Material Research

COCOON

A Manifestation of Self Love and the journey within

Textile testing¶

Bendable Resin Textile¶

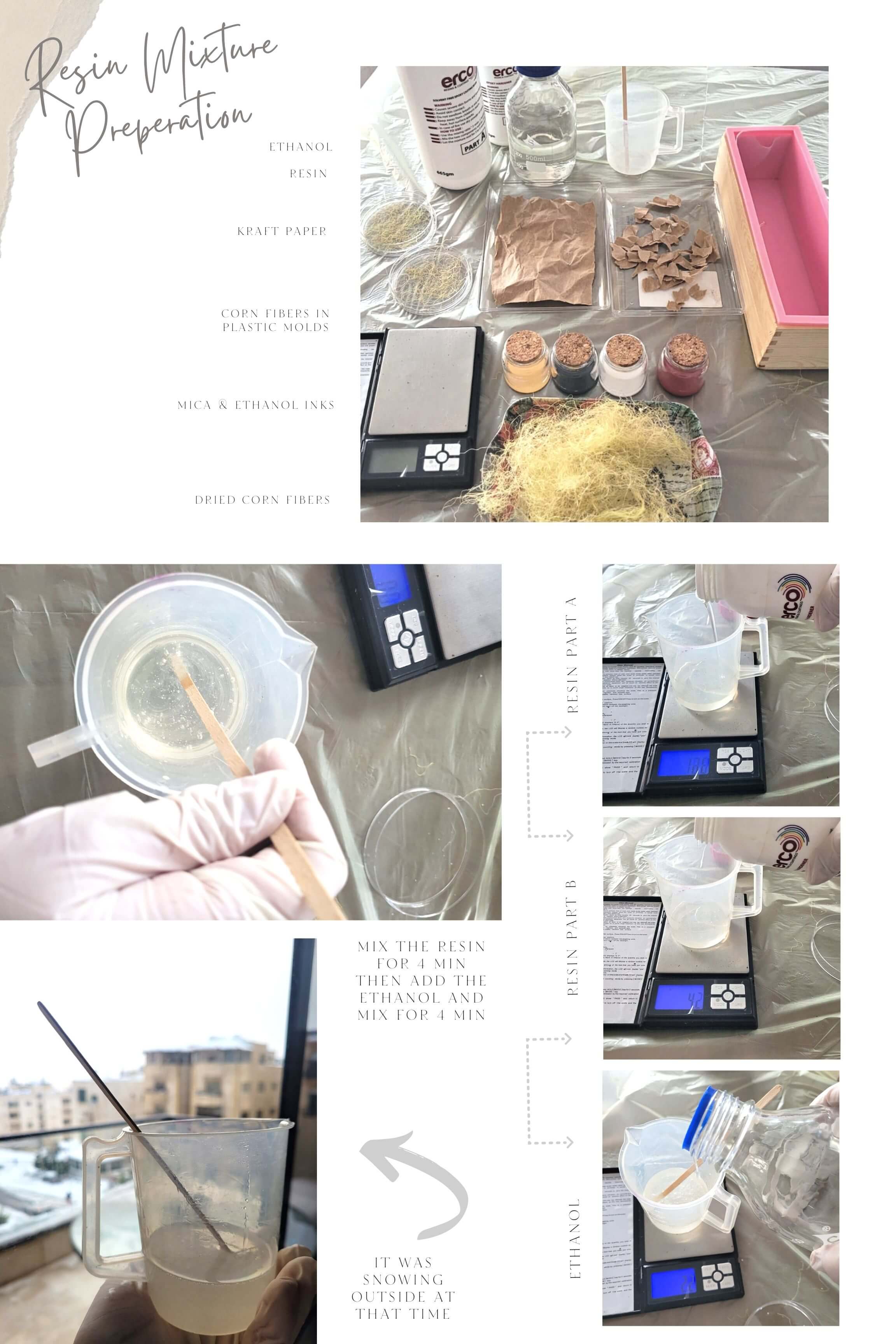

Working on experimenting a flexible resign composite by dilluting it with Ethanol and tweaking the resin parts percentage along as adding diffrent material to be used for the cocoon shell.

