3. Circular fashion¶

Inspiration¶

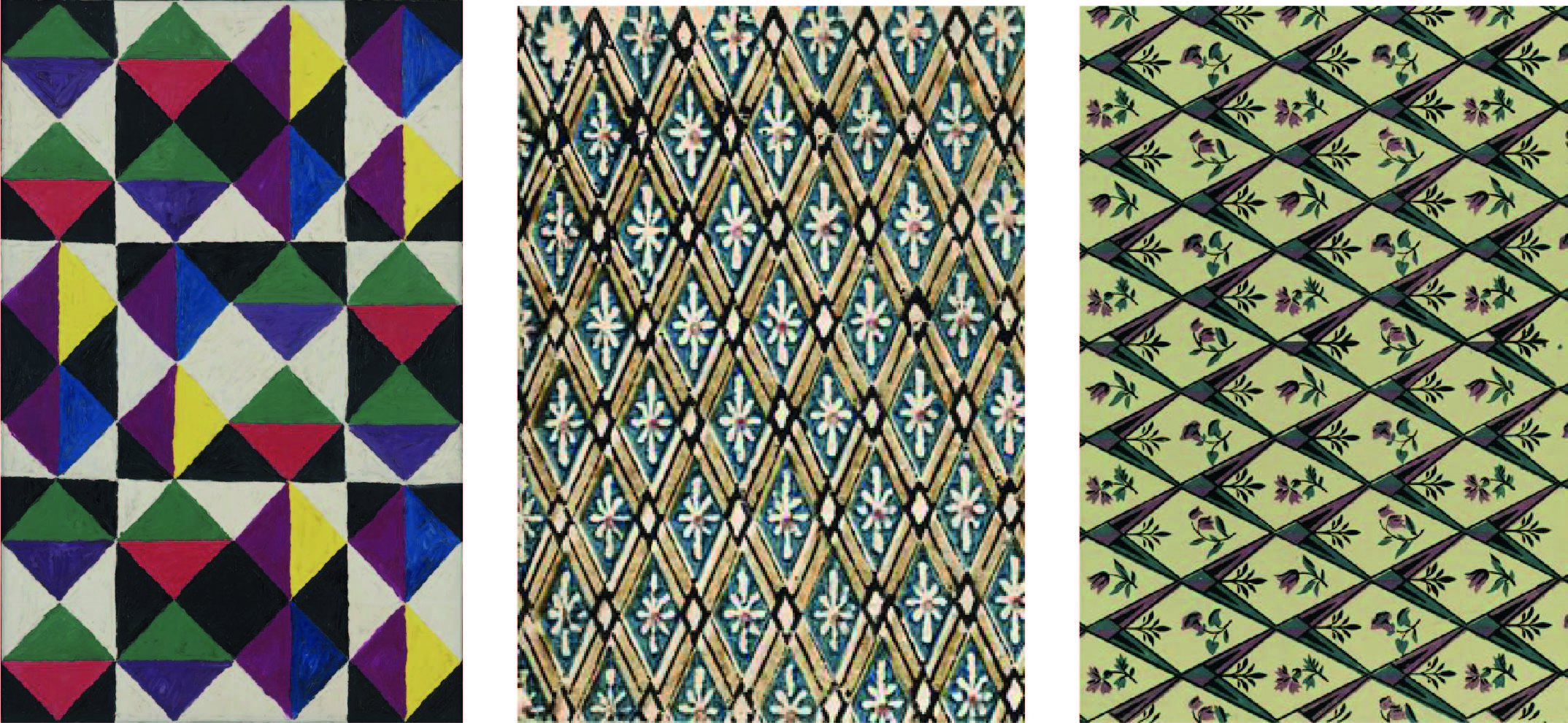

I was inspired by geometrical shapes and patterns.

1/ Alfred Jensen, Clokwork in the Sky 2/ Manufacture Chapillon, wallpaper 3/ Unknown, wallpaper

There are patterns from the italian brand Missoni that I discovered thanks to Surzhana Radnaeva. They are famous for stripes and geometric figures and their patterns are recognizabled among all.

First tests¶

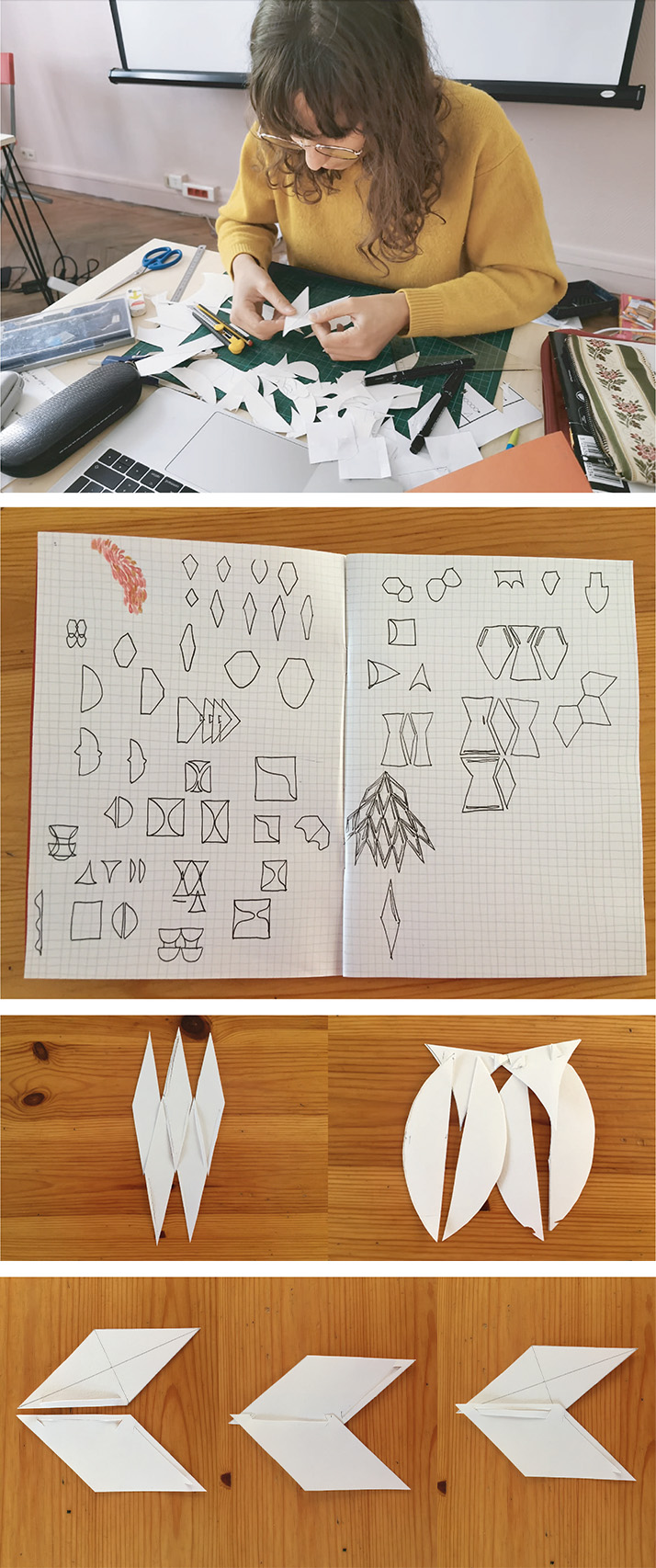

I tried different patterns but each of them let too many textile wastes. I tried to create a pattern that doesn’t leave no waste which is why I started to draw patterns in a boundary box in my notebook.

