8. Open Source Hardware - From Fibers to Fabric ¶

Week 08.

We teamed with Maite and it was great :)

We teamed with Maite and it was great :)

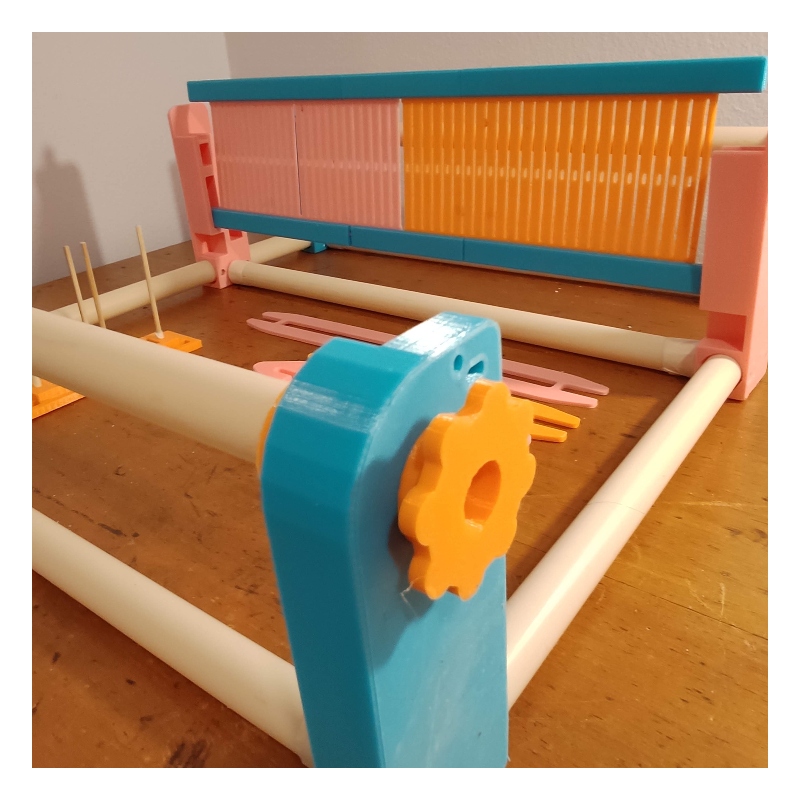

The Loom¶

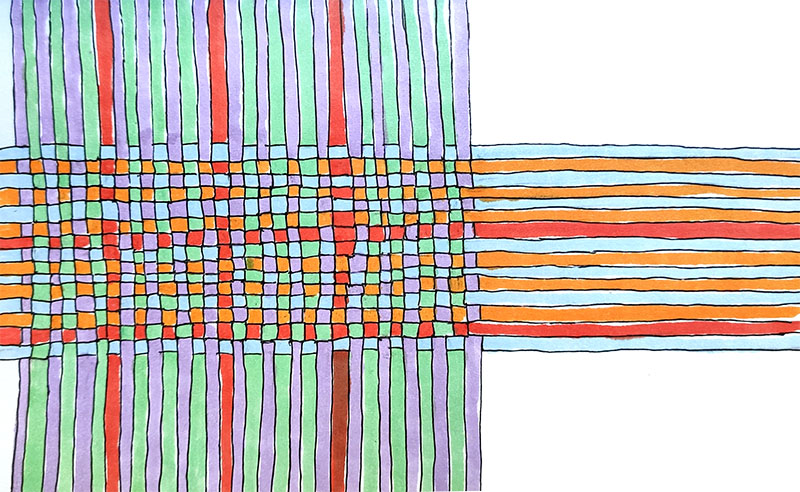

This week, the assignment was about Open Source Hardware: we had to build a machine related to textile world. We instantly decided to go for a Loom as we belive it is a hardware that captures the escence of textiles. Also weaving cloth is something that is harder to do by hand (not the case of knitting, for example)so we thought it would be a good idea to have a new loom in the world.

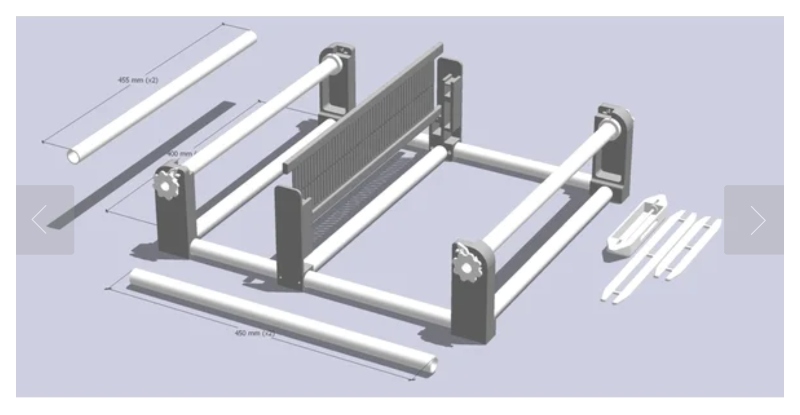

We went through the different Open Source online platforms and reseached for a good loom to make, as starting one from scratch was not our option and we decided that a good challenge was this

Loom on Thingiverse. Is free and ready to download and customize.

