Circular Open Source Fashion¶

References & Inspiration¶

At the beginning, I used keywords to search for references related to modularity. I came across some interesting ideas, but later I realized that some of the design approaches had textures that weren't entirely flat. Instead, they used materials to create some space, making it look like it was somewhere between 2D and 3D. I became fascinated with this "2.5D" texture, and I think the interaction between materials and this small volume is really cool. So I set up my goal to achieve modularity and semi-three-dimensionality.

01 安藤健浩デザイン室

02 atelier oï

03 Mia Cullin

04-05 Anne Kyyrö Quinn

Research & Process¶

1. Modularity and connection¶

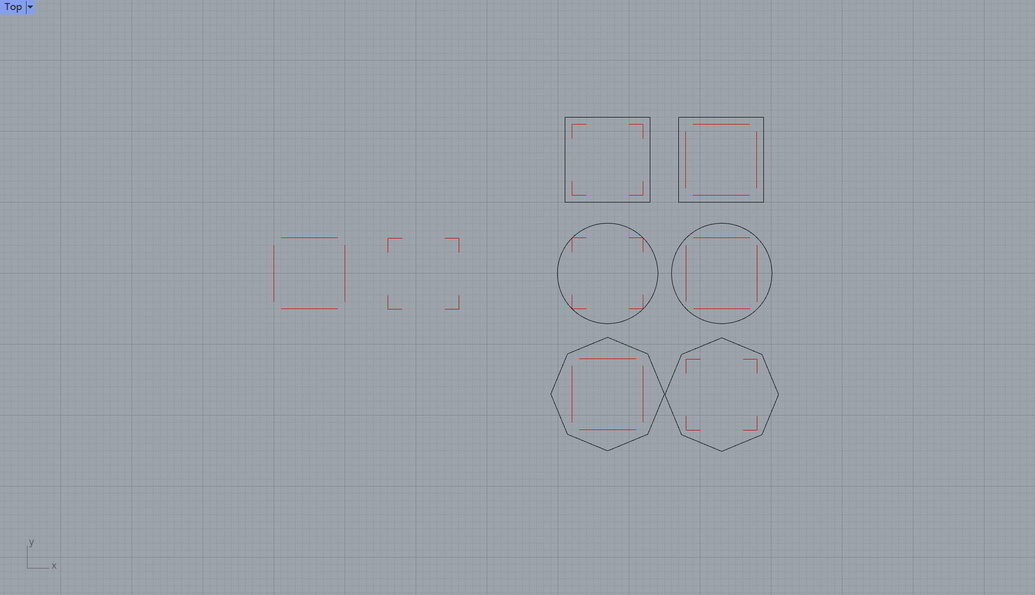

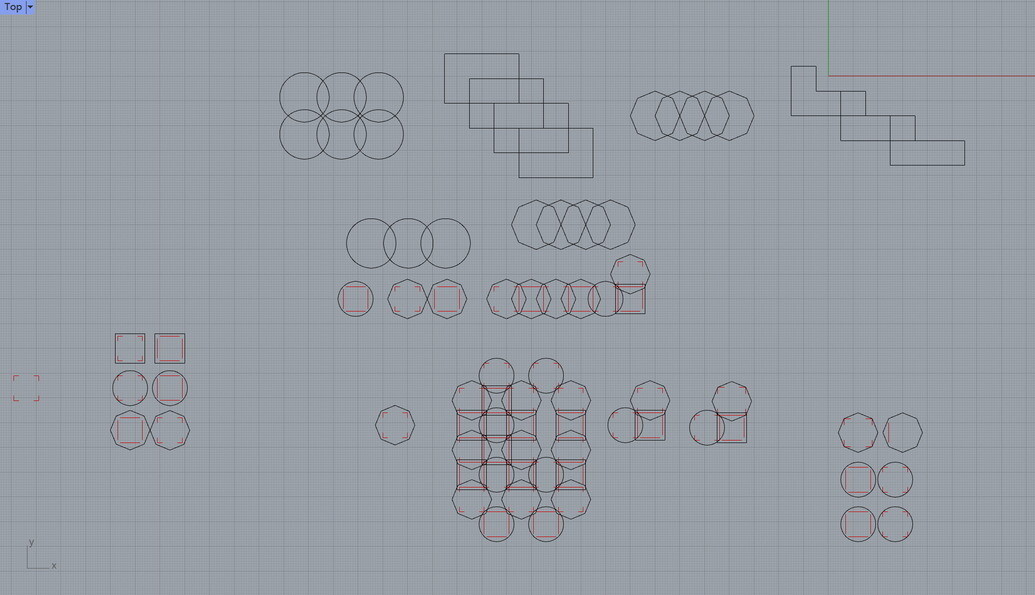

I initially started by researching the male and female for the modules, as the connection method is the top priority for modularity. I work with Rhinoceros to study the connection, shape and measurement.

