9. Textile as scaffold¶

!!!!! Let's go for Scafoldingo Textile Week !!!!!

Lecture¶

The lecture of this week was really huge, and once again, everything was really new and far away from my professionnal universe. I'm a bit ashamed to tell that, but very honestly, it took me nearly the whole week to understand the concept of textile as a scaffold (crazy me ...!!!), and to begin to imagine concretely what I will do this week. In fact, if I try to summerize, it can be seen as a melt of architecture, artistic performance and experimentation, design projects that have all textile as a starting point. So, as far as I'm concerned, it is the first part of the lecture dedicated to composites that made more sense for me, because it is more about how natural fibers or textile that are used to create everyday life products. I chose to work on denim because I'd love to create a composite with it...as an evidence, I didn' manage to do it this week, but let's go step by step !!!

In the end, I really enjoyed this week since I discovered how to make felt (I really loved it !!!), how to make paper, and take a real time to think about how I could reuse denim : GREAT !!!!!

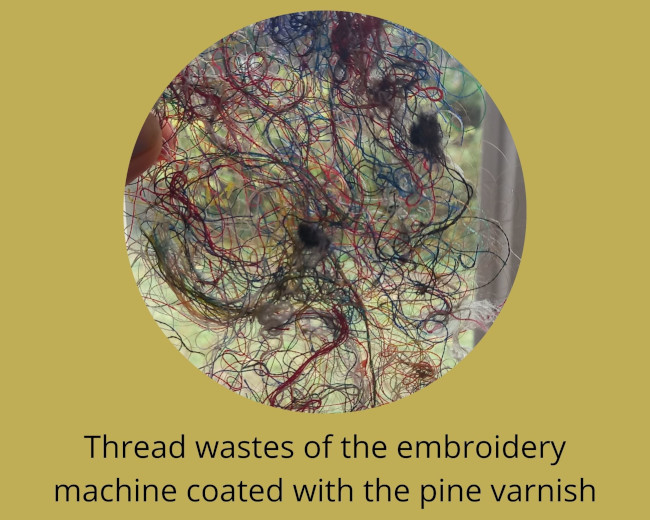

Another good souvenir of this incredible week with Surzhana holding the thread leftovers of the embroidery machine 😁

