6. BioFabricating Materials¶

WEEK 6:

This week has been very experimental and although the results can be counted and concluded only in the next few days, when all the tests are completely ready (dry). Anyway, until today, we have learned a lot about bio materials, or at least in my case I didn't know them at all, and certainly it is an incredible and potentially infinite world.

At the beginning we did some testing between all of us, using the different concoctions prepared by the others, mixing in a more free way, as a first approximation.

In my case, all the concoctions I prepared were basically related to 3 ingredients. Gelatin, Glycerin and water. The higher the amount of glycerin, the more flexible the result, as well as the cooking time. The longer the cooking time, the more rigid the result. Therefore, a preparation with 8 gr of glycerin, which is known as Bio Resin, cooked for up to 10 minutes can result in a very rigid and more fragile material.

Research and Test¶

Bio Resin:, Bio Plastic: and Bio Silicone: use the same ingredients (Gelatin, Glycerin, Water), the difference is in the amount of Glycerine added.

Bio Resin formula:

48 gr of Gelatin

8 gr of Glycerin

240 ml of water

This mixture should be completely dissolved at a temperature of 60 degrees, then let it reach 100 degrees and cook for 5 - 10 minutes. The longer it cooks the harder and more brittle it gets.

Bio Plastic formula:

48 gr of Gelatin

12 gr of Glycerin

240 ml of water

This mixture should be completely dissolved at a temperature of 60 degrees, then let it reach 100 degrees and cook for 5 - 10 minutes. The longer it cooks the harder and more brittle it gets.

Bio Silicone formula:

48 gr of Gelatin

24-48 gr of Glycerin

240 ml of water

This mixture should be completely dissolved at a temperature of 60 degrees, then let it reach 100 degrees and cook for 5 - 10 minutes. Glycerine can be added up to 1:1, that is to say 48 gr of Gelatin and 48 gr of Glycerin. The more Glycerin the more flexible it will be.

The first tests - Bio Resin:¶

Bio Resin formula:

48 gr of Gelatin

8 gr of Glycerin

240 ml of water

In the first 4 tests with Bio Resin, 3 of them had a filler added, but this was put in without a specific amount.

Fillers:

-grated orange peel

-crushed dried nettle leaves

-small crushed eggshells

2 examples of fillings that were prepared, with banana shells and egg shells.

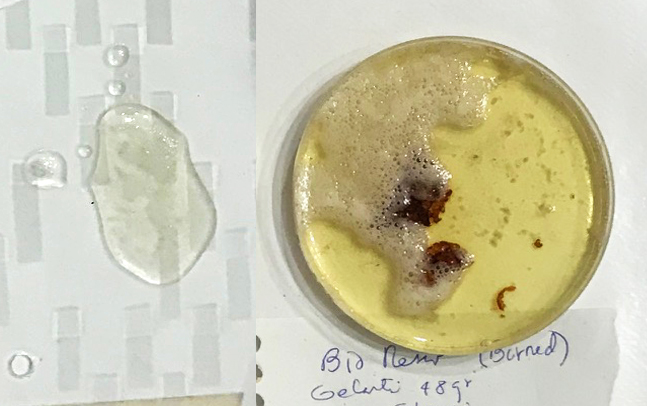

Test 1¶

Bio Resin without any other ingredient, on the left the image of a typical sample, on the right a sample of a first attempt that burned because the pot was too thin to cook at 100 degrees.

Test 2¶

Bio Resin with finely grated orange peel

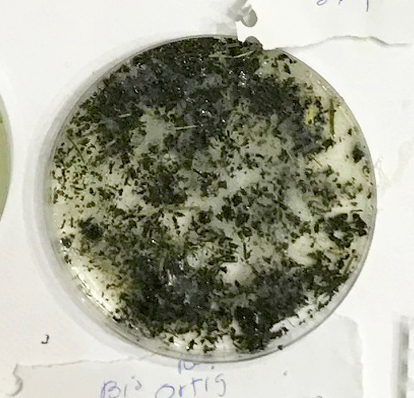

Test 3¶

Bio Resin with crushed dried nettle leaves

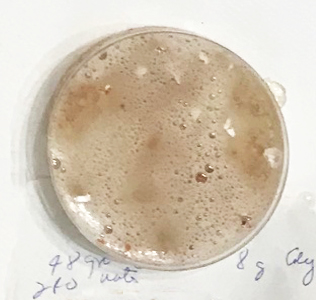

Test 4¶

Bio Resin with small crushed eggshells

The second test - Bio Silicone.¶

Bio Silicone formula:

48 gr of Gelatin

24 gr of Glycerin

240 ml of water

In this test a larger area of approximately 25 cm in diameter was used and within the space different fillers and pigments were placed (no specific amount). There was also a small area with Bio Resin, to test what happened with the union of both, the Bio Resin and the Bio Silicone.

List of the ingredients inside the sample area:

-Bio Resin that had already been poured for approximately 10 minutes.

-Finely ground crystals added by colleague Louise.

-Small crushed eggshell

-Ground coffee

-Dry and fine Madder

-Charcoal pigment (black)

-Blue oxide pigment

-Avocado peel cut in very small pieces

![]()

Result:¶

The bio-silicone has turned out to be flexible but strong.

Analysis¶

What objects are used on the body that are usually made of plastic?

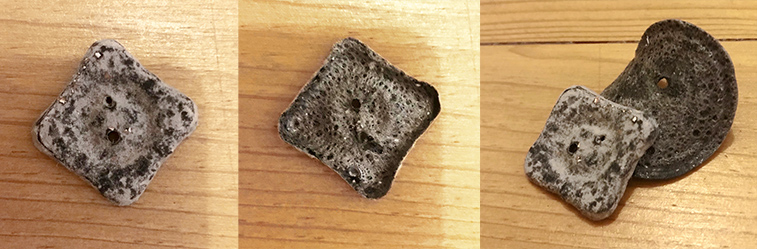

From this I have decided to make a test to mold buttons out of Bio Resin. The Bio Resin formula, among the ones I had made, is the one that allows me to make a harder material, and I have also decided to add as filler, finely crushed eggshell, to give it even more rigidity. These results are still inconclusive because they are not completely dry yet.

An egg carton seemed to me a good shape to use as a mold for the buttons. Internally I have put coconut oil, but when in doubt, except for one, I have put a layer of nylon on each container.

Formula for the buttons¶

48 gr of Gelatin

8 gr of Glycerin

240 ml of water

30 gr of small crushed eggshells

10 gr of Charcoal pigment (black)

The basic formula of the Bio Resin was prepared. Then in a separate container the already cooked formula was mixed with the egg shells and the pigment powder. When the mixture was homogeneous, the molds were filled.

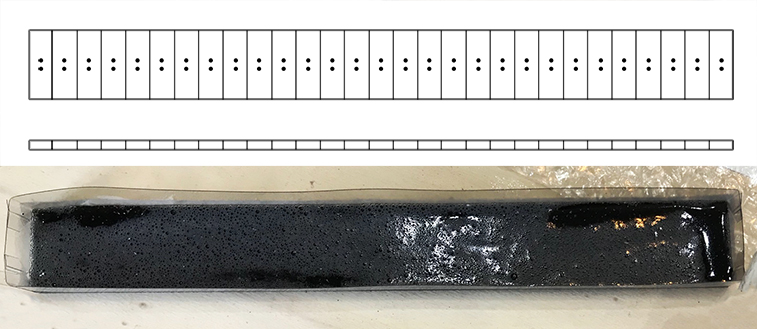

Mold from the egg carton¶

Results:¶

The only test of these buttons that worked, was the one that did not have nylon (first, above right), only the cardboard slightly greased with coconut oil. In the result you can see that some of the cardboard material has stuck. It is quite rigid, although its thickness was greatly reduced.

Mold from 2 milk knob caps¶

Results:¶

This test was also rigid and stronger, but at the beginning it was flat and flexible, when it dried it became hard but curved. The best thing would have been to put a weight on it to keep it flat.

Mold from a candy lid¶

In this case, the mold is a 26 cm long rectangle, for a later test of cutting the buttons using the laser cutter.

Results:¶

It was not possible to cut it with the laser, because when it dried it got too much mold and also deformed, I had to throw it away.