06. BioFabricaition Materials¶

"In my journey towards a more sustainable and self-reliant lifestyle, I've found inspiration in the nomadic way of life. Creating our own bio-fabricated materials, tools, and garments is not just a design choice; it's a lifestyle of adapting to new environments, feeling uncomfortable, and finding comfort within the resources around you. I feel I design in a space that starts from the materials up to its many uses in real life having a practical use but also beautiful because you made it. We imagine a world Where we care about our clothes transforming them in multiple ways adapting them to the environment for a long time or maybe a very short one, minimizing what we need while amplifying what the Earth needs."

Weekly Quest

Week 06 by Cecilia Raspanti

What is the Future applicaitons OF Biologically Derived Materials?

biobased, biodegradable and bio compostable

Key Diferences:

- Biobased materials are about the source of the material and its renewability.

- Biodegradable materials focus on the ability of a material to naturally break down.

- Biocompostable materials go a step further by turning into compost.

Bio-Based:

Definition: Biobased materials are derived from renewable biological sources, such as plants (e.g., corn, sugarcane), algae, or other organic matter. These materials are used as alternatives to traditional petroleum-based products.

Characteristic: Biobased products are made, at least in part, from organic or renewable resources. For example, biobased plastics are made from plant-based sources like cornstarch instead of fossil fuels.

Bio-degradable:

Definition: Biodegradable materials are those that can naturally break down or decompose into natural elements under specific conditions, typically within a reasonable timeframe.

Characteristic: Biodegradable products can undergo decomposition through the action of microorganisms, heat, light, or other environmental factors. This process should not leave harmful residues. Biodegradable plastics, for example, can break down into water, carbon dioxide, and biomass.

Bio-compostable:

Definition: Biocompostable materials are a subset of biodegradable materials. These materials not only break down but also convert into compost or humus, a nutrient-rich material that can be used for enriching soil.

Characteristic: Biocompostable products undergo decomposition and produce compost that can be safely used for agricultural or horticultural purposes. They should meet specific compostability standards to ensure they break down completely and without harmful residues

What is a Polymer?

A polymer is a large molecule made up of repeating subunits called monomers. Polymers are a fundamental class of materials, and they can have a wide range of properties and applications. Here are some basic characteristics of polymers:

Monomers: Polymers are composed of repeating units called monomers. These monomers are linked together through chemical bonds, forming long chains or networks.

Examples of Biodegradable Polymers we explored:

- Gelatine

- Rice Flour

- Alginate (Alginate is a linear polymer of d-mannuronic acid and l-guluronic acid)

- Starch (Starch is comprised principally of two glucose polymers, amylose and amylopectin)

- Agar Agar (Agar. Agar is a polymer, obtained from algae, made up of subunits of the sugar galactose.)

Inspiration¶

My Inspiration

Nomads, non sedetery, bushcrafting living on the road, animlas migrations, following nature, atmospheric agents : water, sun, soil, fire

I've aproched this week of bioplastics like a virgin, but i finally realised that creating something with nature by yourself has always been my part of seeing the world. As my enthusiasm was endless I dived in pleanty of alterations to the basic reciepis to to bio-materials, my favroutite for now are: bamboo agar...impression on textile creating woven texture...bio resins...biofoam...

I'm aiming is to create a sembioatic realtionship between the process in which a bio-based material is created and , adapt co-exist together.

Artists I Like

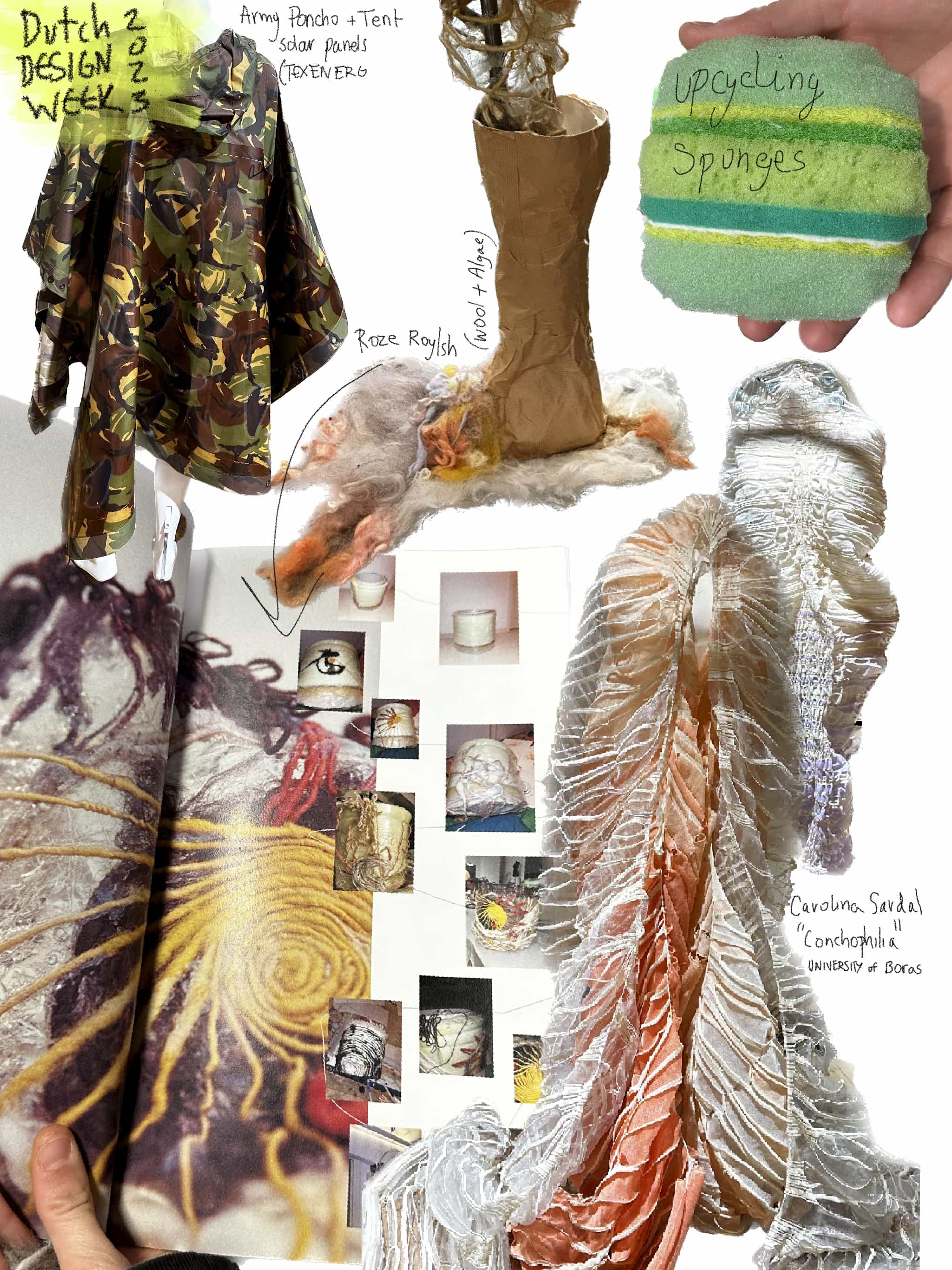

DUTCH DESIGN WEEK 2023 MOODBOARD

Lectures¶

Lecuture 01

Microbial Fermentation

Microbial fermentation is a biochemical process that manages to extract chemical energy from carbohydrates without the oxygen. This chemical reaction occurs in bacteria, yeasts or even in muscles of humans.

