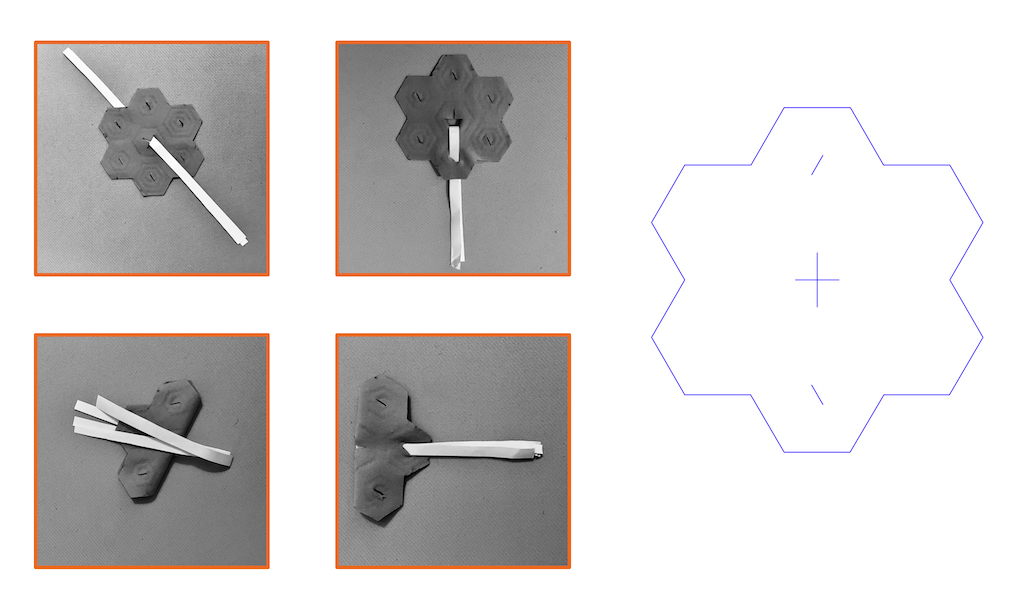

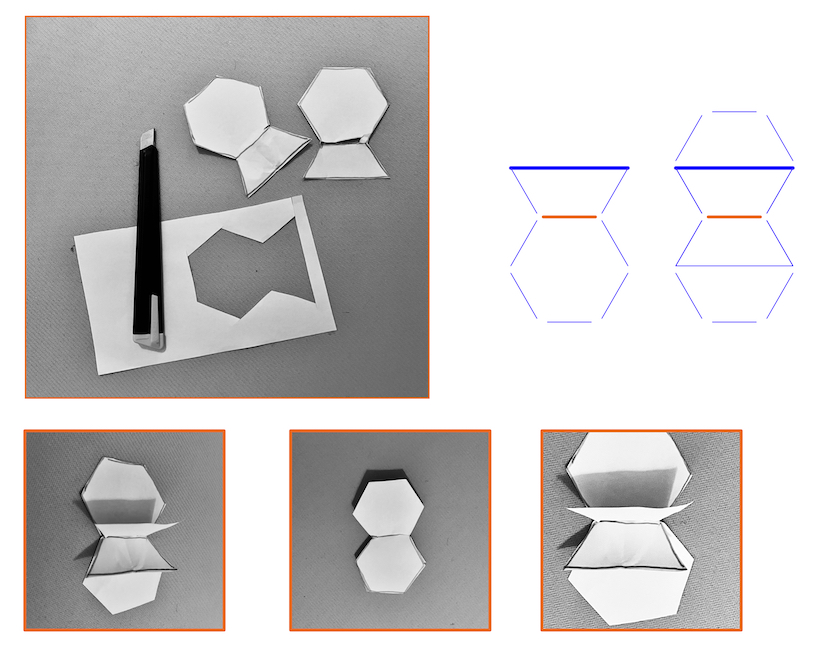

WORKING WITH PAPER¶

When I had an overview of the pattern, I first tested the shapes cut from paper.

