6. BioFabricating Materials¶

Inspiration¶

Female Biophilia¶

MycoWorks¶

AlgiKnit¶

Biomaterials <3

I saw a video about Biocouture and Susanne Lee in 2014 when I was researching new materials during my scientific initiation in the art and technology laboratory of the university where I studied costumes. I was enchanted by the possibilities to grow living materials. After that my algorithm directed me to Materability which made me know about bioplastics. I followed their recipe and made a sample of gelatin-based "tissue".

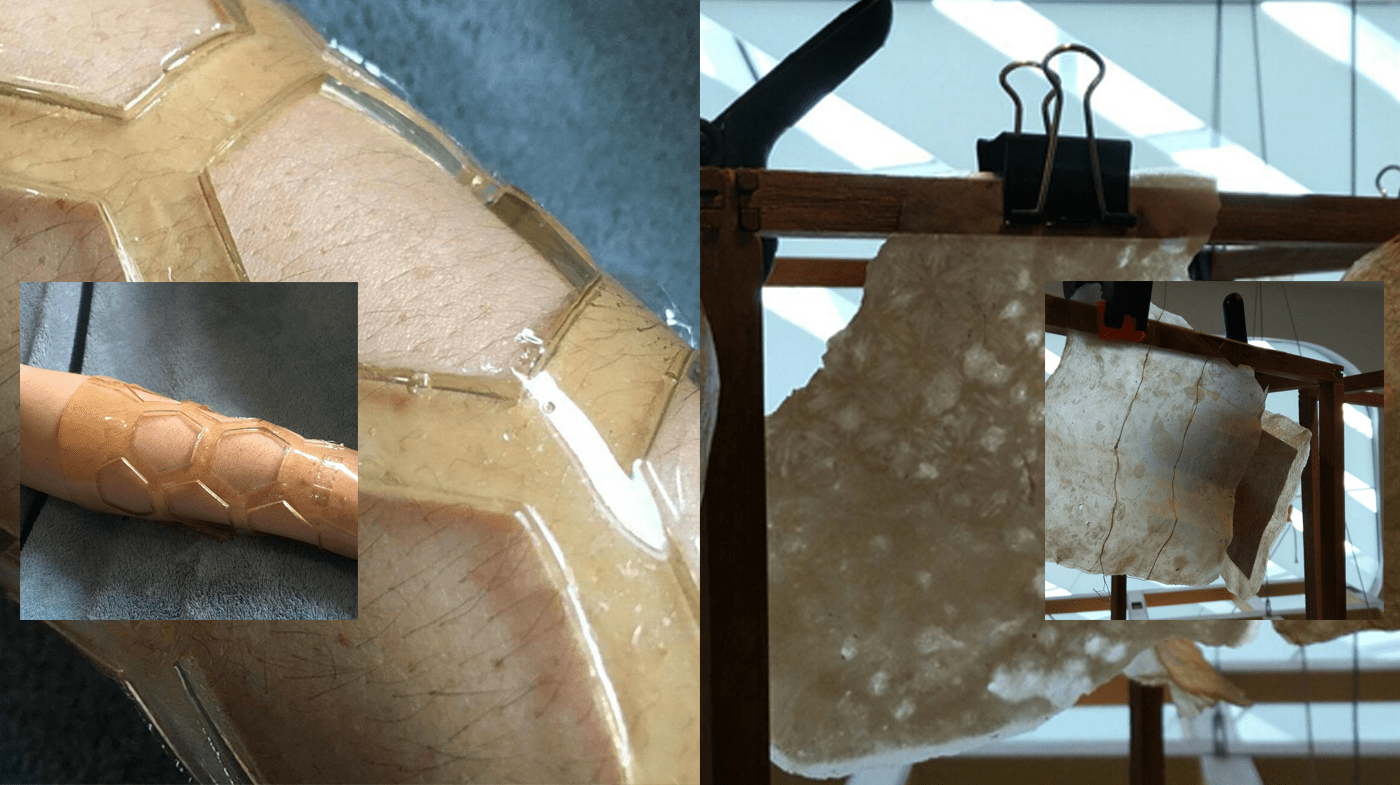

During my residency at the Museum of Tomorrow (Rio de Janeiro - Brazil) I had my first contact with the biofabrication of kombucha. At the time we did some experiments such as placing fabric on top and adding copper wire during the fermentation process.

