4. Biochromes¶

This week we dyed textiles with natural elements. Dyeing textile requires different steps that I'm going to explain and describe. We also made inks and pigments from the dye bath.

Here are some inspirations :

Maison Lenglin : a french workshop of natural dyes

Maison Lenglin : a french workshop of natural dyes

A bacteria dyes technic : Materia Bruta from Surzhana Radnaeva and Fab textile in Barcelona

A bacteria dyes technic : Materia Bruta from Surzhana Radnaeva and Fab textile in Barcelona

The dyeing process :¶

- Preparing the fibers and mordanting

- Preparing the dye bath

- Dyeing textiles

- Iron experimenting : changing the colours

- Samples

We worked the 9 of us together as a team.

1. Preparing the fibers and mordanting¶

Mordanting consists of the addition of chemical substances, in our case alum, in order to create a chemical bridge between textile fibers and natural dyes. It prepares the textile to receive the dye.

It's very important to mordant and dye in stainless steel containers, because iron would modify the colour.

We chose textiles made of natural fibers such as wool, silk, cotton and linen.

We chose to make 3 different mordanting recipes.

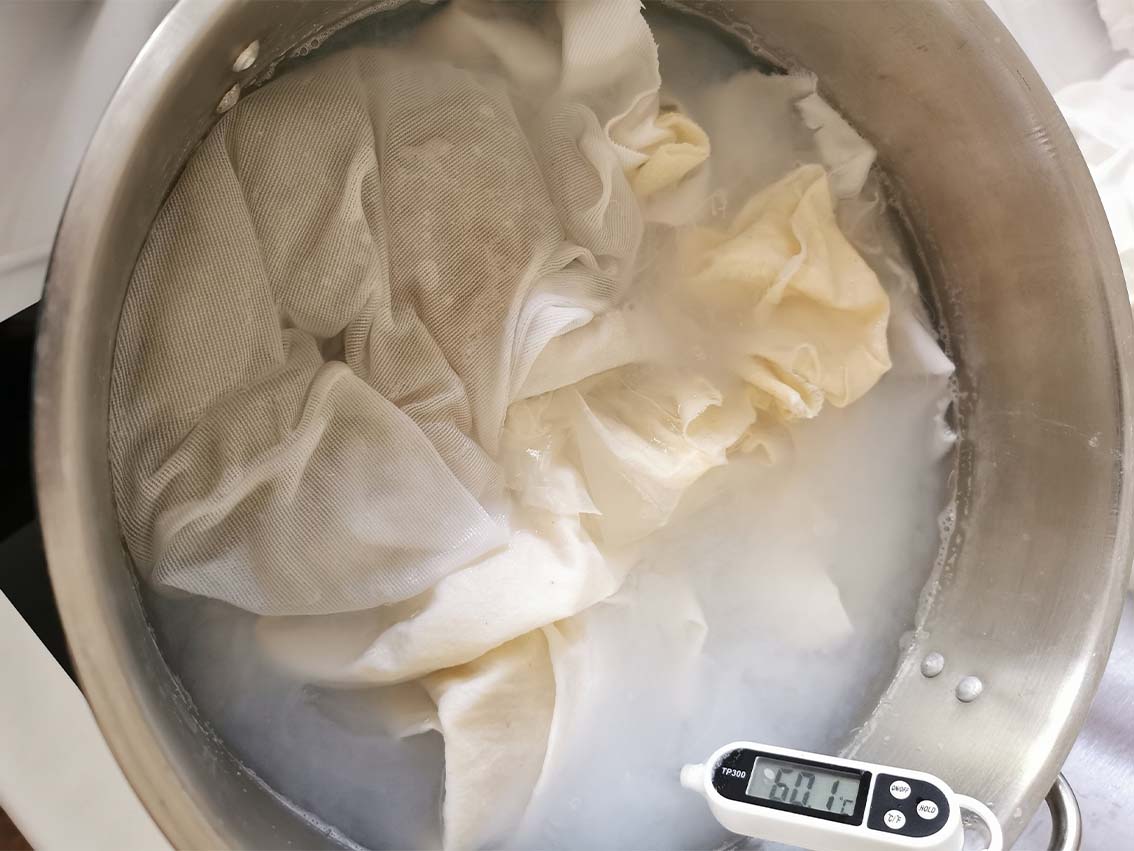

Mordanting 1 (M1) - 20% to 30% of the weight of fibers in alum - half of the alum weight in sodium carbonate - vinegar : 1L for 100g of alum - water (vinegar included): 3L for 100g of fibers