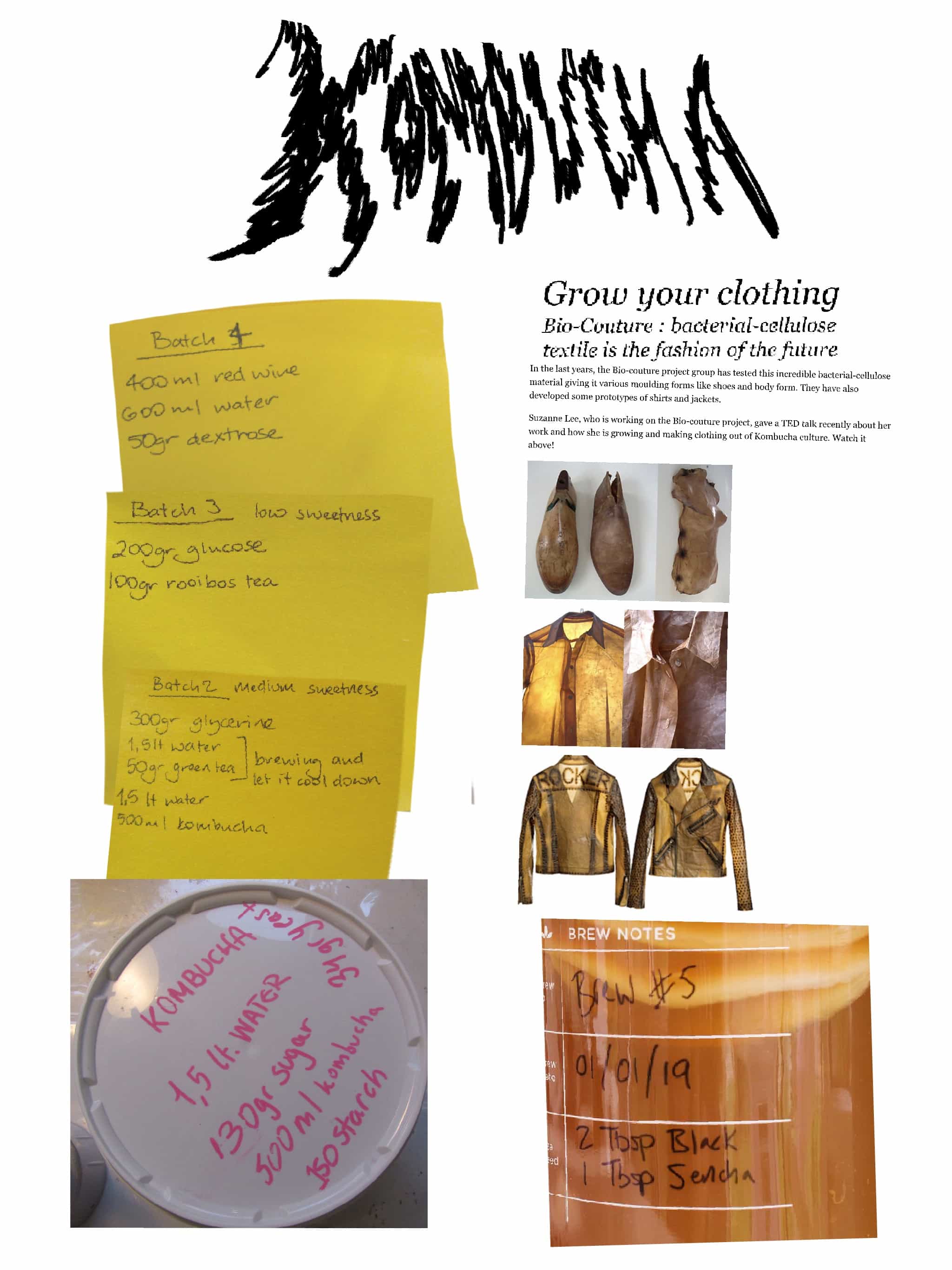

Kombucha:, a popular fermented tea beverage, is also gaining recognition as a microbial fermentation material with several unique properties.

"SCOBY stands for symbiotic culture of yeasts and bacteria. It is the source, hence the nickname mother, of all kombucha brews. This drink supposedly helps with digestion, detoxification, and energy among other benefits. By using the "mother" culture to make kombucha leather.

The amazing thing about growing your own leather is there is no cow slaughter involved. You grow your materials in the privacy of your own home for the affordable price of nearly free. You do have to use cider vinegar sugar tea water and a mother scoby. I already had most of these items."

