6. BioFabricating Materials¶

INSPIRATION¶

Cynthia Nudel was my main inspiration for this week; I follow her on instagram since last year. I like how she tries to find sustainable alternatives in different disciplines, such as bioceramics and biotextiles.

CRAFTING MATERIALS¶

This week was both an inspiring and also frustrating week because a lot of my experiments for crafting biomaterials didn’t give the results I was expecting.

ALGINATE RECIPES¶

I started this week assignment by crafting some biomaterials with ALGINATE RECIPES.

First I wanted to make a sheet of leather with dried tangerine peels I collected over the past year. I used this recipe:

* 2gr of alginate

* 33 ml water

* 5gr of glycerine

* Composite: 2gr of powder of tangerine peel

I mixed everything together and tried to give it some extra net-design by wrapping it in a little net. After 5 minutes I sprayed both sides of the sample with a solution of calcium chloride (10%) and let it rest.

I realized that in the initial recipe they mixed the composite (poudre of tangerine peels) with olive oil, so I did another test with olive oil.

* 2gr of alginate

* 33 ml water

* 5gr of glycerine

* Composite: 2gr of powder of tangerine peel + 2gr of olive oil

After 5 minutes spray both sides of the sample with a solution of calcium chloride (10%) and let it rest. I mixed the tangerine powder with the olive oil before adding to the rest of the ingredients. It resulted in granular packages of both ingredients. I added those to the other ingredients of the recipe but it didn’t make a smooth surface as in test 1. I tried to make a flat surface of it but the whole staid granular. It even became worse after 4 days of drying because then it falls apart when you try to pick it up with your fingers.

I think I made a mistake by adding the olive oil separately with the tangerine powder, so I should do the test again by mixing all the ingredients together at the same time.

I tried another alginate recipe to get a flexible bio-plastic.

* 12gr of alginate

* 200 ml of water

* 20gr of glycerine

* 10g of olive oil

I casted the mixture in a sheet of a 5 mm and for the fun I added some dried coffee debris on top. I hydrated the two surfaces of the sheet after a while with the calcium chloride solution. It looked like a tiramisu 😉

After 4 days the sheet has shrinked but is still not completely dry. It feels flexible and strong at the same time.

I was a little disappointed that after the weekend the sheet was still not dry because I had planned to make some engraving tests on it with the lasercutter. I will wait till it is completely dry.

GELATINE RECIPES¶

For the next batch of tests for crafting materials I used GELATINE RECIPES. I made some bioresin tests with the following recipe:

* 16gr of gelatine powder

* 80 ml of water

* 2,5gr of glycerine

* Some drops of essential oil tea tree + composites

1. Casting inside embroidery loops¶

I made different tests with embroidery loops where a plastic foil was functioning as the removable base of the circular mould.

I casted the mixture in the embroidery loop with removable base, added some fillers such as grounded egg shells, grape pomace, coffe debris. After 1 hour I opened carefully the loop to remove the plastic foil. I then let it dry vertically for a few days.

After 3 days the resins in the embroidery loops where completely dry. I openend the loop and cut them out of the circular loops. I liked the poetic aspect of the bioresins in the hanging embroidery loops. Once the bioresin is cut out the embroidery loop, it feels like a flexible sheet that can be bend carefully.

Because I used the loops to cast the biomaterial and let them dry inside, there was no deformation of the material. Without using a loop there was deformation.

I would like to do further tests with engraving on the bioresins and sewing them with the sewing machine.

2. Pleating biomaterials¶

I wanted to have a pleating effect with a transparant bioresin. So I casted bioresin in a folding paper mould. This was not working because the paper absorbed a lot of the resin and just left a sticky mass in the valleys of the folding.

On Monday Dewi Brunet came by at our fablab. He has a lot of origami-experience with paper, textile and biomaterials. He took his mold with him to easily pleat paper and so he used it on one of the bioresin materials Stephanie made for this week assignement.

And this was the eindresult of his work:

3.Bioresins with debris of pomace grape and tangerine peels¶

I did another batch of tests with gelatin bioresins, this time with using grounded debris of pomace grape and tangerine peels.

I used the recipe alumni (and our fablab manager) Valentine Fruchart worked with:

* 40gr of gelatine

* 200 ml of water

* 7gr of glycerine

* 20gr of grape pomace + some drops of essential oil Tea tree

I casted the mixture in a mold and after 1 hour I took the sheet out of the mold to let it dry horizontally on a surface with enough aeration.

I made 2 sheets with grape pomace as a filler, one of 5mm thickness and one of 1 cm thickness. And I made one with tangerine peels as a filler.

I was really enthousiast about the results a few hours after demoulding the sheets because the texture looked great and so I planned to make a little bag of it.