- heat the water -> do not boil it

- add alum -> it dissolves

- add sodium carbonate -> it becomes white

- add vinegar -> it becomes transparent again

- right temperature should be between 40 and 60°C

- put fibers for 45 minutes

- rinse fibers (don't need to dry them)

Mordanting 2 (M2) - 20% of the weight of fibers in alum - water : 3L for 100g of fibers

It's the same recipe as the 1st one without carbonate sodium and vinegar.

Mordanting 3 (M3) - 20% of weight of fibers in alum - half of the alum weight in lime - vinegar : 0,5L for 100g of alum - water (vinegar included): 3L for 100g of fibers

It's the same recipe as the 1st one without carbonate sodium and lime instead.

Our mordanting baths :

Mordanting bath 1 (for carrot tops and onion) :

- 452g of fibers

- 90,4g of alum

- 45,2g of sodium carbonate

- 1L of vinegar

- 8L of water

Mordenting bath 2 (for madder and annatto) : - 550g of fibers - 110g of alum - 9L of water

Mordenting bath 3 (for nettle and avocado) : - 507g of fibers - 100g of alum - 0,5L of vinegar - 9L of water

2. Preparing the dye bath¶

We decided to make 6 dye baths : carrot's leaf, annetto, avocado, madder, nettle, onion.

Natural elements should be proportioned like this :

- Dry elements : 100% of weight of fibers

- Wet elements : More than 100% of weight of fibers

- Dying extract : 10% of weight of fibers

In our case :

- Leaf carrot : 75g wet and 125g dry

- Onion : 44g dry (because colour is very intense)

- Madder : 28,3 g (extract)

- Anato : 100gr dry (total weight of what we have)

- Nettle : 350 g

- Avocado : 210g dry

Note : onions stain a lot, don't need to put 100% of weight of fibers.

Except the madder, the different dyeing elements were immersed in hot water (not boiled) in stainless steel containers to make the decoction. 1 hour minimum of decoction is needed (the more time the better). We let them in hot water for about 6 hours. We made the madder bath just before we dyed textiles, because it's an extract.

Note : do not boiled the decoction.