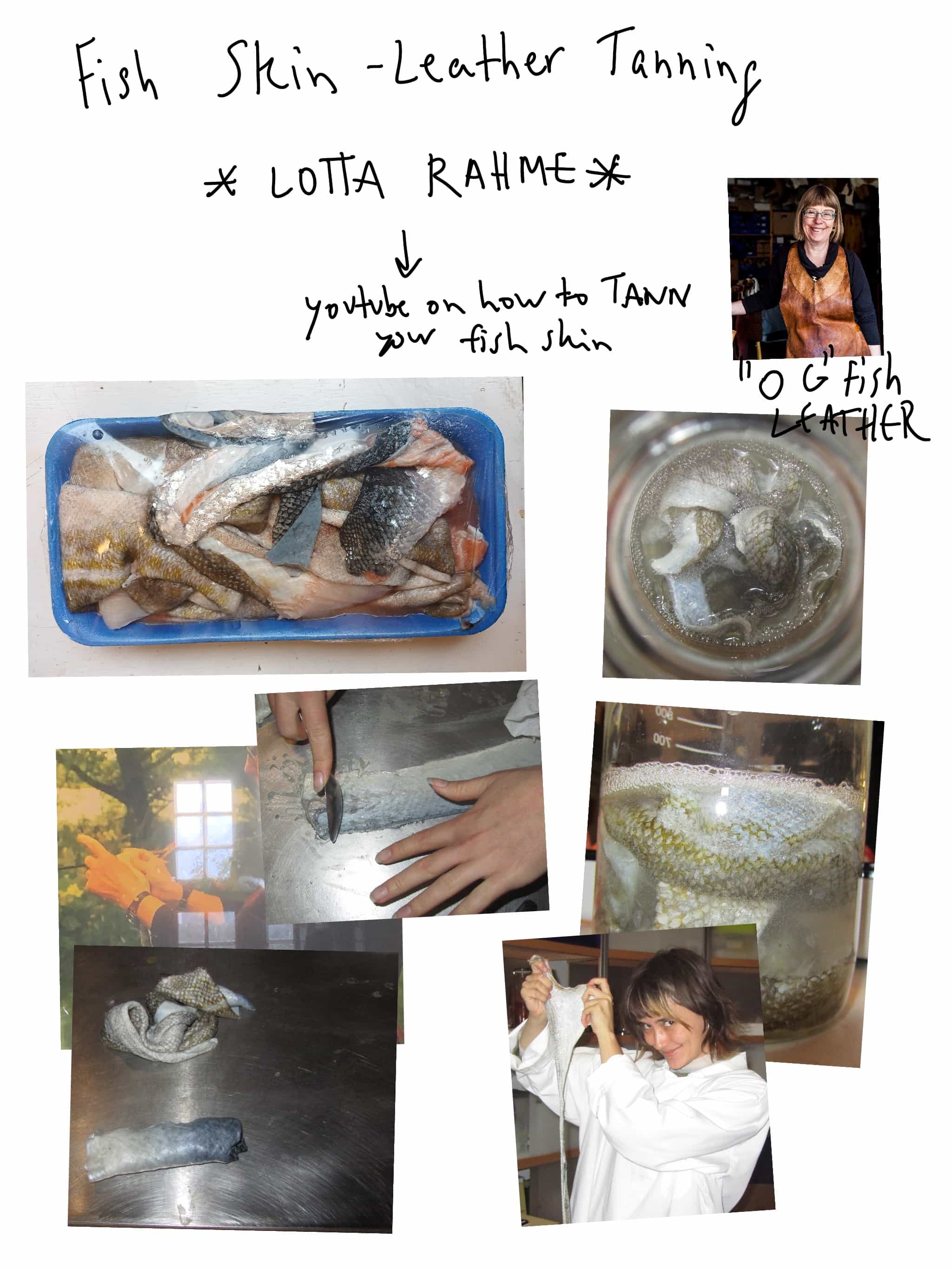

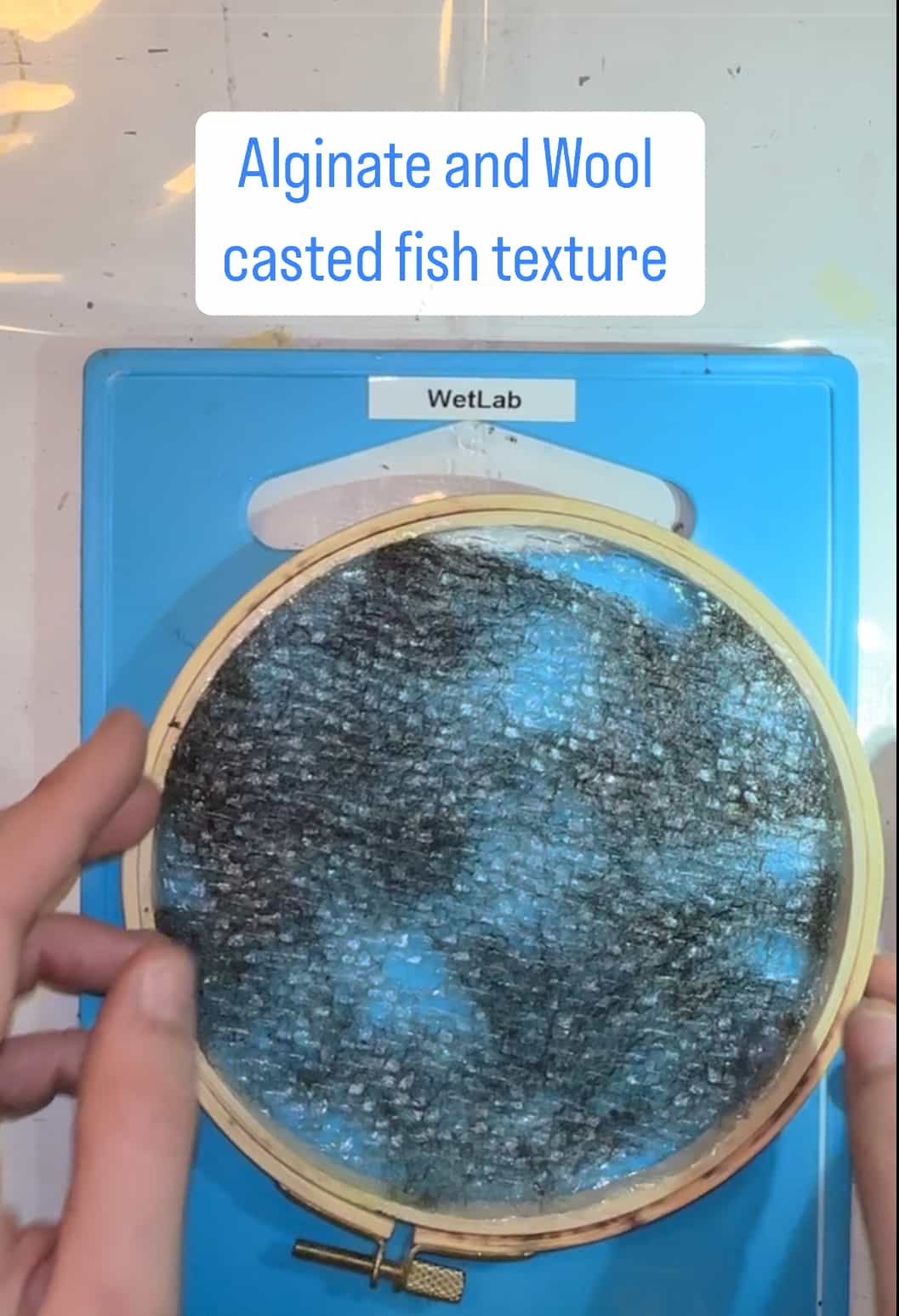

fish skin leather

Ingredients:

- skin of a fish

- 1lt grapeseed oil or olive oil

- egg yolk

- teaspoon of soap

Method:

Remove all the flesh and scales from the fish skin. I used an eel skin for my leather. I found tablespoon as a good tool to remove flech and scales. Squeeze all the water out. Add the above ingredients in a bowl. This mixture can be used for 3-4 skins. Put the fish skin in the mixture and work it 10-15 minutes, rubbing the mixture on the skin. Hang the skin. During the drying, work your skin frequently for better results.

After 3 days, wash the skin in soap and water mixture at 20 degree celcius. The skin is very stiff at this point. You need to work your skin against a sturdy frame to soften it. Ideally, put the skin on a board flat to dry. I did not have a proper place and board so I hung it again to dry.

Credits: Asli Aksan

KOMBUCHA FERMENTATION SCOBY

General Research¶

Q&A

(FLUX OF THOUGHT CHATTING WITH MY FRIEND Chat BTG, WAS PLAYING QUESTIONS AND ANSWERS...)

Gums and Plant Extracts:

Guar Gum: Guar gum is a natural thickener and stabilizer derived from guar beans. It is often used in food and cosmetic products as an alternative to starch. Xanthan Gum: Xanthan gum is a polysaccharide produced through fermentation and is used as a thickening agent in a variety of applications.

Alginates:

Sodium Alginate: Sodium alginate is derived from brown seaweed and is used as a gelling and thickening agent in the food and pharmaceutical industries.

Cellulose-Based Materials:

Download PDF ON CELLULOSED BASED MATERIALS

CMC: Carboxymethyl Cellulose, and it is a cellulose-based material. CMC is derived from cellulose, which is a natural polymer found in plant cell walls. CMC is chemically modified cellulose, where hydroxyl groups of the cellulose molecules are partially substituted with carboxymethyl groups.

Microcrystalline Cellulose: Microcrystalline cellulose is derived from plant cellulose and is used in the pharmaceutical and food industries as a binder, filler, and disintegrant.

Cellulose Nanofibers (CNF): CNF is an emerging material with applications in paper, packaging, and composites. It can replace starch in certain applications.

*Starch:

Starch and it's derivatives are widely used in biofabricating (paper manufacturing, textiles in glues, such as wallpaper glue, cosmetics and even as a lubricant in oil drilling.)

