09. Textile Scaffold¶

Week Assignment¶

Weekly Quest

=by Anastasia Pistofidou=

Check out the weekly assignment here

textile scaffold

-

Technical textiles have various applications, among which agrotech, building, clothes, geotech, sports. In this class we will use textiles for composites, polymerisation, solidification, fabric formwork, crystallization, composites and biocomposites, agglomerates.

-

This class focuses on exploring techniques and applications of technical textiles in the industry. It introduces the concept of designing custom processes that require the design of a set of tools, processes and workflow.

PROGRAM OUTLINE

- Technical Textile applications

- Composites

- Biocomposites

- Crystallization

- Fabric formwork & Concrete or Plaster Casting

- Wood + Textile Composite

MATERIALS

- Bio Resin and Resin

- Borax, Rochelle salt, Potasium sodium, Epsom Salt, Sugar,

- Concrete and Plaster

- Veneer Wood

- Fabric

- White Glue -Vacuum bags or vacuum machine

our Objective

This week we are working in 2 and I'm partnering up with Jiawen

:) We are interested in making pleats with bio materials.**

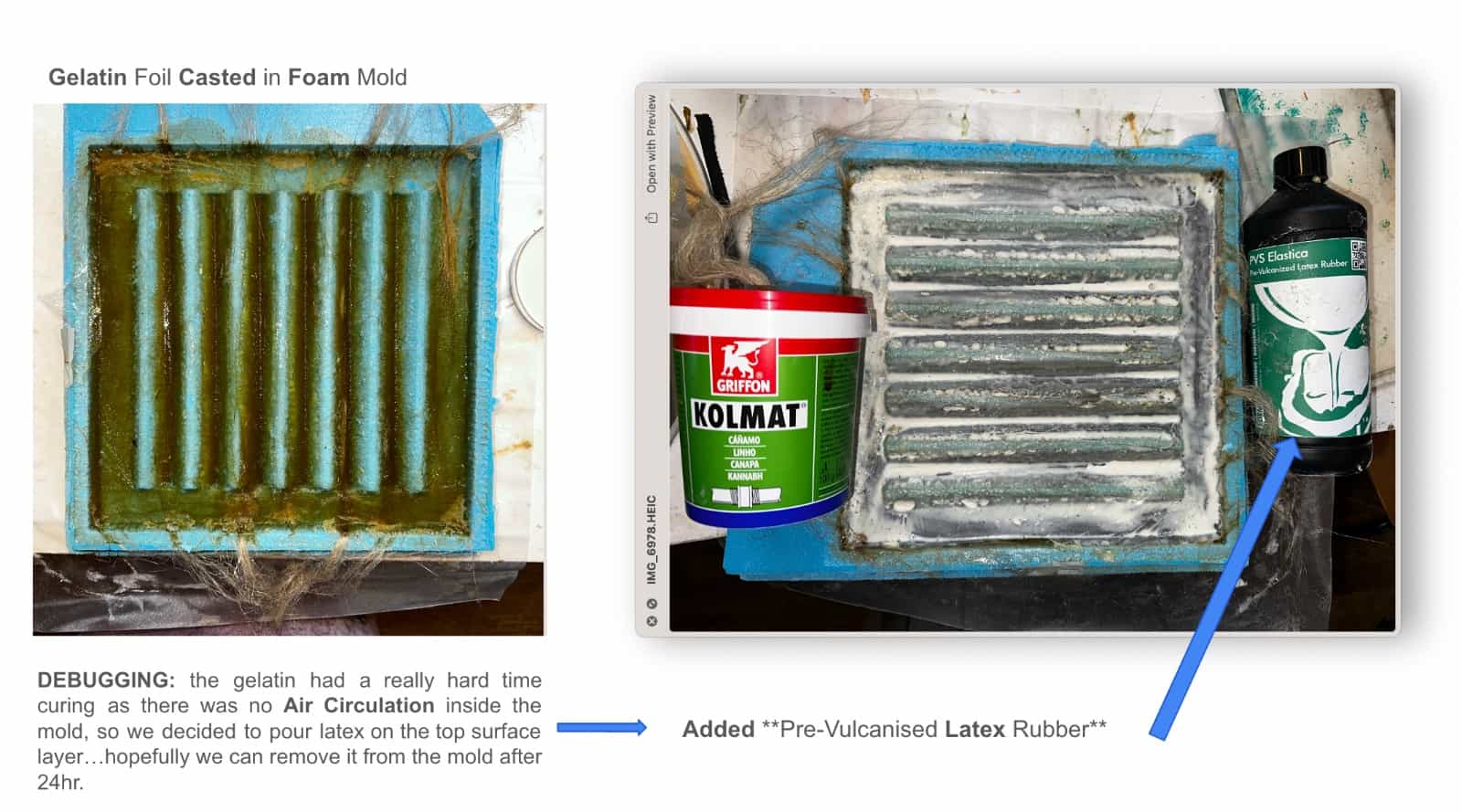

This week, Jiawen and I are =focusing on biomaterials and bio-fabrication in Textile Scaffolding=. Our goal is to use the CNC ShopBot machine to create a foam mold and then cast gelatin and hemp into a two-part mold.

Looking ahead, we aim to explore ways to change the composition and shape of biomaterials. We are eager to see the results of our experiments in the coming week.