After some paper tests, I realized that the different modules didn’t hook on very well, so I wasn’t able to create a resisting surface. My two objectives came out this way :

- As less waste as possible

- resisting surface

So I decided to stay with the diamond shape because I didn’t have time to think of an other shape. When I’ll have more time I may think of something else !

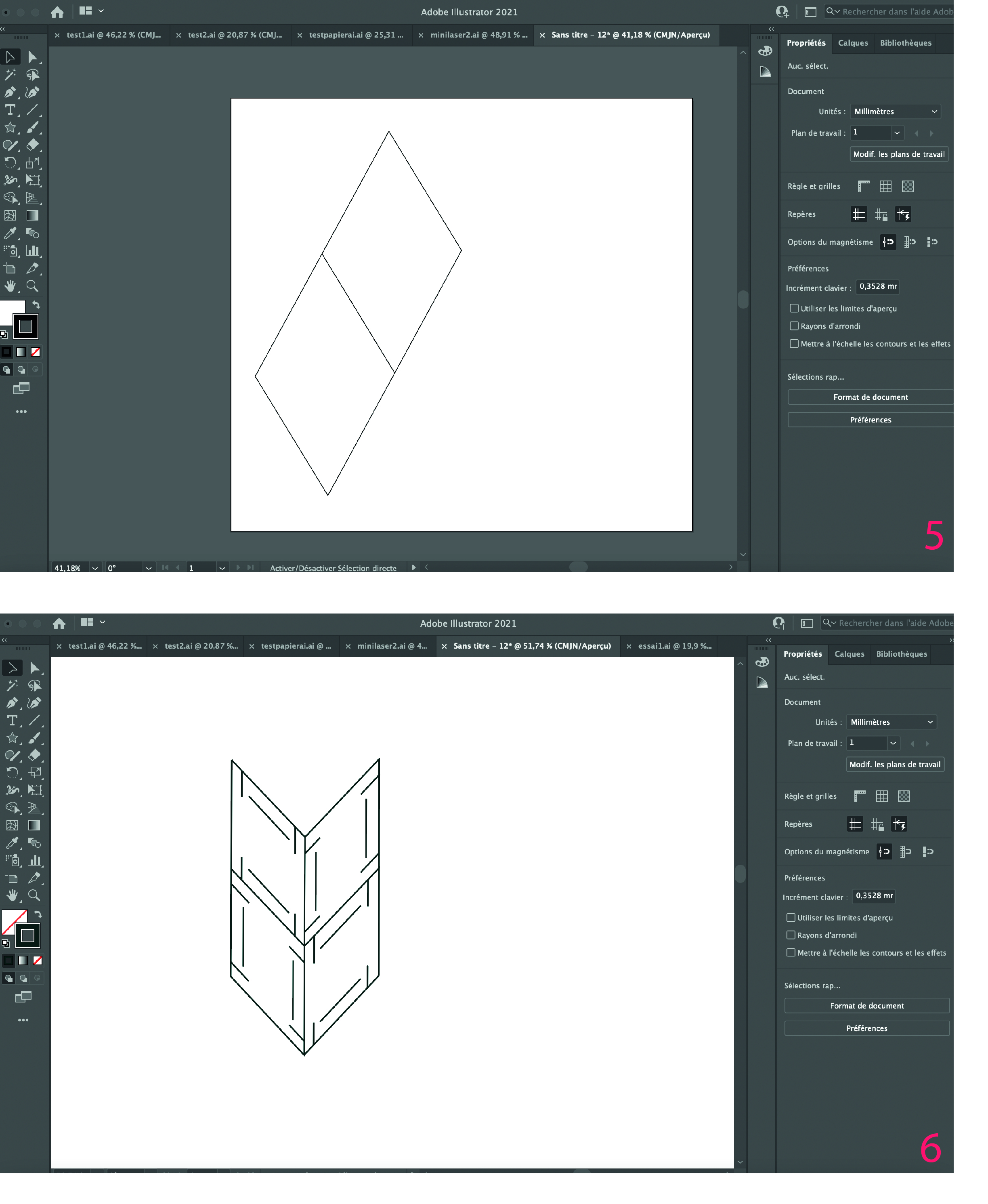

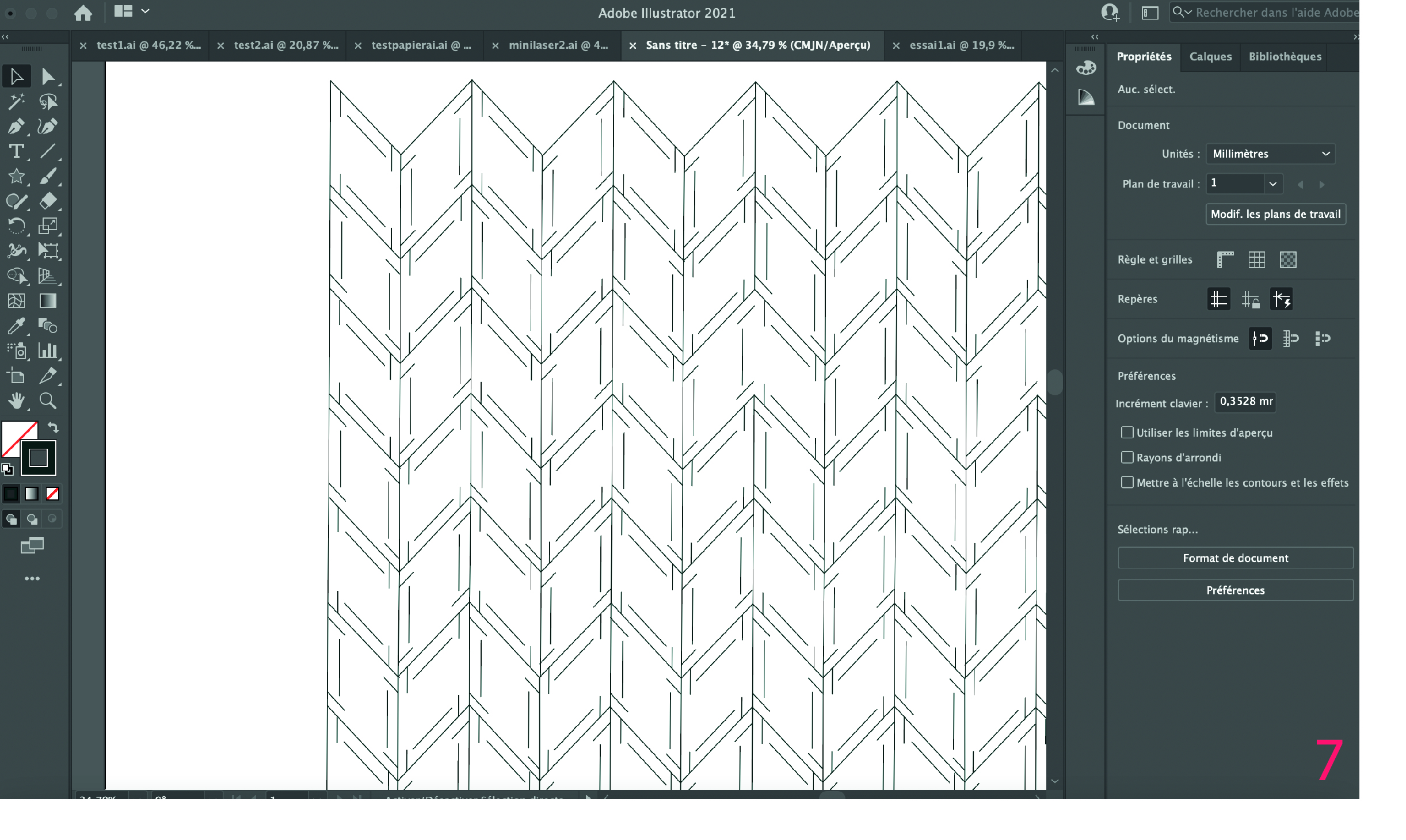

I made paper tests to try the notches together. Once I found a pattern that works I tested it with textile. First, I drew it on Illustrator.