3. Dyeing¶

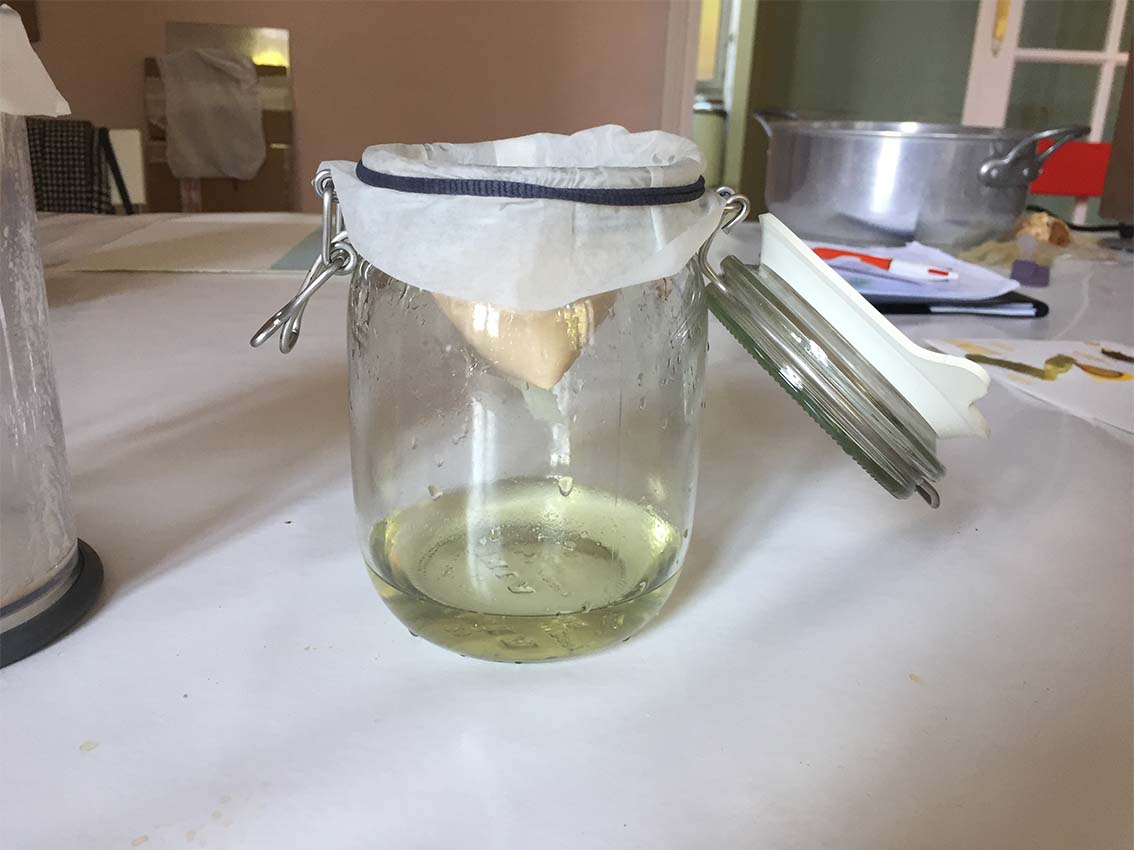

When the dye baths were ready, we took away the natural elements and let them dry. This is the process :

- filter the decoction (it’s possible to add water to the decoction so that the textile are soaked enough)

- raise the temperature of the dye to around 45 °

- once at 45 °, put the fabrics into the bath

- then continue raising the temperature slowly/gradually to around 60/70 °

- once the bath temperature is around 60/70°C, count a minimum of 45min before taking off the textiles of the bath

This is our experiment :

- Leaf carrot : 4h

- Onion : 2h30

- Madder : 4h

- Annatto : 3h20

- Nettle : 3h30

- Avocado : 2h40

| Time in the dyeing bath | |||||

|---|---|---|---|---|---|

| Ingredient | IN | 70° | Minimum Time (45min) | OUT | TOTAL time in the bath after 70° |

| Leaf carrot | 11:50 | 12:35 | 13:20 | 14:10 | 1H35 |

| Onion | 11:15 | 12:00 | 12:45 | 13:40 | 1H40 |

| Madder | 12:51 (decoction at 11:30) | 13:35 | 14:20 | 15:20 | 1H45 |

| Annatto | 11:00 | 11:45 | 12:30 | 14:20 | 2H35 |

| Nettle | 11:55 | 12:40 | 13:25 | 15:25 | 2H45 |

| Avocado | 11:30 | 12:15 | 13:00 | 13:40 | 1H35 |

Notes : - when filtering the bath, keep the ingredients for future experimentations with inks/pigments - place the different ingredients on cardboard and let them dry. - Stir the textiles regularly in the bath. - Textiles should not be too tight in the bath, and be easily submerged so that the dye can act evenly on the fibers, in order to have a more uniform shade and result.

When we took away fabrics from the dyeing baths, we washed them. Wool and silk are delicate fabrics so they need to be washed with attention to avoid thermal shock. In general, fabrics have to be well washed with clean and clear water. Then, we hung them.

4. Iron experimenting¶

A way to modify the colours is to modify them with Iron. This will give you beautiful greys and khakis depending on which plant you used first.

