10. Open Source Hardware¶

** TEAM PROJECT - HACKING THE CNC SHOPBOT - TRAILER **

** SIZZLING SIX - OPEN SOURCE HARDWARE WEEK - PRESENTATION **

Week Assignment¶

Weekly Quest

TEAMS:

Hardware = Stephanie Johnson & Aslı Aydın Aksan Electronics = Riley Cox & Michelle Vossen Brush Design = Jiawen Gong & Ray Formilli Ink / Surface = Ray Formilli & Jiawen Gong Working with the CNC machine / shopbot code generation / design files = Aslı Aydın Aksan & Jiawen Gong Documentary = Ray Formilli & Machteld Zee Project Management = Machteld Zee & Michelle Vossen

credits: Asli Aksan

Check out the weekly assignment here

Saftey Rules for the Shotbot CNC Machine:

- Don’t start without Henk, Michelle or Asli

- Always first Z-level the machine

- Don’t turn on the spindle

- Never leave the machine running

- Clean up ink spills immediately (pause the machine)

- If unsure, do a test run in the air

- No material near the rails / gears of the machine

- Keep it simple stupid

Check out the weekly presentation Presentation Mitchelle

Notes¶

Open Source Hardware

credits: Asli Aksan

OPEN SOURCE HARDWARE

Lecture by Sara Diaz Rodriguez

How to work with open source hardware?

Understand how existing machines work Get to know and overcome your knowledge gap Practice user testing and impact analysis

Documentation

Create a list of materials, an estimate cost, add datasheets Design bluprints, drawings, shcematics, source codes, assembly guides Separate the process into steps and write a summary of the overview of the process Use universal file formats like pdf, dxf, stl. Formats of open software Take pictures in white background and make step by step instructions and gifs Create a video showing the machine functioning....

Safety

Brave hacker, whatever you do..

Don't start without Henk, Michelle or Asli Always first z-level the machine Don't turn on the spindle Never leave the machine running Clean up ink spills immediately (pause the machine) If unsure, do a test run in the air No material near the rails/gears of the machine Keep it simple stupid (kiss) References & examples

Plotters:

drawing machines Axidraw or open source variants like 4xiDraw & Blot Arnaud Pfeffer (axidraw expert) Block printing with shopbot - making the job of block printers easier Brachiograph - easy low tech diy plotter Hacking Machines:

Hacking the shopbot in 2017: a needle punching machine Creality ender pen plotter - asli

Motions:

Dragging a brush (flat or on an angle), a roller Servo motor attachment Cam follower principle Multiple brushes Custom stamps How to get ink on the tool:

External reservoir: going back and forth to paint in gcode How to attach fabric and tool to shopbot

Overview

** TEAM MEMBERS **

Teams:

Hardware: Stephanie Johnson & Aslı Aydın Aksan

Electronic: Riley Cox & Michelle Vossen

Brush Design: Jiawen Gong & Ray Formilli

Ink / Surface: Ray Formilli & Jiawen Gong

CNC / sbp code / design files: Aslı Aydın Aksan & Jiawen Gong

Documentary: Ray Formilli & Machteld Zee

Project Management: Machteld Zee & Michelle Vossen

**SHOPBOT CNC credits to Asli for labled picutre**

credits: Asli Aksan

Project: Hacking CNC ShopBot Machine for Artistic Expression

Overview:

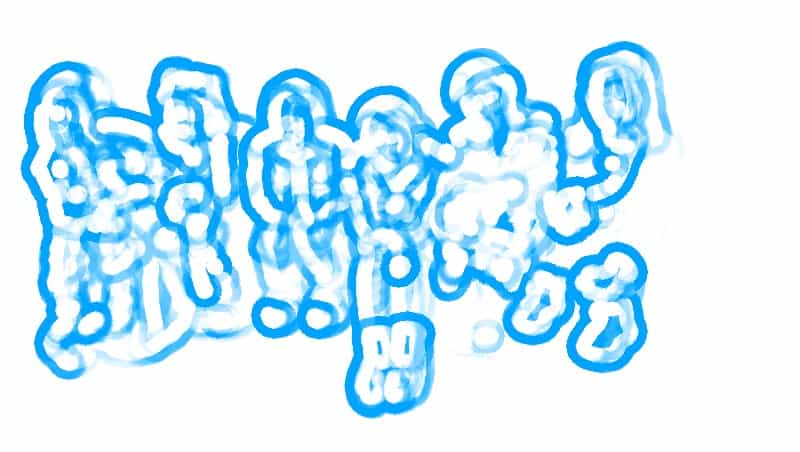

The project involved modifying a CNC ShopBot machine, a Computer Numerical Control milling machine designed for precise material milling. Instead of utilizing a traditional drill bit, the goal was to attach a painting device to the CNC, enabling it to create artistic drawings.