resin 'brand Erco' with a 2 to 1 ration of mixing

20 % of mix - Ethanol

Preparing a mix of Mica Powder and Ethanol

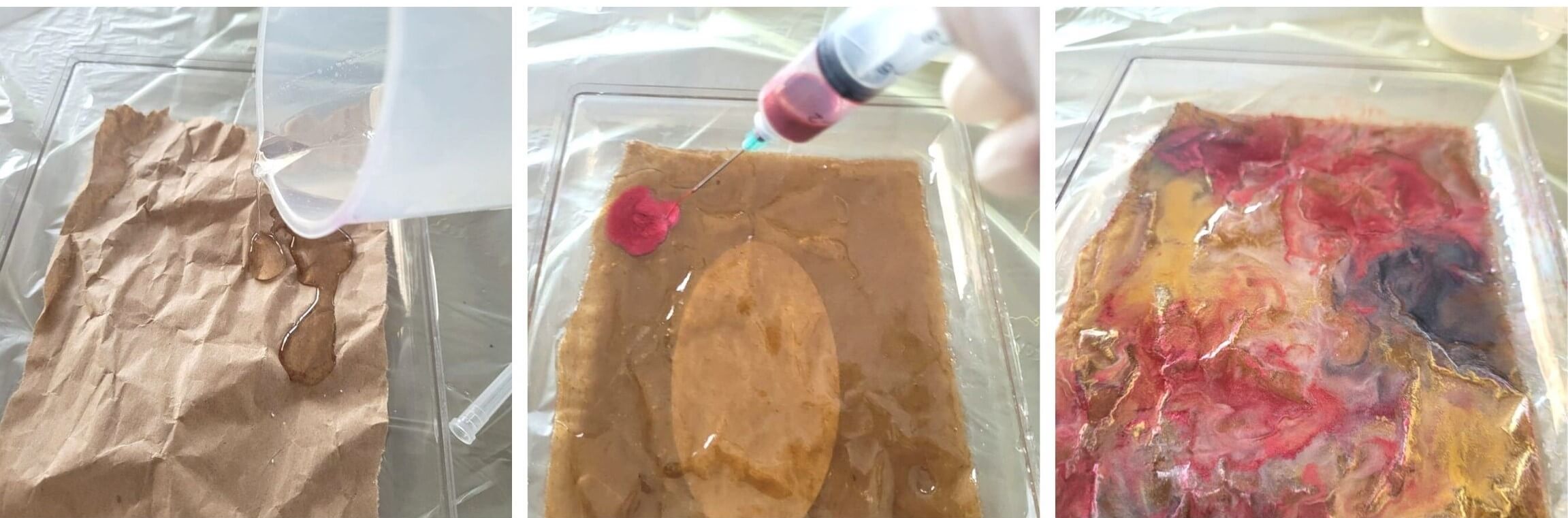

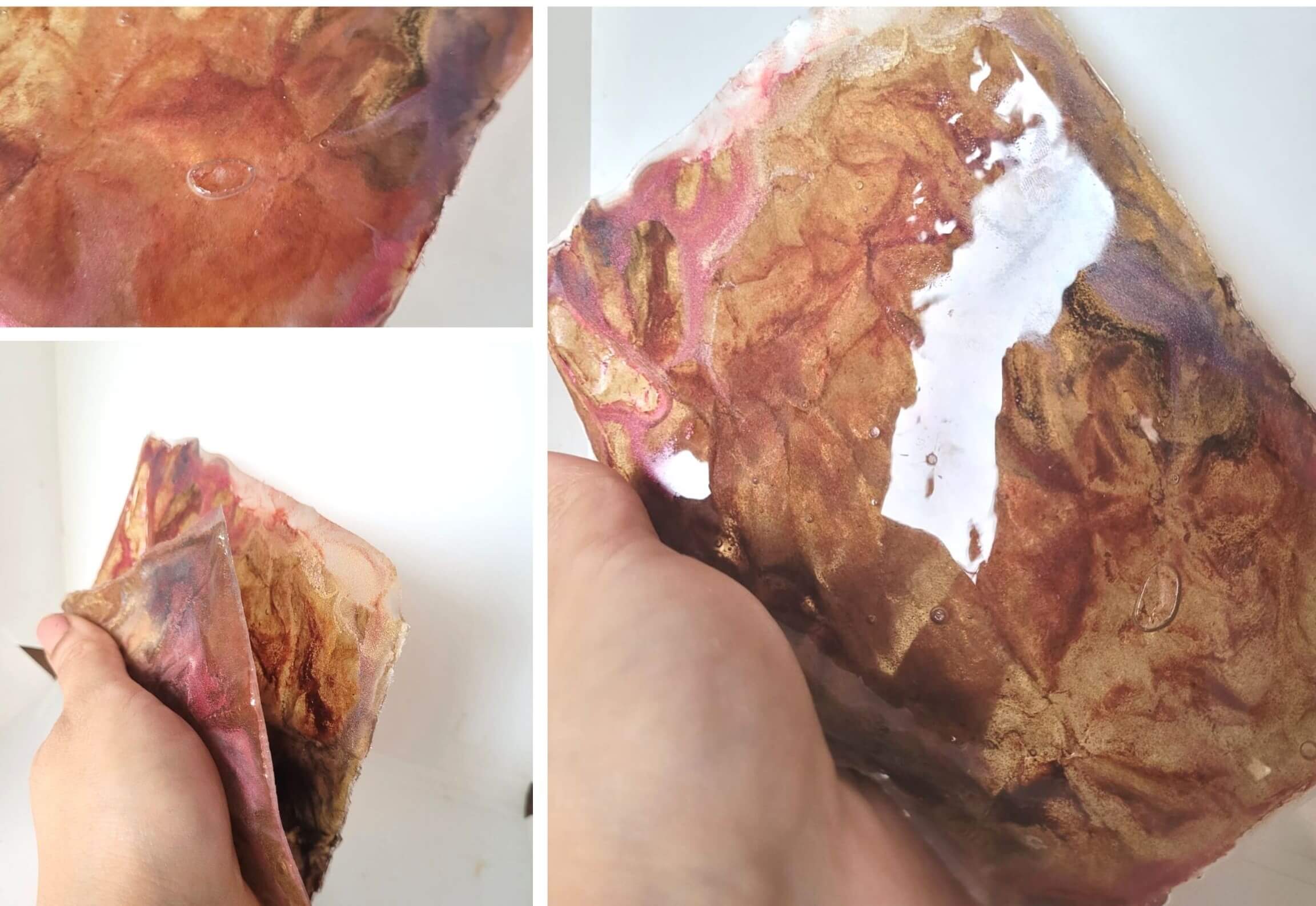

Resin - Kraft paper Composite¶

Fabrication Process

Final Result

!!!! Notes: The First 2 week the result was a somewhat flexible textile of approx 40 % flexibilty , heavily textured at one side, smooth at the other. However, It hardened up after that to an approx 08 % felxibilty rate.