This week I will share the project I am currently developing. This project is sponsored by Rumos Itaú Cultural and for its development a wet laboratory was set up where the raw material will be produced under a sustainable perspective. This raw material is a by-product of a colony of bacteria and yeasts identified in KOMBUCHA (a protein-rich drink made from tea fermentation). Its preparation is only about making tea and promoting it.

After fermenting, a film similar to a cream of milk forms on its surface. The time needed will be according to the purpose of the fabric. A biofabric with a thickness in millimeters requires a short time, but for a leather-like appearance and with a heavier weight it is necessary to wait for a time of at least two to three weeks.

The choice of bacterial cellulose is the result of the search for new resistant and cheap materials that can replace petroleum derivatives of animal origin. Its main characteristics such as biodegradability, UVA and UVB protection and electrical conductivity are essential for the narrative and technological context of the project.

PLASMA project

*In 1987, the Montreal Protocol was signed, which formulated policies to reduce CFC emissions to be followed by the various nations of the world.

What if there was no such discovery? What if they didn't take precautions like the Montreal Protocol?

2020: the year when there would be a similar hole at the other pole of the planet, in the Arctic. Twenty years later the entire ozone layer will be completely gone. What future scenarios can we imagine with the moment when we humans are the limiting factor on earth (Anthropocene Era)?

PLASMA is a laboratory store in a dystopian future of the year 2020, located in Brazil. A futuristic and post-apocalyptic store where there are bio-manufacturing processes for bacteria-grown biotissues. It shifts our vision to a cultivated and full-bodied design with the critique of predatory and extractive action, proposing a way to go beyond the capitalist and post-colonial logic

