12. Soft robotics¶

THE OBJECTIVE OF THE WEEK¶

The theme of the week was creative and fun but I think it was a smooth week probably because all of our energy was used by presenting the personal project !?

This week was devoted to soft robotics, and in particular an introduction to different inflatable techniques.

MY PRODUCTION¶

1_DOCUMENTATION¶

Several examples as astonishing as each other:

THEO JANSEN¶

Since 1990 THEO JANSEN has been engaged in creating new forms of life: the so called « strandbeests ». These are not made of protein like existing forms of lives but they’re made of another basis stuff; yellow plastic tubes. Skeletons made from these tubes are able to walk. They get their energy from the wind. They evolved over many generations, becoming increasingly adapt at surviving storms and water from the sea. In redoing this creation, he hopes to become wiser in the dealing with the existing nature by encountering problems the real Creator had to face.

MATTHEW GARDINER¶

MATTHEW GARDINER is an artist most well known for his work with origami and robotics. He coined the term Oribot 折りボト in 2003, and since works in the field of art/science research called Oribotics: a field of research that thrives on the aesthetic, biomechanic, and morphological connections between nature, origami and robotics and is moderately active on.

AEROMORPH¶

The project AEROMORPH investigates how to make origami structure with inflatables with various materials. We introduce a universal bending mechanism that creates programmable shape-changing behaviors with paper, plastics and fabrics. We developed a software tool that generates this bending mechanism for a given geometry, simulates its transformation, and exports the compound geometry as digital fabrication files. A custom heat-sealing head that can be mounted on usual 3-axis CNC machines to precisely fabricate the designed transforming material is presented. We envision this technology could be used for designing interactive wearables, toys, and packaging industry.

MORPHING MATTER LAB¶

MORPHING MATTER LAB sits at the intersection of morphing materials and design. We discover morphing principles, design material architecture, invent fabrication methods, and develop computational tools for robotic morphing matter. We turn fictional future into the present.

GIADA GERBONI¶

The incredible potential of flexible and flexible robots for certain medical interventions.

MY_PROCESS¶

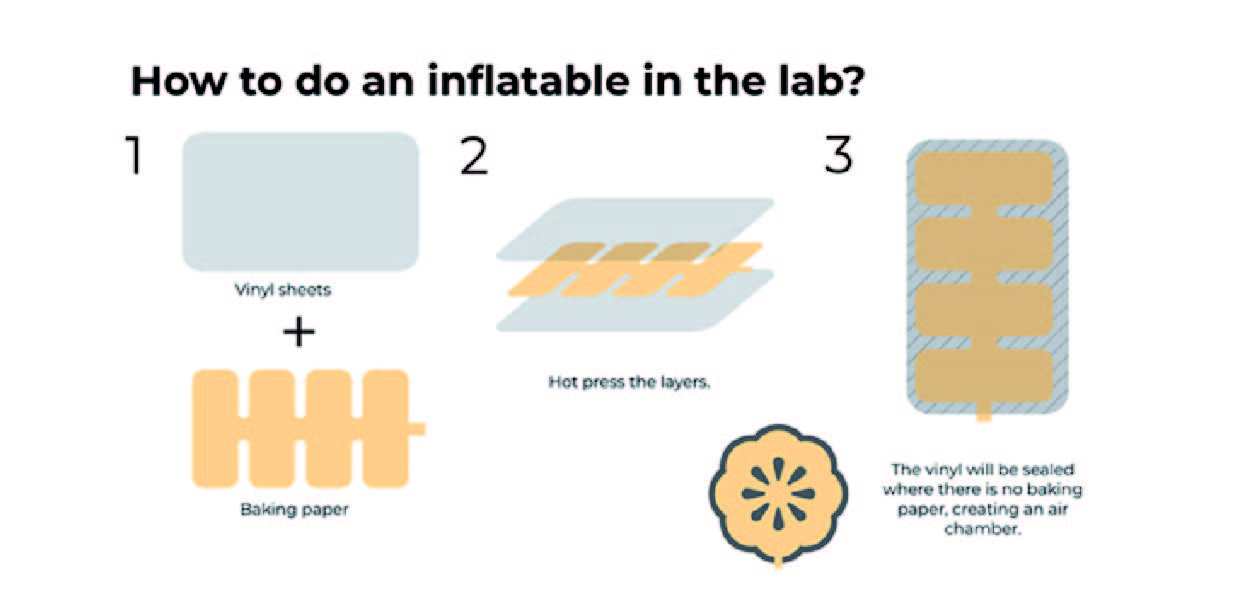

A_THERMO INFLATABLES¶

The principle is simple: Two layers of fabric (coated or thermovinyl) are welded together, with parchment paper between the 2 layers. Where there is baking paper, air can circulate and add volume.