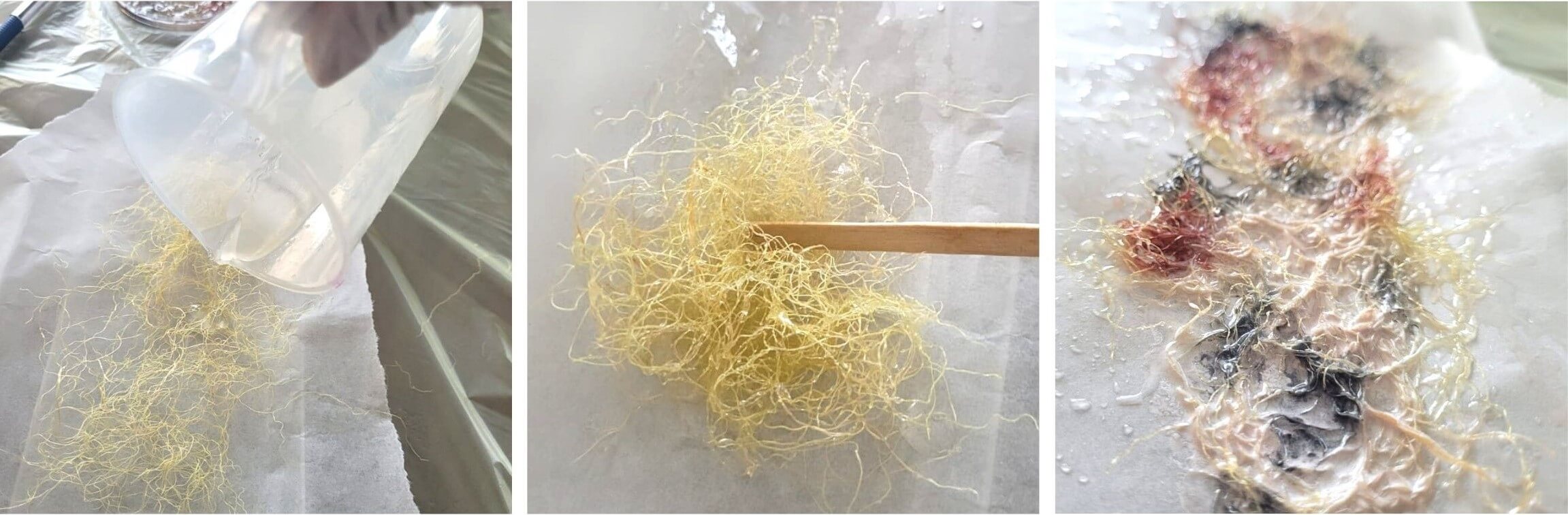

Resin - Dehydrated Corn Husk Fibers Thin & Perforated¶

Fabrication Process

Result

Notes

The First 2 week the result was a flexible textile , heavily textured at one side, smooth at the other. However, It hardened up after that to an approx 20% felxibilty rate.