Getting started¶

KOMBUCHA¶

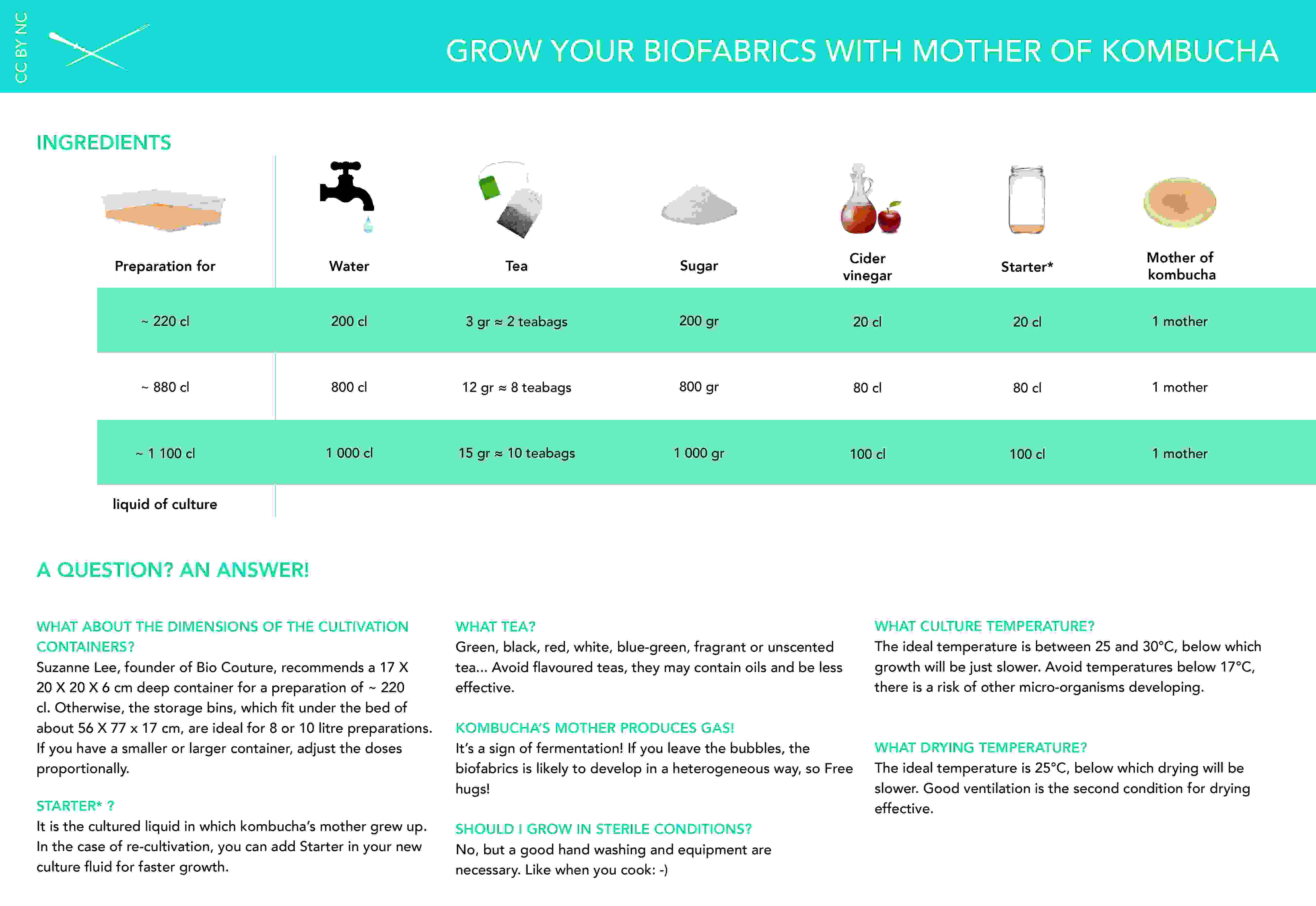

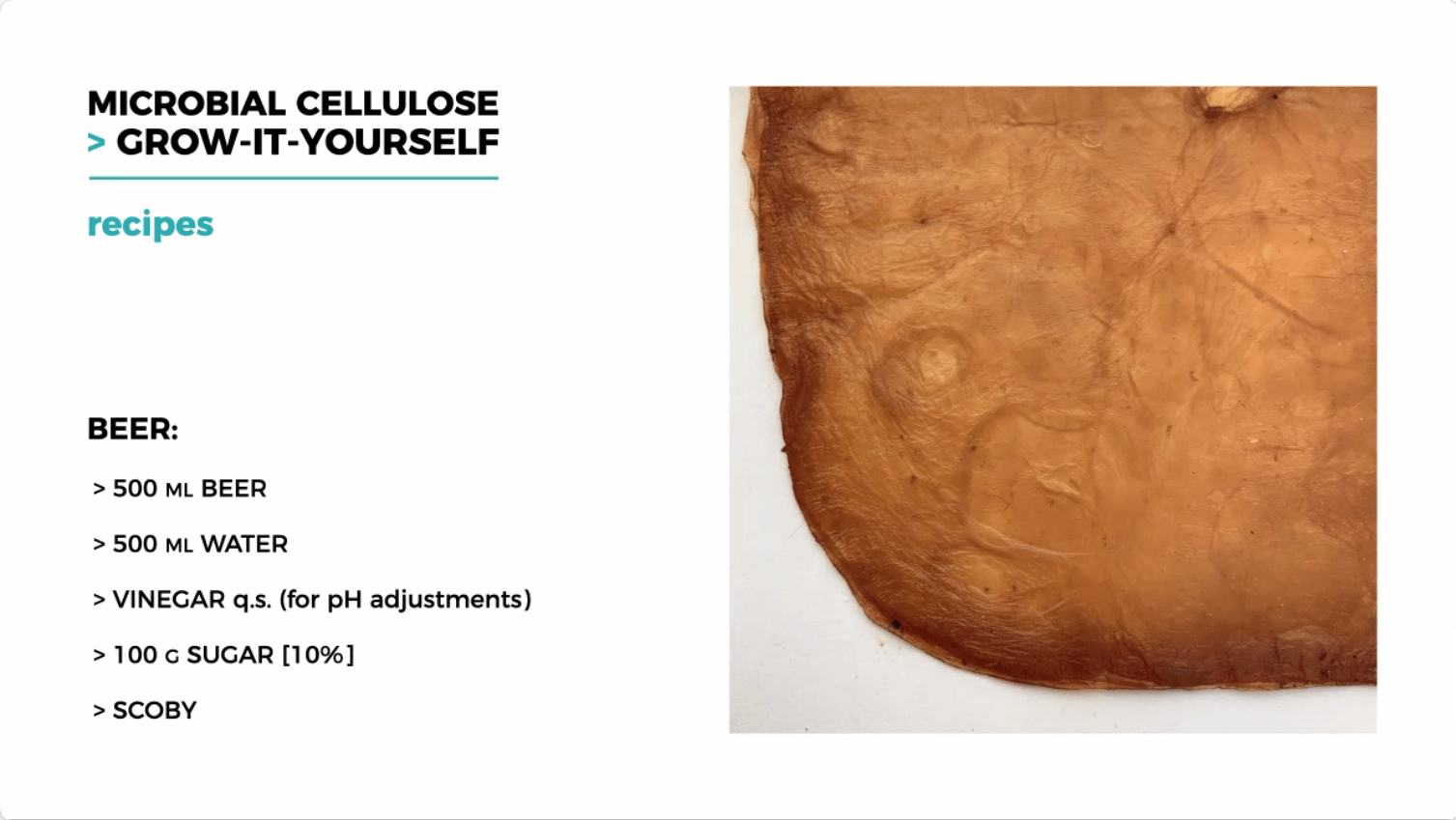

Recipe OpenBiofabrics¶