Drawing with Illustrator¶

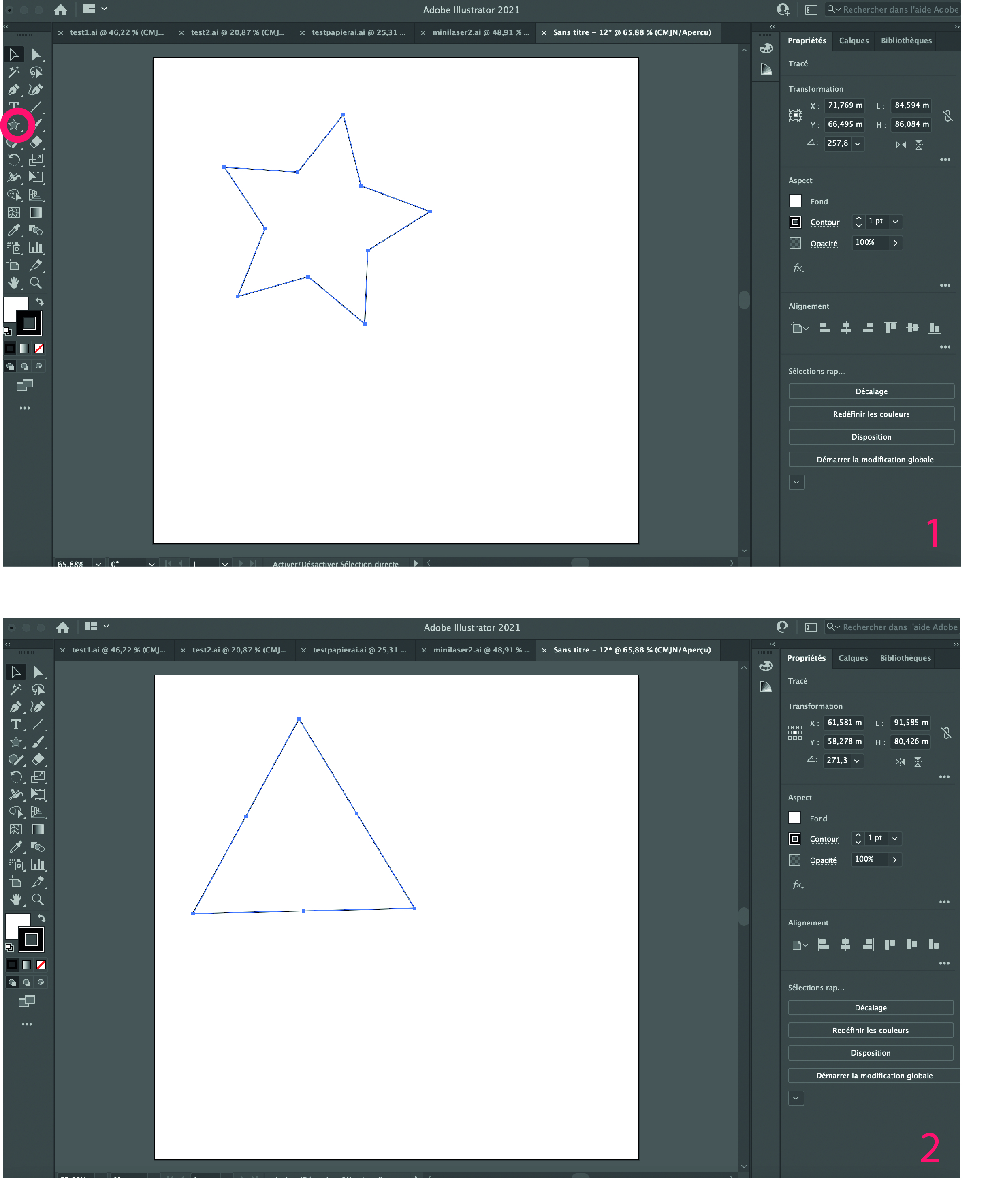

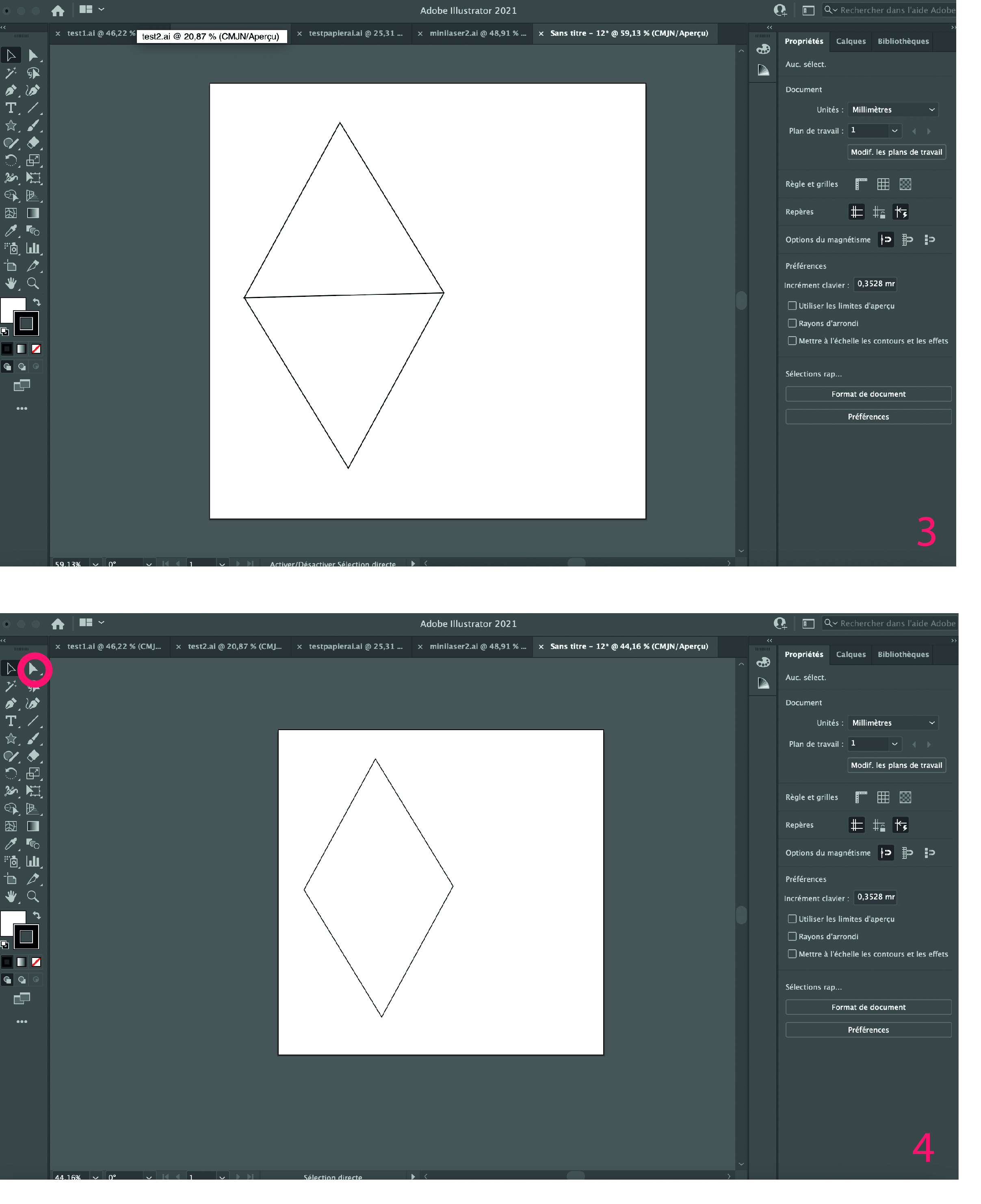

I drew the final pattern on illustrator.

1. To make a triangle, make a star end press together the keyboard keys "option and down arrow".

1. To make a triangle, make a star end press together the keyboard keys "option and down arrow".

4. Click on the white arrow and erase the line in between.

4. Click on the white arrow and erase the line in between.

6. Copy/past the triangle. Draw lines to make notches.

6. Copy/past the triangle. Draw lines to make notches.

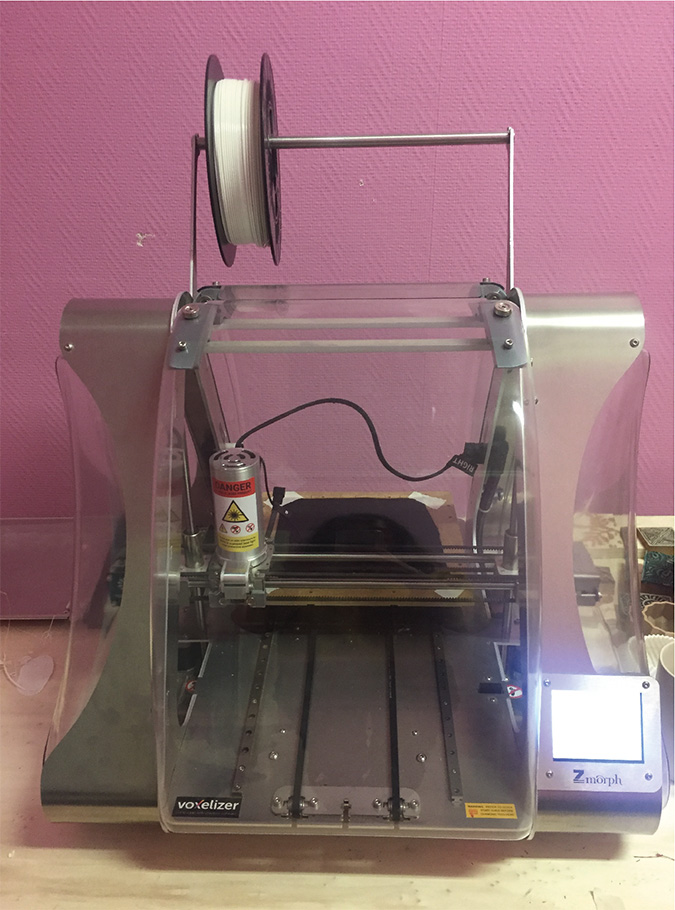

7. Copy/past the pattern.

7. Copy/past the pattern.

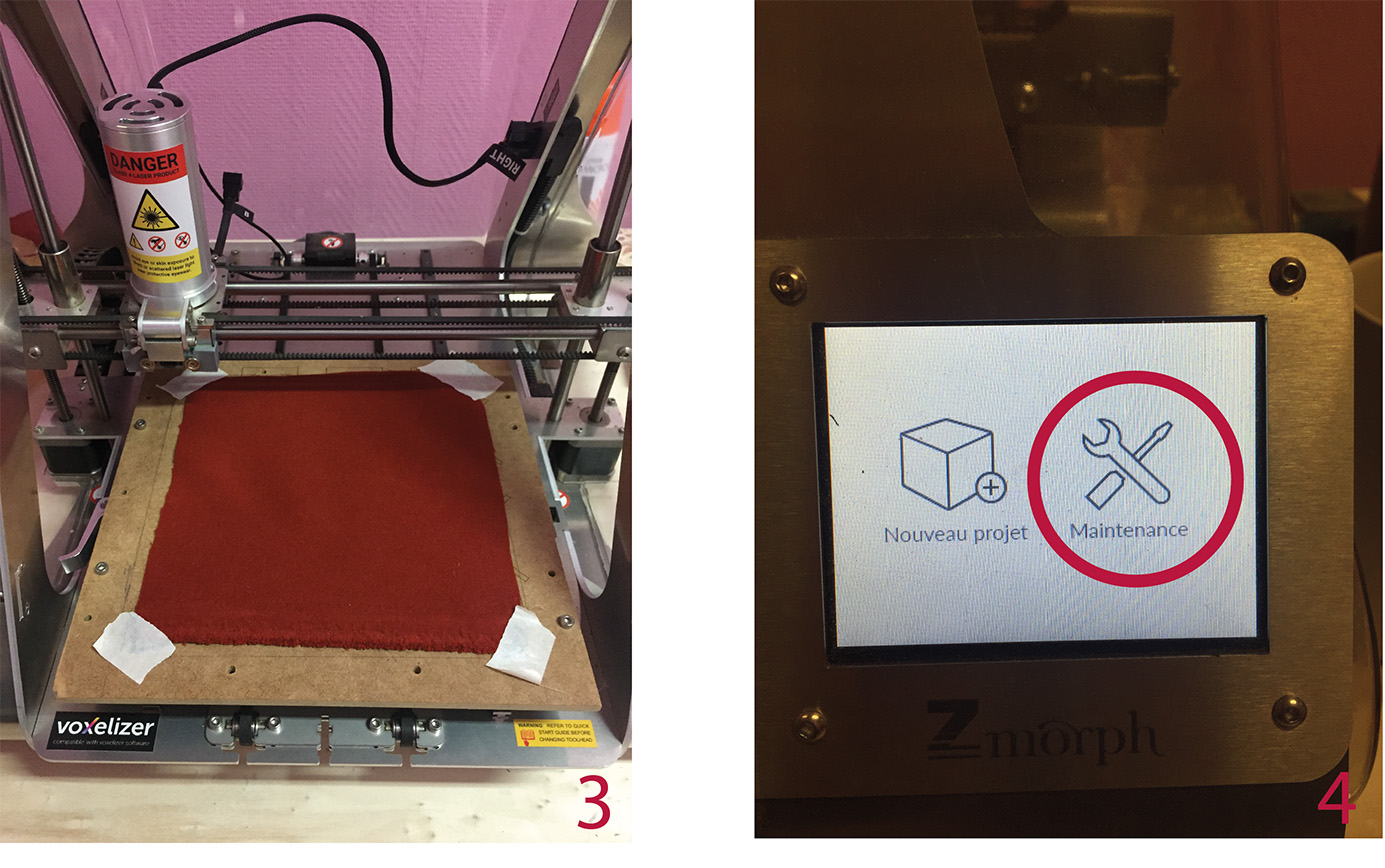

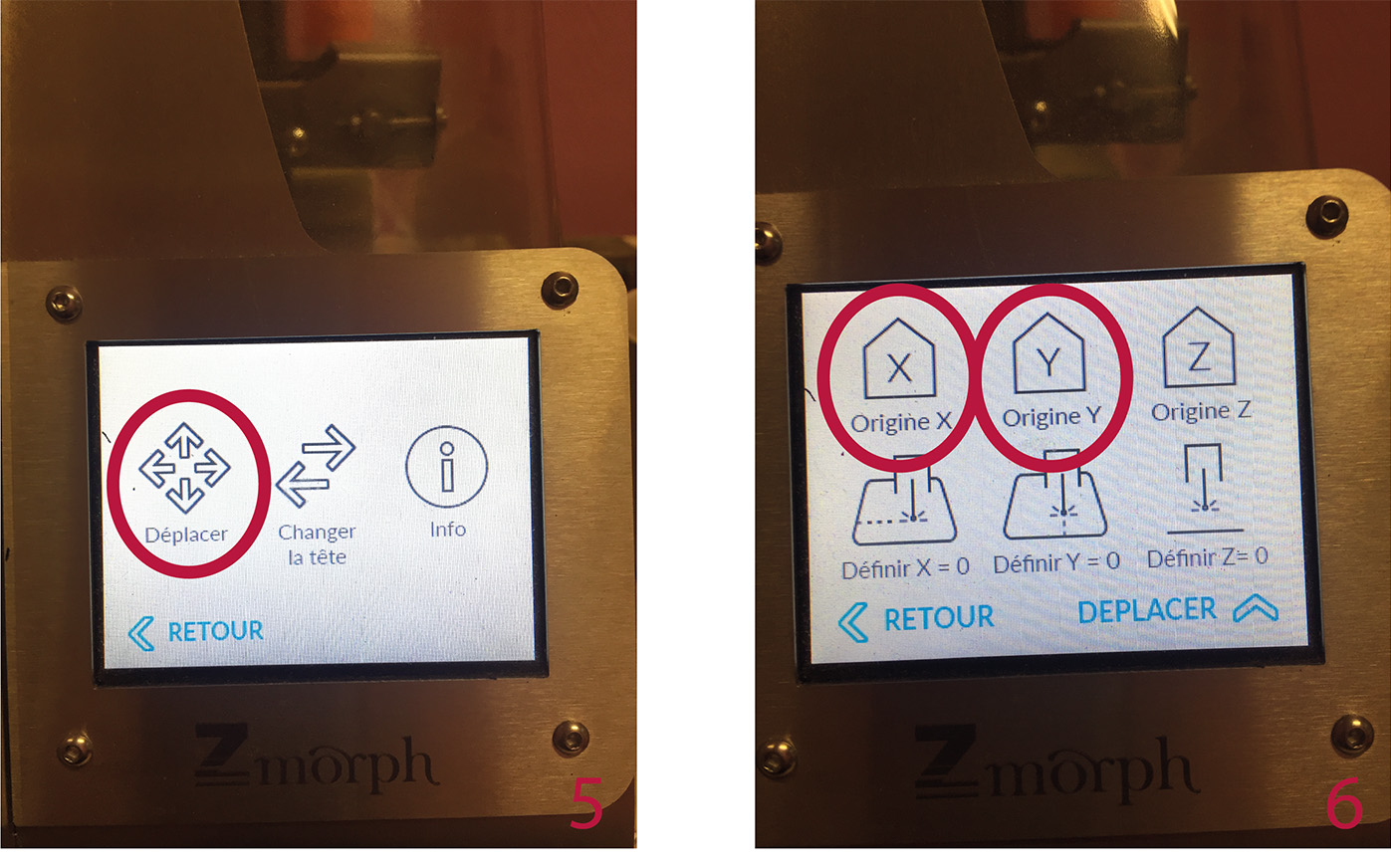

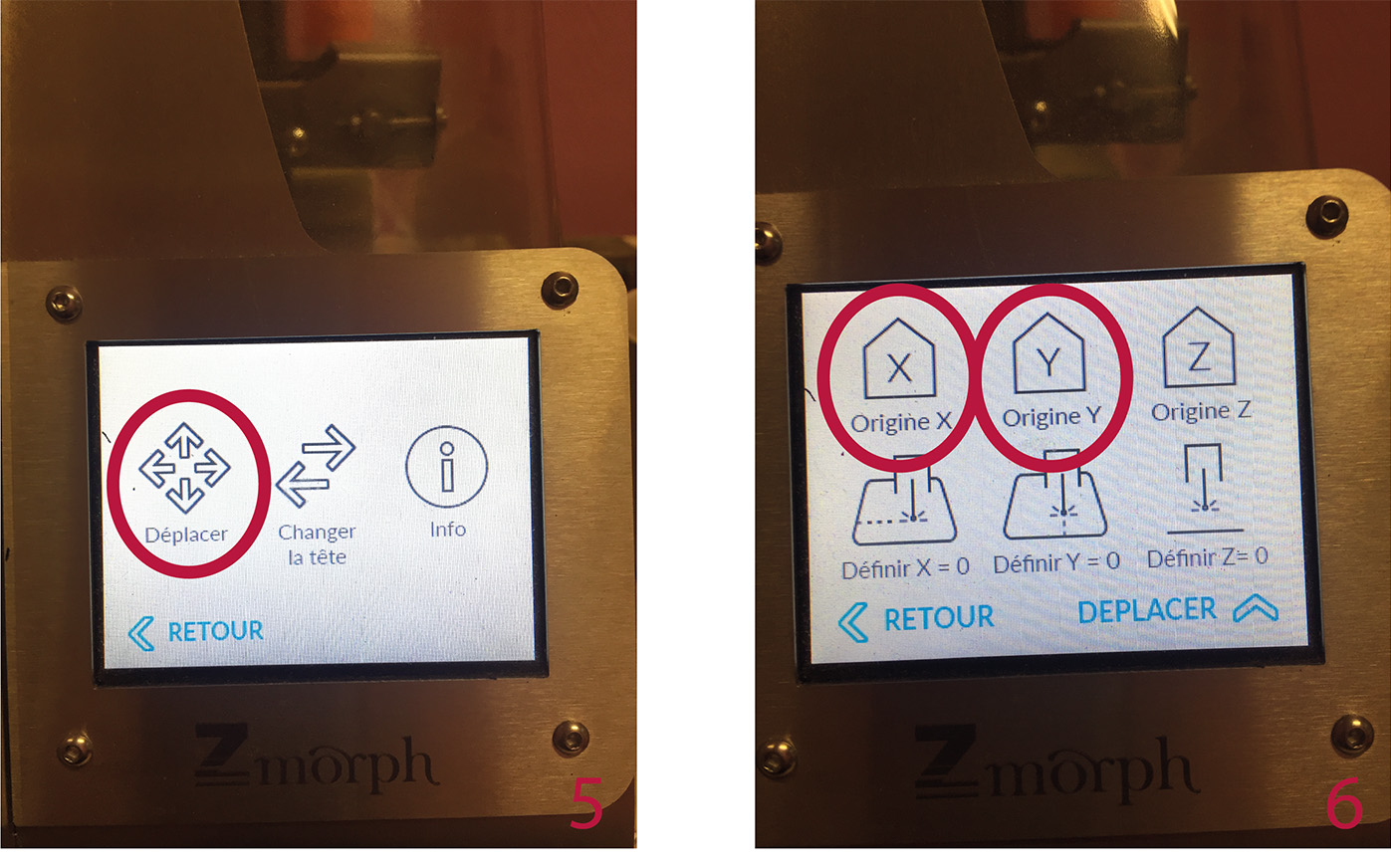

Textile tests with laser cut¶

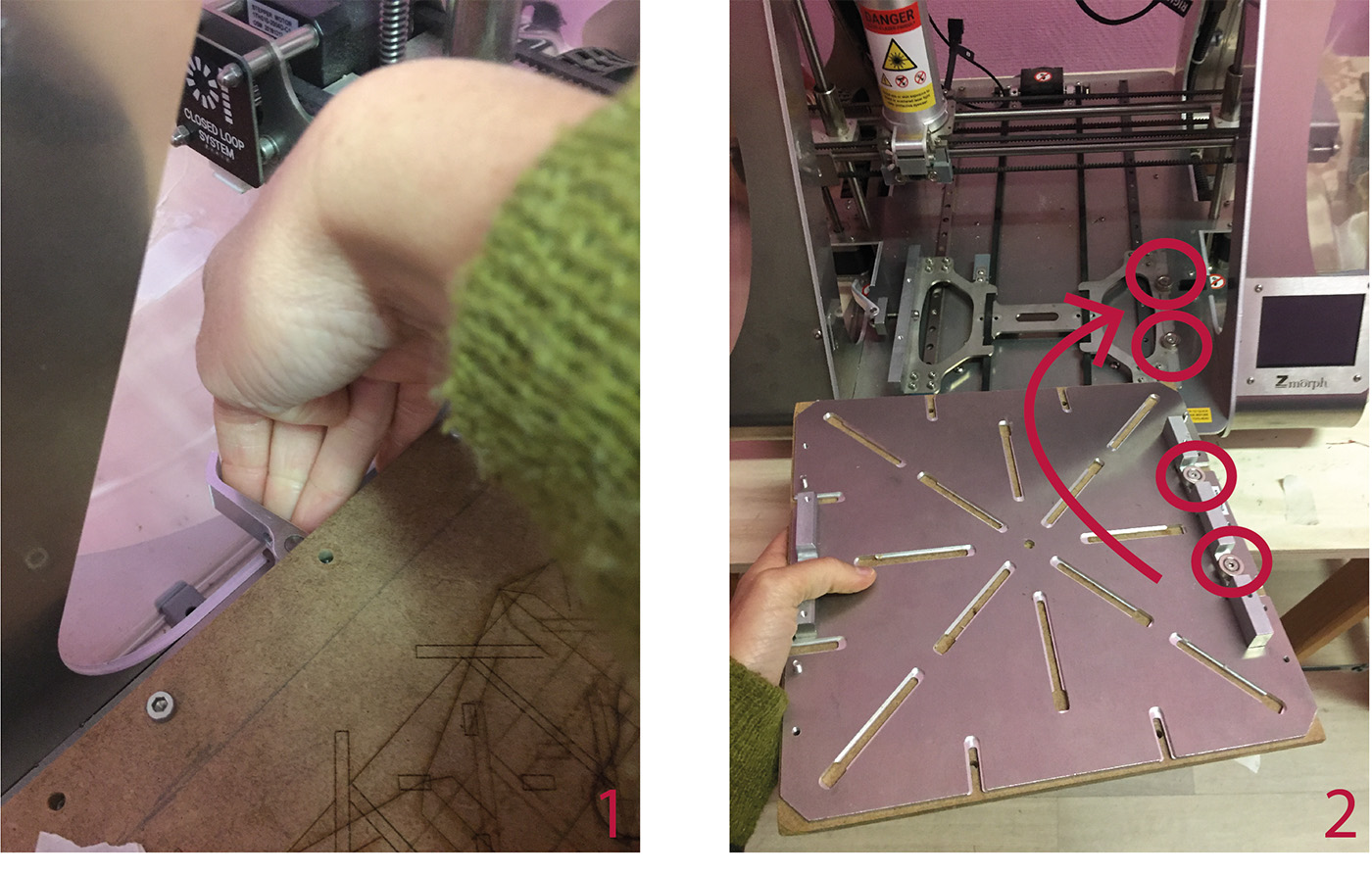

This machine is a Z-morph, it can both 3D print and laser cut. I used it as a laser cut. About the settings, I could only change the speed. The software used for the machine is called Voxelizer. I took pictures that explain the steps for using the machine. Be careful to always wear special glasses ! They protect from laser.

