3. Circular Open Source Fashion¶

The next big thing will be a lot of small things

Thomas Lommée

Mass/modul production¶

A few random thought on how to make modular manufacturing zero waste:

Mass/modul production¶

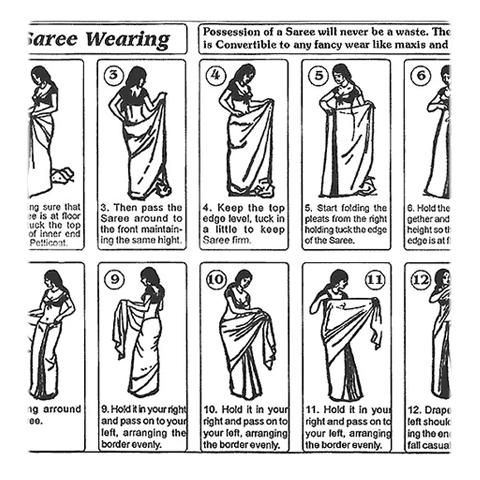

Or, if spending energy/ time weaving the fabric, maybe best would be to just not cut the fabric?

indian sari wrapping instruction

Inspiration¶

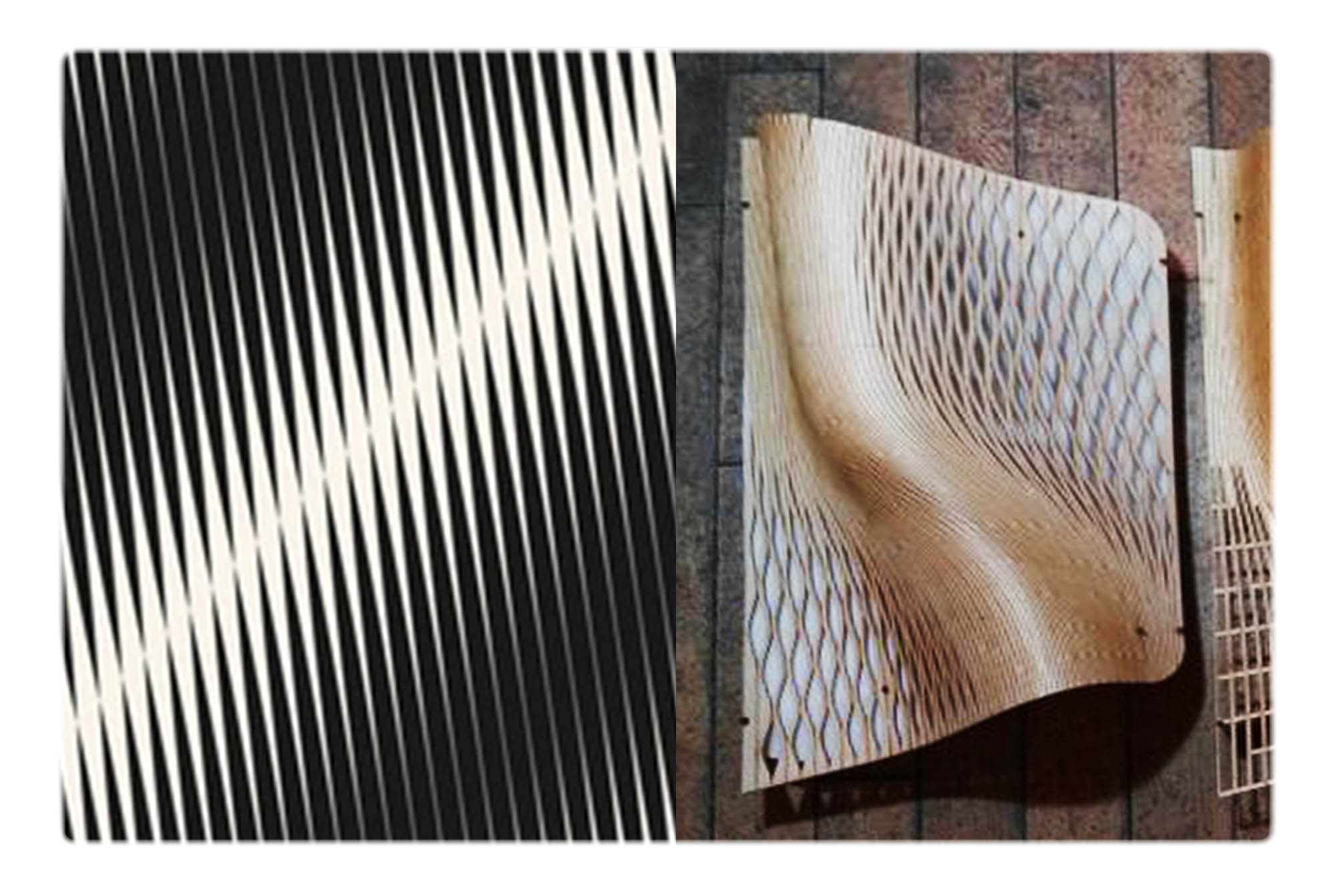

Inspired by the air vase designed by Torafu I decided to see if I could make a garment completly without cutting the fabric into pieces.

Torafu

Mamou-Mani

Mamou-Mani

4-ways stretch

4-ways stretch

Robert van Embricqs-rising furniture

Robert van Embricqs-rising furniture

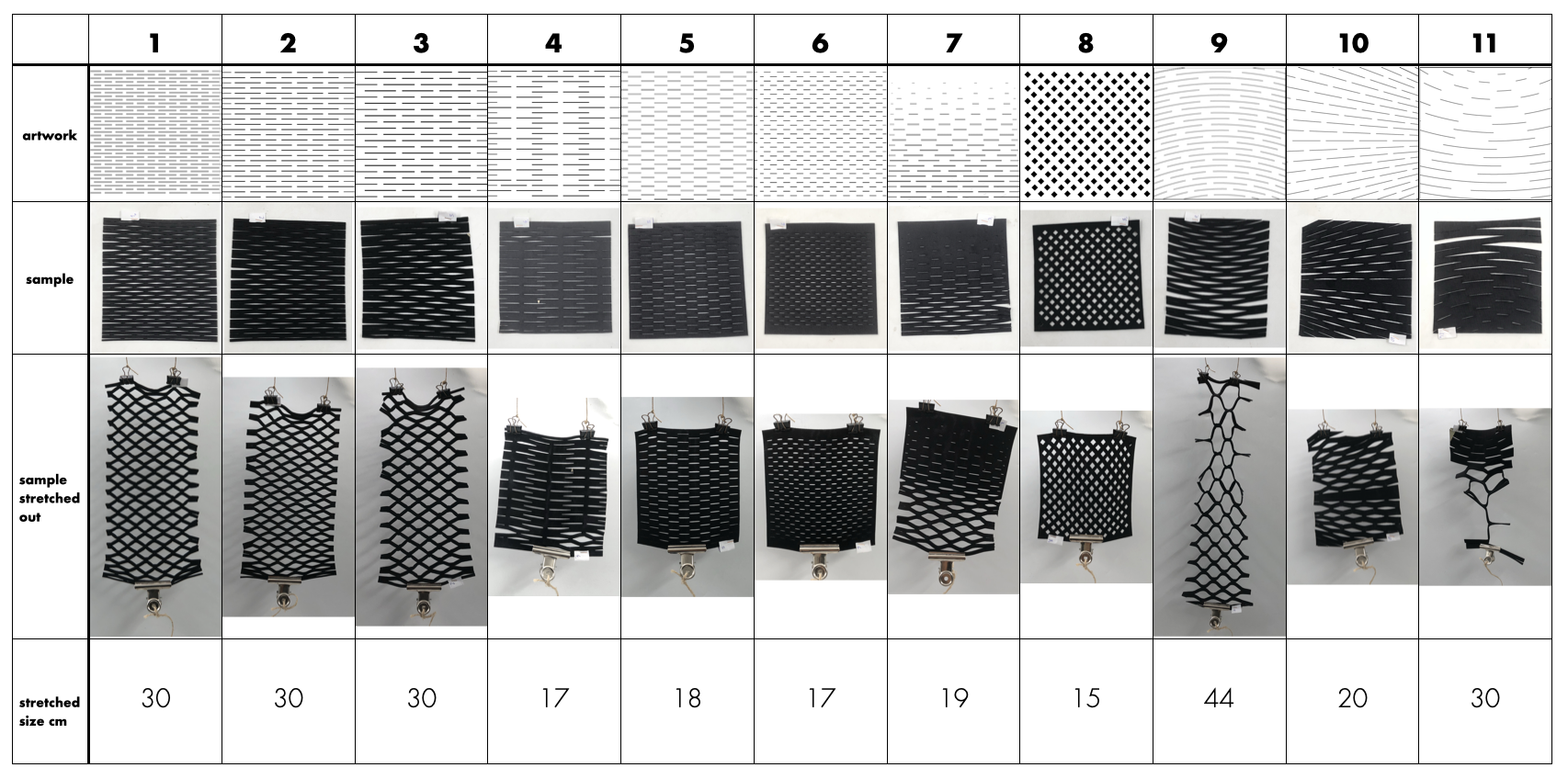

sampling:¶

Sample size 15 x 15 cm before stretching (I used a 40 gram weight for this test)

Sample size 15 x 15 cm before stretching (I used a 40 gram weight for this test)

Interestingly, the size of the hole didn´t affect the elongation much (sample 1,2 and 3) but the placement of the cuts was more important (sample 4 and 5)

After some stretch tests with different kerfing variations, I decided to go for the most basic pattern and instead play with the placements and size of the holes.

Sample 8 was an attempt to create a 4 ways stretch that didnt work out since the holes was to small

I mainly used samples 1 and 7 for my final design.

A few sketches trying to understand how the stretch direction will affect the shape and the size of the garment.

final design:¶

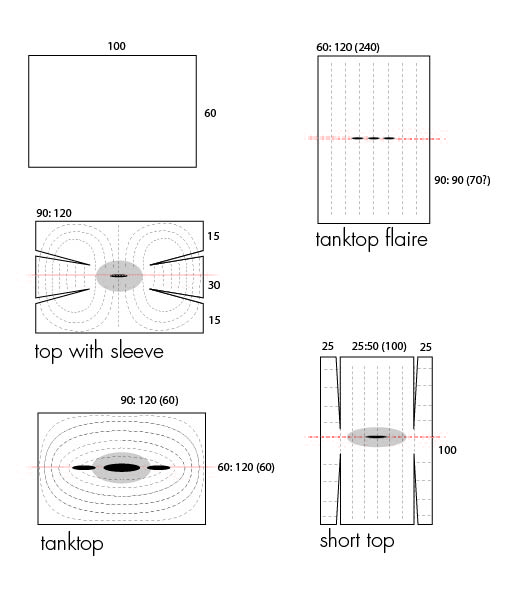

For the final design, I decided to restrict the fabric usage by the size of our laser cutting table, (60x100cm), and from there see how big a garment I could make.

I calculateted with 100% stretch lengh However after fabrication I realised that elongation for the final garment is 173% due to the weight of the fabric.

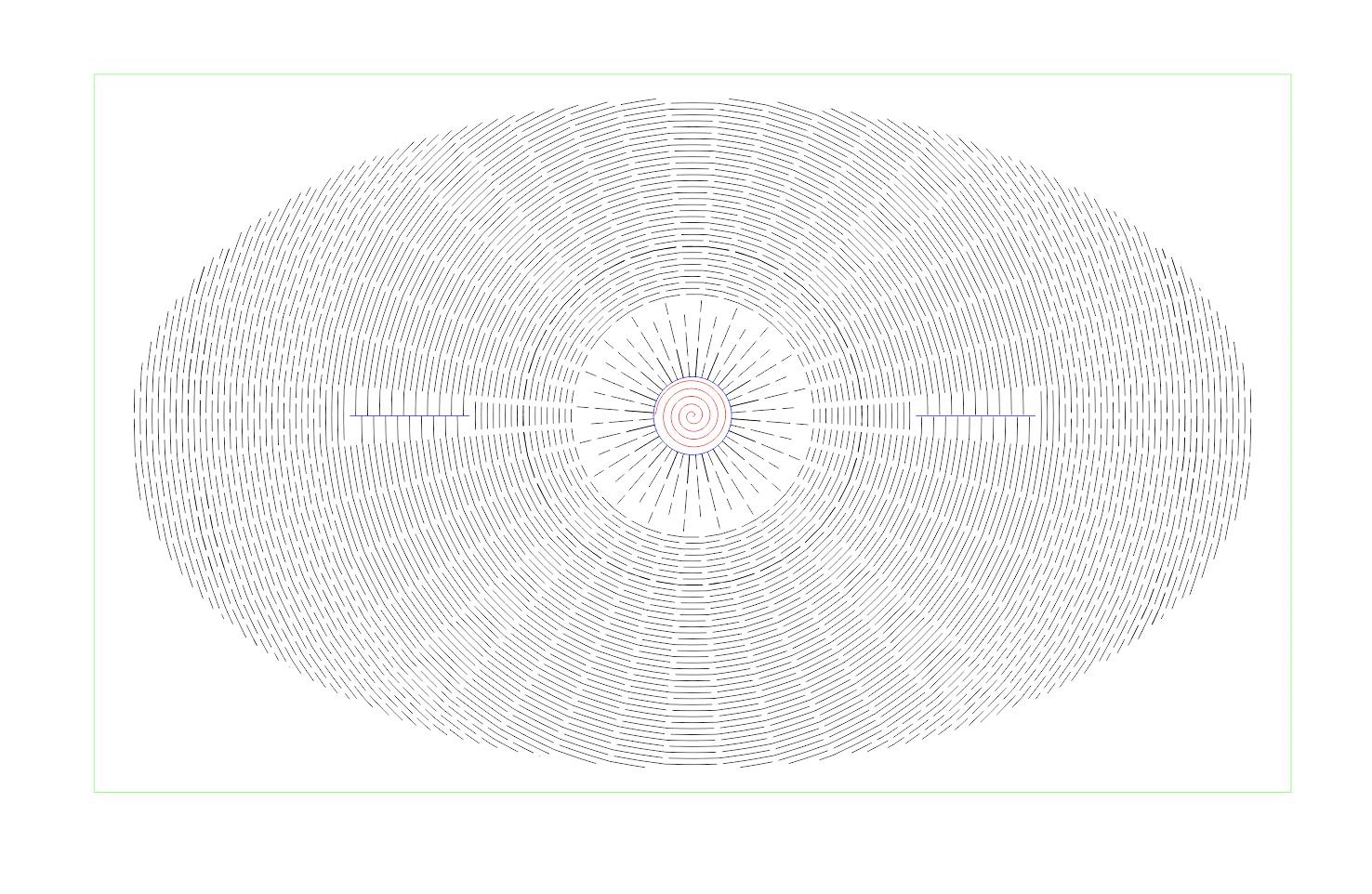

From the previous samples, I realized that for the garment to have enough tear strength I need at least 5mm of fabric. So, I decided to place the cuts in a circular pattern starting from the neck with an even spread of 5 mm gaps while the cut length grows proportional along the artwork.

From the previous samples, I realized that for the garment to have enough tear strength I need at least 5mm of fabric. So, I decided to place the cuts in a circular pattern starting from the neck with an even spread of 5 mm gaps while the cut length grows proportional along the artwork.

I draw the design in Rhino using the following steps:

• Draw a straight pattern with a minimum of 5mm gap

• Array polar to create trim lines

• Cut the straight artwork into a repeat pattern

• Array polar to repeat the pattern

Fabrication:¶

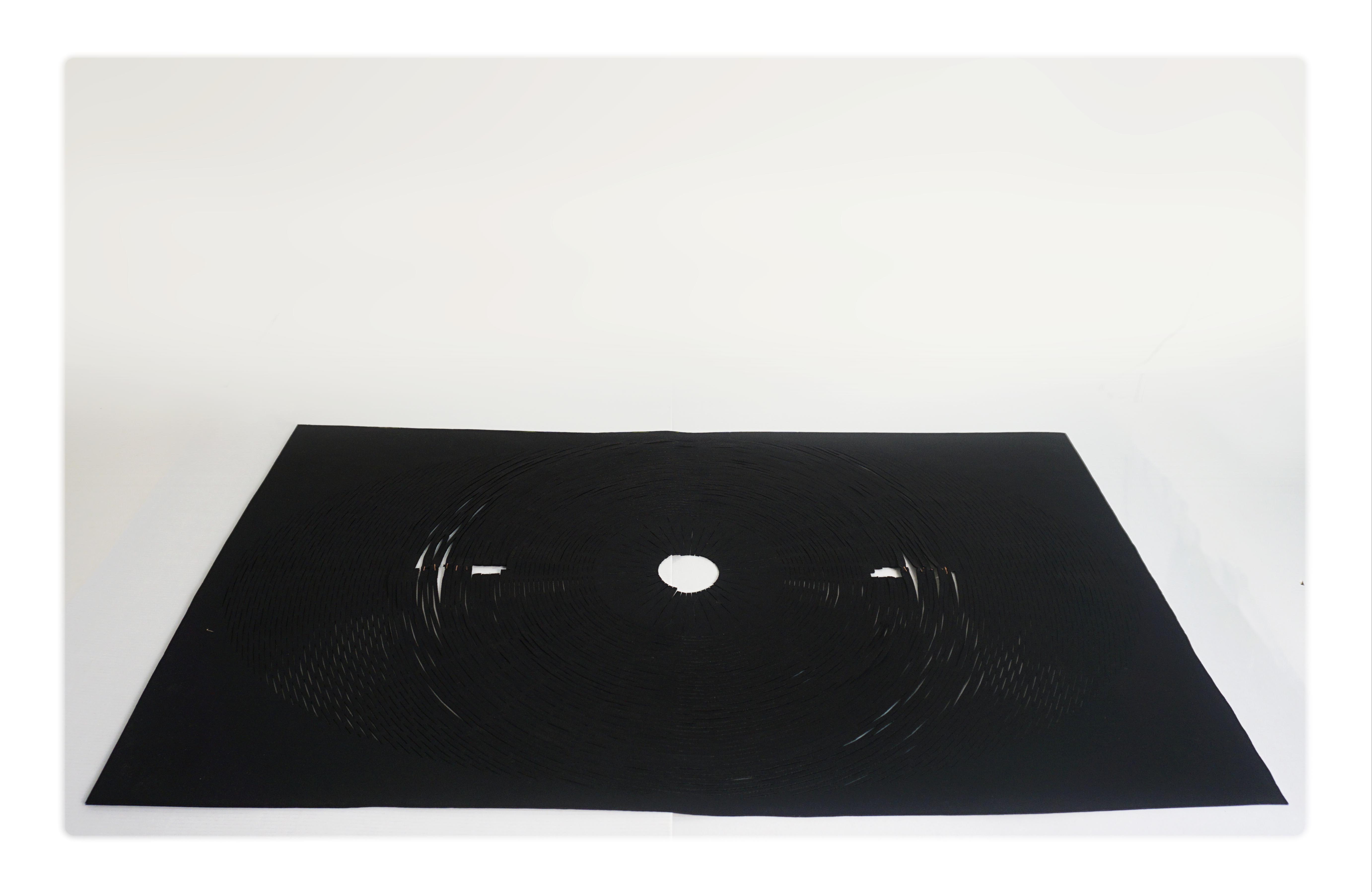

I used a 1mm neoprene fabric with the following cutting settings:

Power: 22

Speed: 1

Hz: 1000

Cutting time ≈ 50 min

Conclusion:¶

I think the kerfing effect is quite interesting and fun, a few things I would revise if I would continue the development:

a) The cuts opened more than I was expecting them to, especially in the center of the artwork (because of the weight of the bottom part) which lead to the armhole stretching much more than expected.

b) the finishing of the arm and neck opening could be more interesting design

c) it would be interesting to continue to develop a 4-ways stretch solution

From a sustainable perspective:

the cutting plane is definitely easy to make with minimum waste, and the making process is extremely labor efficient however I suppose 1h of laser cutting requires a lot of energy.