Recipe for a solution with 100% Iron :

- 200g Iron (sulfate)

- 2L Vinegar

- 100g Sodium carbonate

Be careful it blows up if you add the Sodium carbonate entirely ! You need to do it step by step. To use it for modifying the fibers' colours, you need to dilute this solution and make it with a maximum concentration of 10% Iron otherwise it will damage the fibers.

For example, if you made 1L of solution 100% Iron and you want to have 10%, you need to dilute 100mL of Iron 100% in 900mL of water (at room temperature).

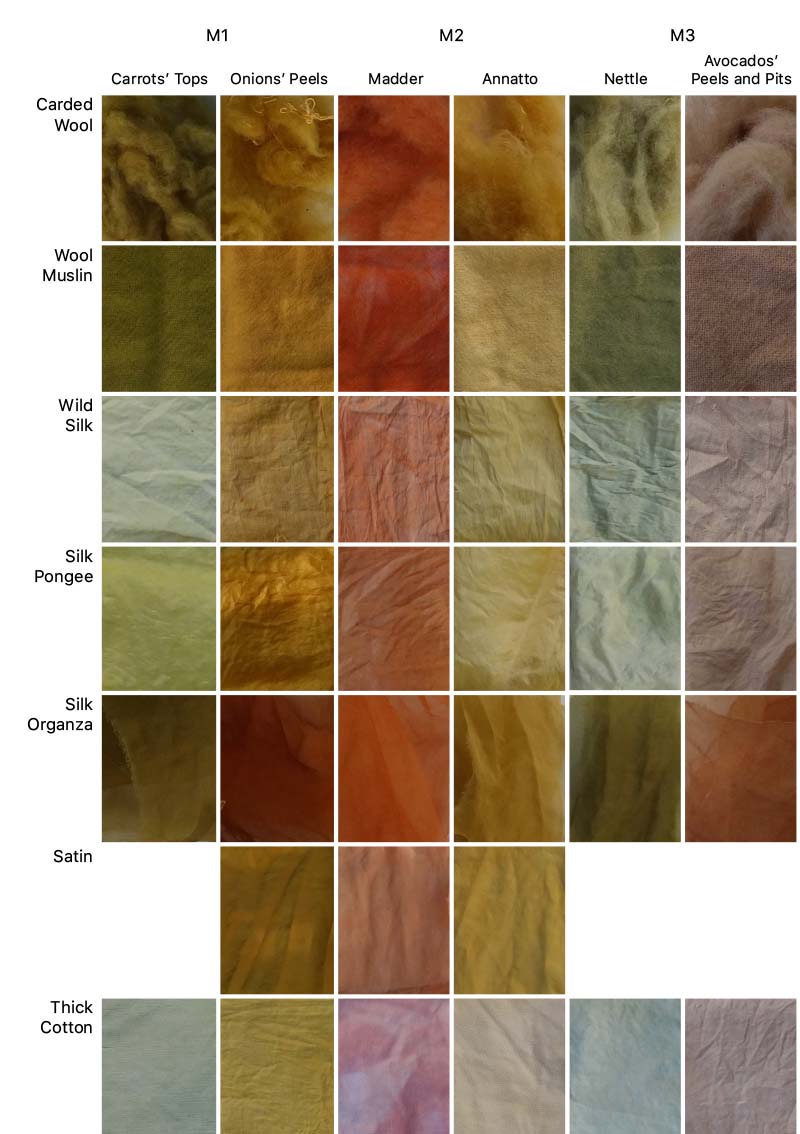

5. Samples¶

When the fabrics were dry, we took pictures of every pieces. Then we made compositions out of it. Last step was to organise and cut a piece of every fabrics with the different dyes in order to put it on a book. One per fabricacademers and one for the TextileLab.

For not making mistakes we drew our last board: - per dye - fabrics names (fr/eng) - piece of fabric

Inks and pigments¶

Pigments¶

We made pigments from the red onion dye bath. Pigments can be used for inks, biomaterials, oil paint… Pigments dissolve very well in oil but not in water.