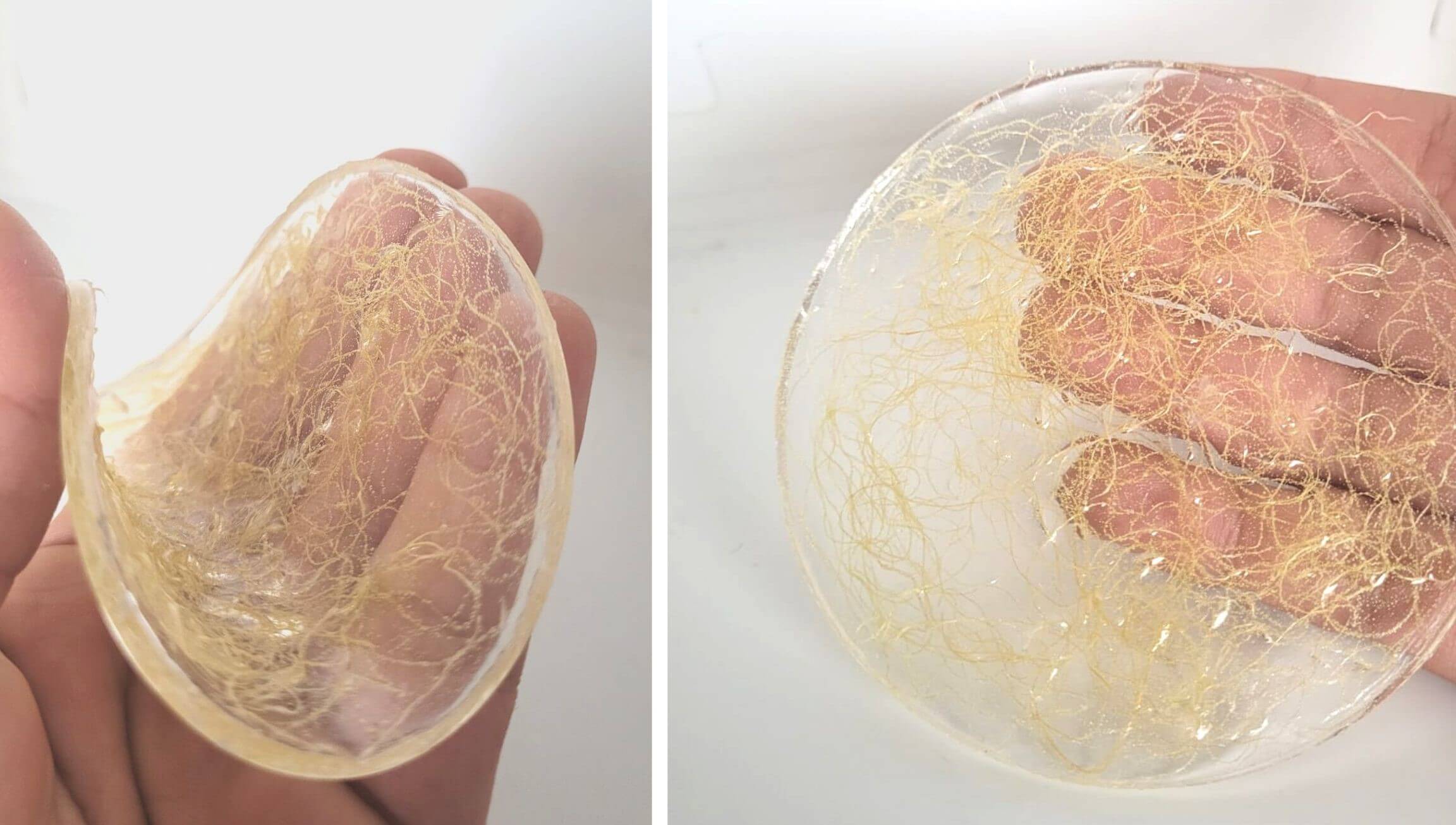

Resin - Dehydrated Corn Husk Fibers¶

Fabrication Process

Result With colouring

Result With Mica Powder

!!! Notes : The First 2 week the result was a somewhat flexible textile of approx 40 % flexibilty , heavily textured at one side, smooth at the other. However, It hardened up after that to an approx 08 % felxibilty rate.

Resin - Tull Mesh Fabric¶

Ink to Resin Tull Composite by haneen ja'afreh

The result looked like this

!!! Notes : The First 2 week the result was a somewhat flexible textile of approx 50 % flexibilty , heavily textured at one side, smooth at the other. However, It hardened up after that to an approx 10 % felxibilty rate.