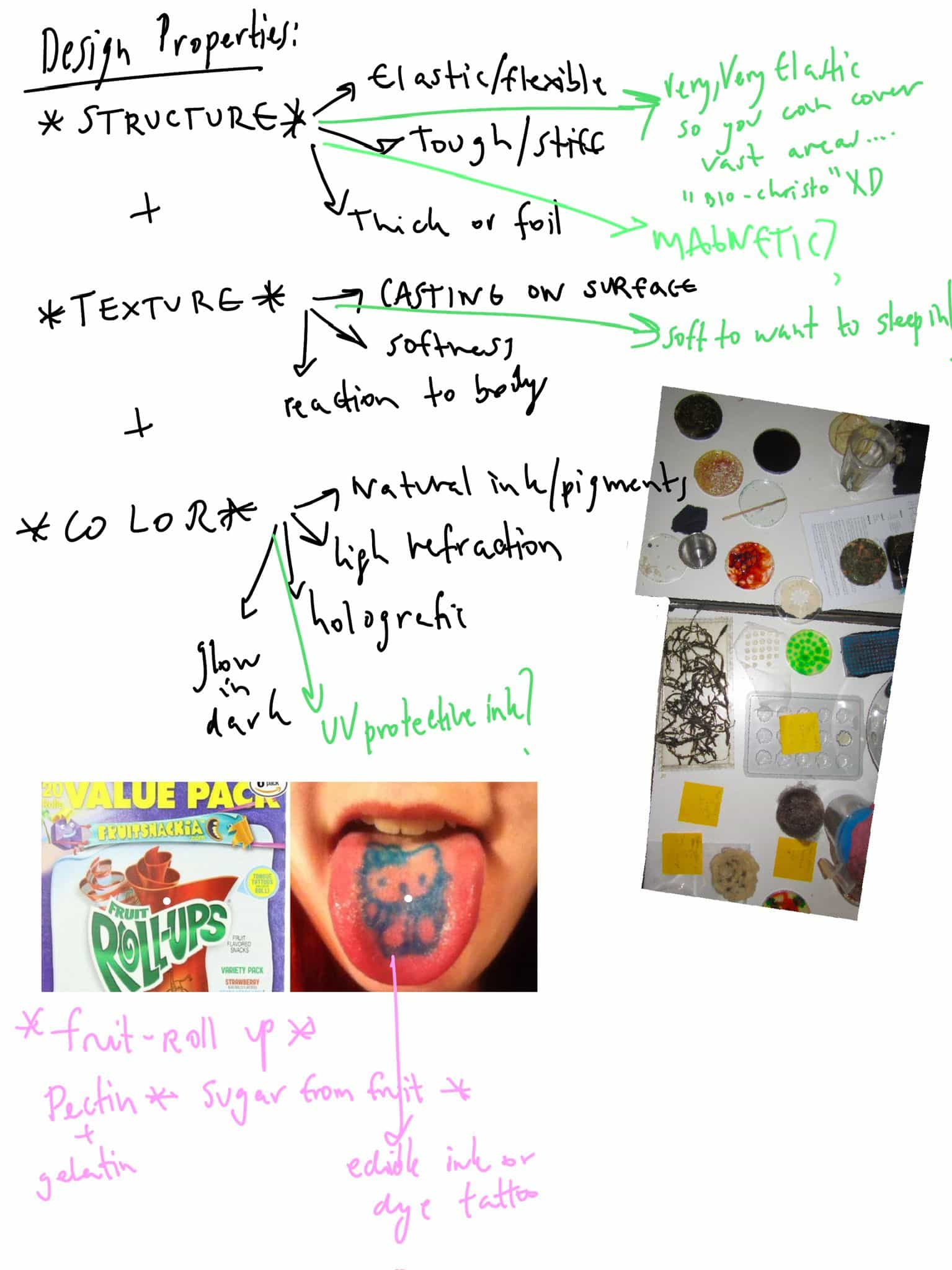

Pectin:

Pectin: Pectin is a natural polymer found in fruits and is used in food products as a gelling agent. It can be used in place of starch in jams, jellies, and other products. Fruits like apples, citrus fruits (oranges, lemons, and limes), and berries (strawberries, blackberries, etc.) are known for their relatively high pectin content. Extraction: To obtain pectin for industrial use, it is typically extracted from fruit peels and cores. These fruit byproducts are heated and treated with acid to release the pectin. The extracted pectin is then further processed and dried into a powder or used in liquid form.

Protein-Based Biopolymers:

Soy Protein Isolate: Soy protein isolate is used in food products as an alternative to starch for its thickening and binding properties.

Q:

What are some Bio-based materials that provide insulation for heat ?

A:

Bio-Based Foam Insulation: Some foams are derived from bio-based sources, such as soybean oil or castor oil. These bio-based foams can be used for thermal insulation in buildings and appliances. They offer good insulation properties while being more environmentally friendly.

Natural Fiber Insulation: Insulation materials made from natural fibers, such as cotton, hemp, or wool, provide moderate heat insulation properties. They are commonly used for thermal and acoustic insulation in construction.

Cellulose Insulation: Cellulose insulation is made from recycled paper or cardboard treated with fire-resistant additives. While not entirely bio-based, it incorporates natural materials and is an eco-friendly choice for heat insulation in homes. Straw Bales: Straw bales are a traditional and bio-based insulating material used in construction. They offer excellent thermal insulation and are a sustainable choice for building walls.

Cork Insulation: Cork, derived from the bark of cork oak trees, provides good insulation for both heat and sound. It's used in construction for walls, floors, and roofs. Hempcrete: Hempcrete is a bio-based building material made from the inner fibers of the hemp plant mixed with lime and water. It offers thermal insulation properties and is also lightweight and breathable.

Rice Husk Insulation: Rice husks are a byproduct of rice milling and can be used to create insulation materials. These materials have some insulating properties and are sustainable. Wood Fiberboard Insulation: Wood fiberboard insulation is made from wood fibers and is used in construction as an insulating material that combines thermal performance with sustainability.

Mycelium Insulation: Mycelium, the root structure of fungi, can be grown into insulation materials. It offers thermal insulation properties and is biodegradable. Cotton Insulation: Recycled cotton fibers can be used to create insulation materials for buildings. While not as effective as synthetic options, cotton insulation is eco-friendly.

Q:

Examples of Bio-Based Fire-Resistant Additives

A:

STARCH

Flammability Tests. It is proposed that starch is used as a flame retardant due to its non-Newtonian properties.

GRAPHITE

“Facile fabrication of starch-based, synergistic intumescent and halogen-free flame retardant strategy with expandable graphite in enhancing the fire safety of polypropylene”

What is a flame retardant containing phosphorus?

Phosphorus-containing flame retardants primarily act in the solid phase of the polymer. The flame retardant is transformed into phosphoric acid by thermal degradation, and water is released from the substrate in the solid phase.

Alginates: Alginates, derived from seaweed, can be used as a bio-based fire-resistant additive in some applications.

BioFabrication¶

Class Recipes

Credit Material Archive TextilaLab Amsterdam | Cecilia Raspanti | Fabricademy BloFabricating materials lecture 2023

AGAR RECIPES

flexible foilL?

stretch foil 8gr Agar 15 gr Gycerine 250 ml Water This recipe works best when casted in very thin folls. The foll will shrink and condense in both size and thickness, but it will be strong and durable Cook =20-30 min at approx, 80C degrees 3 gr

Agar 20 gr Gelatine 15 ml Glycerine 400 ml Water This recipe needs a long and slow cooking time for the best results. Usually =45 min at 80 degrees give the best structure. Always start by making sure the agar is well dissolved.

BIO-PLASTIC 1 4 gr Agar 25 gr Glycerine 400 ml Water This recipe has a large ratio agarwater, keep in mind that when casting this mixture it is important to have reached a thicker liquid state, honey like, rather than a fully liquid. Shrinkage can affect the shape and cause deformation

BIO-PLASTIC 2 4 gr Agar 12 gr Glycerine 200 ml Water This recipe needs +15 min at 80 degrees. Always start by making sure the agar is well dissolved in the water.