- Open and close

- Magnets help to fix it properly

- Put tape on textile to keep it from moving

- Set up the machine

- Move the head

- Click here to put the head at the origin

- For the "z" origin, set it manually, millimeter by millimeter

- Start a project

9. Choose a file, a start

9. Choose a file, a start

real time : it's quite slow

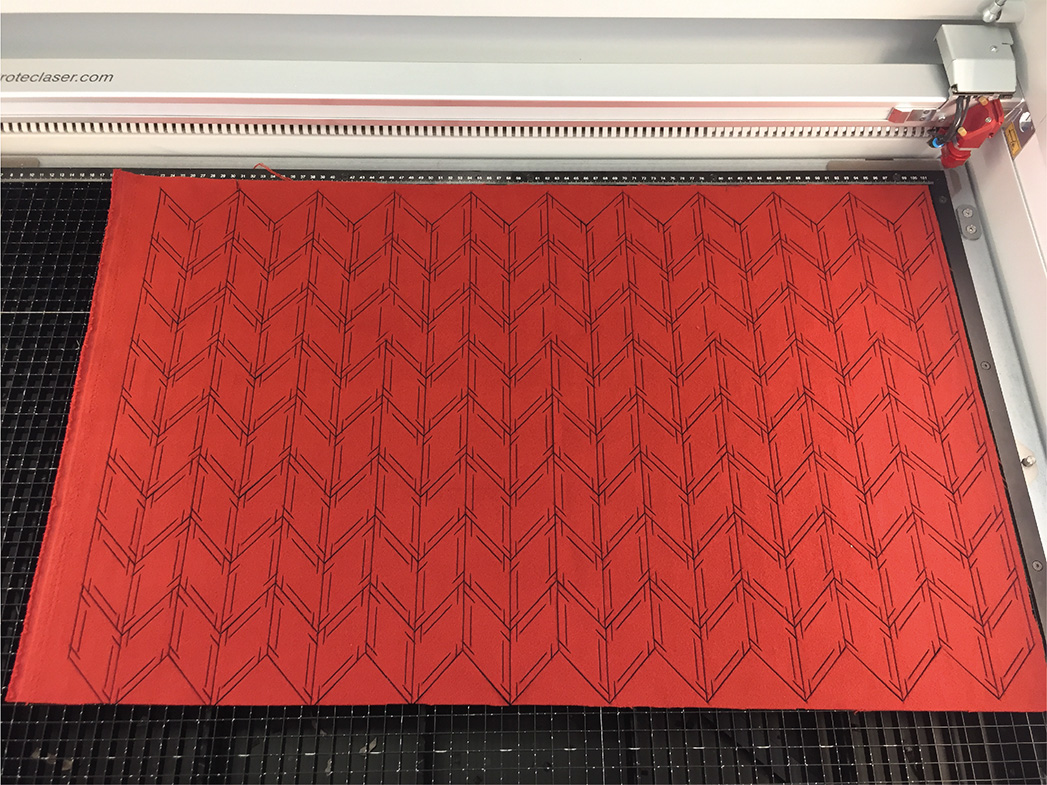

I tried with neoprene (1mm). Speed -> It wasn't the right setting because the edges are not sharply cut. The notches were to thin and the surface too fragile. So I decided to arrange the notches by making them bigger. I found that the slit should be at least at 5mm from the edge of the module.

Then I used a woolen-aspect synthetic textile (2mm) which is the one in the tutorial pictures. Speed -> 20mm/s.