WITH COATED FABRIC¶

My first exploration a started with coated fabric and baking paper

1ST PATTERN

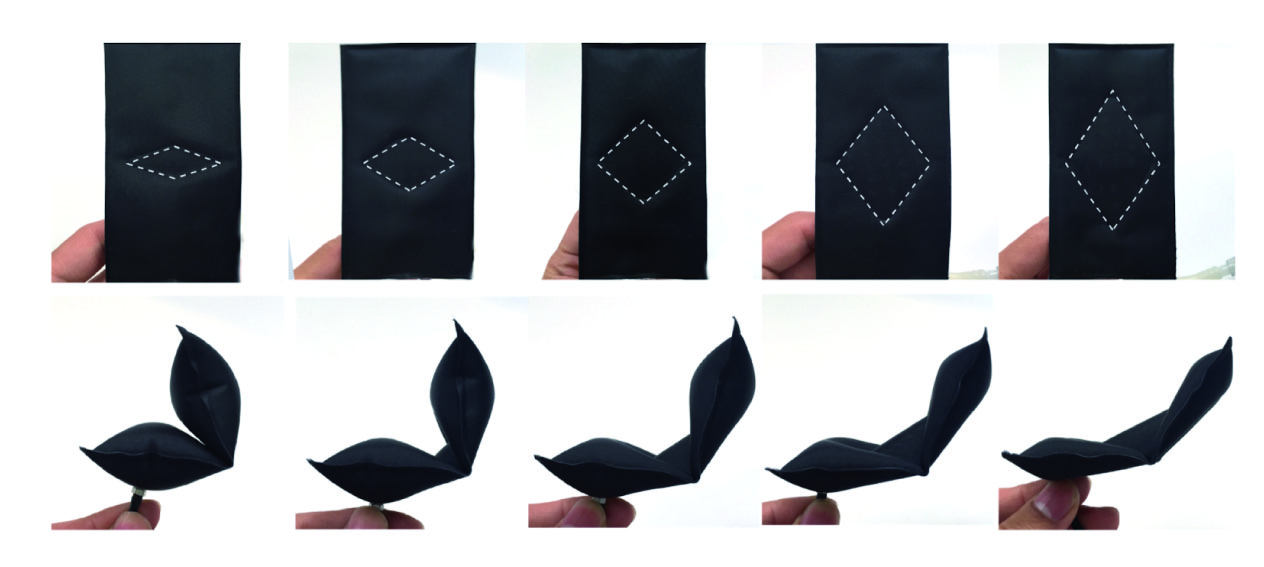

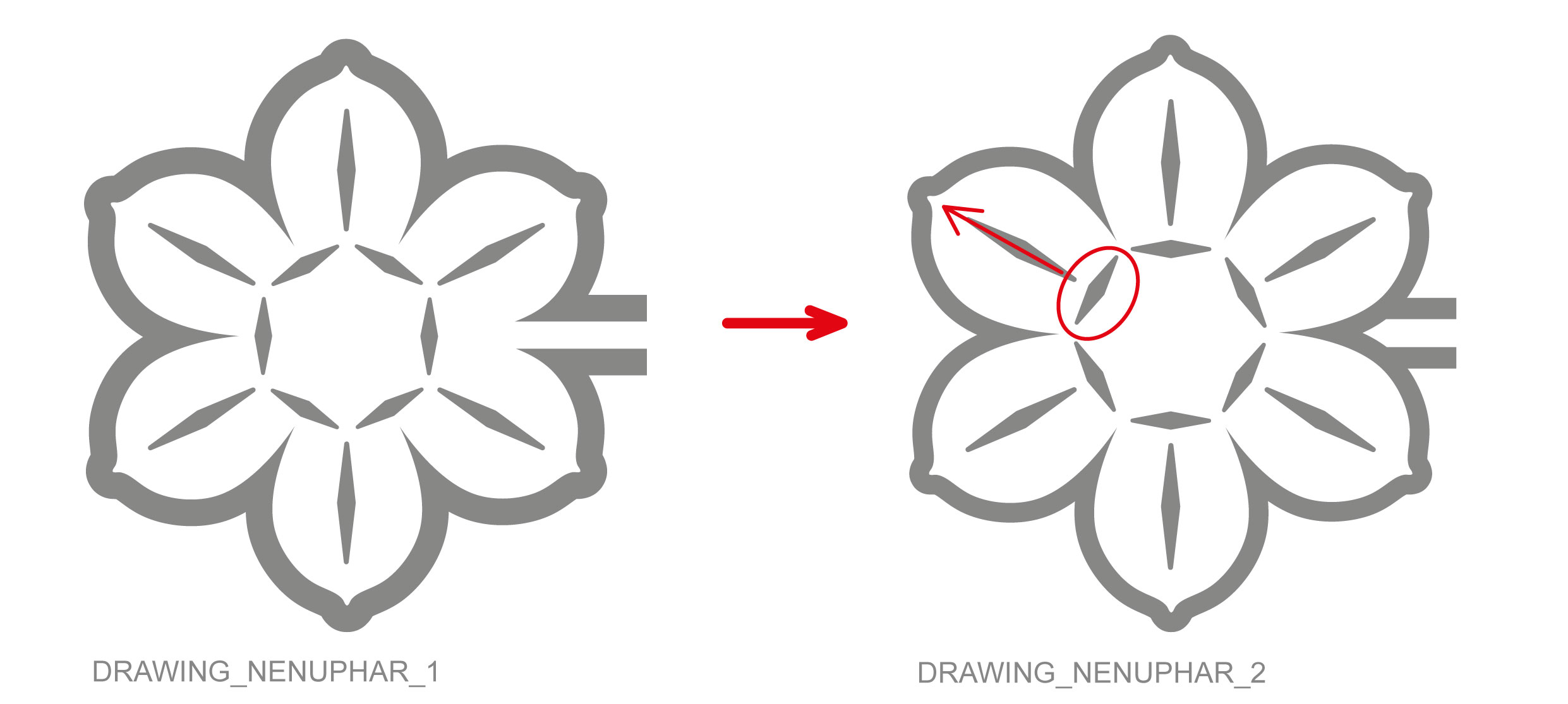

I started with the idea of a water lily flower:

Following the basics as described by Adriana in the lecture, in which the smaller the welded diamonds parts, the more easily the structure can bend.

I generated the 1st drawing. Then in doubt, I shifted the diamonds at the base of each petal, thinking that this would allow each petal to take off better.

