Final Project8¶

WEEK 8: From February 27 - March 5

Project Costing¶

To develop a product, in which I intend to make it available to a majority of people, either to download and print it on your own, either to donate or to put it on sale, it is important to consider and know in advance its total cost.

My intention is to create design variants for two technologies. For 3D printing with TPU filaments and for laser cutting using cardboard as raw material.

3D Printing¶

How much does 3D printing cost?

List of costs to consider:

-

Cost of the operator: Its function: Preparing the print, choosing the right laminate, which is done with slicing software such as Cura, Slic3r or Simplify3D, is the basis for the piece to be the most resistant and with the best possible finish. Make sure at the beginning that the printing starts correctly.

-

Amortization cost of the machine: The way to calculate the amortization is to divide the price of the printer by the number of hours we are going to use it until we consider it amortized.

-

Electricity cost: Electricity consumption of printers is one of the cheapest inputs. If you calculate the kWh at €0.15 (which is approximately the cost) and a printer consuming 500W, the price is only 8 euro cents per hour.

-

Cost of 3D printing material: Generally the cost of filament is going to be small, because 3D printed parts are practically hollow and because bobbins are not expensive. But if we use premium or special materials, or when we use large nozzles and a lot of filling, the cost will be much higher. A formula to calculate the cost of the material is that after the piece is printed, we weigh it and the result in grams we divide it by the 1000 grams that weighs the kilo that constitutes the total weight of the filament wheel. For example, if the kilo has cost 34 euros and the piece that we have made weighs 200 grams, we divide 1000 by 200 and gives us 5. Therefore the cost of the material that we have printed is 6.8 euros.

-

Cost of failures: Depending on the complexity of the piece and our experience, we must take into account that many times there will be an expense for errors that occur frequently in 3D printing.

Laser Cutting¶

How much does Laser Cutting cost?

-

The main cost of laser cutting is based on the time it takes to cut the parts, and this depends mostly on the area of the engraving, type of cutting material and thickness of the material. Therefore, a per minute charge is calculated for each minute of machine usage while cutting.

-

Some services prefer to charge a price per centimeter of cut instead of per minute of use, this is another way to reflect the laser work in the price of the piece.

There are two ways to use the laser, engraving or cutting. Engraving is more economical because it is faster than cutting. Of course the hardness of the material and the level of details will also influence the total time of the job

Both cost information were extracted from the website bitfab.

Technical tips for printing TPU in 3D printing¶

All metal: An upgraded all-metal extruder can help prevent the filament from bending in the extruder, but if your budget isn't enough, this extruder upgrade from Thingiverse may solve the problem. Some users have even recommended using a straw to keep the filament straight; the key is to keep it from bending. As mentioned earlier, an improved all-metal hotend can make printing with TPU easier, as it eliminates the PTFE tubing that could cause problems with flexible filament. In addition, this type of hotend can reach higher temperatures, which puts a whole range of other materials within your reach.

TPU printing requires a higher printhead temperature than PLA printing. Typically, the temperature for TPU filament is around 220-230 °C, while many users print PLA filament at about 200 °C. You will probably also need to increase the temperature of the heated bed and you will need to use adhesive tape or lacquer for bed adhesion, even if your PLA sticks to the bed unaided.

Speed: Don't exceed 30mm/s and if you want very, very, very precise prints, set it around 5-10 mm/s. 10 mm/s is the one used when your extruder is not specialized. If your extruder jams or generates unpolished, stringy prints, you may need to adjust the retraction to low or even zero. Deactivates the retraction.. You will also need to adjust the distance from the head to the print bed, as TPU filament does not require as much "squashing" as PLA.

The temperature will depend on the range given by the manufacturer, as I have already said, each filament bobbin is different. Recomended: TPU: 250 ºC ±10 ºC and for the hot bed 50 ºC ±10 ºC.

- Test with TPU pending to continue on this way

About cardboard way¶

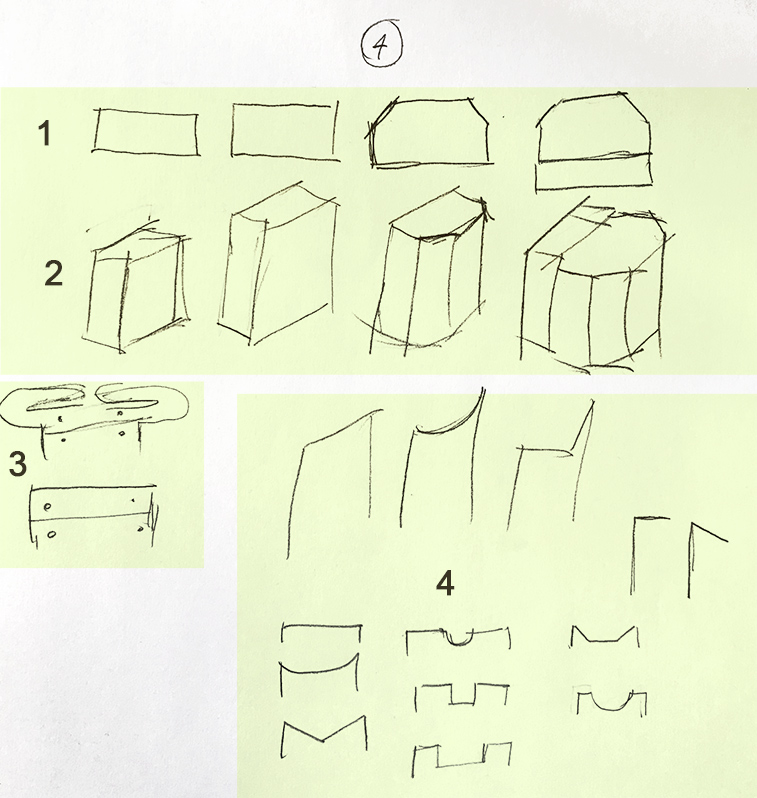

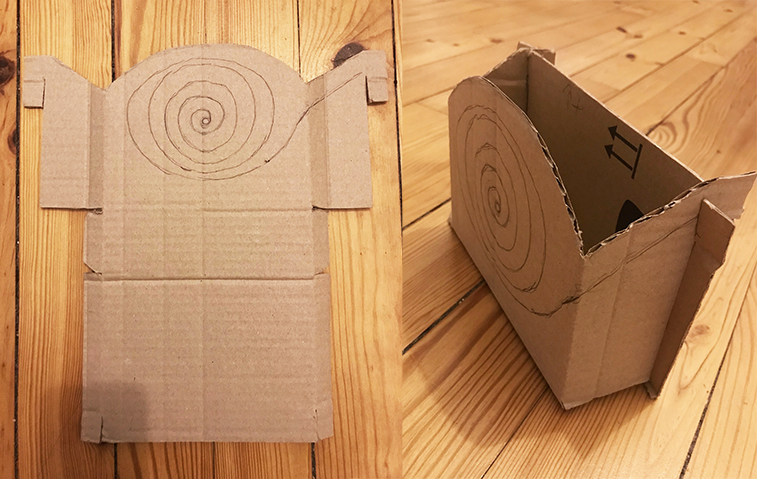

After several tests with the cardboard I have defined up to this point, because I have to close the project, 4 variants of volume. Image 1 and 2:

- The small basic volume

- The medium basic volume

- The larger volume defined by the size of a coffee glass.

- The double compartment volume (medium and larger).

Image 3: It has to do with definitions of grips, one with the cardboard itself, the other with holes to use with extra accessories (under study).

Image 4: Has to do with variants of cuts of the volume for the front of the object, aesthetic variants according to taste and need.