Trotec showroom¶

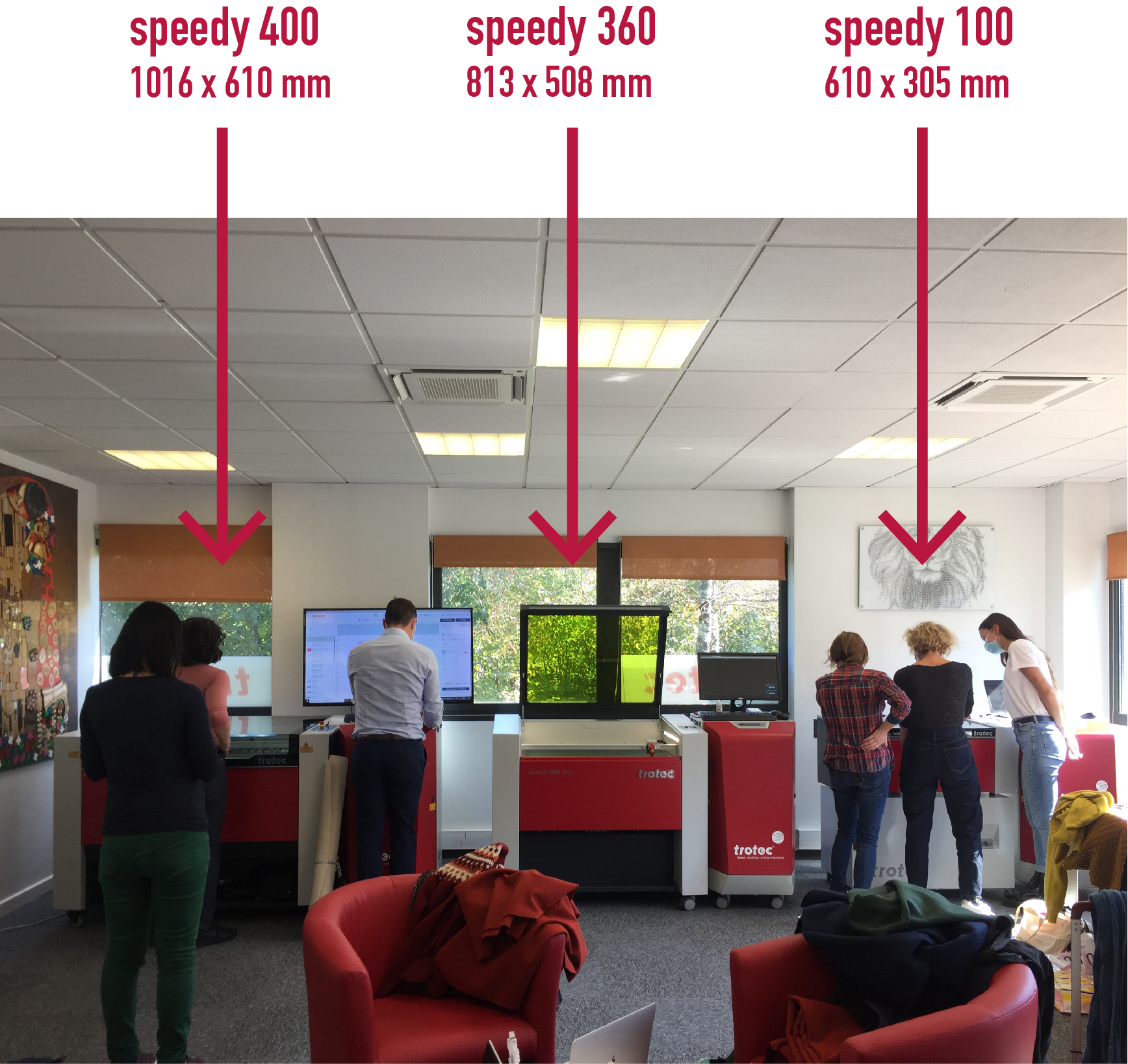

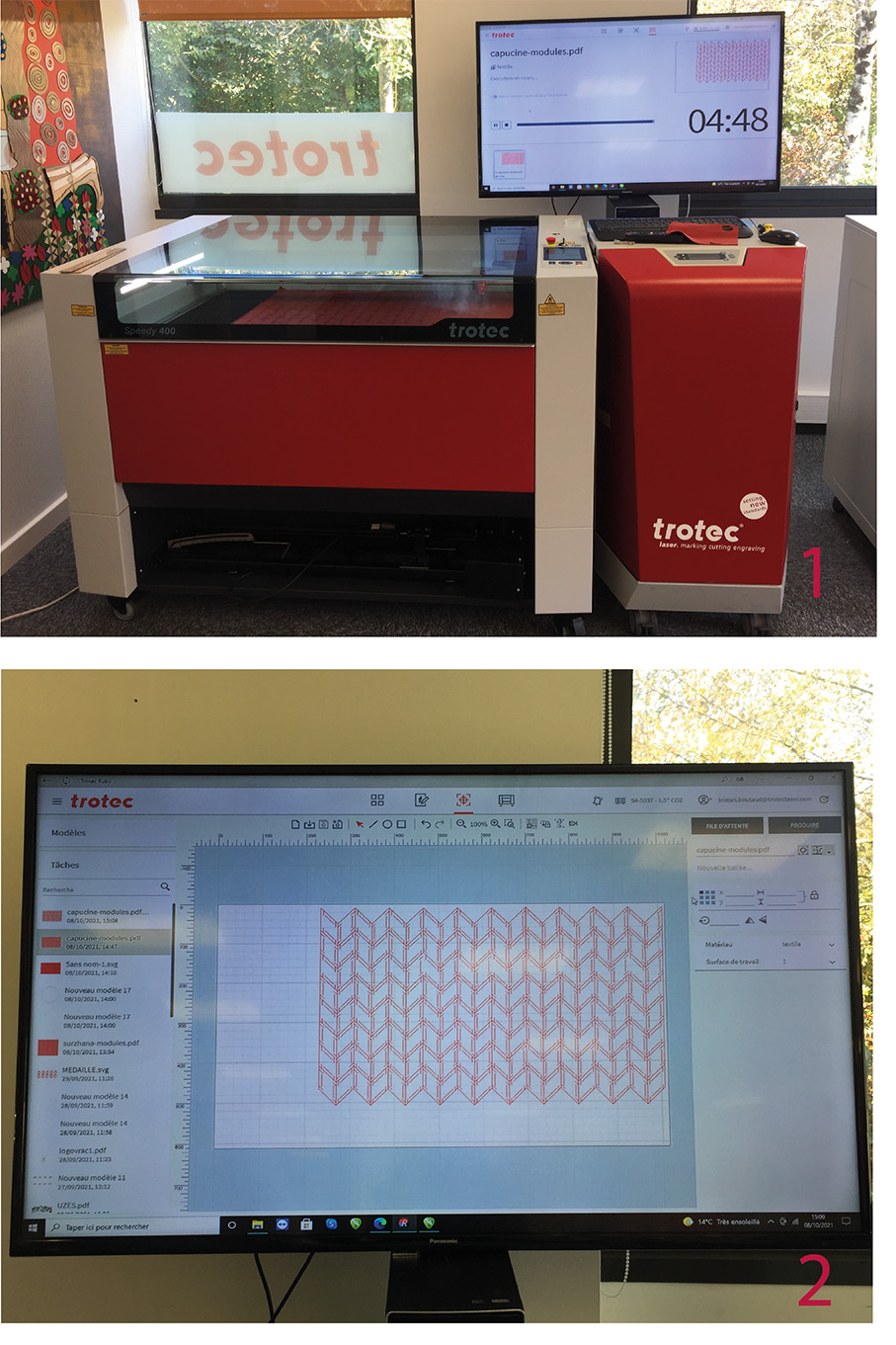

We went to Trotec showroom to have access to a bigger laser cut. There were 3 laser cut :

I used Speedy 400. The settings for my textile :

- power : 45

- speed : 5

The software was "Trotec Ruby". Unfortunately, we didn't get to do the settings by ourselves.

real time : super fast

The difference of timing between this laser cut and the one in Oullins :