CUT & WELDING

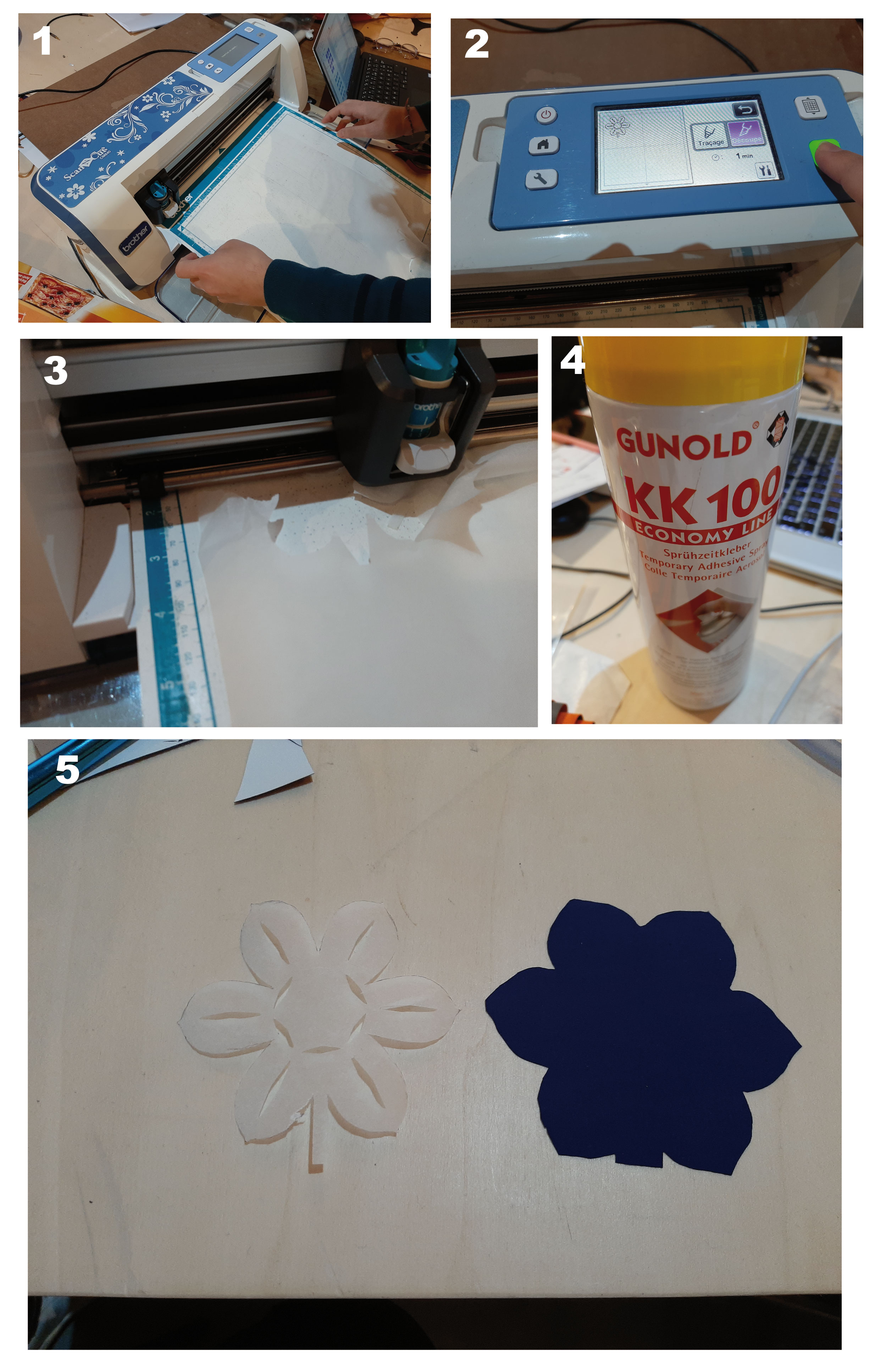

For the cutting of paper and fabric, we used a BROTHER CM 840 Scan & Cut machine (1+2) that we have driven with the PE_DESIGN interface to generate .WMF files (which we mainly use to use the embroidery machine and which is also a BROTHER model): So that the paper adheres well, and does not move when cutting, I used a repositionable glue spray (4).

Then after 1 minute inside Heatpress at 200°C.