- [x] CNC MOLD

- [x] ALGINATE EXPERIMENTS

- [x] GELTIN CASTING

- [x] MAGICAL GREEN POT (STARCH & YEAST EXPERIMENTS)

IDEAS OF MATERIALS WE COULD USE:

Polymers: gelatin, agar, alginate, yeast, starch, tapioca, cellulose

Composites: sea shell, nutrimate(yerba mate), grinded leaves, hemp fibers, wool, hair

Plisse Traslucent

inspiration

**Issey Miyake" Autumn Winter 1995 1996 Paris**

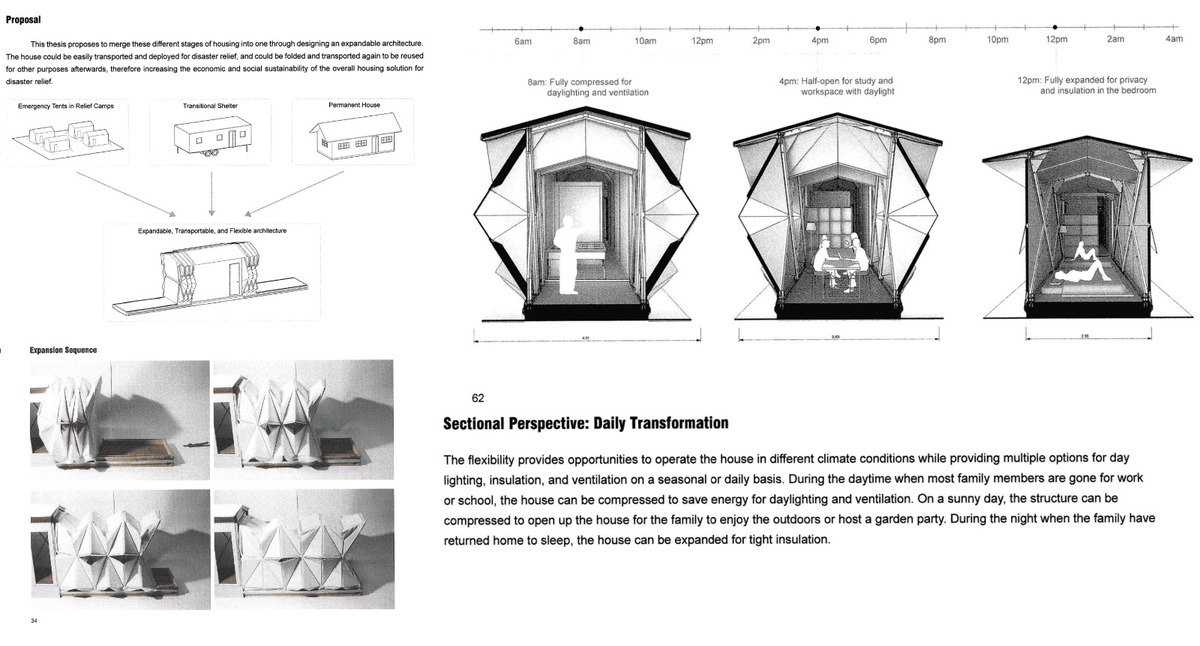

Expandable House by Mimi Ho Chu

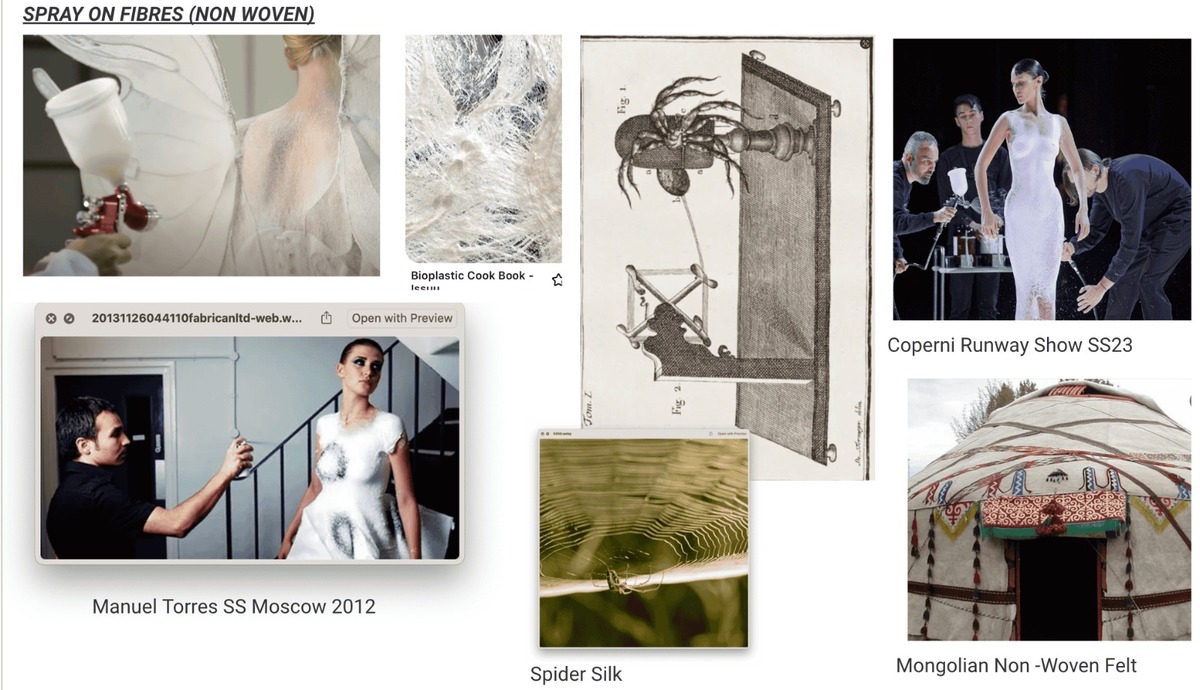

**Spray on Fibres - Manel Torres 2011 Fabrican**

“The wearer can recycle the clothes themselves or perhaps they can take the used clothing into a shop and exchange it for a refill,” Torres explains. “There are many possibilities, but that’s really thinking further ahead.”

**Spray on Fabric**

**Issey Miyake Analysis by Bliss Foster**

**Issey Miyake Philosphy**

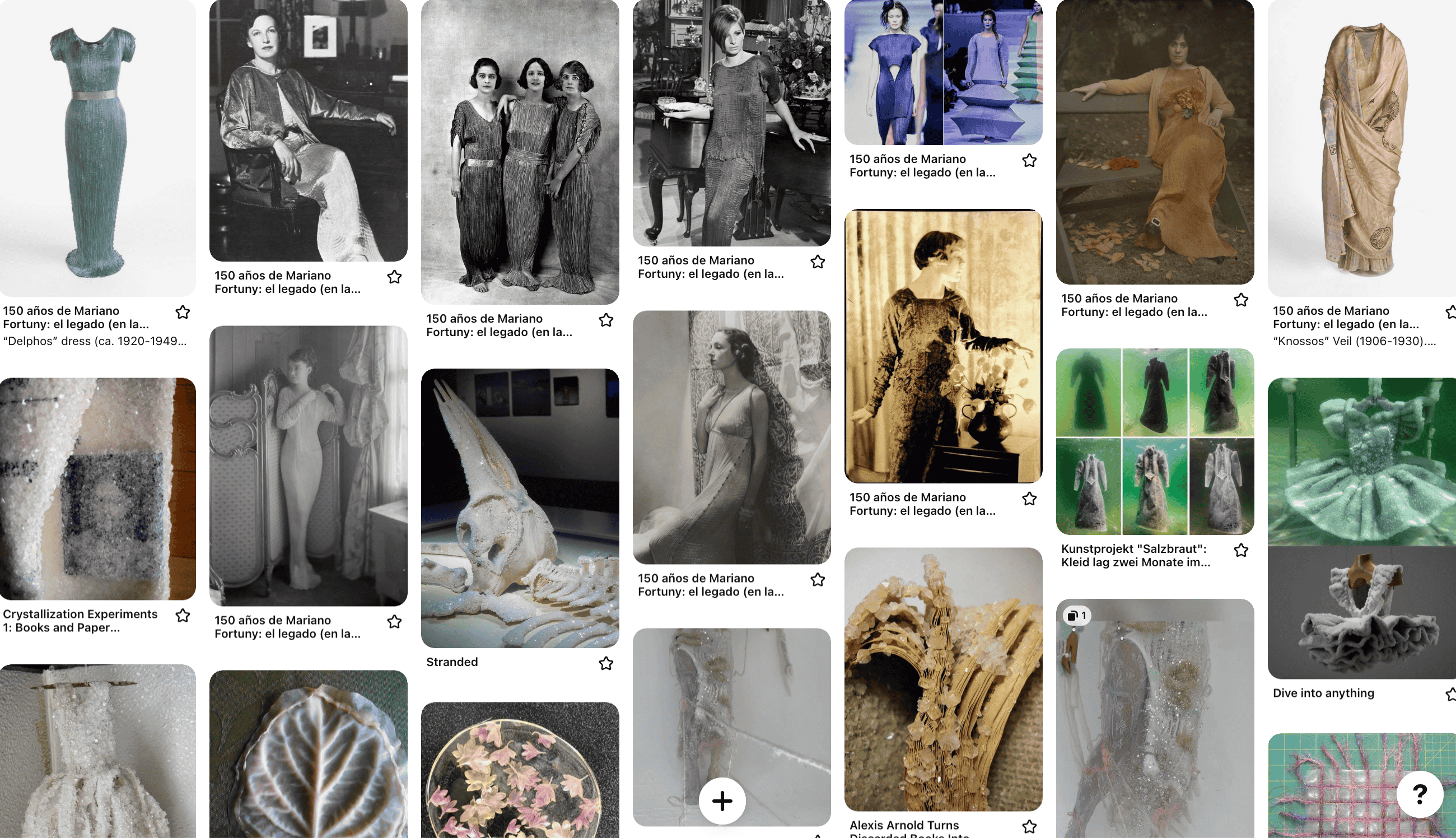

1Granary Article onf Mariano Fortuny

"The invention, which was patented in 1909, used a system of heated porcelain tubes to warm the wet silk as it was pressed between these tubes to form permanent pleats."

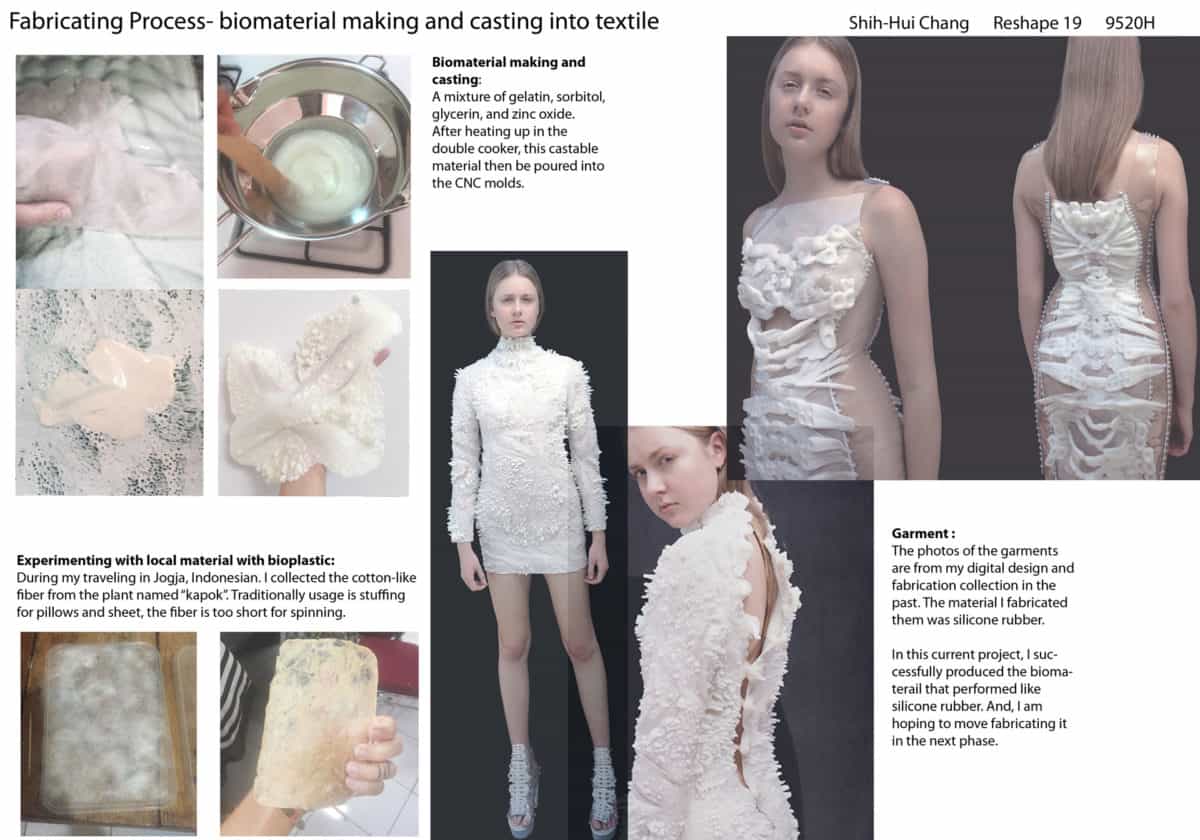

FOAM CASTING INSPO: Shihi Hui Chang Digital Fabrication Ref

GELATIN CASTING INSPO: Shihi Hui Chang Digital Fabrication Ref

**Henry Ford** Hemp Car

**Mariano Fortuny Plisse God**

**Alum Accessory - Earing**

**class examples of alum crystallisation on fabrics

Alum Crystalisation Tutorial

Equipment and Ingredients:

- Glass or Beaker

- Fishing Line

- Popsicle Stick

- Coffee Filter or Paper Towel

- Alum

- Water

**tip: The crystals are very delicate, if touched or moved, they tend to fall apart.**

Starch/Latex DIY

DIY Magic Pot:

WORKFLOW (explain what we did)

- Fabric + Water starch + boil = soak in fabric

- Water + starch + PVA glue = paint on fabric

- Add Pre-Vulcanized latex rubber to the dried fabric (for more elasticity and waterproofness) = paint on fabric

step by step:

-

**choose a mold (any objcets with a surface that won't adhere and easliy pel off and clean)

-

Fabric choice is open both Natural and Synthetic fibres work well.

-

**cast your objects by either have pre bolied the fabric or directly model it on your object and brush latex/glue/biopalstics..

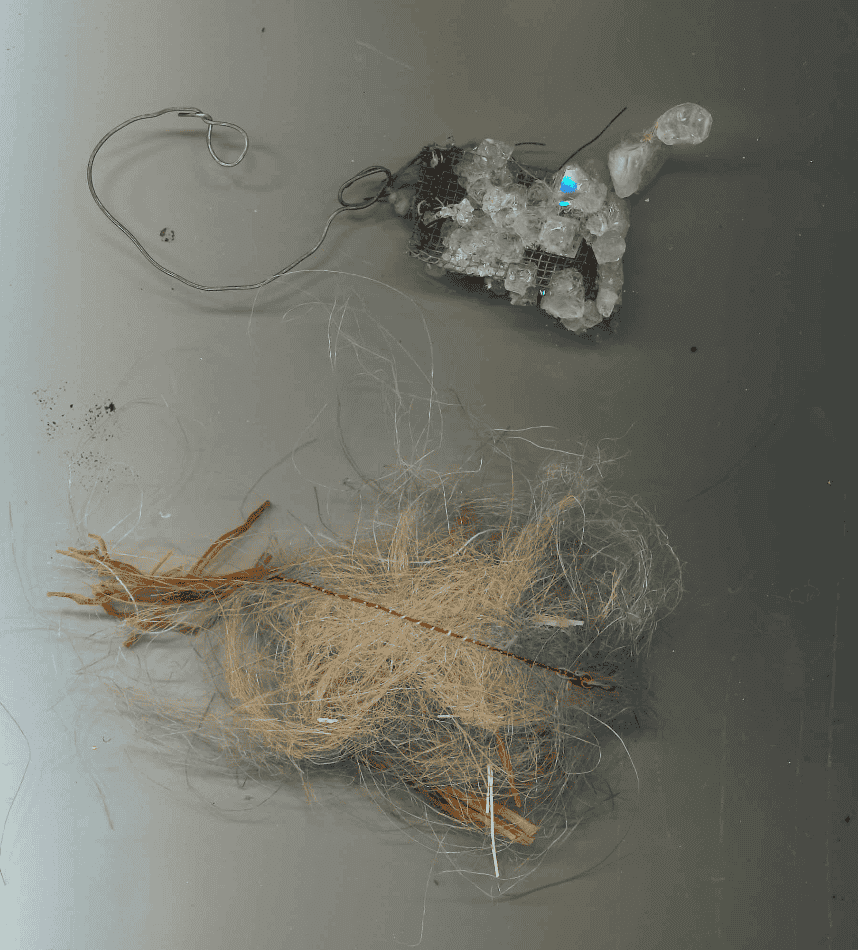

IMAGE DESCRIPTION

Top left = magic water (hot water,tapioca starch, chalk) / Plissed fabric with the aid of tin foil or parper and applied the paste onto it / wrapred it and dried it out / top right latex cotton canvas casted and modeled on a glass jaar.

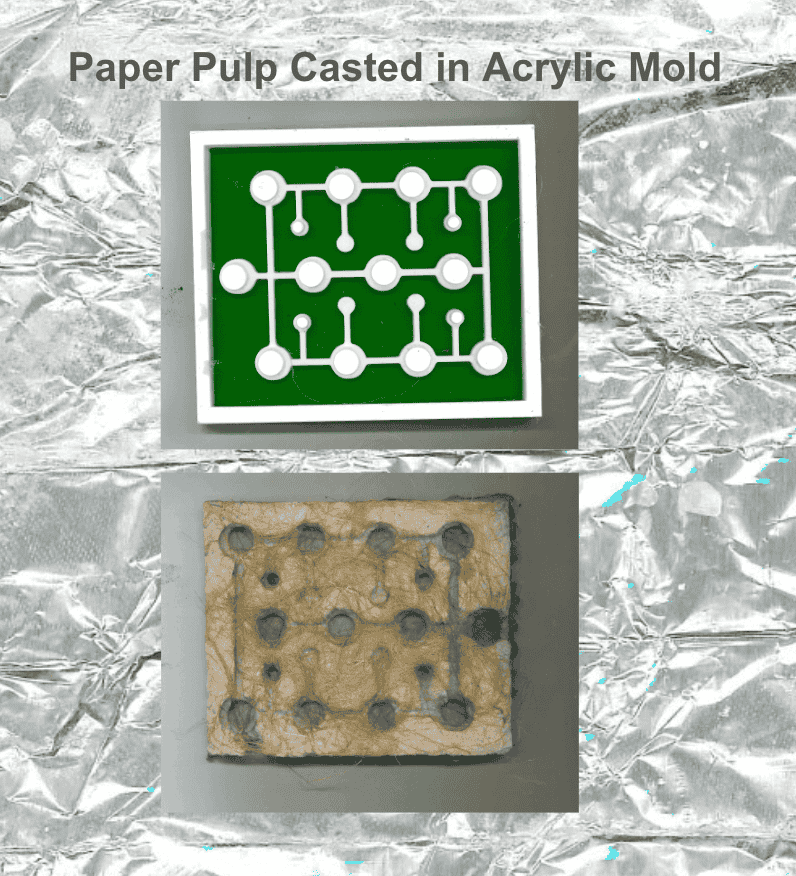

**Upcycling paper pulp from green/starch recipe and casting it on @riley_cox acrylic mold**

Pink Alginate Paste

**this waa a recipe an discovery of Biofabrication - week 06

Alginate:

Sodium Alginate: Sodium alginate is derived from brown seaweed and is used as a gelling and thickening agent in the food and pharmaceutical industries.

**Experiments with: Cotton Scraps + wool + hemp**

Alginate Paste

**INGREDIENTS**

- 60 gr Alginate powder

- 1 litre of water

- 100 gr Glycerin

- 20 gr Dried Yeast

- 20 gr Wheat Yeast

- 20 gr Tapioca Starch

- 1 spoon Olive Oil

- 5 drops of Lavender Essential Oil

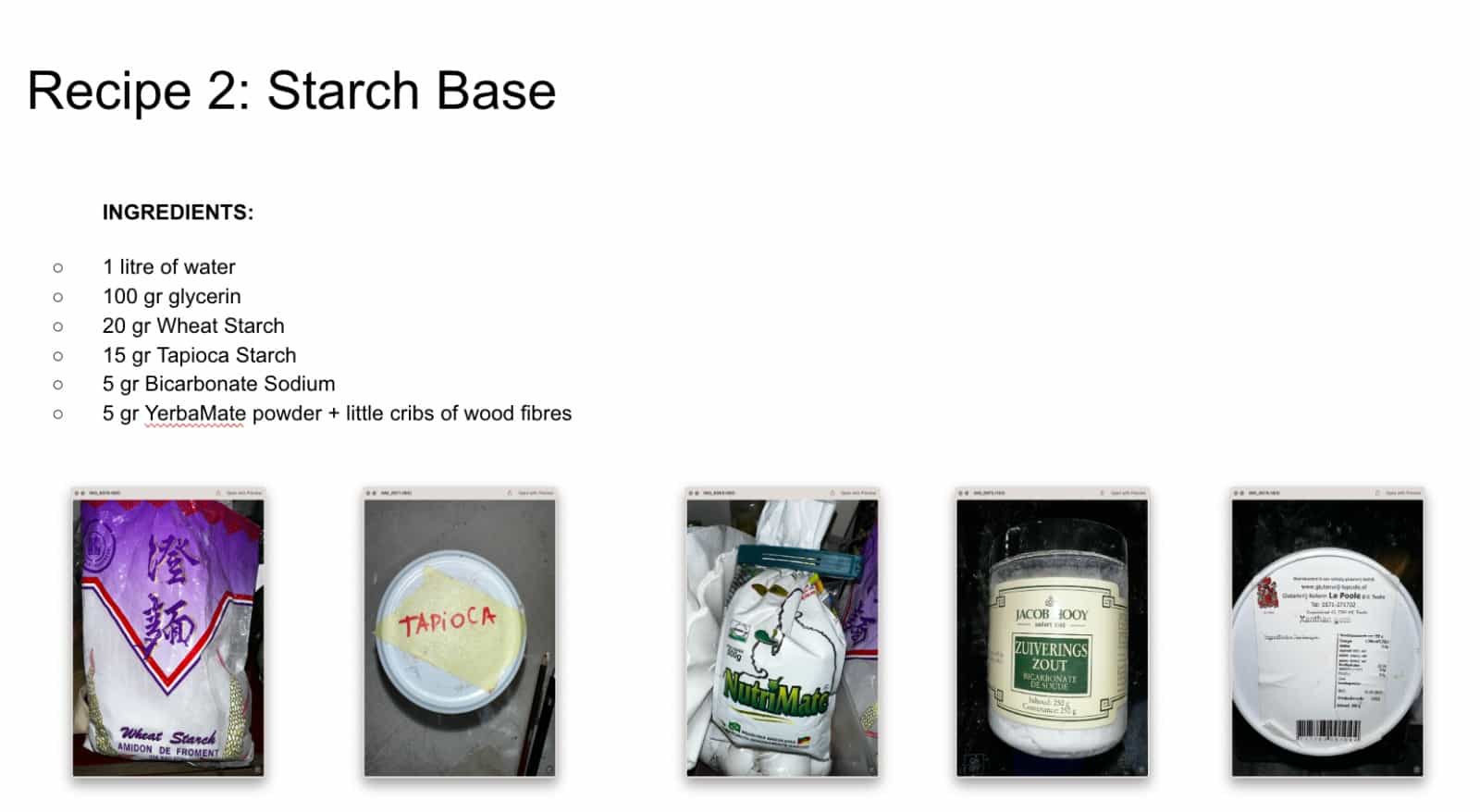

Green Starch & Yeast & Cellulose Paste

**NEW RECIPE - Necessity is Virtue**

adding cellulose paper pulp as polymer is the key...

Experiments with: Cotton Scraps + wool + hemp + funghi

**Cold Blender Recipe**

**Casting Paster + Composites**

GREEN PASTE (Starch & Yeast)

INGREDIENTS

- 1 litre of water

- 100 gr glycerin

- 20 gr Wheat Starch

- 15 gr Tapioca Starch

- 5 gr Bicarbonate Sodium

- 5 gr YerbaMate powder + little cribs of wood fibres

-

Grinded and starched, boiled paper from egg packaging

What is the difference between CMC and starch?

"Google says: Another key advantage of CMC is that it is cold-water soluble. Starch on the other hand, is not cold-water soluble and requires 'gelatinisation', a process by which the native granular structure of starch is disrupted to unravel and solubilise the amylose and amylopectin polymer molecules that constitute the granules."

"Ray says: in the recipe I didn't heat in warm water the starch....it works also very well starch without heating it up...but I think there is still heat during the blending stage

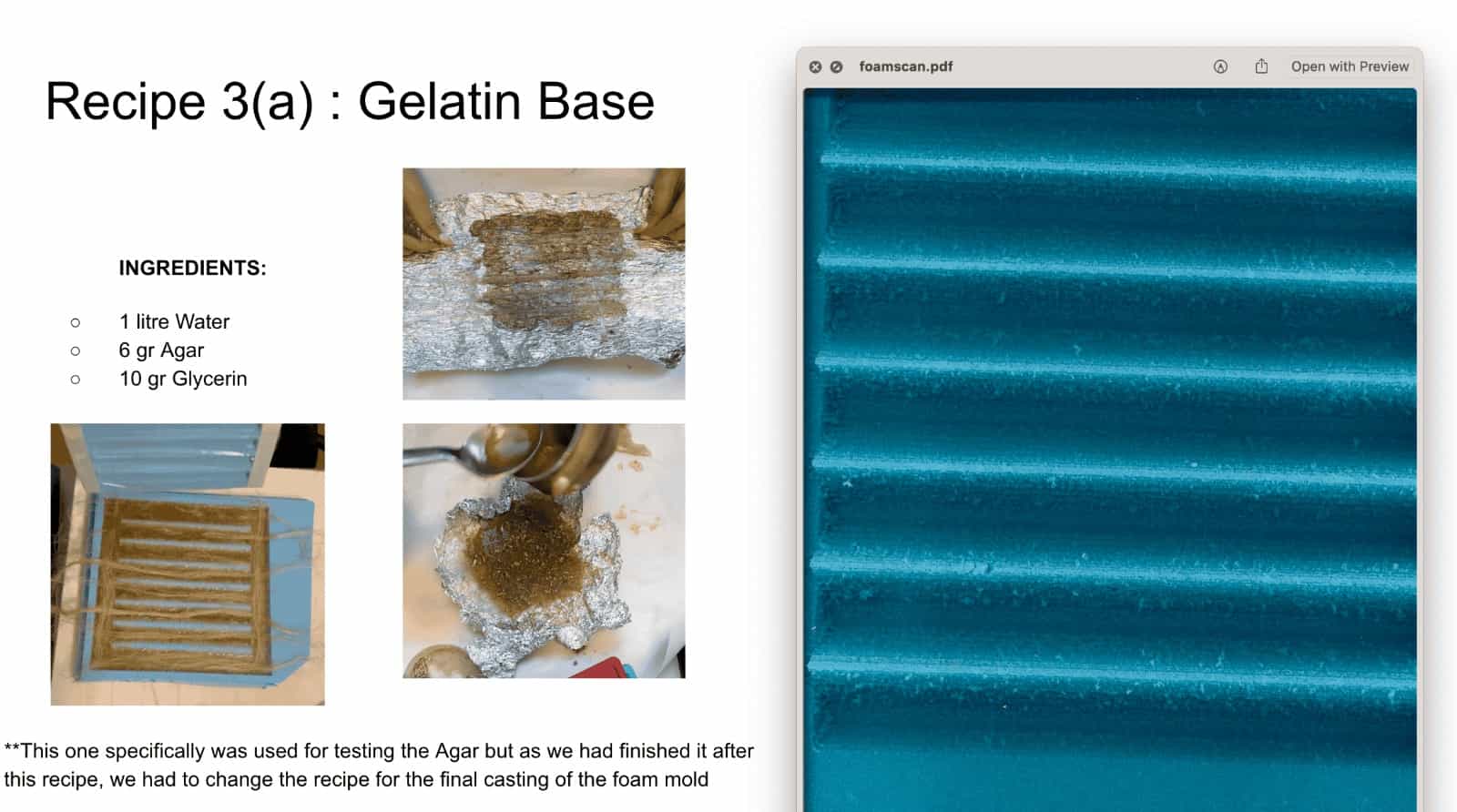

Gelatin Paste (a) & (b)

WORKFLOW (explain what we did)

Hemp Fibres

**Cook your Gelatin**

**Foam Casting with Gelatin**

**Leaf Deacy in Gelatin**

GELATIN RECIPE (a&b)

**INGREDIENTS:**

- 1 litre Water

- 6 gr Agar

- 10 gr Glycerin

GELATIN RECIPE (b)

**(alternative for Agar Agar... + gelatin + starch)**

- 2 litre of water

- 20 gr glycerin

- 80 gr Gelatin

- 5 gr Wheat Starch

Notes¶

Starch 101

what is starch?

Wheat Starch: Derived from wheat flour, fine white powder, good thickening properties, used in Asian cuisines, sauces, soups, puddings, and baking.

Cornstarch: Made from corn kernels, common thickener in various recipes, excellent thickening power, used in gravies, sauces, custards, pies, neutral flavor, light and tender texture in baked goods.

Tapioca Starch: Extracted from cassava root, gluten-free, smooth texture, used in soups, sauces, desserts, and gluten-free baking, provides a glossy finish.

What is the effect of starch in cake?

Starches provide the viscosity in the batter and help with moisture migration in the finished product. Rice-, potato- and corn-based flours and starches are the workhorses of gluten-free formulating. They approximate the structure and eating quality of wheat ingredients, even if they have flavor difference.

What is extruded starch? Extrusion. Starch is composed of two α-glucan polymer molecules, amylose and amylopectin. Native starch is deposited in the form of granules that are partially crystalline. [22,23] In general, starch consumed by humans has been gelatinized, with the exception of a few foods, such as carrots.

**Suitable naturally occurring starches can include:**

corn starch, potato starch, sweet potato starch, wheat starch, sago palm starch, tapioca starch, rice starch, soybean starch, arrow root starch, bracken starch, lotus starch, cassava starch, waxy maize starch

Yeast 101

**YEAST**

-

Once reactivated, yeast begins feeding on the sugars in flour, and releases the carbon dioxide that makes bread rise (although at a much slower rate than baking powder or soda). Yeast also adds many of the distinctive flavors and aromas we associate with bread.

-

What happens if you add yeast to cake? How Is Yeast Used in Baking? When combined with liquid and sugar, yeast makes dough rise. Yeast, while also providing flavor, creates carbon dioxide in the dough. This stretches and expands it.

-

Yeast produces the enzyme maltase to break maltose into glucose molecules that it can ferment. Once the starch has been broken down into these simple sugars, other enzymes in yeast act upon simple sugars to produce alcohol and carbon dioxide in the bread making step called fermentation.

Cellulose 101

**credits [Jue Yang] (https://class.textile-academy.org/2023/jue-yang/assignments/week06/) notes on cellulose**

What is cellulose?¶ A definition by Christopher Brigham, in Green Chemistry, 2018; sciencedirect link:

Cellulose is one of the most abundant biomaterials on the earth. It is generally synthesized by plants, but it is also produced by some bacteria. Like starch, cellulose is a homopolymer of glucose, and yet unlike starch, glucose monomers are joined by β-1,4 linkages (Fig. 3.22.4B). During the lectures we mostly learned about microbial cellulose. A definition by Elena Fortunati, ... Luigi Torre, in Biomass, Biopolymer-Based Materials, and Bioenergy, 2019; sciencedirect link:

5.2.2 Bacterial cellulose (BC) BC, also called BNC, microbial cellulose, or biocellulose, is formed by aerobic bacteria, such as acetic acid bacteria of the genus Gluconacetobacter xylinum, as a pure component of their iofilms. These bacteria are widespread in nature where the fermentation of sugars and plant carbohydrates takes place.

