Textile Scaffold¶

Reference & Ideation¶

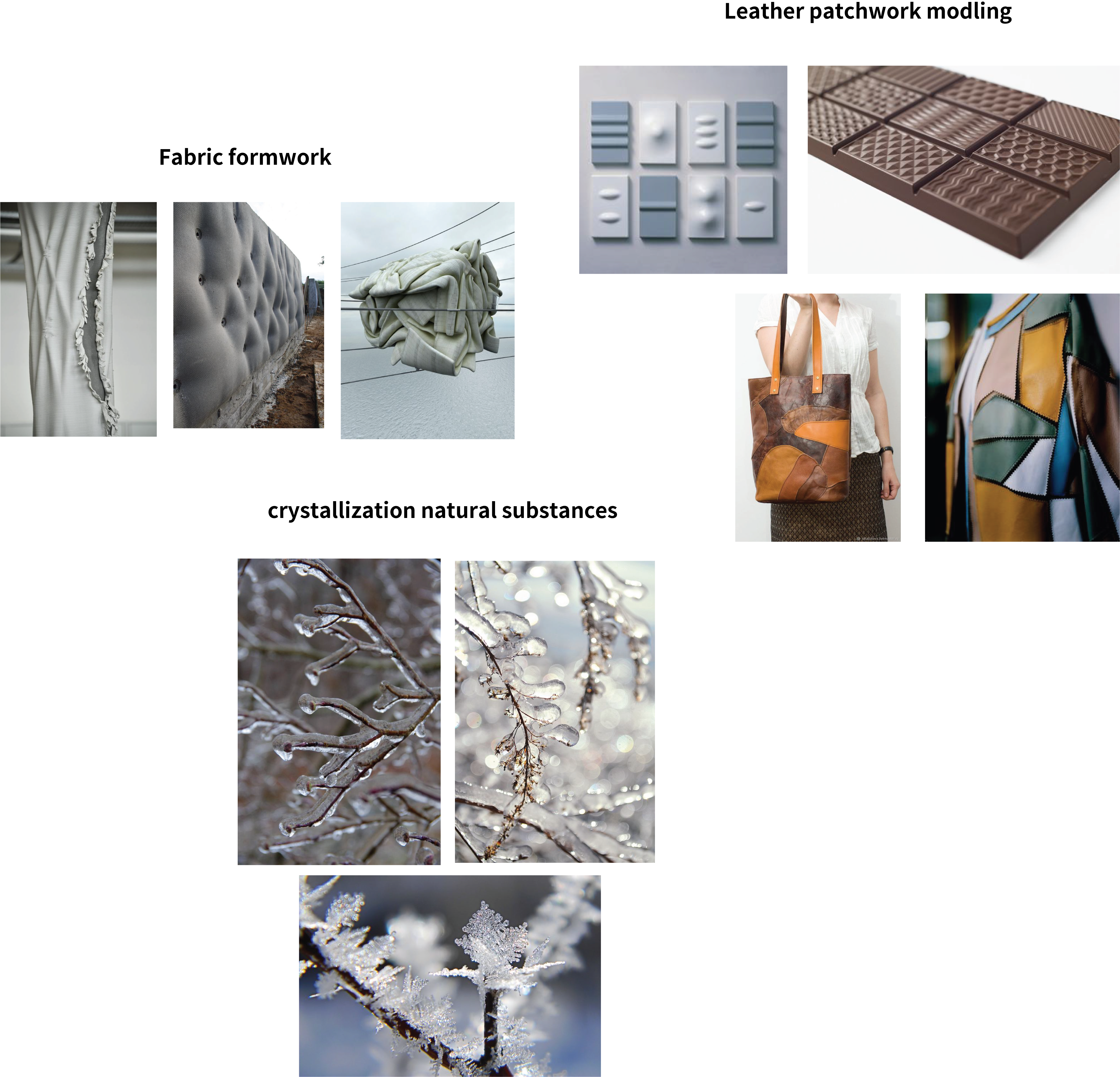

For me, this week feels more like an exploration of aesthetics between soft and hard aspects of textiles or materials. There are various directions to explore, including molding, fabric formwork, crystallization, wood on textile and more. This week, we also learned to use CNC milling to create molds, allowing soft textiles, leather, etc., to take on the forms we design through molding. This aspect is quite intriguing.

01 Normal Design

02 Nendo

03 Julia Jukova

04 Hettabretz

Crystallization¶

Using minerals to crystallize objects is a fascinating and decorative technique. This process is not only simple and fast, but the unpredictable outcome often results in surprises.