Unfortunately after the weekend the tree sheets were wasted because of growning fungus. Probably because central heating was not working during the weekend in our fablab.

So on Monday, when central heating was working, I made other tests with again grape pomace and tangerine peels.

This time I added some drops of Cosgard instead of some drops of Teatree essential oil.

* 40gr of gelatine

* 200 ml of water

* 7gr of glycerine

* 20gr of grape pomace + some drops of Cosgard

After taking out the sheet of grape pomace of his mold, I tried to fasten the drying process by put in the oven and warming it at very low tempature. I thought it was like 40 degrees but I am not sure because the oven has no correct tempature indicator below 90 degrees. So the sheet starting melting in the oven.

I decided to melt the sheet again by cooking it so that I could cast it again. This time I left the sheet near the central heating to dry. I put the sheet of tangerine peels also near the central heating.

This second try was a lucky one because those biomaterials dried without getting fungus on it!

AGAR-AGAR RECIPE¶

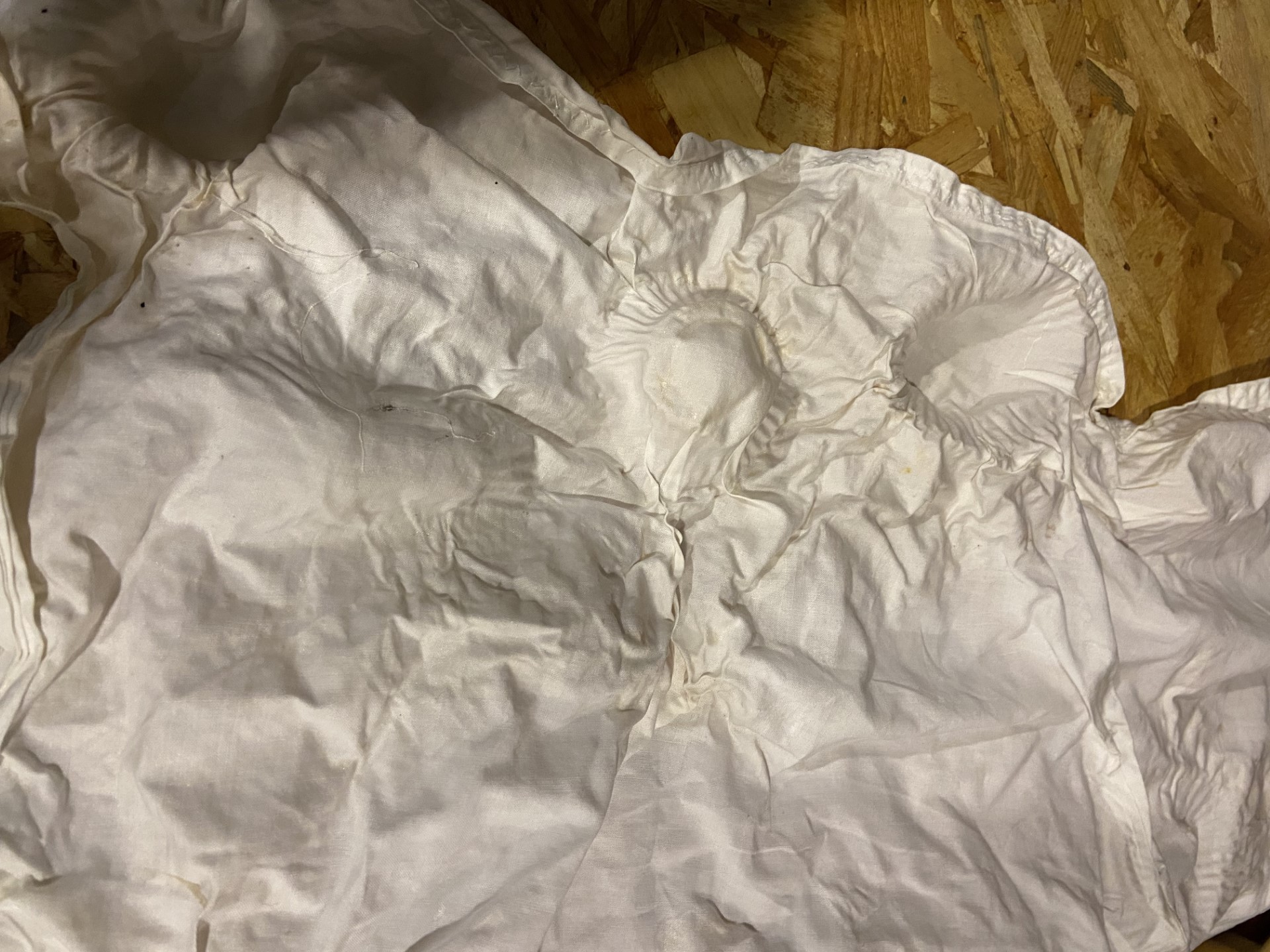

During the weekend I tried an AGAR-AGAR RECIPE to make a flexible composite of agar-agar that can be used to mould textile.