This is the recipe :

Ingredients : 200mL of the dye bath, 20g of alum, 5g of sodium carbonate

- put 200mL of dye bath in a jar

- dissolve 20g of alum in hot water in a pot

- dissolve 5g of sodium carbonate in hot water in an other pot

- put the alum solution in the jar (with the dye bath)

- add slowly the sodium carbonate in the jar, be careful because it may go up

- let the jar oppen for 2 hours

The solution will separate into 2 phases, one liquid and one solid. After 2 hours, it must be filtered (we used a coffee filter), then dried and grinded. We didn’t have time enough to grind it because it wasn’t dry.

Inks¶

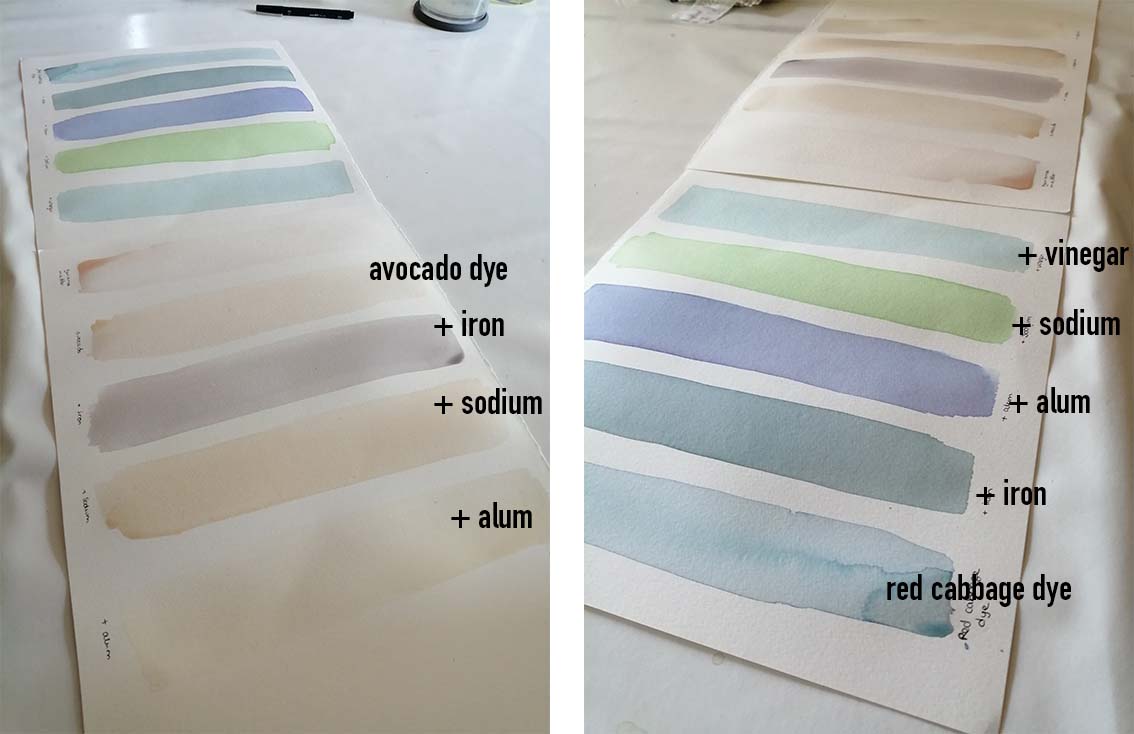

Diane showed us how to make ink from red cabbage. She immersed it and boiled it in hot water for 1h. Then, we took some of the liquid and put it on paper : it gives a purple. Then, we tried to add different elements in the ink to change the colour :

iron (from steel wool) : it becomes blue alum : it lightened the colour vinegar : it becomes pink sodium carbonate : it becomes green

There is another way to make ink with 90% ethanol that we didn’ tried. For instance it works very well with turmeric, we have an example of this ink in Oullins.

We also tried to make screen printing ink with guar gum. We mixed 200mL of madder dye bath with 20g of guar gum and we heated it up. This experiment was not successful : the mixture was too thick and viscous, moreover guar gum didn’t melt properly.