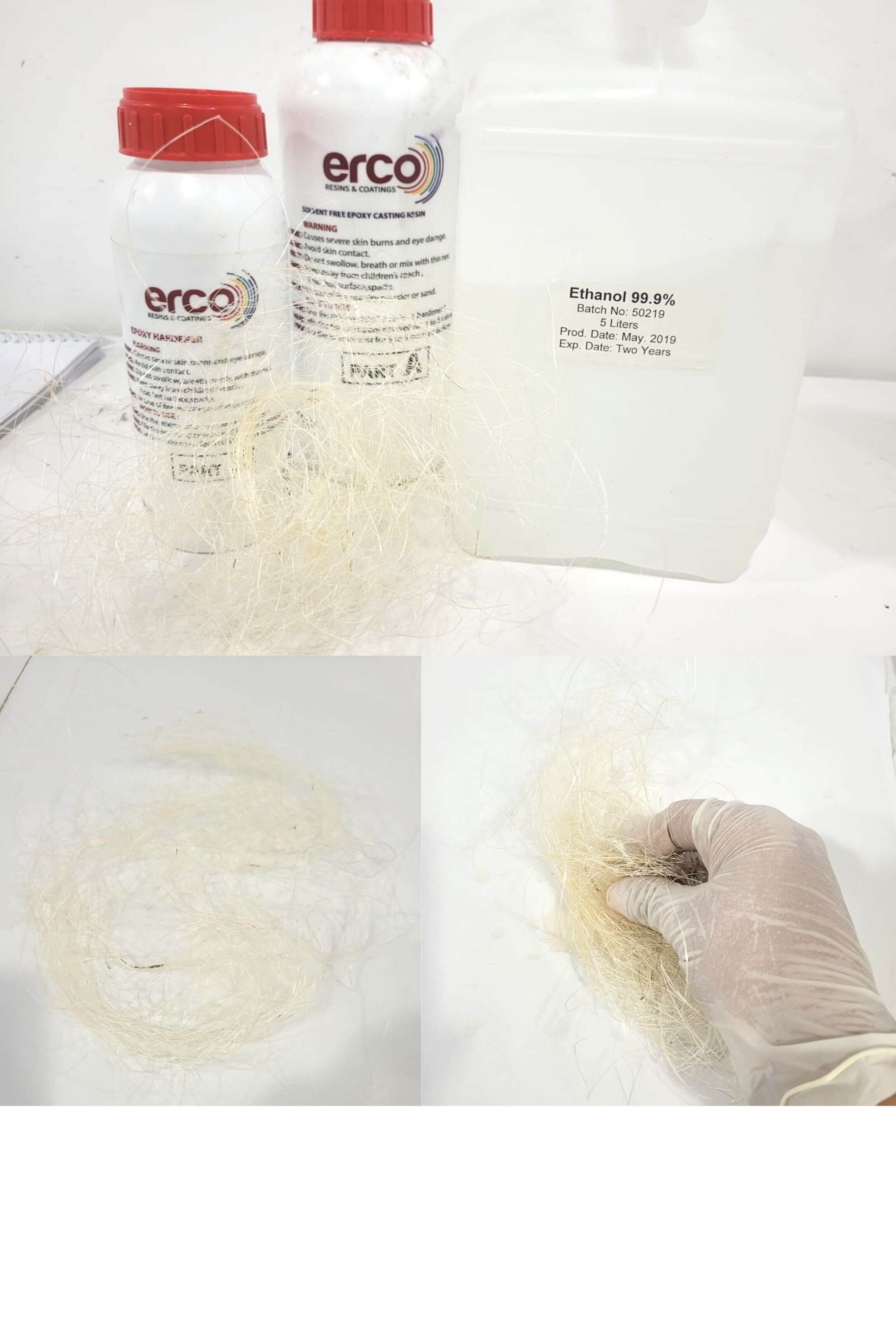

Comparing two brands of Epoxy¶

Using Recyceled Jute Fibers box filler as the additive in this composite.

- First brand is Erco , same one as what's used for all the previous experiments in this page

2 to 1 mixing ratio

25 % Ethanol

The result looked like this.

!!! Notes : The First 2 weeks the result was a somewhat flexible textile of approx 80 % flexibilty. However, It hardened up after that to an approx 30 % felxibilty rate.

- The second one is Entropy Resins One

2 to 1 mixing ration

25 % Ethanol

!!! Notes : The First 2 weeks the result was a somewhat flexible textile of approx 90 % flexibilty. However, It hardened up after that to an approx 50 % felxibilty rate.