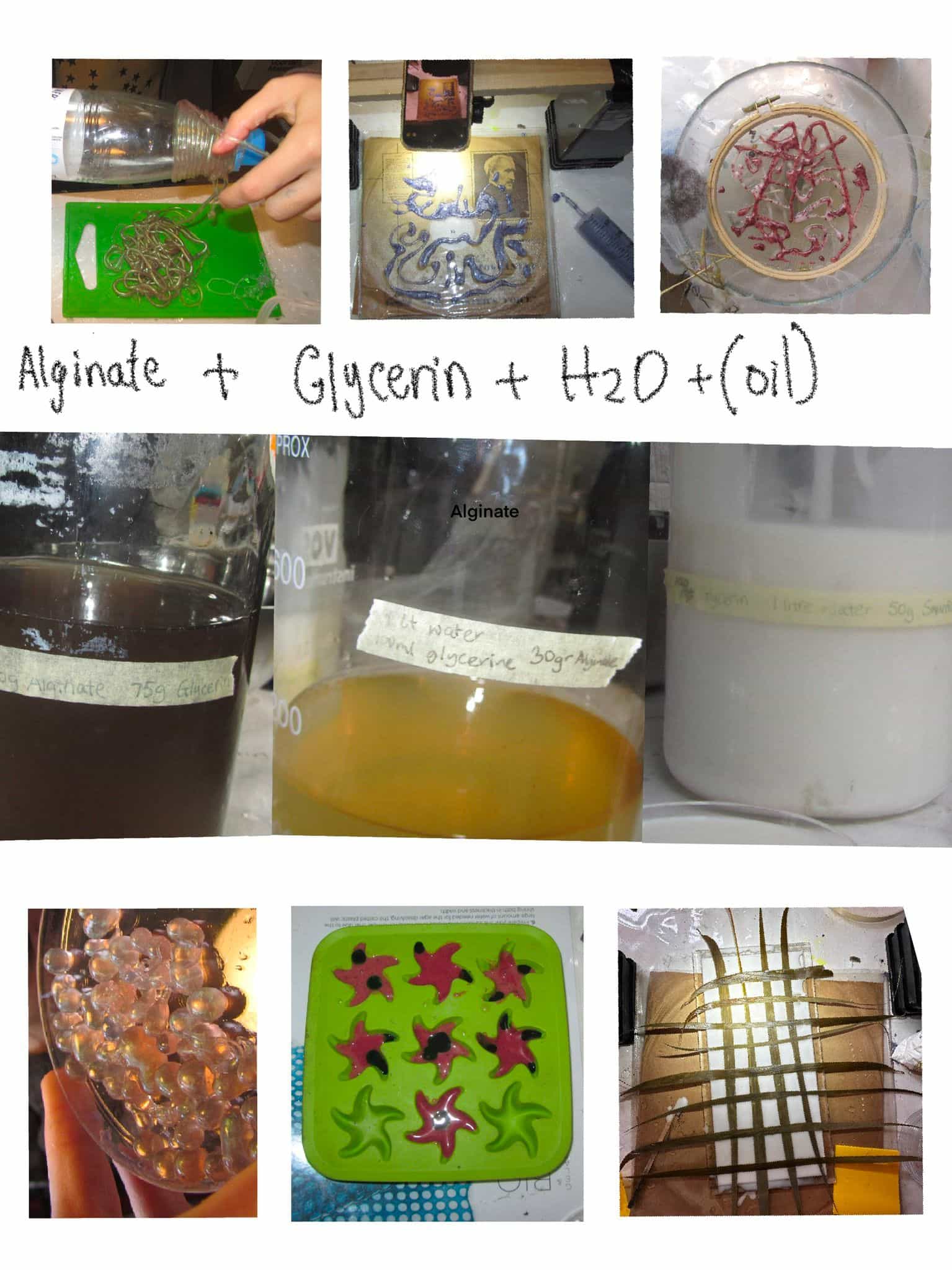

ALGINATE RECIPES****

flexible thin BIO-FOIL 12 gr Alginate 30 gr Glycerine 400 ml Water 10 ml Sodium Chloride hydrate 100 ml. Water This recipe works best when casted in very thin foils. The foil will shrink in both size and thickness, but the amount of water will help the material in casting very thin even sheets.

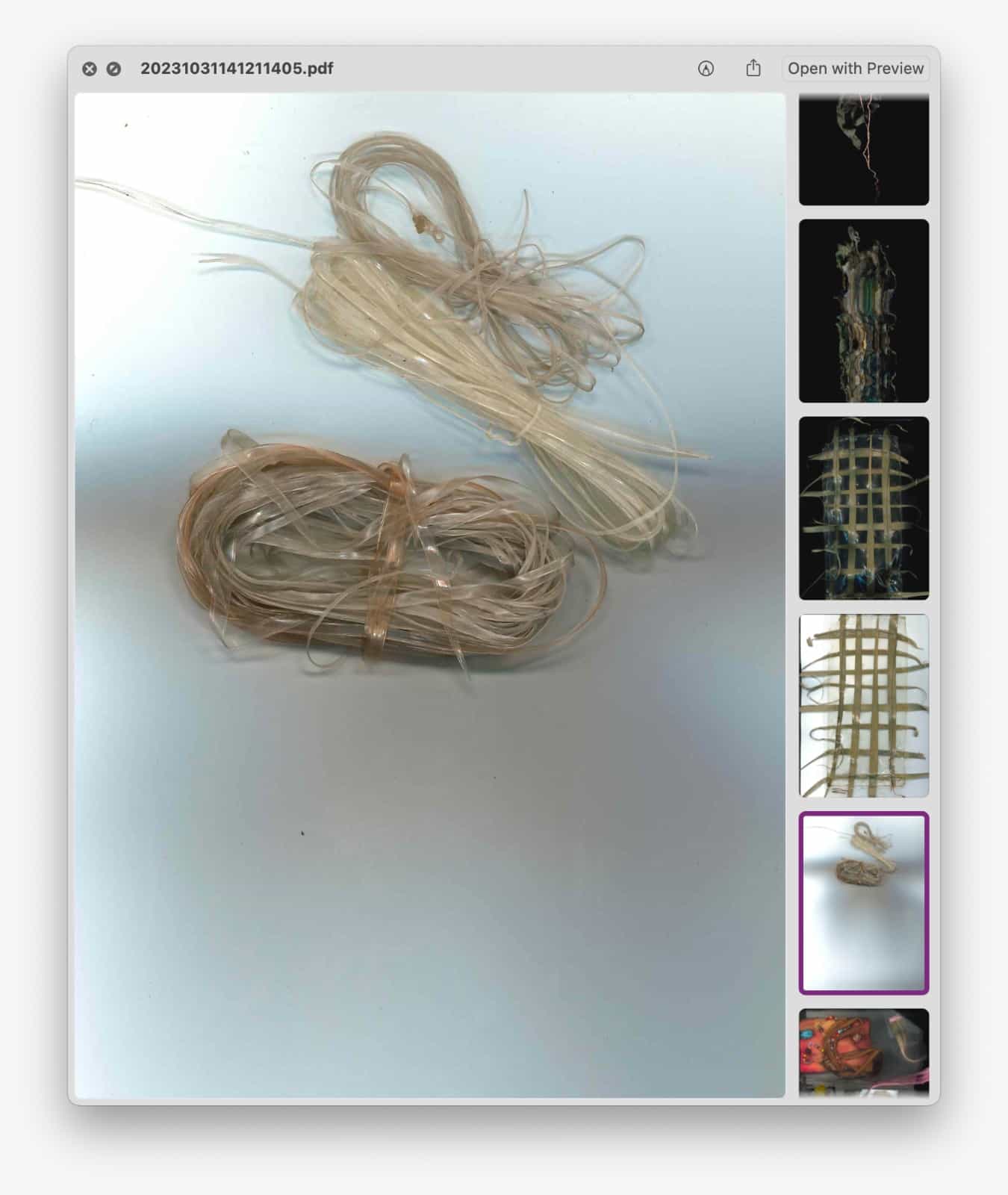

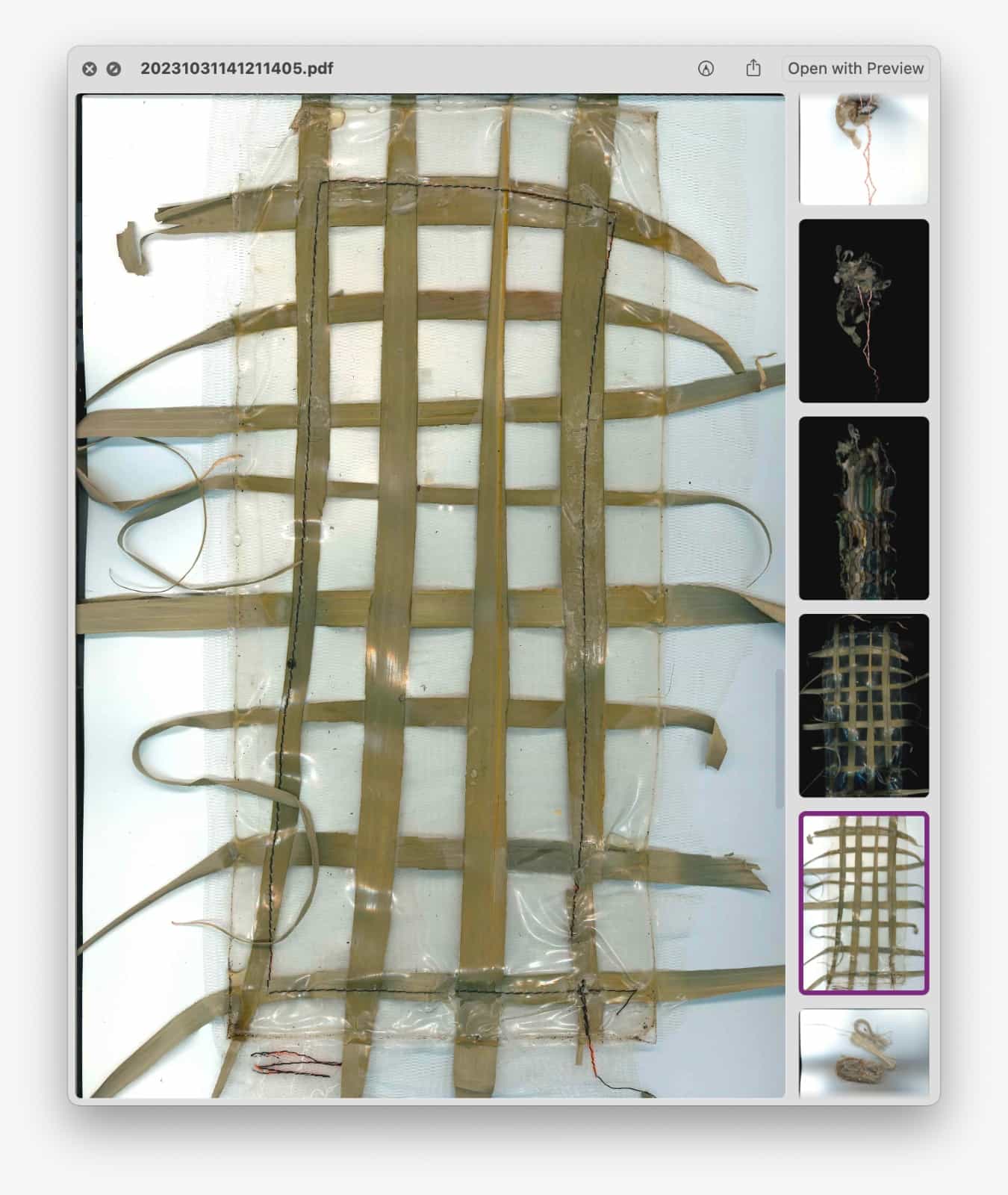

flexible BIO-SHEET & YARNS 12 gr Alginate 40 gr Glycerine 400 ml Water 10 ml Sodium Chloride hydrate 100 ml. Water This recipe works best when casted in sheets or extruded as yarns. It will shrink in size and thickness, but less than the foil - when made into foils make sure you let the liquid sit and spread before you start curing it.

flexible BIO-PLASTIC 12 gr Alginate 20 gr Glycerine 10 ml Sunflower oil 200 ml Water 10 ml Sodium Chloride hydrate 100 ml. Water his recipe works best when casted in thicker sheet foils. The foil will shrink in both size and thickness, but it will be strong and durable.

GELATINE RECIPES

BIO-PLASTIC?

BIO-RESIN 48 gr Gelatine 8 gr Glycerine 240 ml Water This mix should be first mixed all the components at 60degrees until smooth and then boil at 100degrees for 5-10 min Boiling the plastic will change the chains and make it harder but slightly more brittle 48 gr Gelatine 12 gr Glvcerine 240 ml Water This is the basic mix from which you can start playing around with more or less glycerine. It is also a great recipe for composites and mixtures with other powders or dry elements.

BIO-SILICONE 48 gr Gelatine 24-48 gr Glycerine 240 ml Water

BIO-FOAM This is the starting recipe for silicone mixtures, from here you can add even more glycerine, until 11 ration, were you will only add a solash of water and slowly mix by heating 48 gr Gelatine 12 gr Glycerine 240 ml Water 10 ml Soap For this mix it is important that you use also compressor or a simple electric milk foamer, or even a straw. These tools will help you create different size bubbles, air/gelatine ratio.