- 20 x 20 cm cut in 15 minutes

- 813 x 508 cm cut in 6 minutes

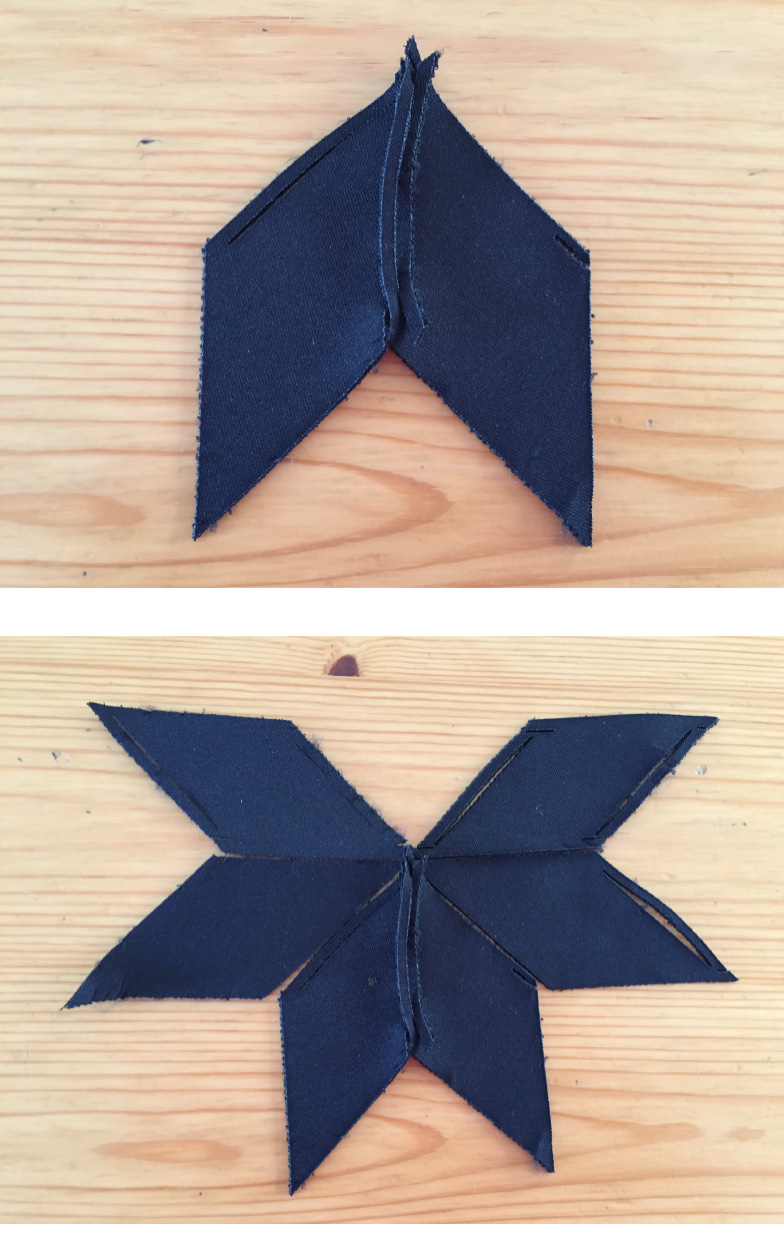

Modules¶

There are many ways of assembling it :

I made my first idea which is an "epaulette". It makes me think of a costume in Moonrise Kingdom (Wes Anderson) a movie I love. He creates geometrical spaces and plans in his movies. He inspired me a lot.

I should now try with different colors.