Using both can make a great head piece

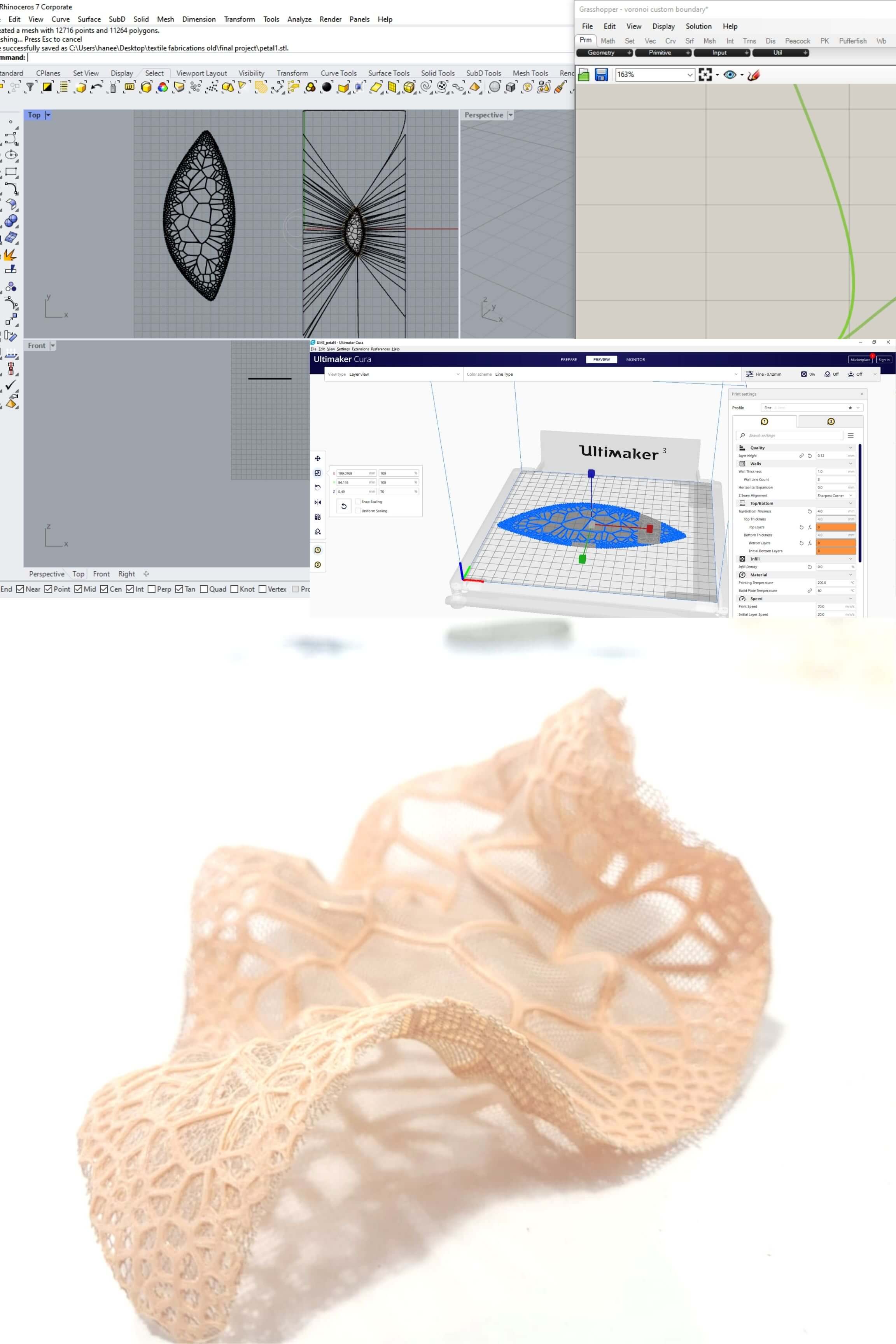

3d Print on Stretched fabrics¶

Looking into a natural shape shifting textile idea I experimented using some parametric design the degrades in density to create a textile that can create a space

Printing on Stretched Lycra mesh Using TPU

Loved the outcome. However the printer size is too small for my needs and the big 3d printer that is available prints Using PLA Pallets.

Cork Textile¶

Using Cork texile that I got my hands on through a friend I laser cut it into Stripes , joined the strips at the ends and manipualted the items for a stretchable shape changing textile and experinted it on the cocoon shell prototype.