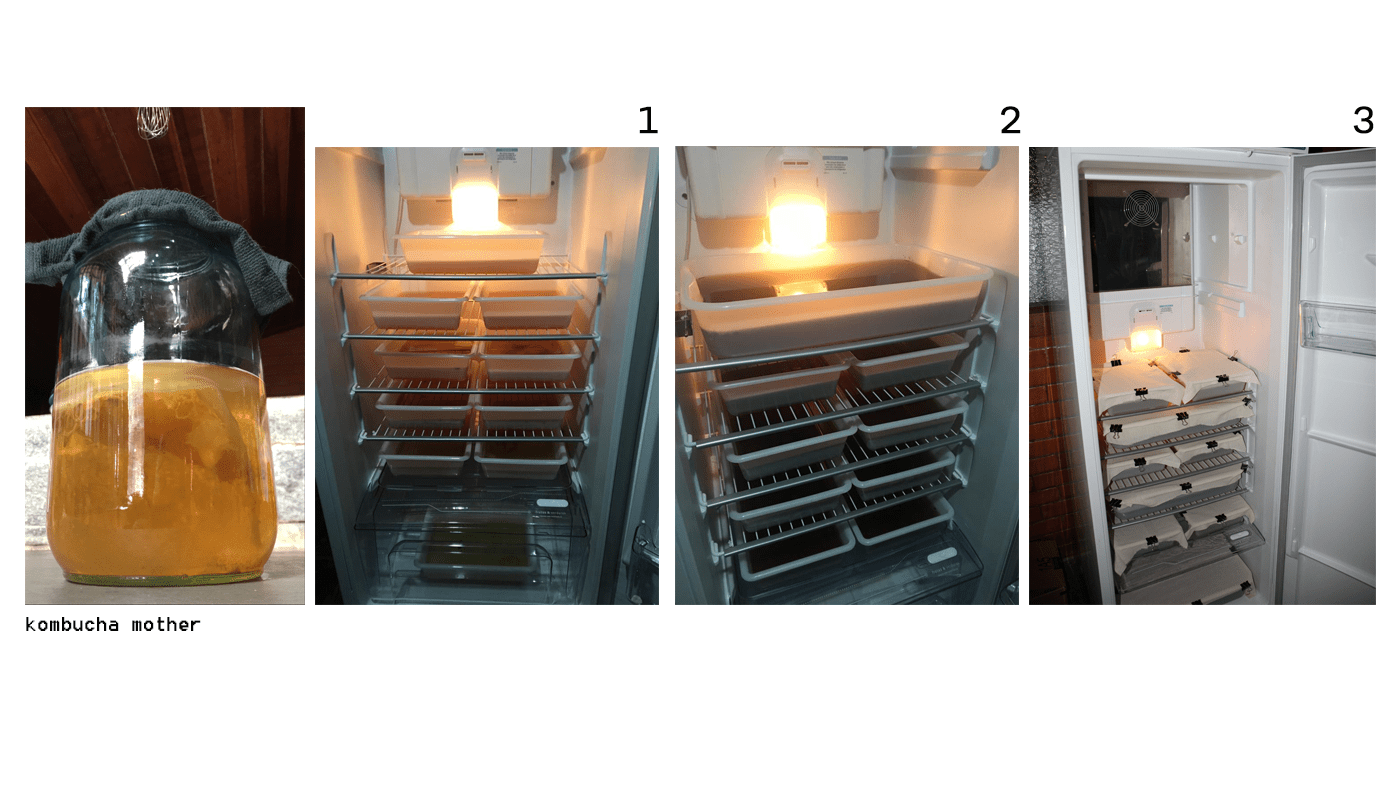

Last year I bought a scoby through a facebook group and with this recipe above I made a "hotel" to host what I called mother culture.