Objectives:

Transform the CNC ShopBot for artistic applications. Replace the conventional drill bit with a painting device.

Design Process:

Utilize Rhino for creating intricate and artistic designs. Generate G-code instructions compatible with the CNC machine.

Artistic Expression:

Explore the machine's capacity for drawing and painting. Expect and embrace surprises in the artistic output.

Components Used:

Hardware: Corrugated perforated iron band (1 spool) Self-Adhesive Rubber Seal (1 roll) Cable ties (plenty) Clamp (2) Nuts and bolts of various sizes (plenty) Bike phone holder attachment (1) Threaded insert (1) Servo motor & pen holder attachment (1, 3D printed with PLA)

Electronics:

- Arduino Uno (1)

- Attiny85 (1)

- Attiny85 dip socket (1)

- Battery pack (1)

- Breadboard (1)

- Jumper wires (plenty)

- AA battery (3)

- Solder

Ink/Pigment: - Ecoline ink (various colors, plenty) - Sicotex screenprinting ink (various colors, plenty) - Acrylic paint (various colors, plenty)

Brushes and Tools:

- Various brushes

- Various sponges

- Various molotovs

- Pipets

- Marker pens

- Scraper

- Squeegee

Surface Materials: - Paper (A2 size) - Cotton fabric with acrylic gesso primer - 120 gr copy paper (A3 size)

Software: - Arduino IDE (for programming Attiny45 for servo motor) - Rhinoceros (to prepare design files) - Grasshopper (to create custom shopbot code) - VCarve Pro (to prepare toolpath for the shopbot) - Shopbot Console (to communicate with the CNC machine)

Project Outcome:¶

The project aimed to push the boundaries of the CNC ShopBot machine, turning it into a tool for artistic expression. By combining precise CNC technology with creative design, the team expected the machine to draw, paint, and surprise them with unique and unexpected results.

credits to Stephanie

Inspiration¶

inspiration

** HACKING EVERYTHING **

** ALEXANDER MCQUEEN ROBOT ARMS SPLATTER "SYNERGY" **

** ALEJANDRO JODOROSKY - ENDLESS POETRY SCENE "HACKING EMOTIONS" **

**Bruno Munari - "La scatola dei giochi / The Toy Box" - (1976)**

**Inspirational Music for Video Sound thanks <Stephanie>**

**Gianni Pellegrini - Painting- - Light Study - **

** Jackson Pollock**

**Experimental Drawing Workshop**

Workflow & Experiments¶

Trailer Movie

Documentary Title: "HACKING UNIVERSAL: The CNC ShopBot Experiment" "art in motion"

Visual Style:

- Utilize a mix of documentary-style interviews, behind-the-scenes footage, and close-up shots of the CNC machine in action.

- Incorporate vibrant colors to capture the essence of artistic expression.

- Use visual effects to emphasize the contrast between the precision of the CNC and the organic nature of art.

Tone: - humorous, entertaining, visual, chaotic, inspiring yet blending technical insights with the joy of artistic creation, celebrate the beauty of unpredictability in art.

Music: - Energetic and uplifting music during moments of experimentation and discovery. - Reflective and contemplative tunes for interviews and reflective segments.

This movie board serves as a blueprint for a documentary that explores the educational and artistic dimensions of hacking a CNC ShopBot machine for creative expression.