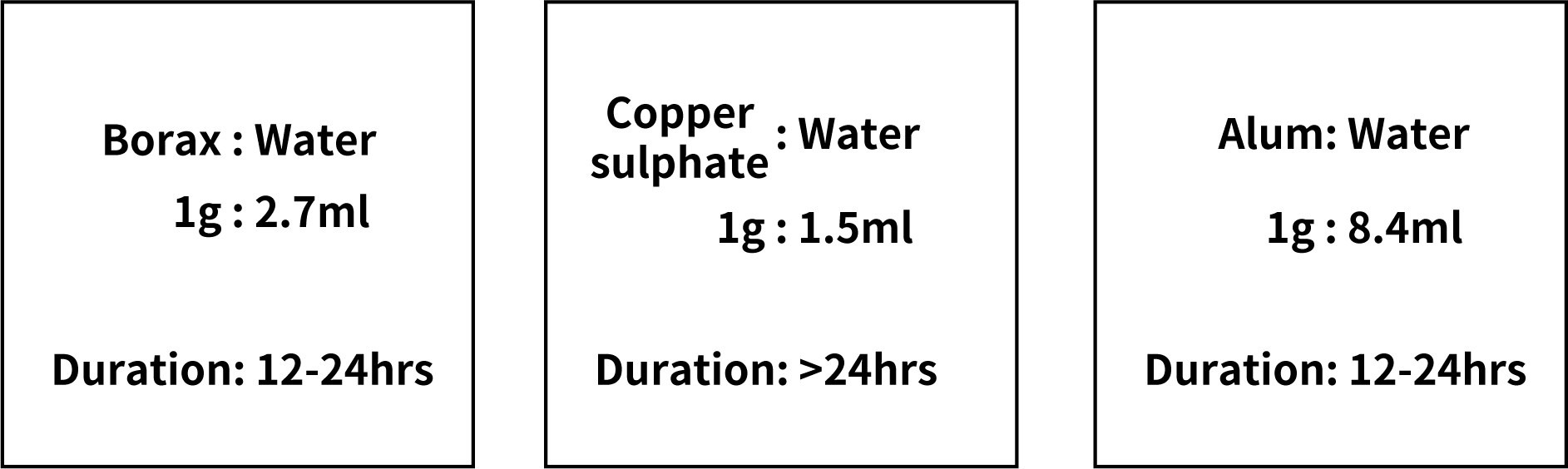

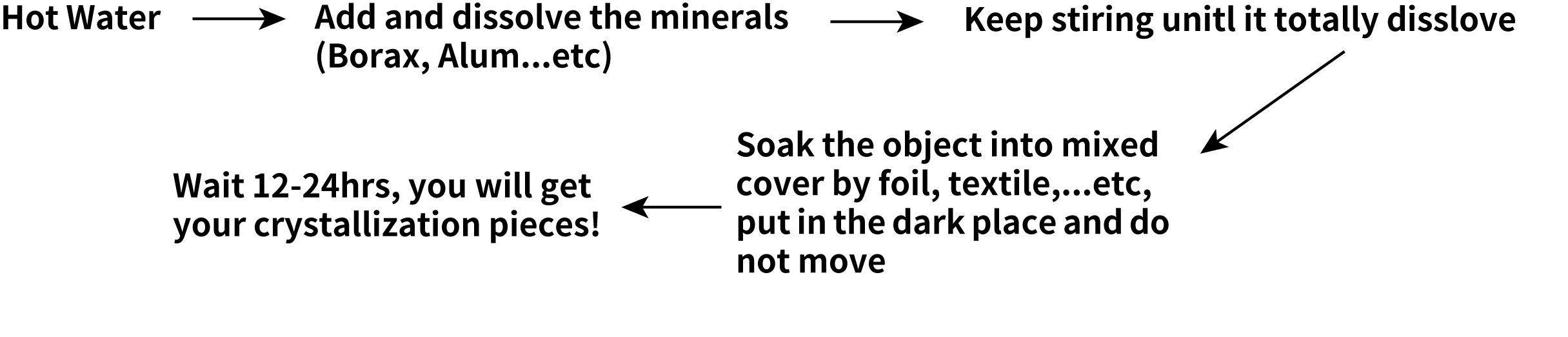

Recipe¶

Here are three main recipe for the crystallization, based on the recipe you can explore the interaction between objects and crystallization.