I based on the recipe that uses the amount of water of two litters and green tea. However, I did not use cider vinegar because I wanted to use the stater residue from a previous production that was collected and stored. The idea would be to use less material and use the water residue as vinegar and starter at the same time.

I didn't use scoby because I assumed that starters from other generations already had a small amount of bacteria.

I didn't put scoby on for two reasons: 1. assumes that starters from other generations already had a lot of bacteria. 2. In other experiments I noticed that when the cellulose grows above the initial scoby it ends up leaving the surface with a spine.

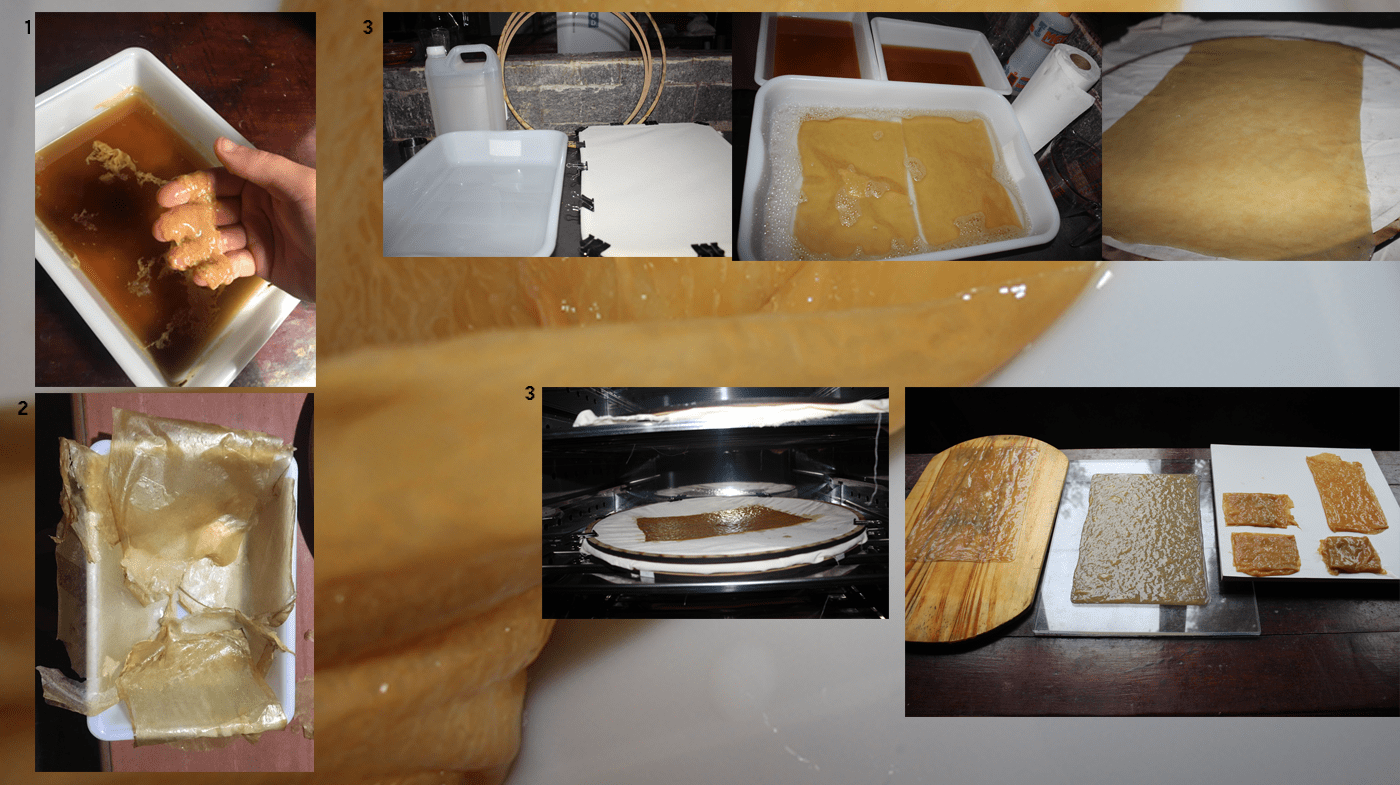

Biocellulose production was done using an incubator at twenty eight degrees Celsius.

I collected the first production after 15 days and the pulp was falling apart. I couldn't use any material to dry.

I collected the first production after 15 days and the pulp was falling apart. I couldn't use any material to dry.

I collected the second production a month later and the samples despite having been produced were very thin and papery.

The collection of the third production with a month of fermentation coincided with the week of the assignment and fortunately I was able to collect biotissues with greater thickness.

Biotissues were dehydrated in a drying oven for five hours at fifty degrees Celsius.

I dried the hydrated tissues on the surfaces:

wood, glass and raw cotton. The best surface is wood because of its porosity. The tissue and glass need to cool to collect the biotissue.

Biotissues were dehydrated in a drying oven for five hours at fifty degrees Celsius.

I dried the hydrated tissues on the surfaces:

wood, glass and raw cotton. The best surface is wood because of its porosity. The tissue and glass need to cool to collect the biotissue.

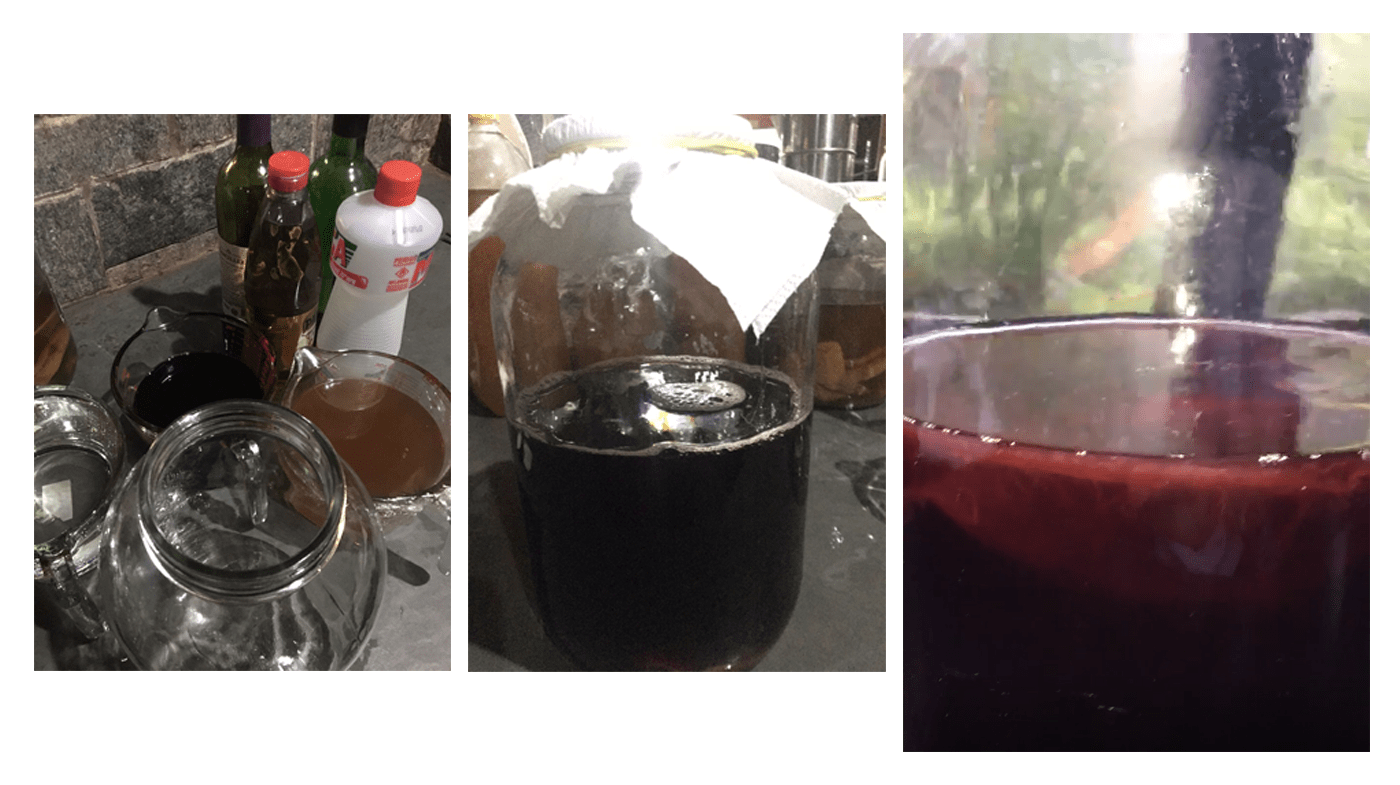

## kombucha Leather [wine]

I saw Lorena Tibbi's tutorial and I was super enchanted with the colors of bacterial celluloses in the wine. I followed her recipe.