My little Hack Recipe

INGREDIENTS

- 60 gr Alginate powder

- 1 litre of water

- 100 gr Glycerin

- 20 gr Dried Yeast

- 20 gr Wheat Yeast

- 20 gr Tapioca Starch

- 1 spoon Olive Oil

- 5 drops of Lavender Essential Oil

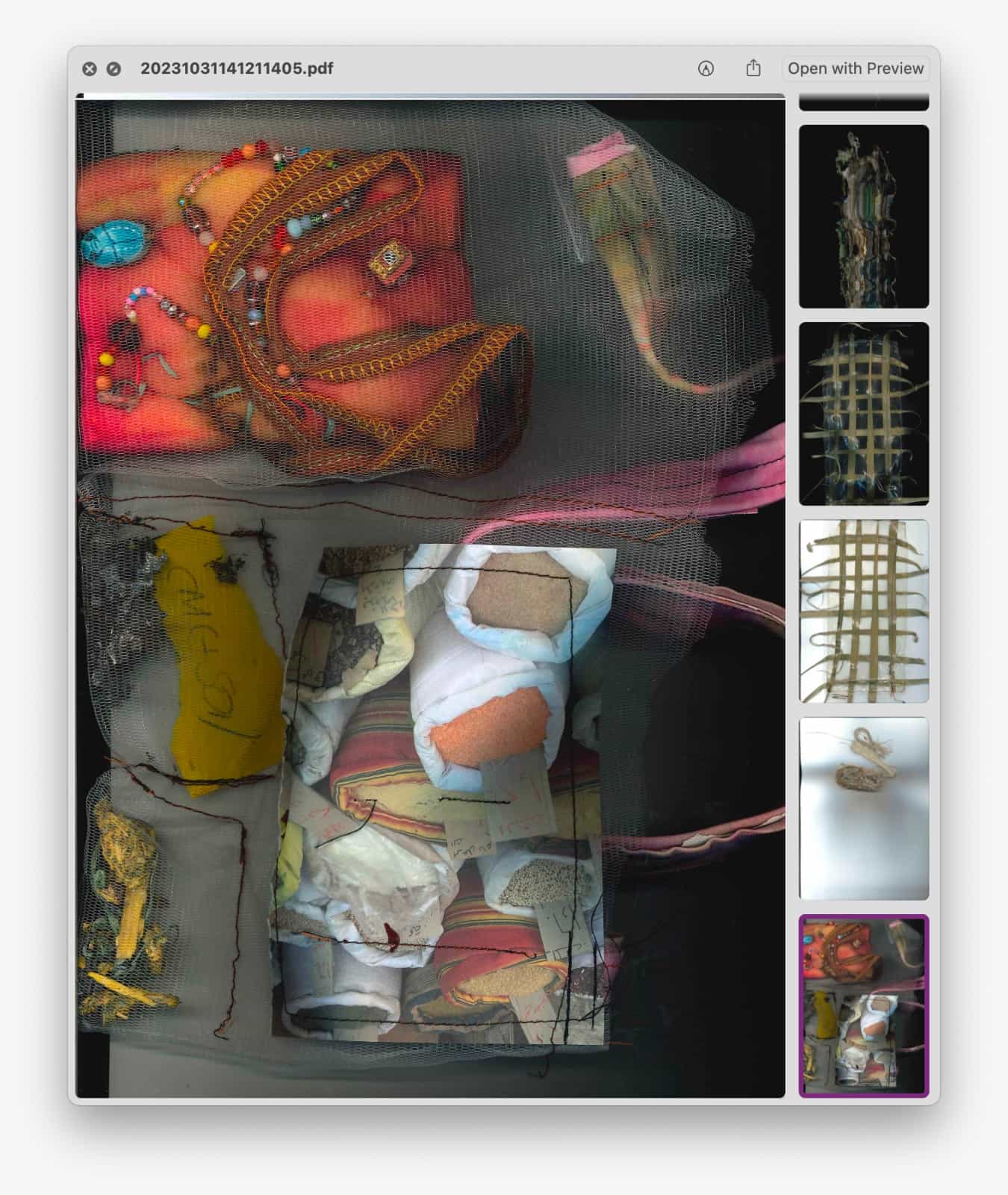

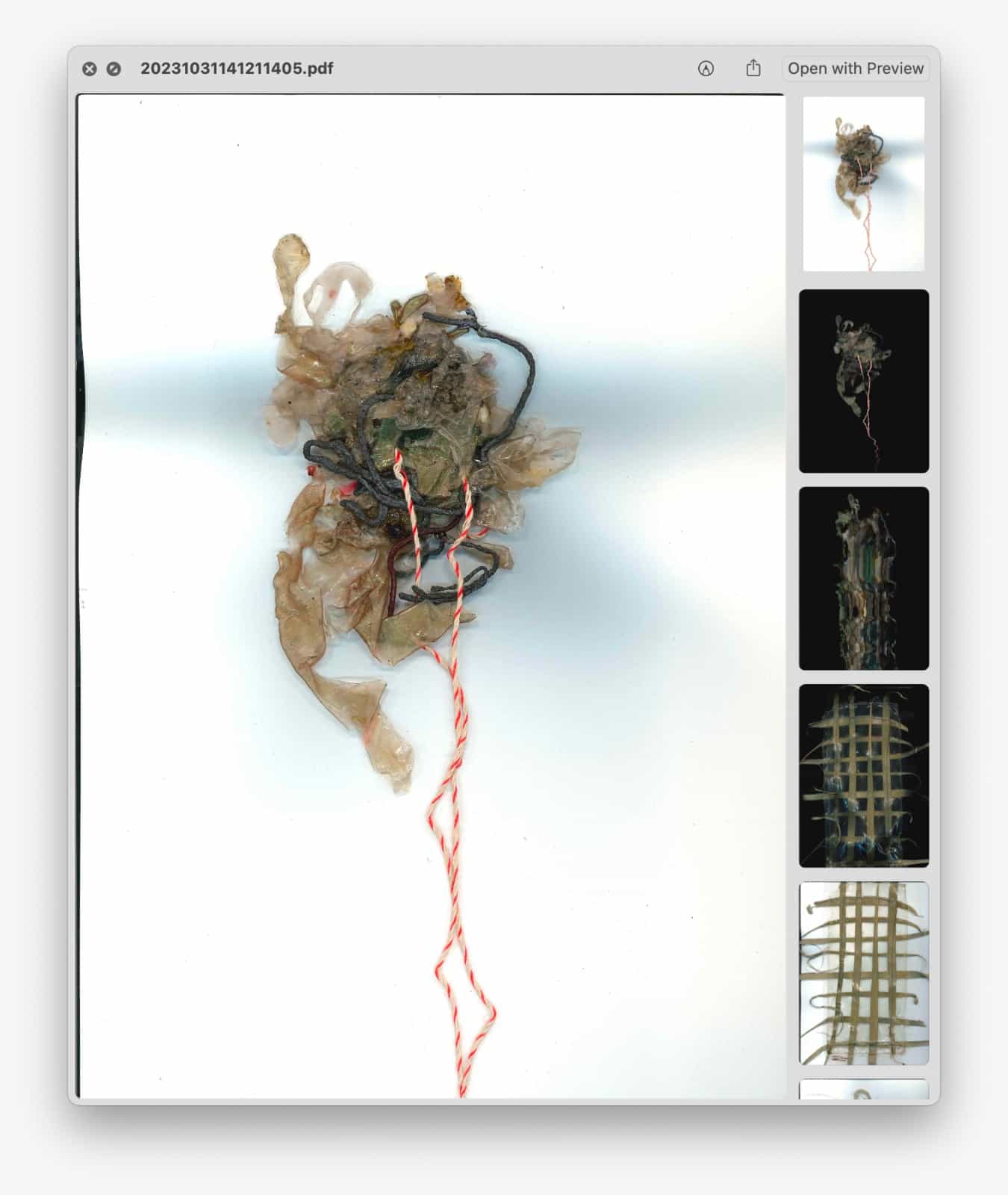

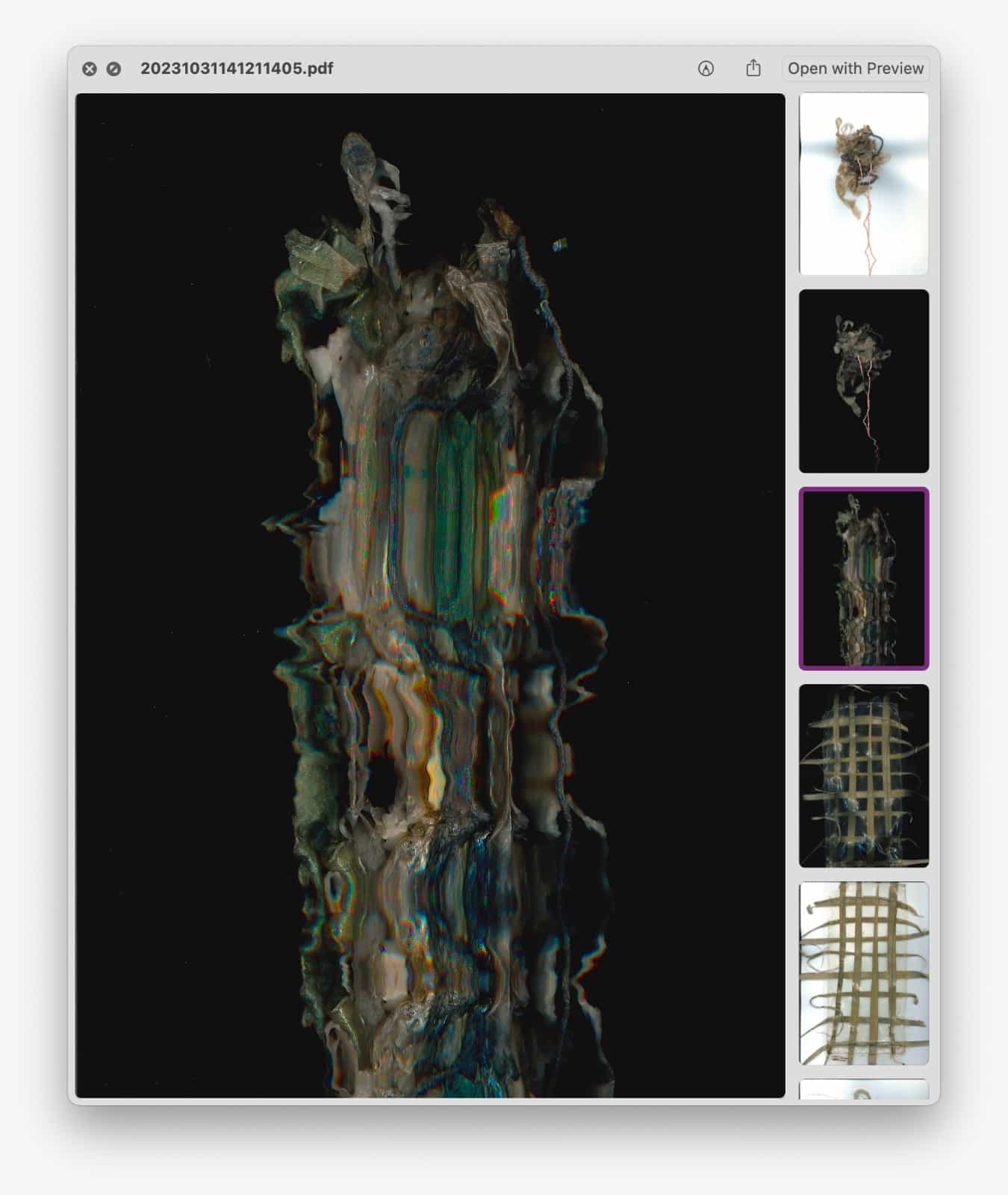

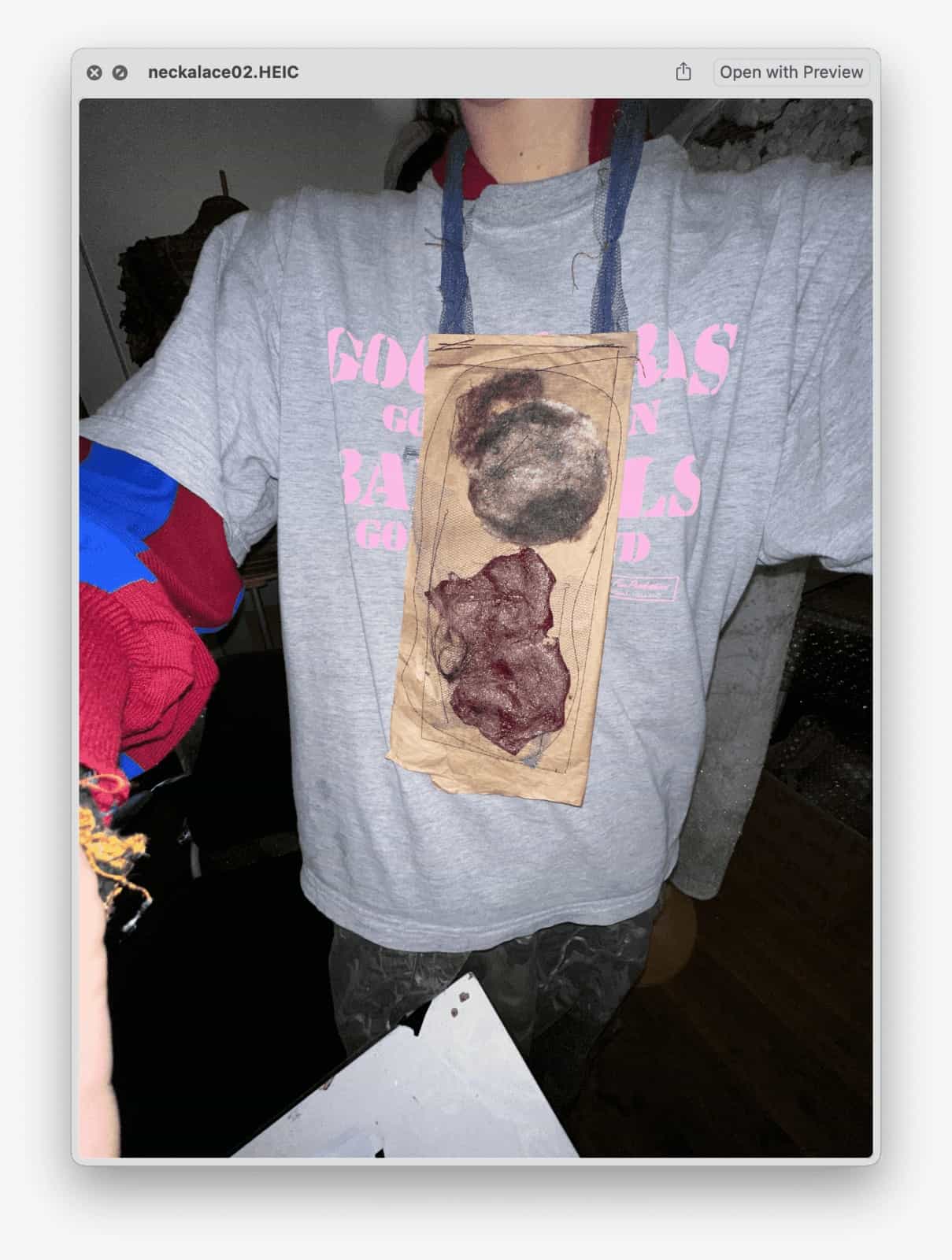

Visual Experimentation

credits : Asli Aydin Aksan

credits : Asli Aydin Aksan

Results¶

Reflection 01

In my journey towards a more sustainable and self-reliant lifestyle, I've found inspiration in the nomadic way of life. Creating our own bio-fabricated materials, tools, and garments is not just a design choice; it's a lifestyle of adapting to new environments, feeling uncomfortable, and finding comfort within the resources around you. I feel I design in a space that starts from the materials up to its many uses in real life having a practical use but also beautiful because you made it. We imagine a world Where we care about our clothes transforming them in multiple ways adapting them to the environment for a long time or maybe a very short one, minimizing what we need while amplifying what the Earth needs.

Favorite Outcomes

Future References¶

Dig Deeper

next swatch: try and use only starch nad yeast and hemp fibre

- LIFE CYCLE

- BIODEGRADATION

- WATER RETENTION

- printing and garment making...

- yeast with kombucha and alginate -how to better document stuff

BOOKS

Entangled Life: How Fungi Make Our Worlds, Change Our Minds & Shape Our Futures The Mushroom at the End of the World: On the Possibility of Life in Capitalist Ruins Braiding Sweetgrass Why Materials Matter I Contain Multitudes: The Microbes Within Us and a Grander View of Life Being Material Wasted: When Trash Becomes Treasure

PODCAST

Next Generation Materials The Mushroom Hour Biofabrication: From Fungi to Fashion

MOVIES-SERIES

Fantastic Fungi A life in color Abstract, The art of design

CREDITS ANASTASIA

Hacks

"youtube shorts" replace shorts with embed credits riley

( )

© [2023] credit : ray