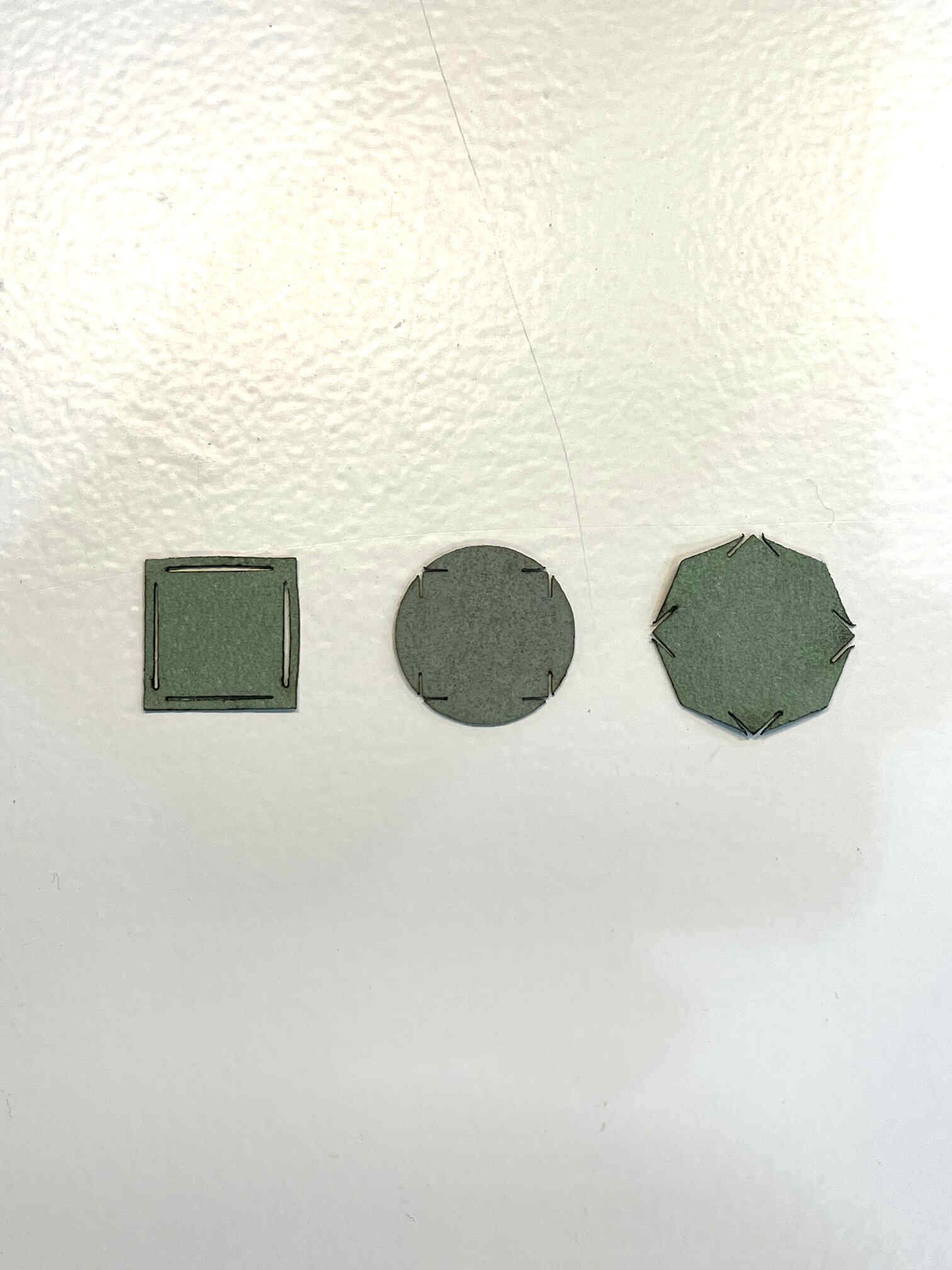

In order to see how this type of connection design actually looks in the material and if it can be assembled, I laser cutting 50% in size (length 2cm for each shapes) as prototype to see if the connection is work or not. The material I choose leather, there's no particular reason, it's more like an intuitive choice, the tactile feel of leather is always quite appealing.

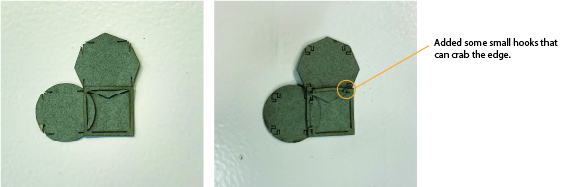

But somehow I found maybe because the size or there's no extra support for the connection, it's very easy to pull apart, so I add some small hooks that can crab the edge.

2. 2.5D¶

After some initial experimentation and understanding of the modules and connections, I began to focus on how to achieve a 2.5D texture while maintaining modularity and zero waste (where all cut parts have their own meaning and function).

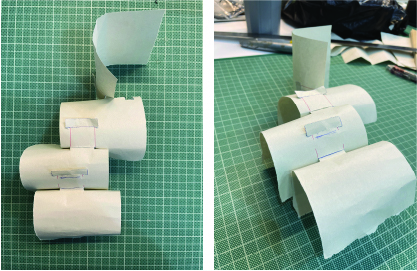

I was randomly testing some interlock with paper, to generate some volume through bending and tension.This try out is interesting, just like building a small-scale structure through paper and volume.

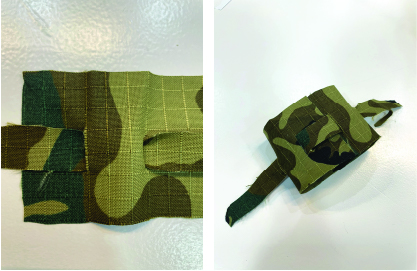

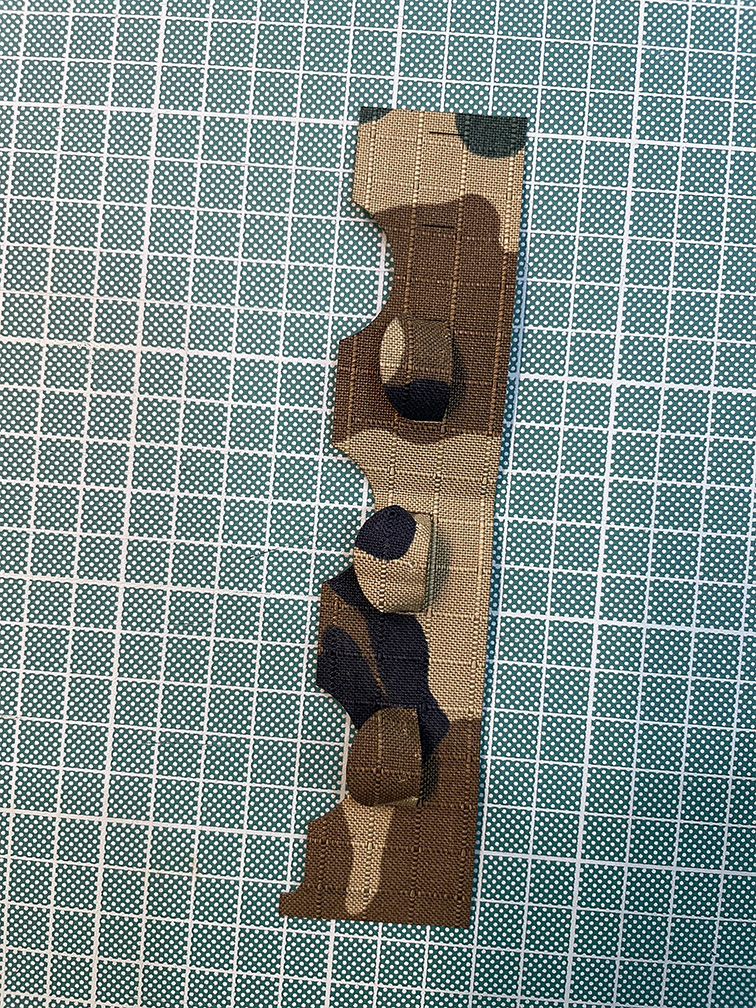

Now let's move to the material which I'd like to work with. The material is camouflage textile, with a thin layer of coating underneath(guess it's for waterproofing), it's quite tough, not very elastic, has poor stretchability, but not easy to cut with a knife.

I tried to connect this fabric into a loop by a simple interlock.

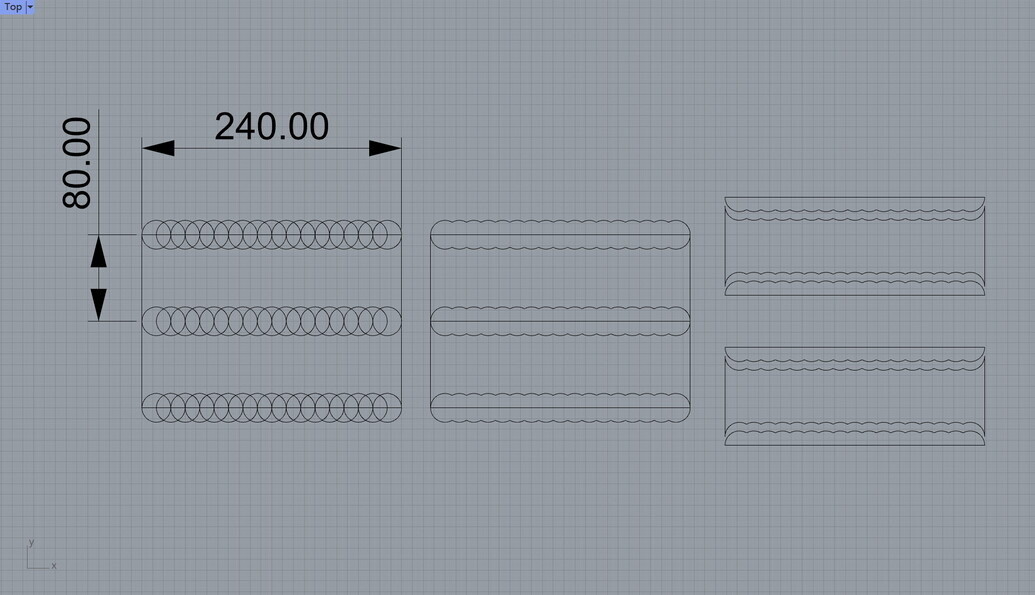

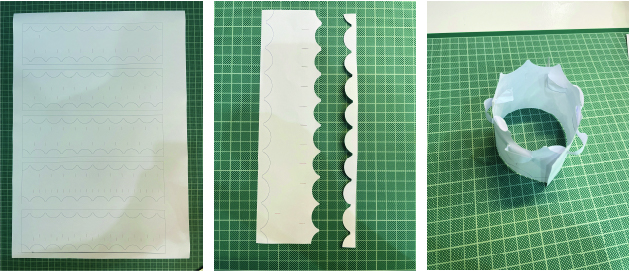

After having some ideas about the connections, my next challenge was to creating some cuts insdie a rectangular piece, with the aim of use every part that was cut out. I found continuous semicircles quite appealing; the cut arcs could correspond to the cut-out radii, adding more fun through the shapes.

I added some holes in the central section, allowing the pieces cut from both sides to create a 2.5D effect by interlocking in the central area. Printing on paper and tried assembling it to see how it works.

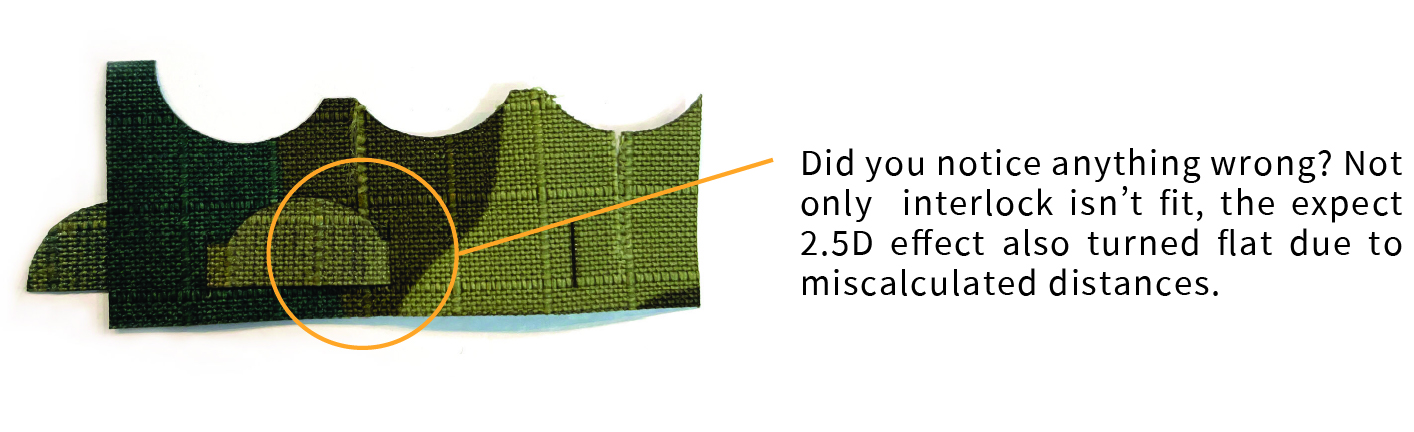

But I found that the spacing was too large, causing the joints around the holes to be quite loose, and the details are not as refined.

Considering the difference in thickness between the military fabric and paper, I decided to laser cut small sections of military fabric to see if the designed interlock dimensions fit properly.

Adjusting it once more, it looks much better now!

Detials refine¶

Finally, the first single set are done, all modules are produced from a single rectangular piece, zero waste! I first attempted to coil it into a bracelet.

But somehow I fell the interlock still alloewed slight sliding. It turned out that the bends were not securely locked, after discussed with local instructor, I create some small slots to lock the passing materials securely at the bends, maintaining the stability of the 2.5D form.