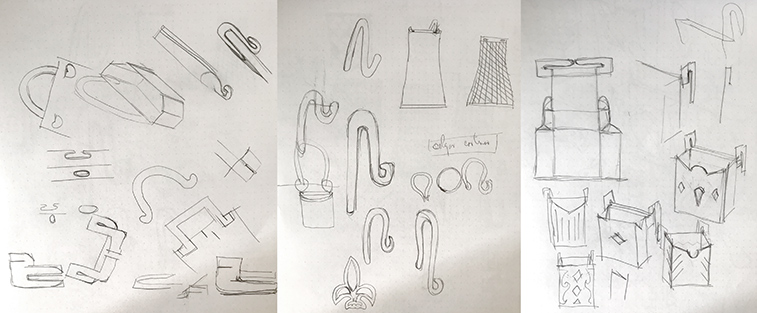

Study of hooks or ways to attach the product to our accessories (both for 3d and laser cutting)

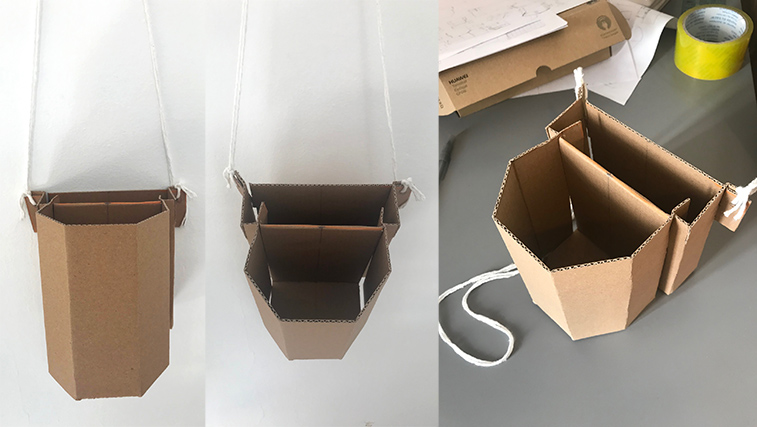

Some of the tests made of the volume and forms of attachment (These cardboard proofs are handmade for now):

I have presented these cardboard tests to my 15 year old son and explained the idea to him, his response has been: Ok that may be, but the question is: who is going to want to wear a cardboard object?

His question-answer made me understand and remember that when we approach a human problem, even if its utility and its social function is the most important thing, the question of our emotions is just as important, it is just as much a necessity. And as I presented at the beginning of the project, Ally pockect aims to empathize with its consumer and not only to facilitate certain actions. We suffer both from practical issues due to the speed and complexity of life today and from a deficit of empathy with the products we consume, mostly industrial. The tendency is to consume and throw away at all levels. So new technologies could be, or already are, another branch of craftsmanship, the craftsmanship of the future.

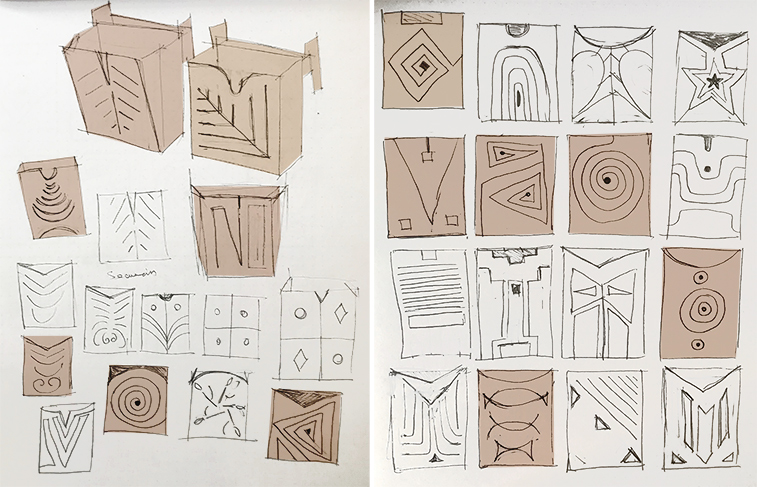

About the aesthetic approaches that I have been thinking about, I started at the beginning looking for specific well defined cultural symbologies, such as a pattern from Algeria or the fleur-de-lis from France. But then I moved on to find a more open symbology or graphic, more abstract, less specific to anyone and more a mixture of all. Where one can find empathies that sometimes you can not understand.

It is important to clarify that even if this product can be open to customization, we must think that many prefer to choose among what exists, and that these products can be donated to institutions, already made. As it could be an institution for the elderly or a hospital.