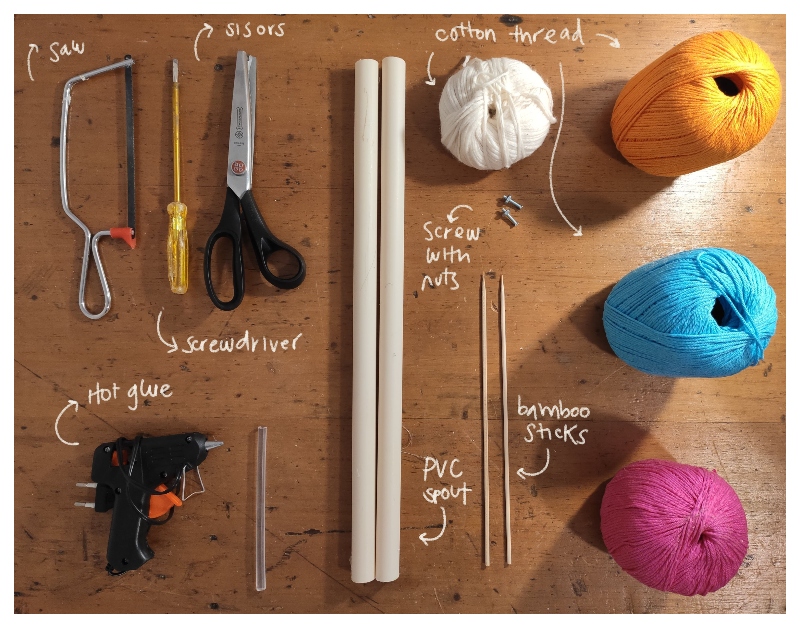

"Ingredients"¶

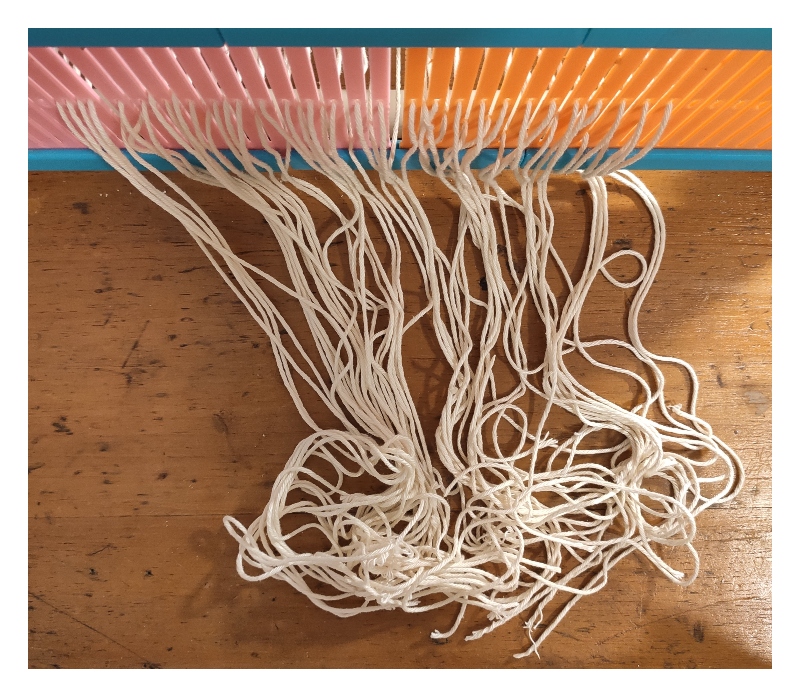

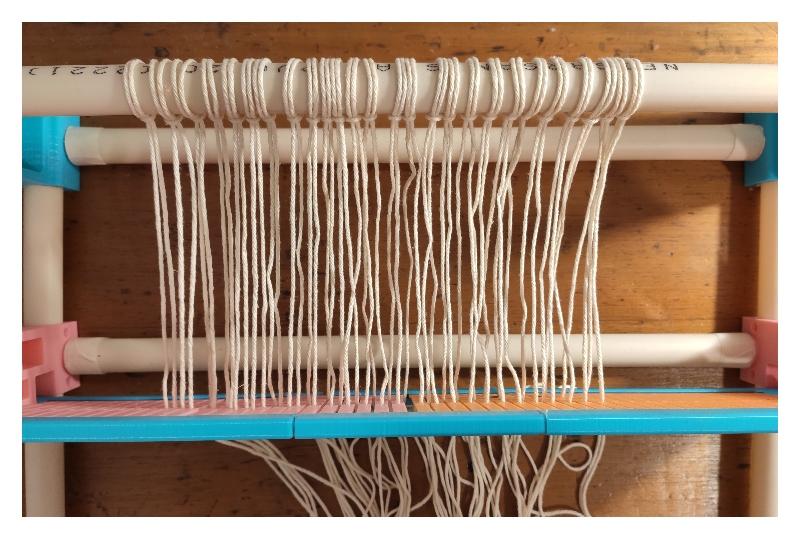

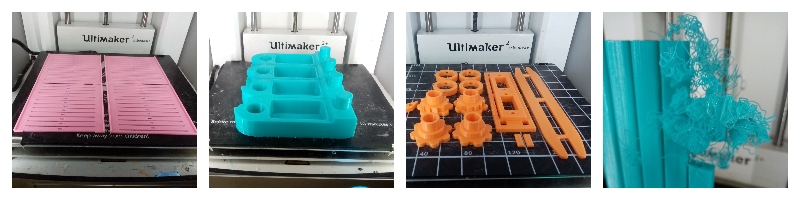

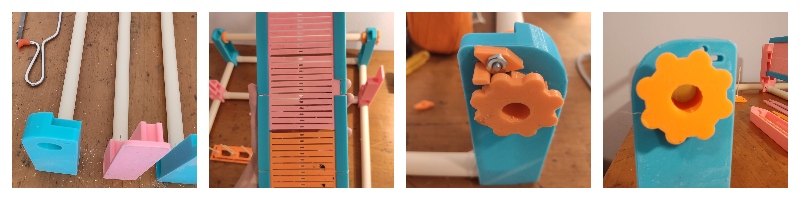

This rigid heddle loom is mostly 3D printed, with some extra pieces. The instructions for assembling were not very specific and clear, though! Some of the pieces, were useless. That is why below I indicate whether is optional or not.

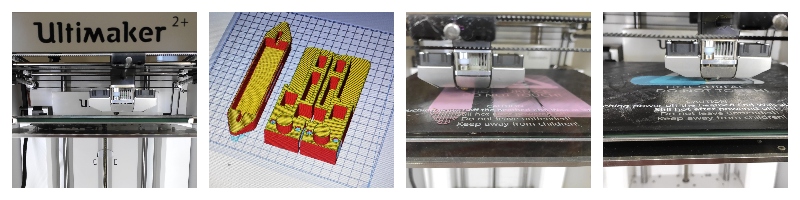

3D Printed parts

-Heddle half frames(x2)(necessary)

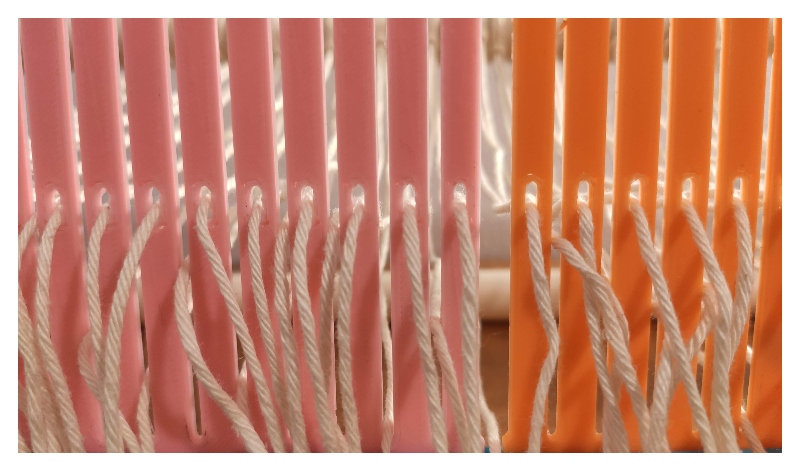

-Heddle (x2)(necessary)

-Heddle frame (x4) + (x2small) (necessary)

-Warp cogs (x2)(necessary)

-Warp knobs (x2)(necessary)

-Warp pawls (x2)(necessary)

-Warp pegs (x2)(necessary)

-Shuttle 280mm (necessary)

-Warp beam washers (x4)(Optional)

-Shuttle boat bobin (Optional)

-Shuttle boat (Optional)

-Shuttle 190mm (Optional)

-String heddle (Optional)

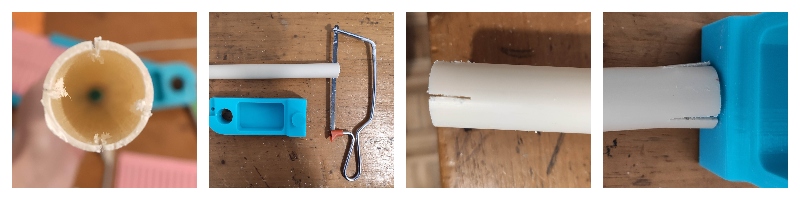

Extra components

-Screw with nuts (x2)(2mmx12mm)

-Bamboo sticks (3)

Printing¶

DOCUMENTATION_WORK IN PROGRESS

Assembling¶

If you do not find a 22mm PVC pipe (like us) you can use a smaller size, but you will need to adapt it to match the original structure (by cutting Use the three backticks to separate code.

Knitting¶