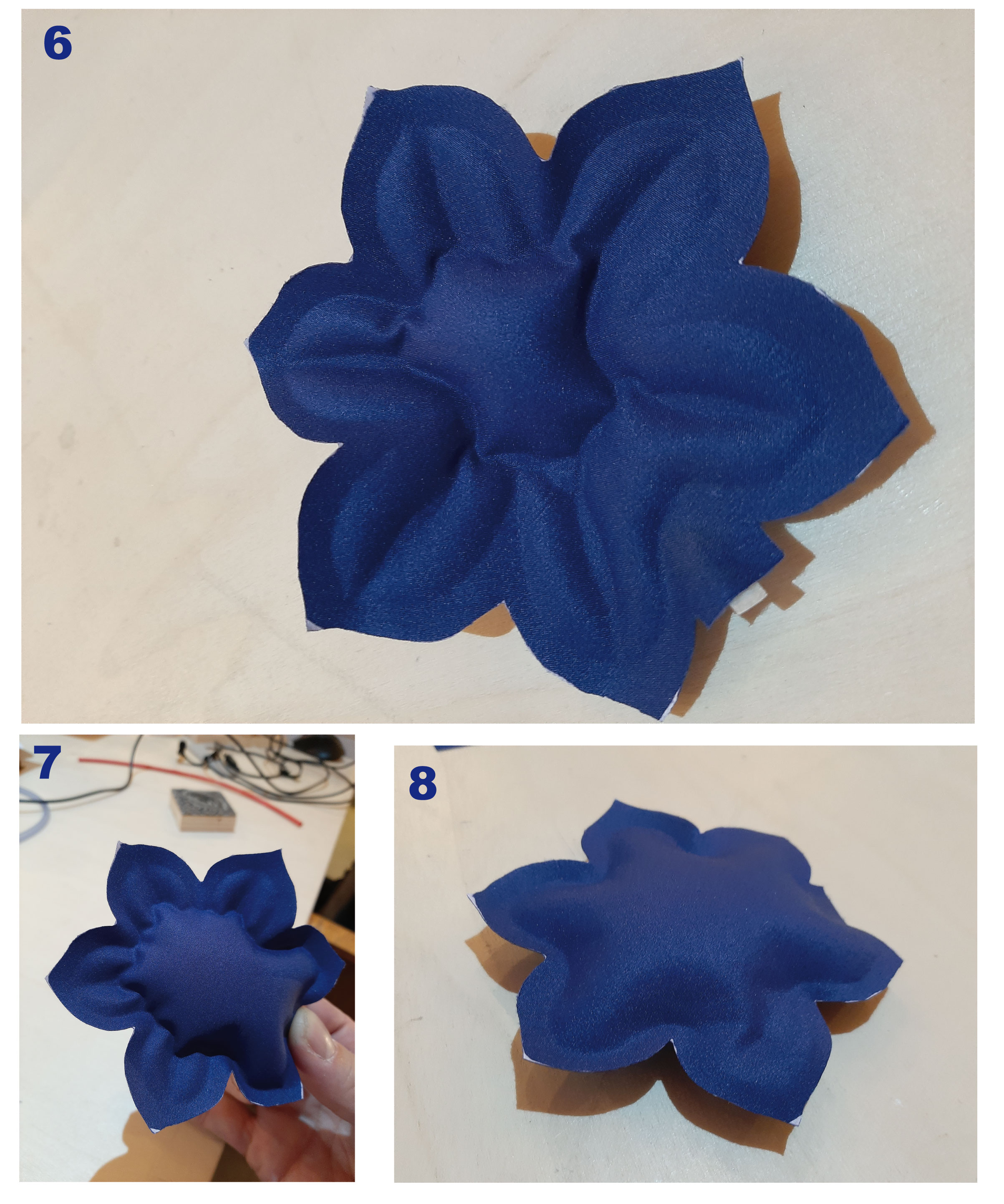

The result is almost good during the first pumping but very quickly (6), the small welded parts broke (8).

CONCLUSION:

- Either the small welded diamond parts are too small, or the heating time in the heat-press was not enough.

- Lengthen the petals and position several diamonds on the height so that the movement is facilitated.

2ND PATTERN

A second test with increasing the petals length and adding several diamonds on each.

But in the end, 2 air leaks prevented inflation, so the result was not conclusive !!

CONCLUSION:

- diamond parts didn't resist again during the pumping.

- try with thermovinyl should be more secure...

WITH THERMOVINYL FABRIC¶

A new test with the 2nd pattern

CONCLUSION:

- The Thermovinyl attaches well to small parts

- The movement of the petals is more pronounced but the welded parts are perhaps still too wide

3RD PATTERN

I tried one last test with the rest of thermovinyl. I wanted to go back to my first idea with the welded parts offset from the petals.

B_SILICON INFLATABLES¶

Unfortunately, we did not have time to go to the end of the experiment FIRST STEP: After 3D printing the mold, we poured the silicone. (100gr of silicone + 10gr of catalyst)

![]()

SECOND STEP: this morning, we sealed the 2 parts of the cross.

![]()

THIRD STEP: The pumping....