* 5gr of agar-agar

* 250 ml of water

* 15gr of glycerine

* A piece of textile + 3D mold

I let it dry for 12hours. The result wasn't really satisfying because at some places the textile took the shape of the cupcake-molds I used but the shapes didn’t remain very well. The textile felt stiffer where I casted the mixture.

The leftover of the agar-agar composite felt like rubber so I decide to use it as a Gelliplate. My children made some nice prints with it on paper.

GROWING MATERIALS¶

On Monday we received a scoby of kombucha. We devided it in two parts so we could try two differents recipes, one with beer and one with tea to make kombucha grow.

* 500 ml beer

* 500 ml water

* 100 gr sugar

* scoby

* 3 teabags

* 1000 ml water

* 100 gr sugar

* vinegar (for pH adjustements)

* scoby

Now we have to wait until the kombucha grows.

BLOB¶

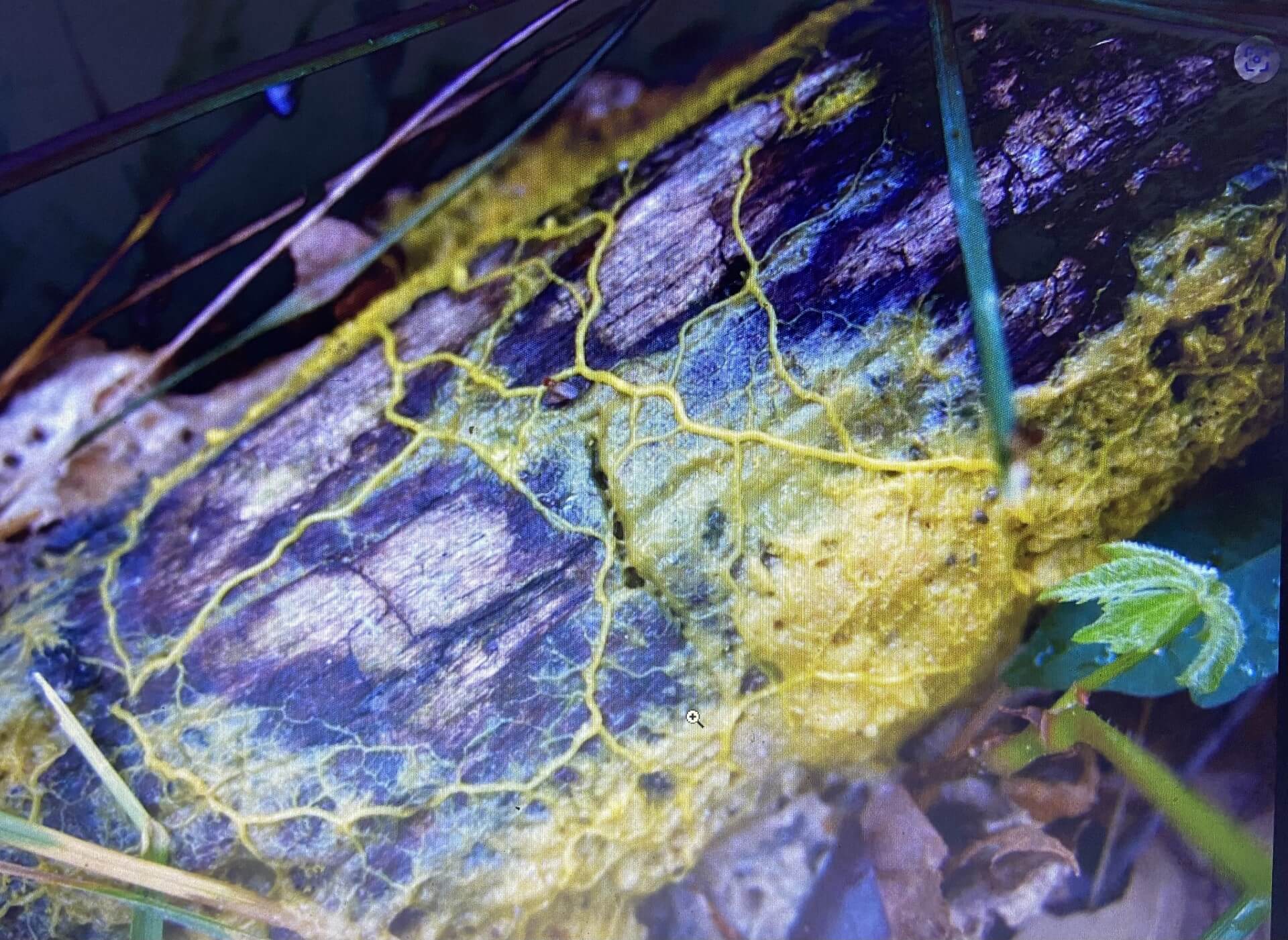

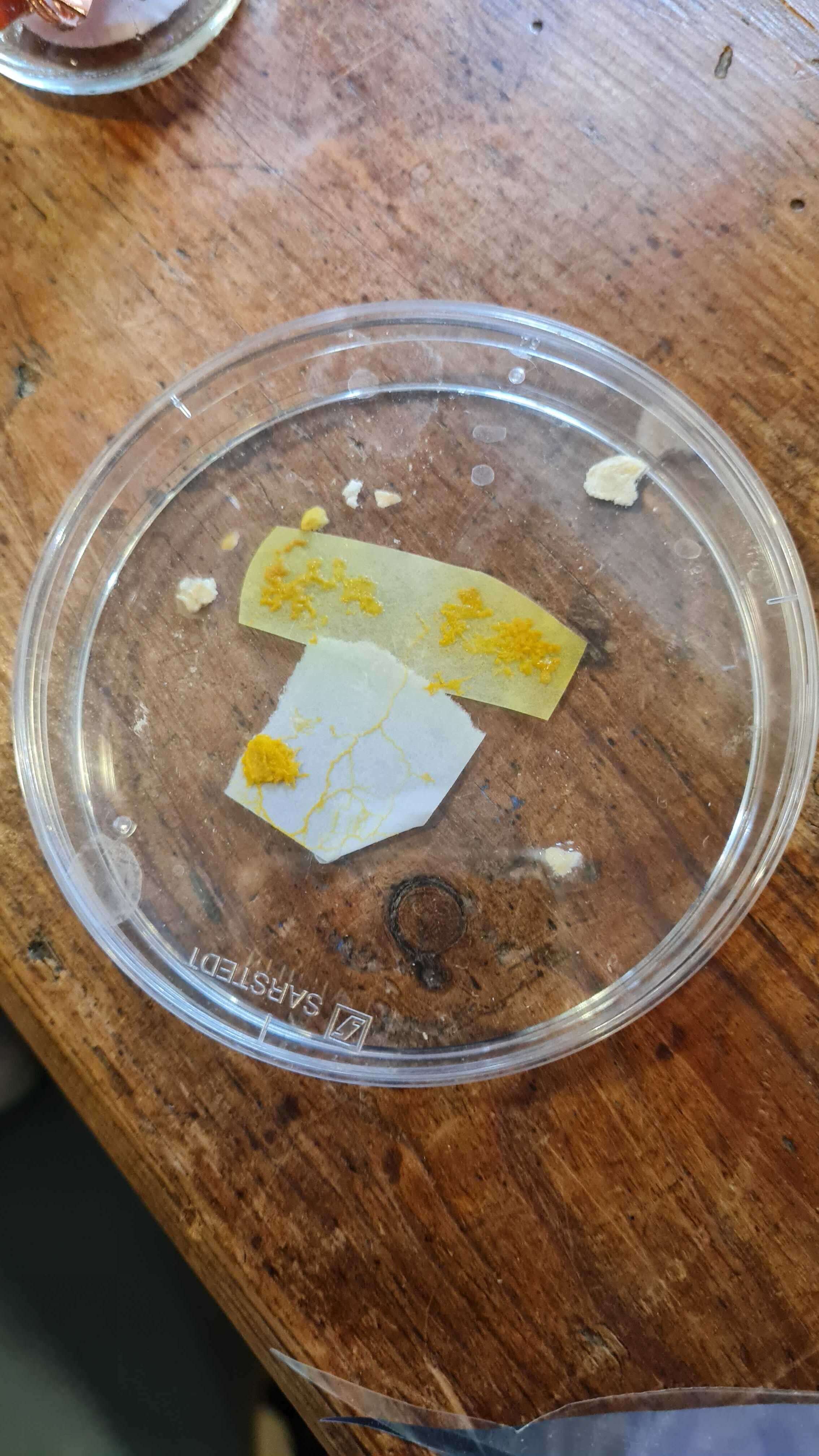

We also received a blob, a protist (not an animal, plant or fungus) on Monday.

For the moment it is sleeping, but we will make it more awake by giving it oats to eat.

The French biologist and researcher Audrey Dussutour made tutorials how to cultivate blobs.

I think it is really excited to do some further exploration with it on textile/biomaterials because in nature it can make very nice tentacles on wood: