3. Circular fashion¶

WEEK 3:

The production of surfaces through laser cutting is an old desire. And although each week is just an introduction to a new technology, it is a tool that has earned a place in the future, and one that I hope to develop over time. I am very grateful for the many technological doors that are opening up to us through this FabLab Course!

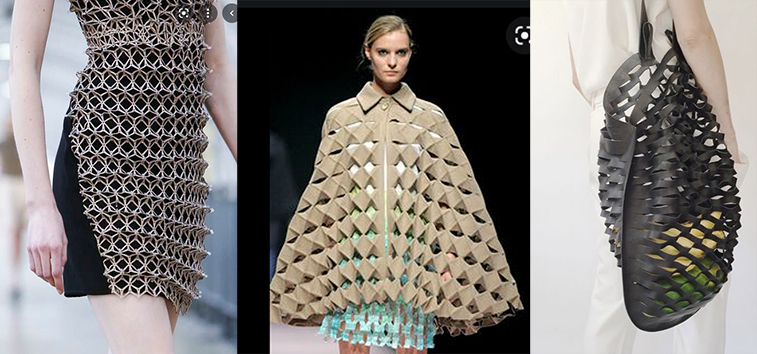

Research¶

We can see many examples online about the infinite potential of laser cutting, where designs that until a few years ago were unthinkable are generated. I also realize that we must take into account what happens to the waste generated by most of these designs! Technology has to go hand in hand with sustainable design!

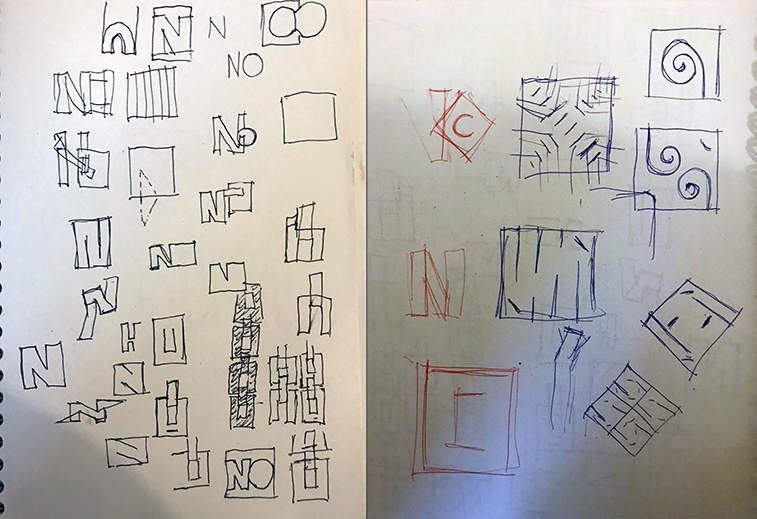

Sketches of my first ideas¶

Test 1

Test 2

Test 3

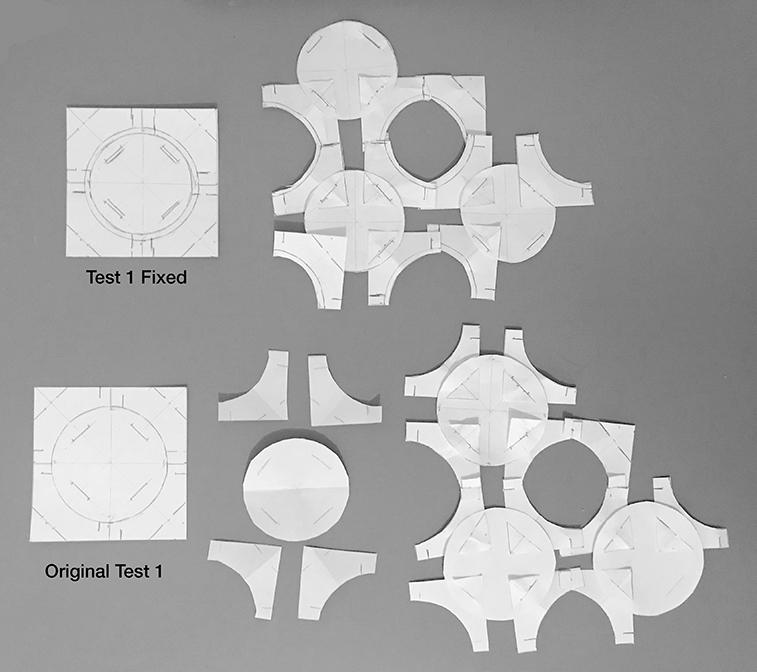

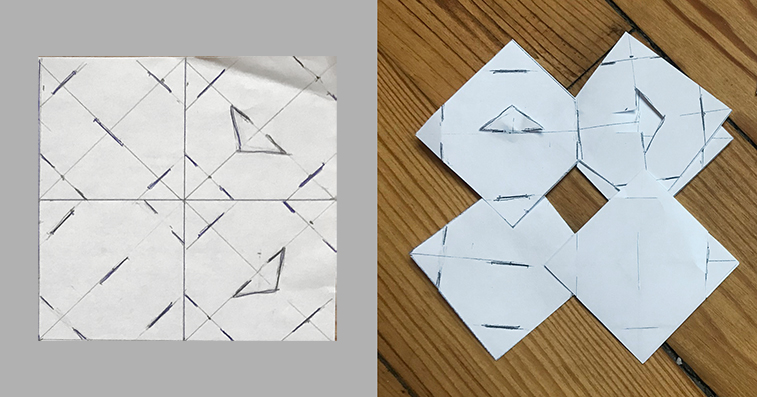

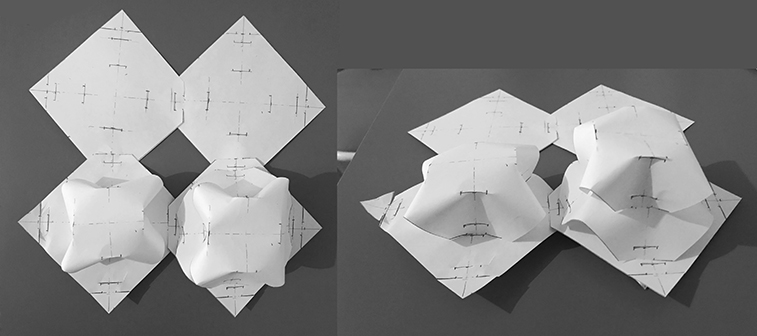

Sketch selected (paper model)¶

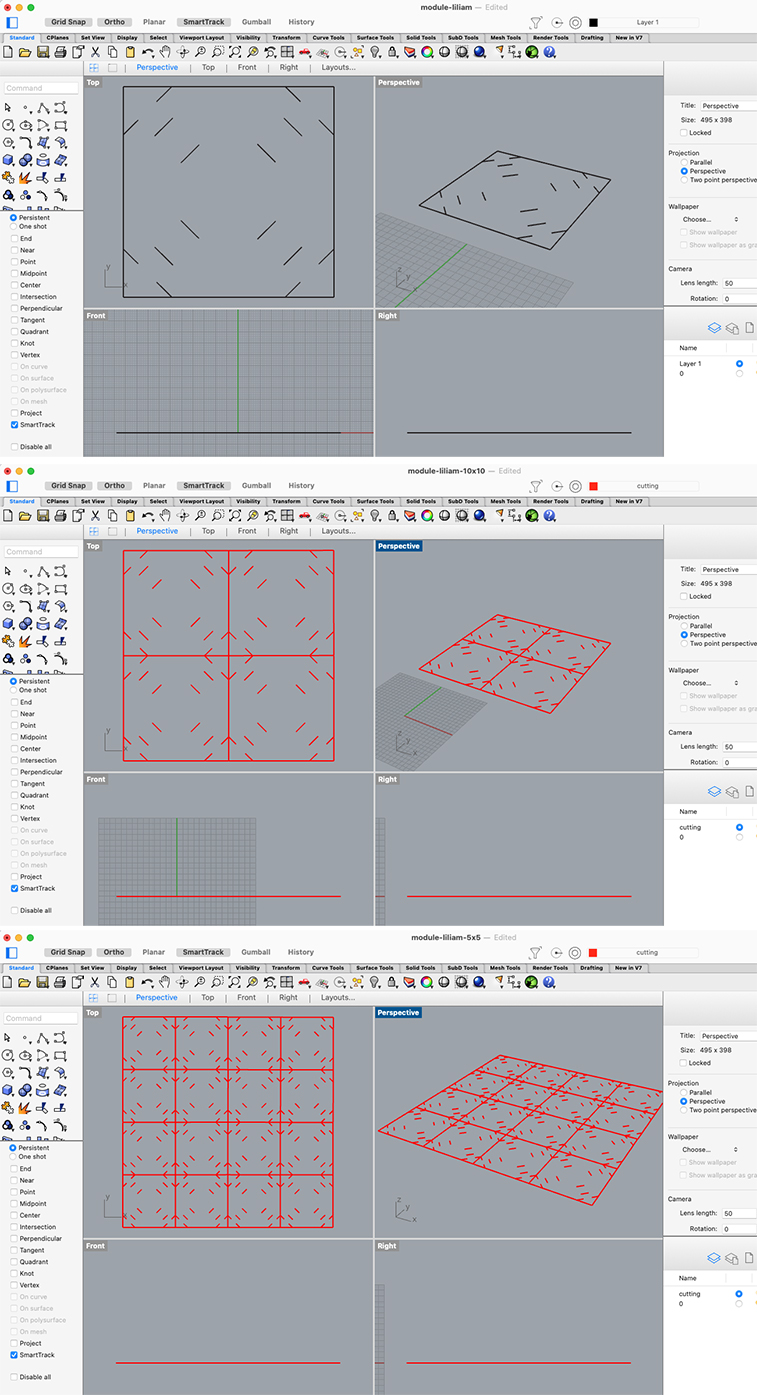

Rhino¶

The sketch was developed in Illustrator, then corrected in Rhino by Diane.

They were made of 10 x 10 cm and 5 x 5 cm. The idea is that it was a square with 0 waste.

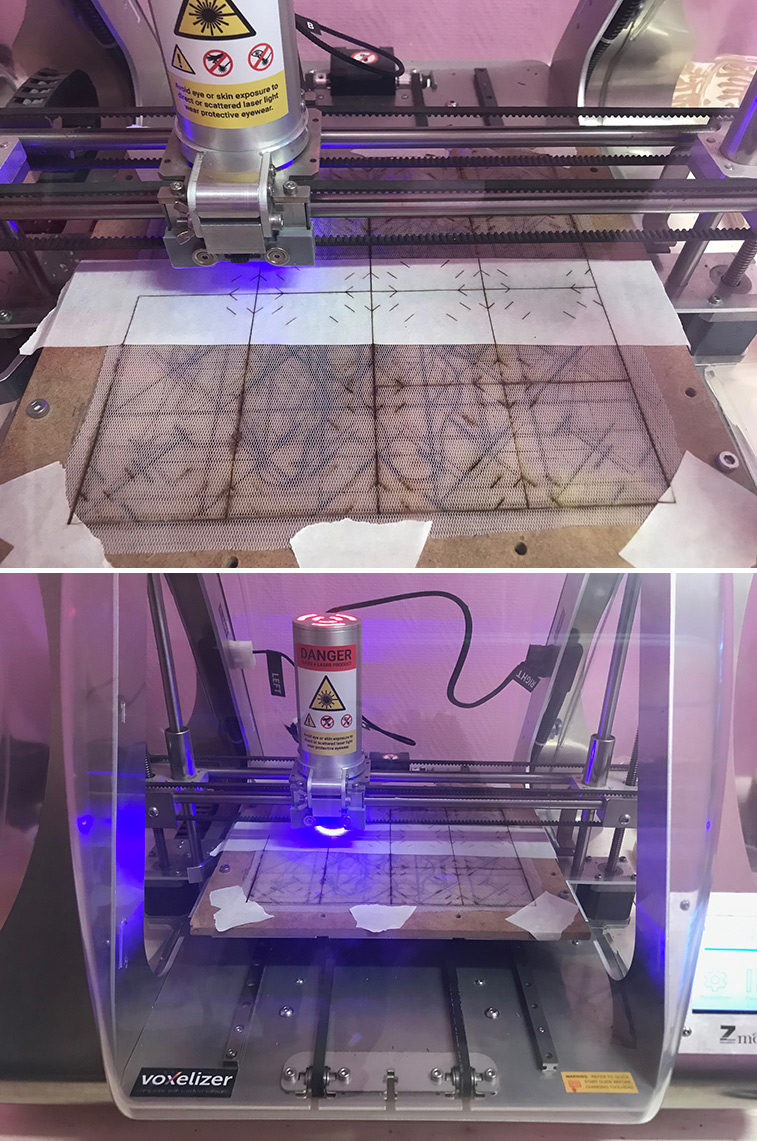

Laser cut Test 1¶

With the smaller one, 5 x 5 cm, a test was cut in tull and it didn't work, the lines and points were too small, they didn't mesh correctly and the laser burned the fabric, although maybe it could be cleaned up later.

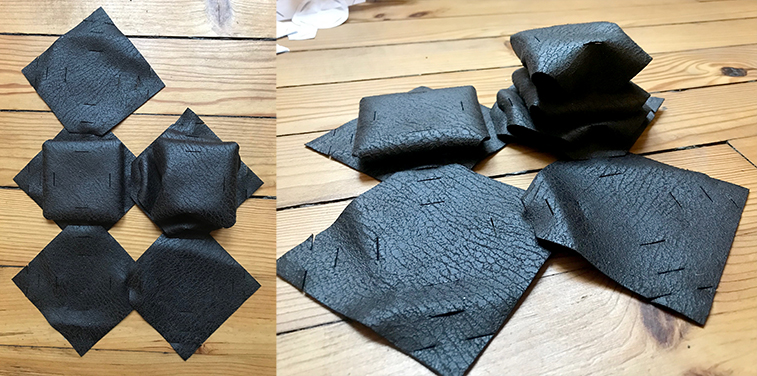

Laser cut Test 2¶

With the larger one, 10 x 10 cm, a test cut was made in a flexible and resistant material (fake leather type) and the cut worked perfectly. Easy to assemble. This model has the possibility to increase in height, so it can be designed with different levels in mind. With this size it could work on various materials. It is not recommended to cut certain types of fake leather, because they can be contaminants at the time of cutting.