Bill of Material

Hardware

credits to Stephanie

H A R D W A R E¶

-

Mechanics - How to connect brushes etc to the ShopBot

-

How humans vs machines hold pens (angle vs straight up, fluid vs mechanic movement, idea vs programmed)

C O N S I D E R¶

-

Things to think about when designing the hardware:

-

Size (of brush / shape / thickness)

-

Secure (tightly held in place)

-

Pressure (does it need a gentle brush or a heavy sweep)

-

Angle (straight down or adjustable angle)

-

Movement (incorporated into hardware)

-

Reservoir (included for ink etc built in)

-

Weight (will weight be an issue?)

Brush Experimentation

**[check out for Jiawen's documentaiton](https://class.textile-academy.org/2024/jiawen-gong/assignments/week10/)**

**credits: Jiawen for the amazing editorial work**

1ST Itiration

Brush + Squeezer Bottle + ecoline ink on Paper

2ND Itiration

Brushes + Pipette + ecoline ink on Paper

3RD Itiration

Brushes + ecoline ink on Paper

4th Itiration

Molotow's on Paper

5th Itiration

Roller Sponge on Paper

6th Itiration

Sponges on Paper

Fabric Prep

Materials Needed:

- Cotton canvas

- H2O

- Acrylic white paint

- Gesso (or chalk or calcium carbonate)

- Paintbrushes

- Palette or mixing tray

Procedure:

1: Clean the Canvas

2: Dilute Acrylic White Paint

3: Apply White Paint

4: Apply Gesso/Chalk/Calcium Carbonate Mixture

5: Let it Dry

**canvases used with primer**

HAIR Brush-Making

**Making Human Hair Paint Brushes** (youtube tutorial I watched)

**Hair Brush Textures**

DIY INSTRUCTIONS WITH RAY & CHAT BTG

Materials:

-

Fibres / Hair / or any other works just fine

TIP (start with a small amount; human hair works well)

-

Liquid glue

- Wodden Stick

- String

- Needle and thread (Optional for more complexity)

- Wax

Step-by-Step Procedure:

**COLLECTING/CUTTIN FIBRES** --> CUT the Hair/ @JIAWEN.WONG THANKS FOR THE DONATION

Collect a small amount of hair. Ensure it's clean and free of any products. Trim the hair to a manageable length, depending on the desired brush size. Create the Brush Base:

Take a stick of appropriate length for the handle of your brush. Apply liquid glue to one end of the stick.

Attach the Hair:

Arrange the trimmed hair neatly and evenly. Press the arranged hair onto the glued end of the stick, ensuring it adheres securely.

Wrap with String:

Once the hair is attached, tightly wrap string around the base of the hair where it meets the stick. Continue wrapping until the string is secure and forms a tight bundle.

Apply Additional Glue:

Apply more liquid glue to the wrapped area. This helps secure the hair and string in place.

Let It Dry:

Allow the glue to dry completely. This might take some time, so be patient.

**Optional: Add Reinforcement (Needle and Thread):

Add Wax:

Apply a thin layer of wax to the entire brush, including the wrapped area and the base of the hair. This helps protect and seal the materials.

For a more durable brush, you can reinforce the hair attachment by sewing through the wrapped area using a needle and thread.

Hack - Portrait Drawing -

**[WEBSITE THAT WE USED FOR IMAGE CONVERTER INTO STIPES AND BLOBS](https://elektrobild.org/photo-filter/round-lines)**

HACK-ing ELECTRICITY

*+credits to our amazing team member Riley Cox and her passion with electricty for delving into making our project ever more intresting:

"Servo Motors and Electronic addons¶ To add an extra variable to our CNC hacking adventure, we decided to make an adapter to add a servo motor to the brush attachment allowing for extra movement and more complex mark-making. I haven't worked with servo motors before so I was really excited to get to play around with them. Servo motors are actuators that allow for precise control of position/angle."

for more the rest of the documentation please visit her webpage:

Material Cost¶

| Qty | Description | Price | Link | Notes |

|---|---|---|---|---|

| 1 | Material one | 22.00 $ | Order Now | Order now |

| 1 | Material two | 22.00 $ | Find Alternative | Find alternative |

| 1 | Material three | 22.00 $ | View |

Tools¶

Files

Future References¶

Dig Deeper

SCAFFOLDING WEEK VACCUM FABRIC MACHINE: EMMA PICANYOL [VACCUM FABRIC MACHINE] (https://class.textile-academy.org/2023/emma-picanyol/assignments/week10/)

© [2023] credit : ray