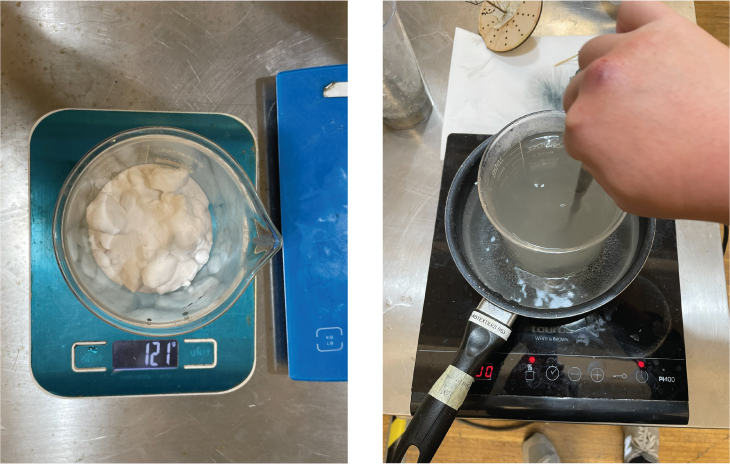

Process¶

Things I want to experiment with¶

-

In natural substances with a certain structure, such as tree branches, the goal is to have crystallization in the emptiness of the branches structure.

-

Utilizing laser-cut waste leather edges for crystallization.

Borax Prepare how water and add borax in Keep stiring.

Use the lascer cut piece to hold the object you would like to work, try do not attach the glass to avoid the crystallization failed.

Alum

Same process as borax.

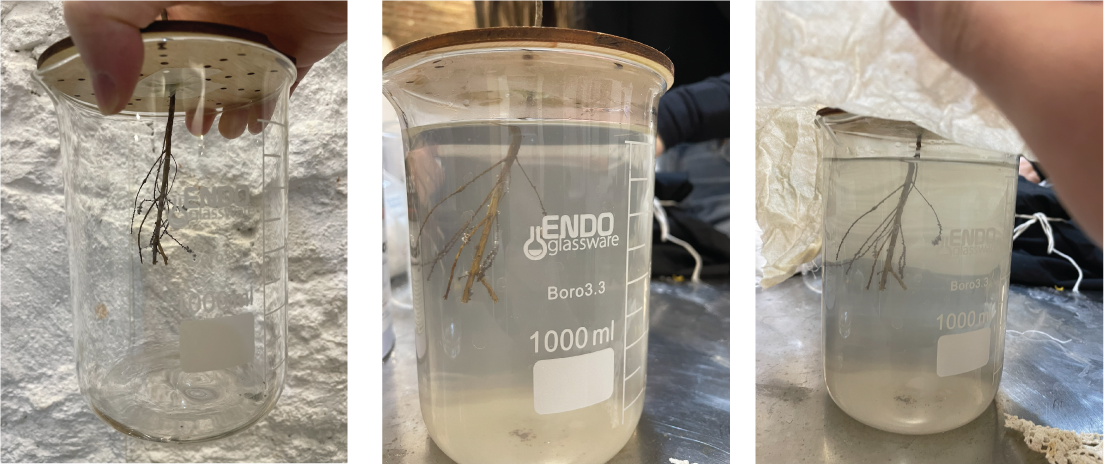

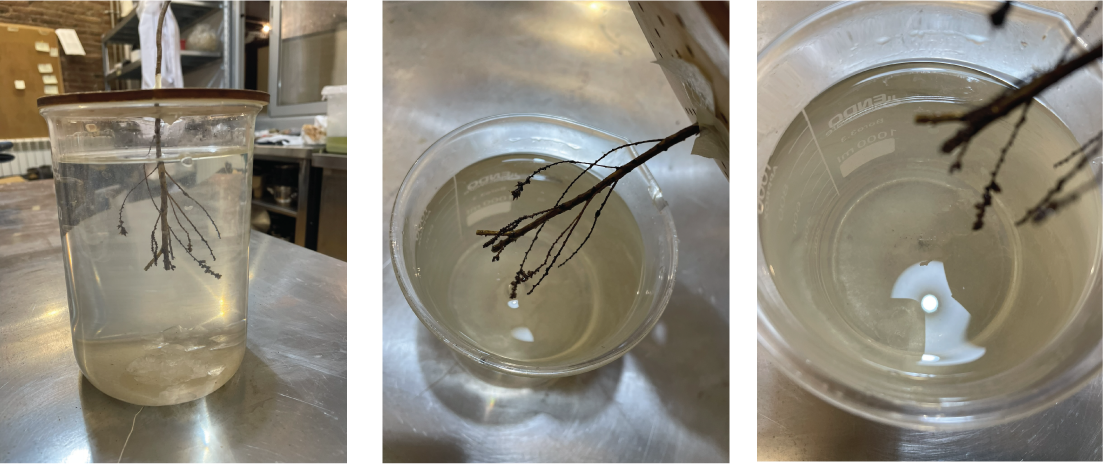

Outcome

Borax

There are way more crystallizaion than I thought! its almost cover whole the part which I soaking in, but I enjoy the color that leather gives.

Alum

It's quite pity that it didn't crystazllization on the branches, only some crystallization occurred at the bottom of the glass.

Leather Moulding¶

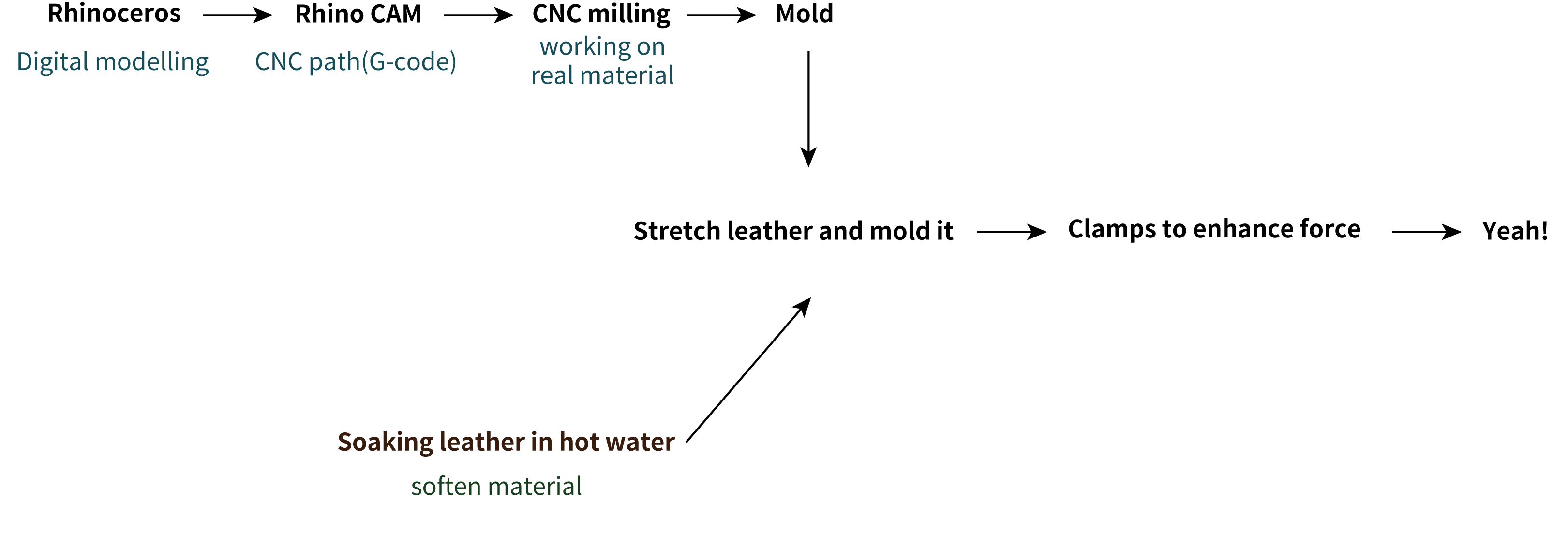

Workflow

Mold making¶

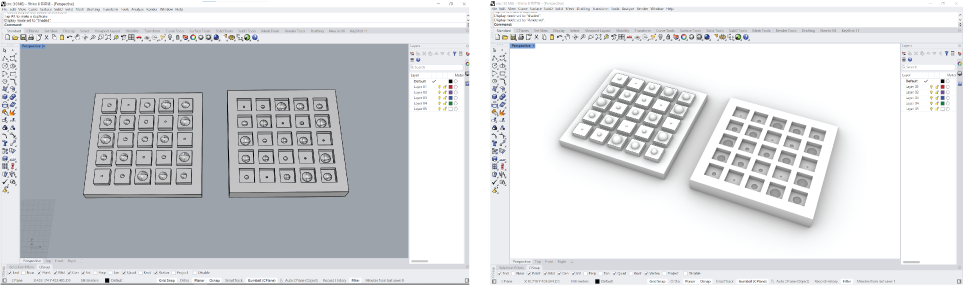

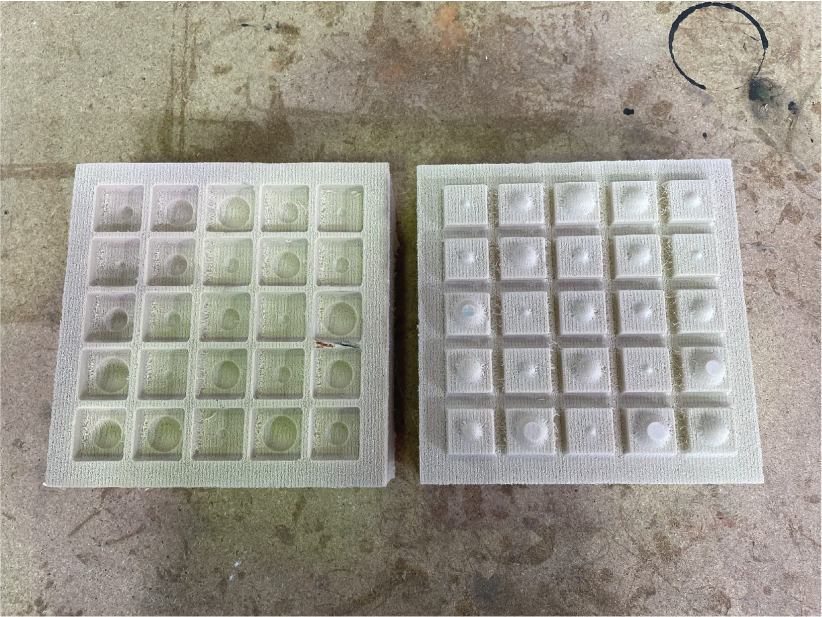

Digital modelling in Rhino

The idea is to creating the mold which link to the key words: modular, tile like.

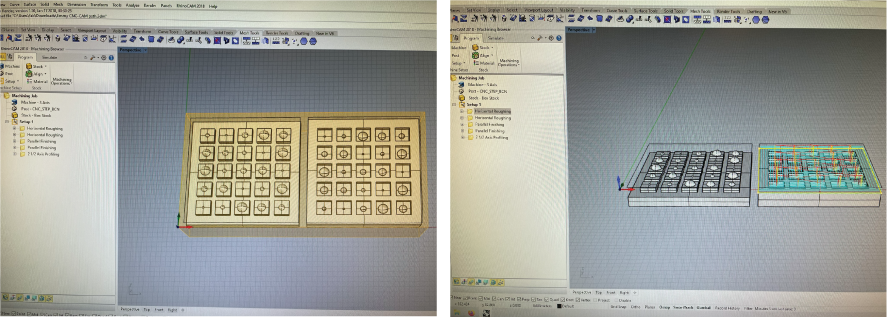

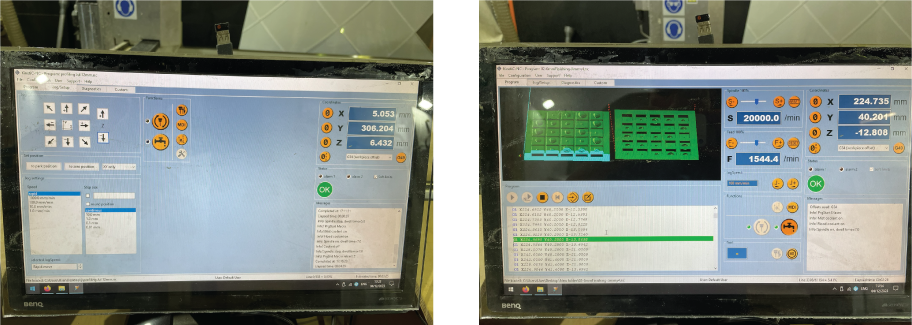

Rhino CAM Settings

The three main concepts to working with Rhino CAM is: 1. Roughing, to get roughly outframe of mold. 2. Finishing, to refine the surface of mold. 3. Profiling, to cut outframe of mold.

Depending on whcih step you are working, remember set up the right size spindle with related parameter to generate cnc path, in order to get nice mold.

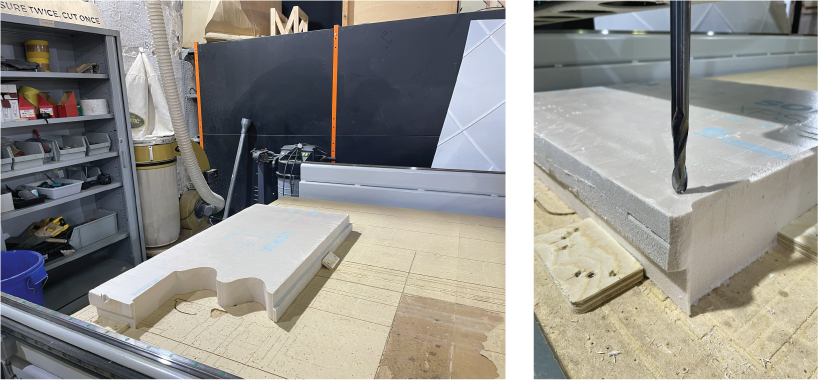

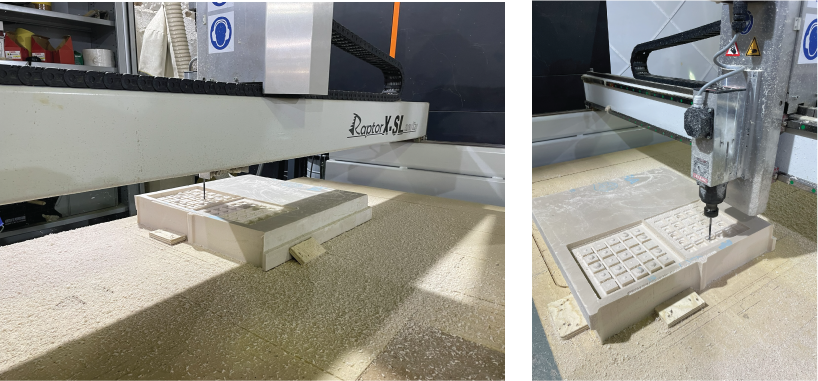

CNC Milling

Clamp all the 4 sides of material before milling, change the size of right spindle depending on the cnc file which you are going to work and setting up the cnc origin.

Milling Process

During the cnc milling process, remember to wear proper protection such as goggles, ear muffs.