After 5 days of fermentation I can already see a small film of scoby.

Dehydrated biotissue

Bioplastic¶

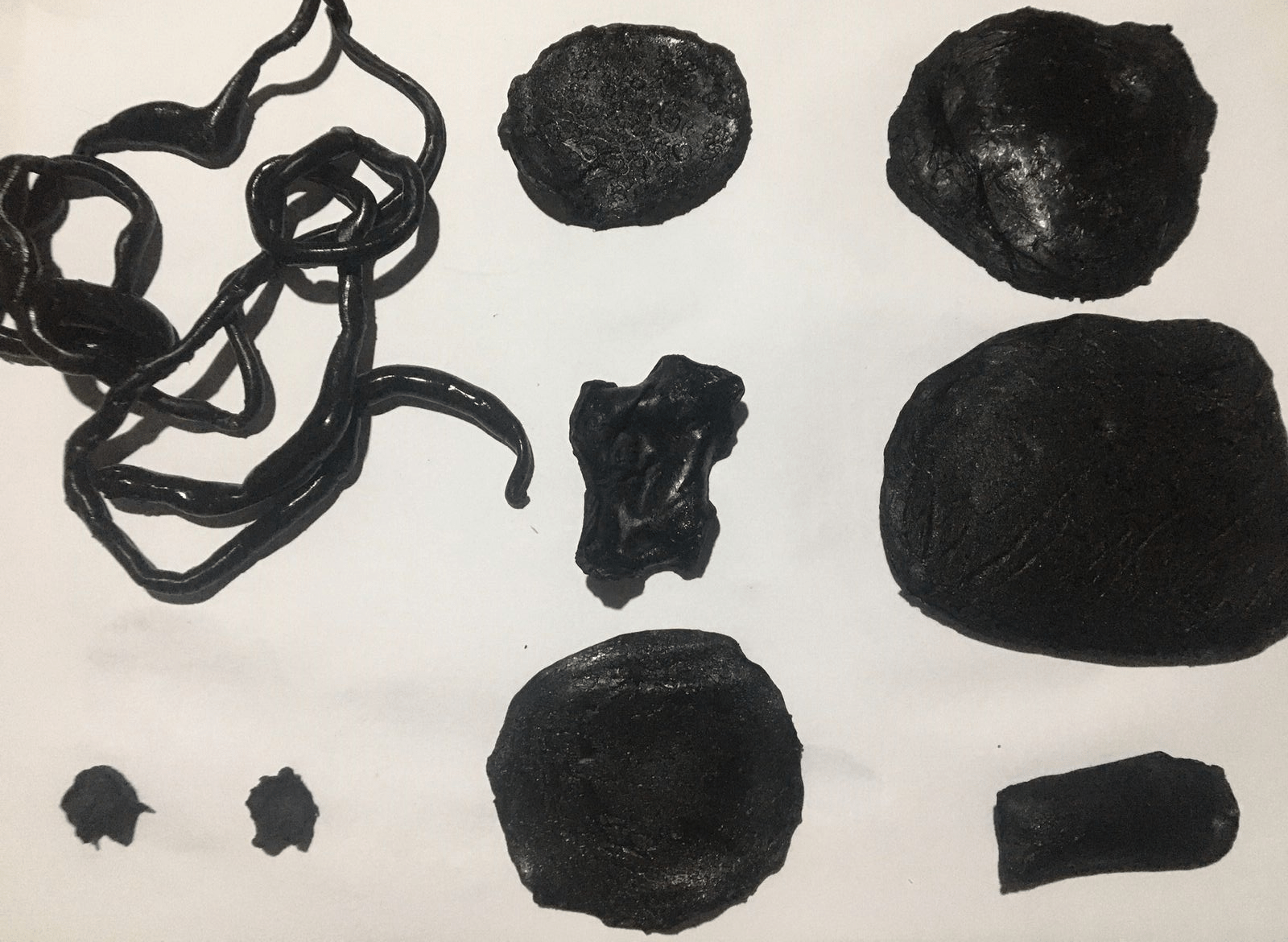

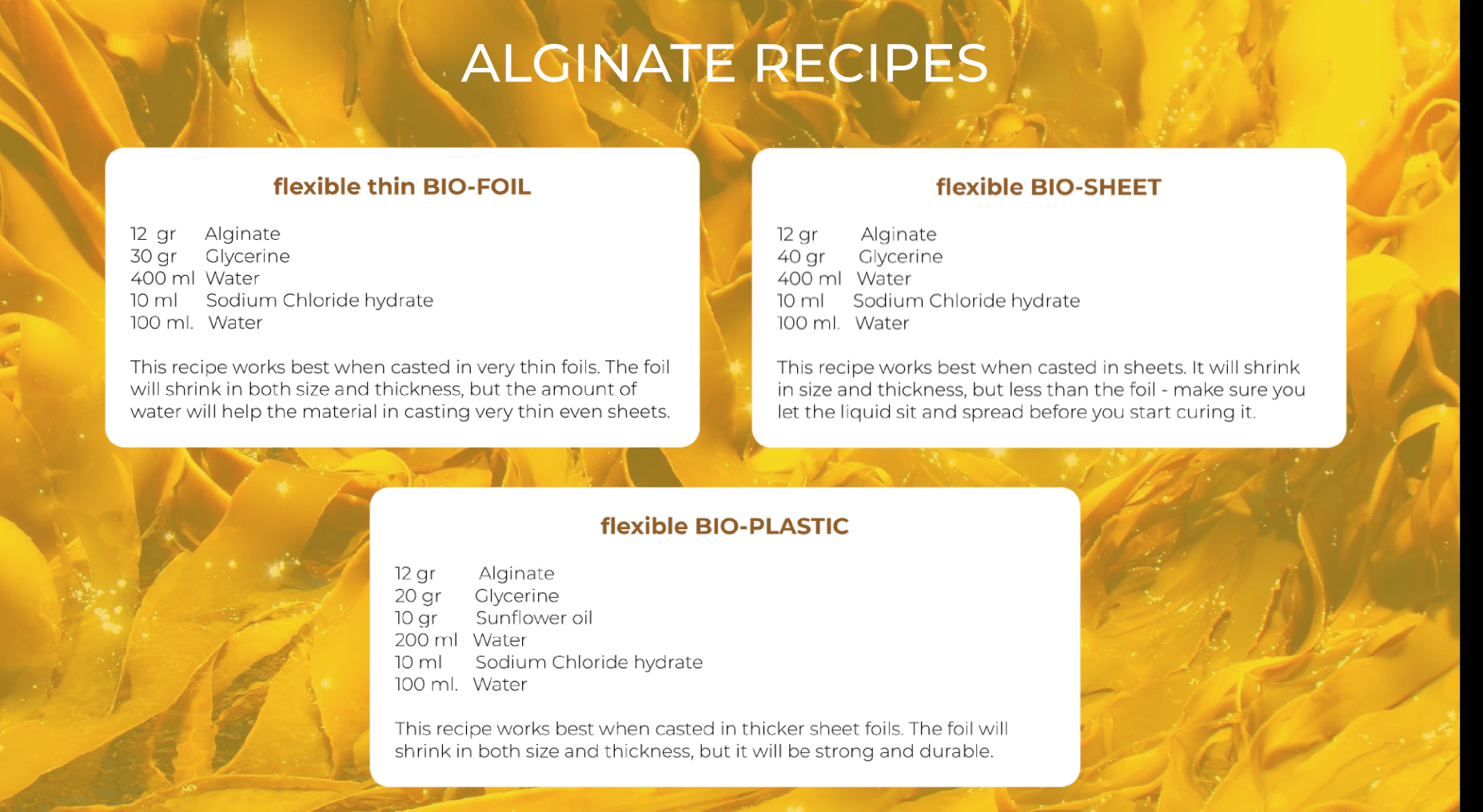

I chose to create my bioplastic with alginate. It was a material I already wanted to try because of its water resistance. I used the shared recipe on Cecilia's slide and added varying amounts of activated charcoal. My goal was to try to develop a "bioelectronics" thinking about the issue of electronic waste in wearable technologies. The idea is to manufacture a sensor with characteristics similar to the velostat material.

I made three additions of activated carbon in the recipe " Flexible thin Bio Foil: - Recipe A with 10g of activated carbon, - Recipe B with 25gr of activated carbon - Recipe C with 30gr of activated carbon

Alginate Samples¶