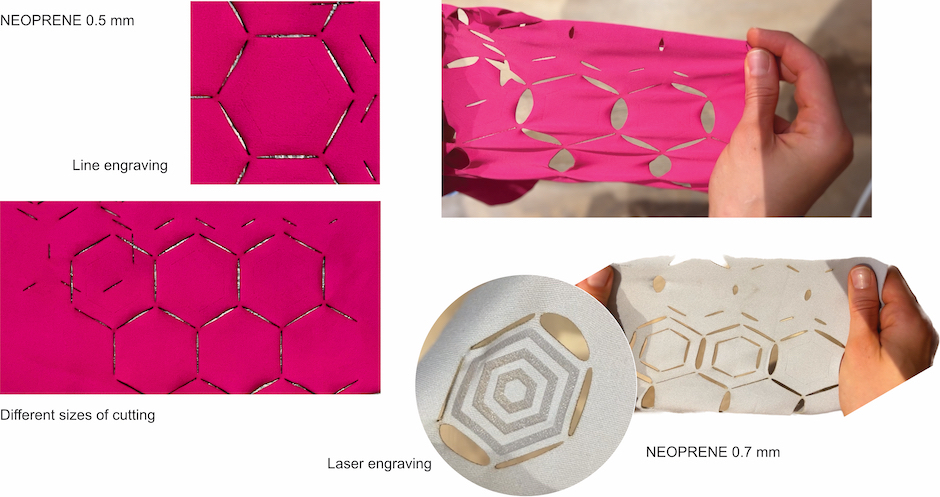

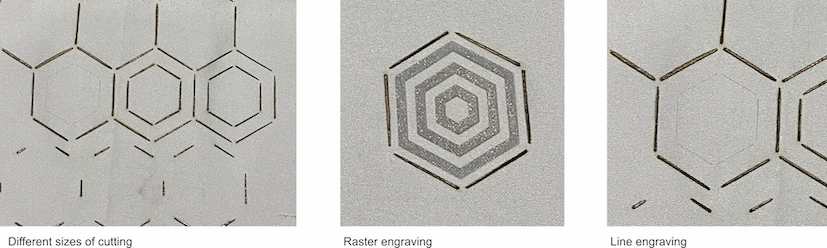

MATERIAL TESTING¶

Even though it's already October, Barcelona is still experiencing warm temperatures around 28 degrees Celsius during the day. As a result, I've decided to create comfortable and lightweight clothing suitable for leisure activities, with a unique fashion twist. I've been considering using neoprene fabric from the start, as it offers excellent chemical stability and flexibility across a wide range of temperatures. Tt is also possible to laser holes into the material. Thanks to advancements in manufacturing techniques, the environmental impact of the neoprene production process has been minimized, and the material is of high quality, ensuring a long lifespan. Even though neoprene is not of natural origin.