Final Mold

Leather preparation¶

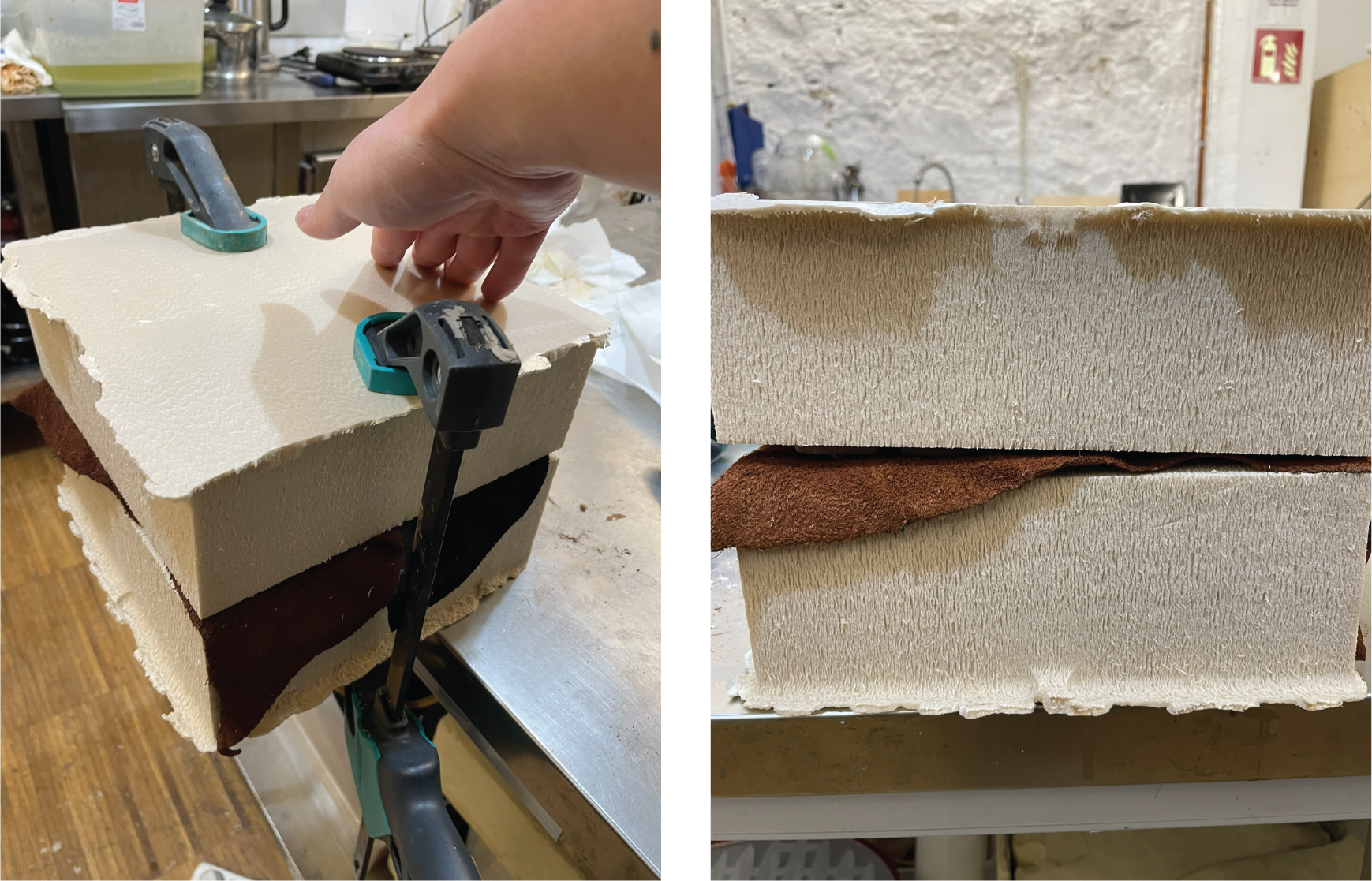

I found out there are a lot of cutout leather in the material box, so I came out an idea: why not to use these leather leftover to create the leather for molding? So I strat to do some patchwork of leathers.

In order to soften the leather, leather has to soaking in the hot water for at least 1 hour, after leather become soft, squeeze the leather to let the water out then stretch it place into mold, use the clamps to give as much force as you can(but of course do not destroy the mold), leave it for at least 24 hours.

Outcome

Things to improve:

- Try to use the leather which has closed elasticity.

- Perhaps can try doing patchwork during the molding process.

fabric formwork¶

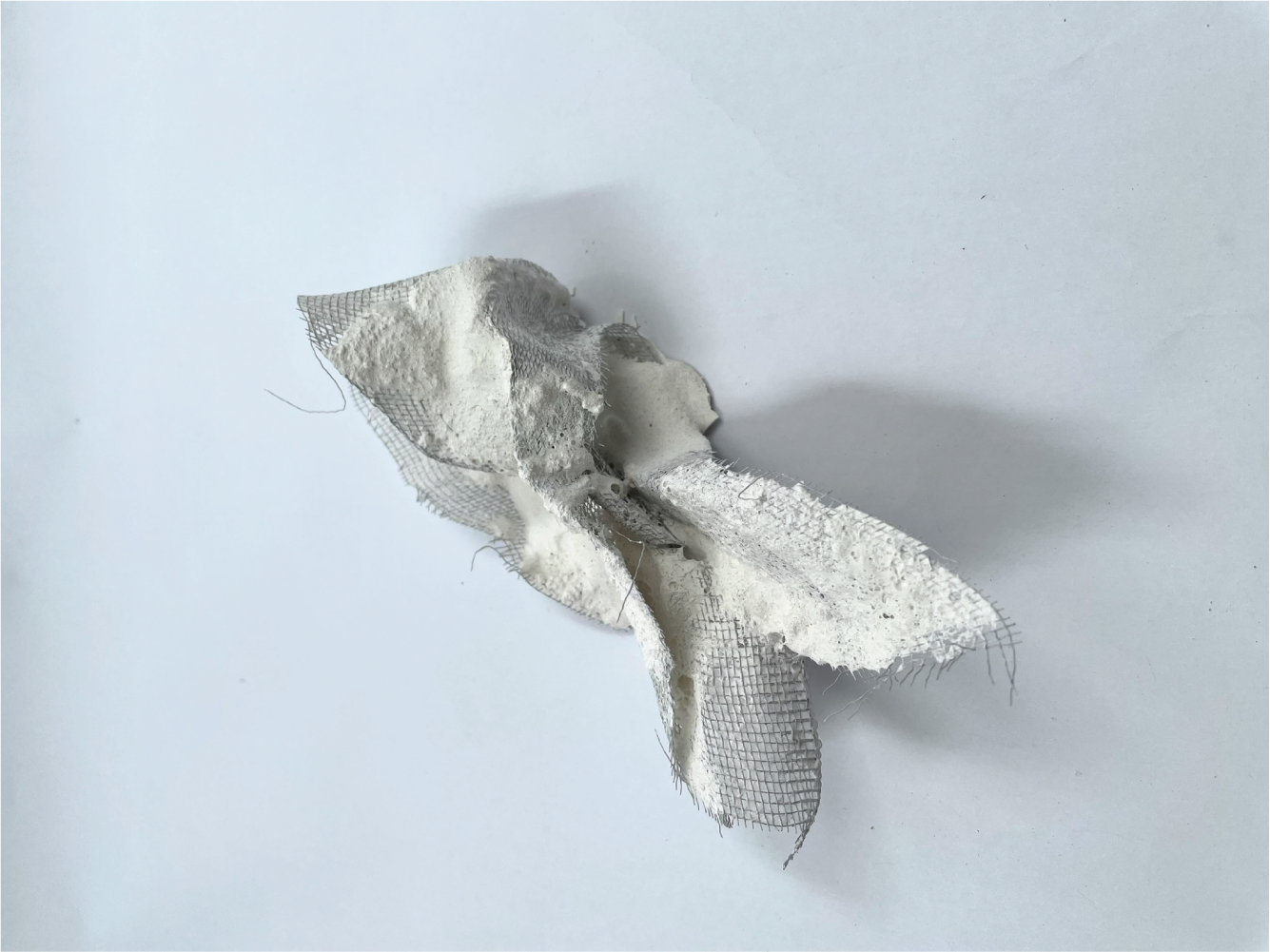

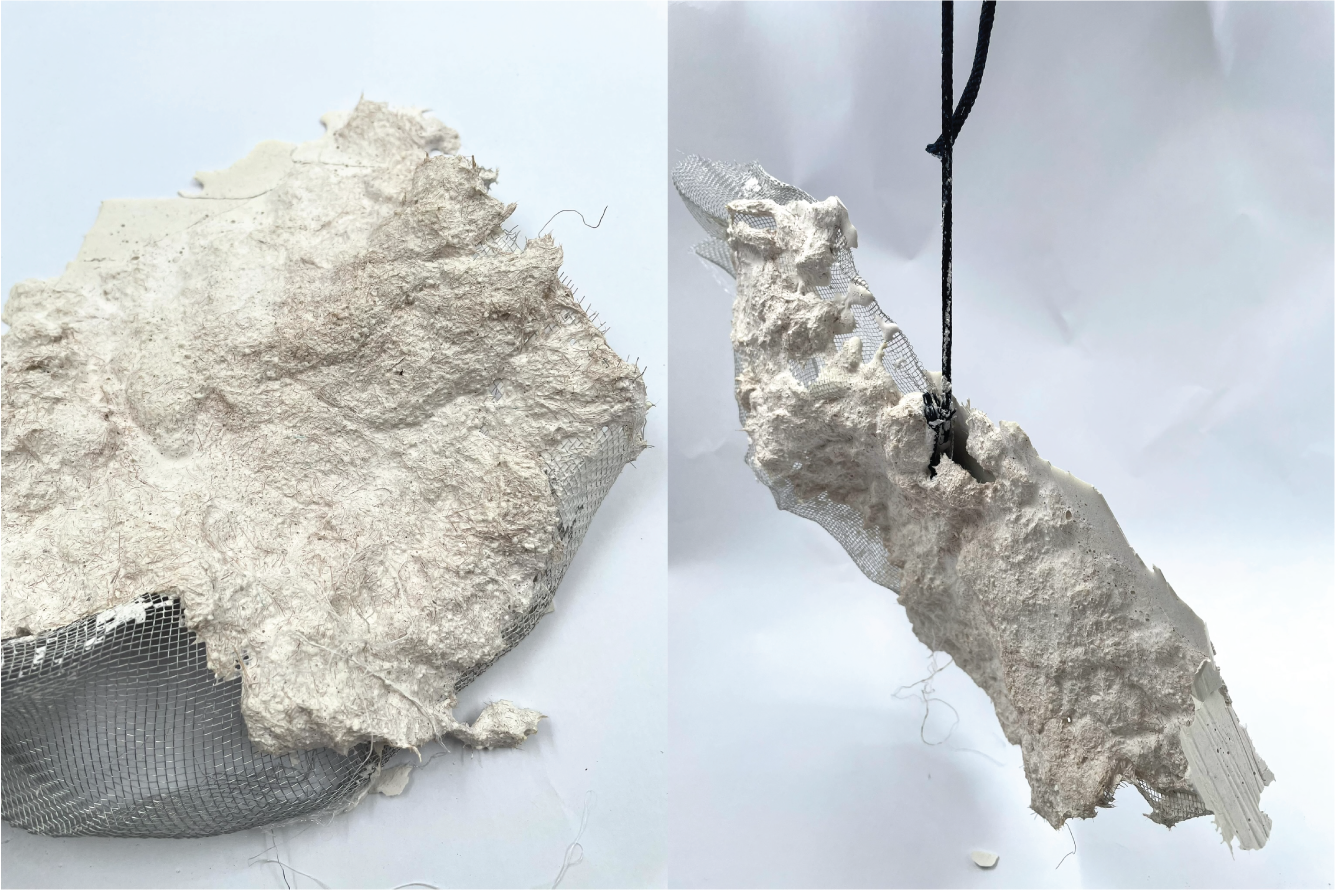

fabric formwork is an idea which use plaster, cement or calcium carbonate...etc, to solidifed the form and shape which textile created.

Not only calcium carbonate, we also mixed some jute into calcium carbonate, to get kind of composite which could be interesting.

Apply the material on the form you create, you can directly saoking structure into calcium carbonate liquid or use brush.

Outcome