Digital Fabrication¶

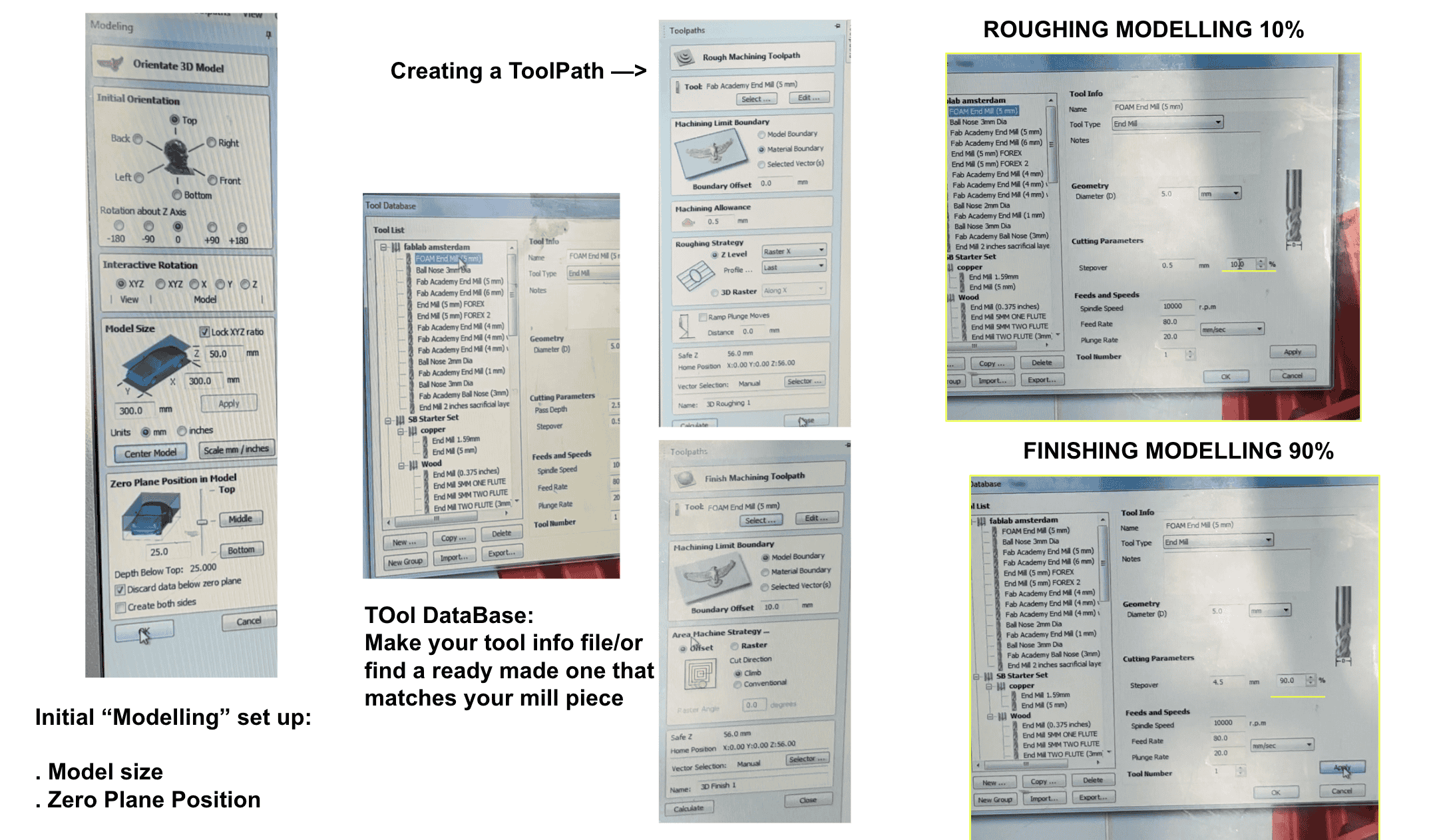

VCarve

STEP-BY-STEP:

- Save your 3D model in .STL

- Import it in VCarve

- Fill in the section regarding your material (size and margins)

- Material Setup —> Z position click on the left bottom corner in the diagram

- Toolbar click on : tool database —> choose the right tool for you or create a new one yourself… we used a ready made one called “foam end mill 5mm”

- We changed the speed and feed of the foam tool we choose : (spindle speed: 1000 r.p.m) (feed rate 80%) (plunge rate 20mm/sec)

- Create tool path: ROUGHING —> click on the roughing icon —> Limit Boundary “Material Boundary” —> Rough Strategy “Boundary Z level Raster X FINISHING —> click on Icon finishing under toolpath —> Limit Boundary “Model off-set 10mm” —> Area Machine Strategy “off-set/climb”

- Save the toolpaths separately, ready for shotbot import

Shotbot

**credits: Asli Aksan**

3D MILLING WITH SHOPBOT¶

STEP-BY-STEP:

- Open shotbot software

- Fix your foam on the sacrificial layer (we nailed wood to the sacrificial layer so make our foam even more stable)

- Click on XY axis

- Click Z axis to home your position

- Position the metal plate under the mill ready for homing and recording your position (very important) TIP take a picture of the XYZ numbers just in case

- Open your file now

- Turn on ventilation and spindle

-

START!!!! (remember to keep you hand on the spacebar in case things go wrong to pause it)

IMPORTANT

-

Tie your hair up when operating the machine.

-

Turn on ventilation.

-

Keep your fingers on Space key when you start your job. If something were to go wrong, it's mostly likely to happending in the beginning.

-

If something has gone terribly wrong, press the STOP button located under the milling bed.

-

We used foam boards with 5cm thickness for milling. We used double sided tape to place it on the bed and secure it with wood sticks screwed around the board.

- When placing your foam board, make sure it's parallel to the milling bed.

- Something to notice is that, you can change the toolpath to a direction that worked better with your design. In our case, we have a lot of vertical lines, and we have the bottom mold milled horizontally and the top mold milled vertically. And the top mold had a finer result whereas the bottom mold had a rougher finish."

for more : Jiawen Gong notes

Files

Reflections¶

Reflection

necessity what a week great coolaboration with my partner jiawen we focused on biomaterials....

alum

alginate

greeen

pleats volume

Tips

- when using Starch, melt it in hotish water ...said a recipie to make turkish bread

Results¶

Favorite Outcome

why and what

recipie green and dried yeast pink are really giving me the thrills

Hacks

-

center images and text:

-

mp4 in loop:

(((

(.

)))

HYPERLIKNG IN A SENTENCE:

((( Check out the weekly assignment [here] (http://fabricademy.fabcloud.io/handbook/assessment/criteria/#12-soft-robotics) )))

HIGHLIGHT WORD: (==) before and after the words.

I need to highlight these ==very important words==.

Future References¶

Dig Deeper

Frei Otto Tent Structures

Frei Otto pioneered the use of modern, lightweight, tent-like structures for many uses. He was attracted to them partly for their economical and ecological values. As early as the 1950s, he built complex models to test and perfect tensile shapes.**

**Eps 6: Michael Rakowitz & paraSITE**

The social art practice of Michael Rakowitz sometimes takes the shape of custom-built inflatable shelters designed for homeless people. The structures attach to the exterior outtake vents of a building’s Heating, Ventilation, and Air Conditioning (HVAC) system. The warm air leaving the building simultaneously inflates and heats the double membrane structure. Built and distributed to over 30 homeless people in Boston and Cambridge, MA and New York City.

"Michael Rakowitz has created a series of inflatable temporary plastic shelters for the homeless he calls “paraSITE.” The work, which began in 1998 and was later added to the MoMA’s Architecture and Design online collection, is both a form of social protest and an ingenious, budget-conscious design (most units cost around $5 to construct)."

Michael Rakowitz - Parasite Infaltable Home-

**Tutorial DIY Grass Paper ... and Printing On It**

**This Lane Doesn't Exist Trailer - If you can't buy it, is it still art?**

[RUSSIAN FELTING WEBPAGE](https://gallery.ru/watch?ph=AbZ-eoMgB#feature=topscroll)

[mycelium casting] https://class.textile-academy.org/2023/jue-yang/assignments/week09/

BE CURIOUS

Join me on my adventure on Instagram and Pintrest

IG@JOINTSCIENCE¶

PINTREST INSPIRATIONS¶

© [2023] credit : ray