Material Parametres¶

| Material | Thickness | Power | Speed |

|---|---|---|---|

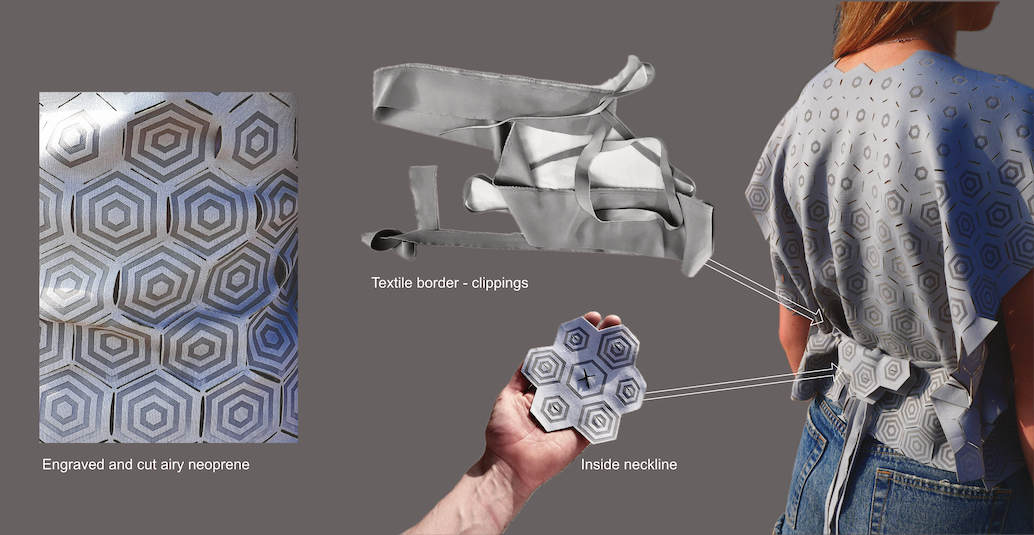

| NEOPRENE - engraving | 0.5 mm | 80 | 70 |

| NEOPRENE - cutting | 0.5 mm | 30 | 1 |

| NEOPRENE - engraving | 0.7 mm | 85 | 70 |

| NEOPRENE - cutting | 0.7 mm | 30 | 1 |

PROCESS OF MAKING - HONEYCOMB TOP¶

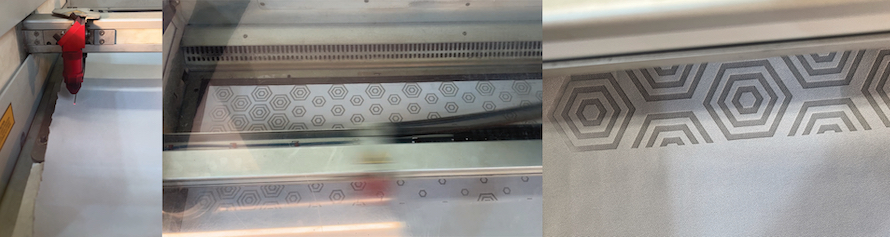

A waste-free variable production process can be operated on demand. The machine (laser-cutter) took exactly two hours to complete the order, allowing for direct production at the studio or small manufacture.

LASER-CUTTING¶

| Material | Thickness | Power | Speed |

|---|---|---|---|

| NEOPRENE - engraving | 0.7 mm | 85 | 70 |

| NEOPRENE - cutting | 0.7 mm | 30 | 1 |

- Total leser-cutting time was about 1 hour and 30 minutes. Longer time caused engraving.

- If you use the correct dimensions of a rectangular piece of fabric (1000 x 600 mm fabric), you won't have any leftovers.

I tried to make the system as simple as possible to motivate everyone to make the honeycomb top. I also wanted to show that a rich pattern can be achieved without adding material or color.

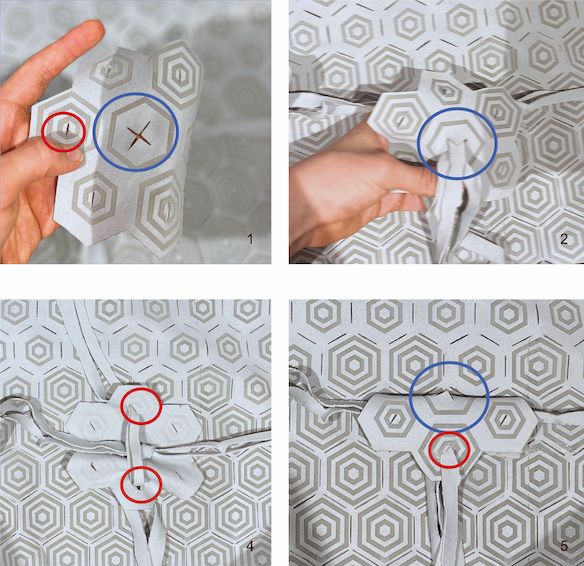

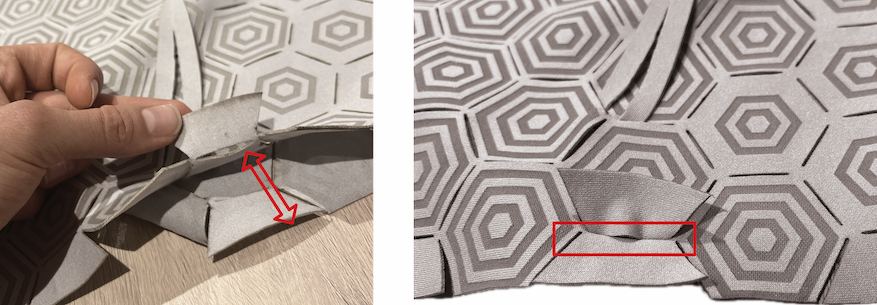

The tightening system consists of a band (stripes of leftover cut-outs) and a cut-out of the neckline, which serves as an auxiliary system while hiding the knot and forming a decoration.

USER EXPERIENCE¶

- Perceptions of usefulness, ease of use and effectiveness.

I wanted to test the top in a real-life situation, so I asked my friend for help. I wanted to know her reaction to the material, whether she was able to assemble the top according to the instructions, and if it would be comfortable to wear in warm weather.