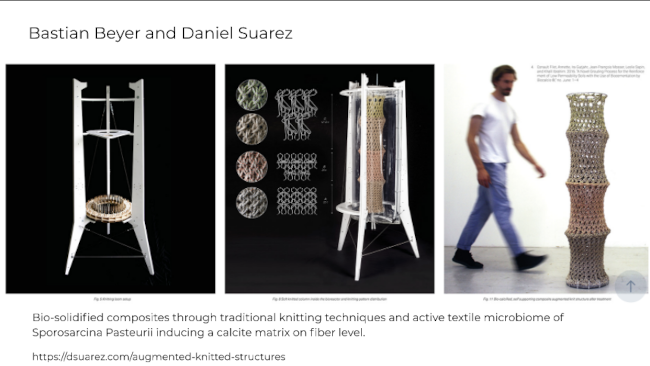

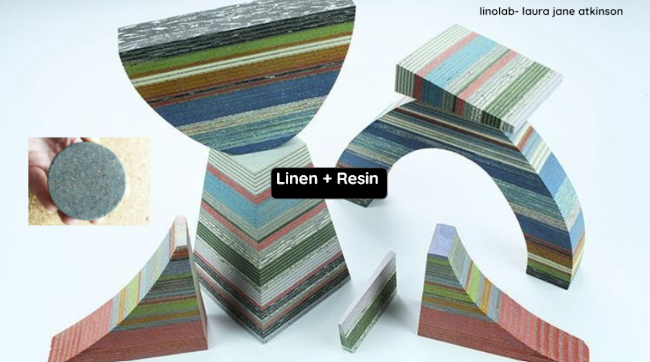

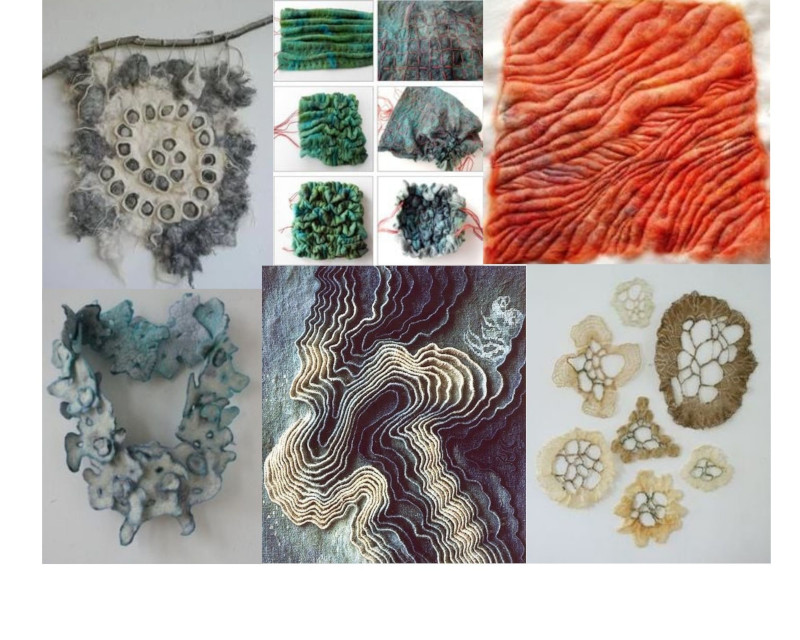

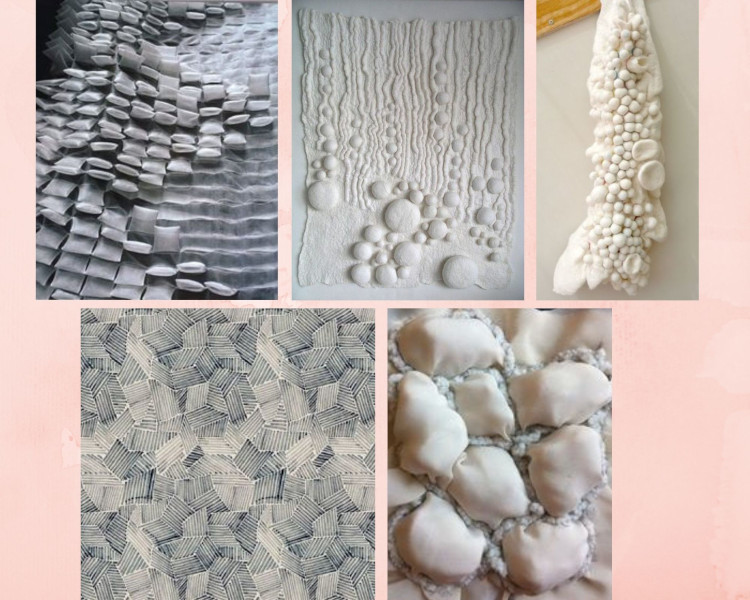

Here are some slides that inspired me :

Inspiration¶

ORGNANICO by Philipp Hainke

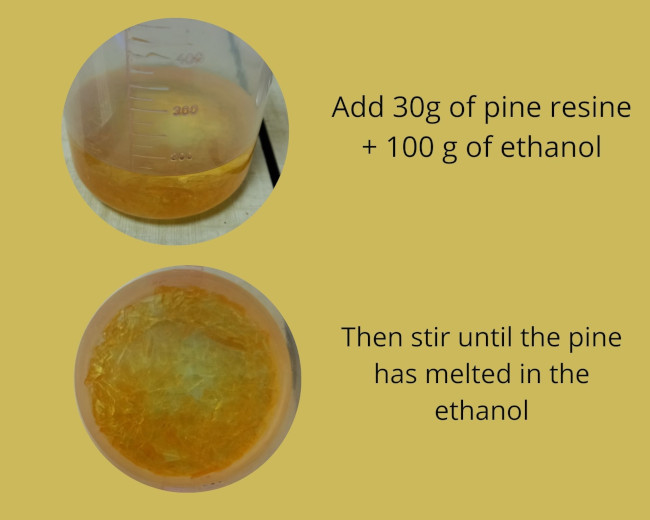

Pine Resine, Collophane¶

We had a really large choice of materials to experiment.

One of them, Collophane, was attracting me, since it reminds me the time when I used to practice ballet !

A quick definition from Wikipedia to understand better what is Collophane :

Rosin, also called colophony or Greek pitch, is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene components. It is semi-transparent and varies in color from yellow to black. At room temperature rosin is brittle, but it melts at stove-top temperature.

Rosin is extensively used for its friction-increasing capacity in several fields, as instance:

- by ballet dancers to reduce slippage, gymnasts, handballers, or rock climbers to improve grip

- Violin rosin can be applied to the bridges in other musical instruments, such as the banjo and banjolele, in order to prevent the bridge from moving during vigorous playing.

With Segolene, we were also attracted by this material since it seems a natural one, harvested from pines. We thought about doing a resine, interested by its transparency which could be interseting with textile.

We found a recipe that melted this resine with Ethanol, which in fact was a varnish recipe

Paper of textile wastes¶

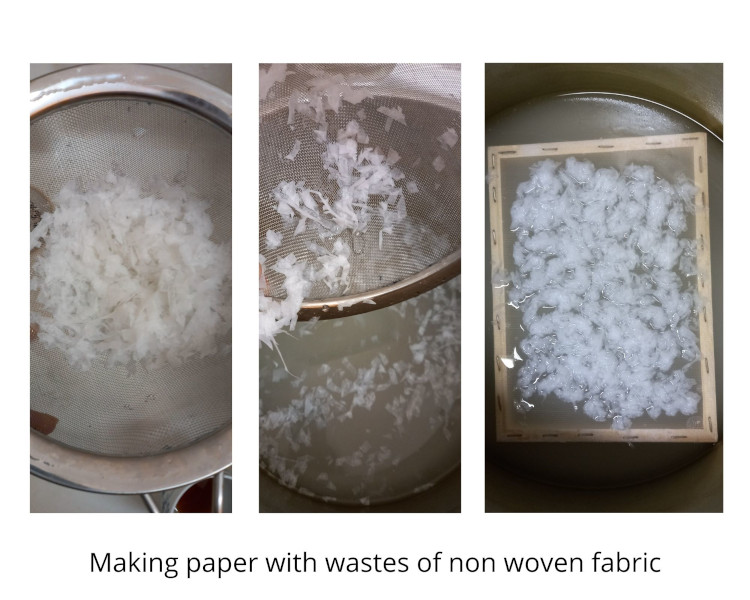

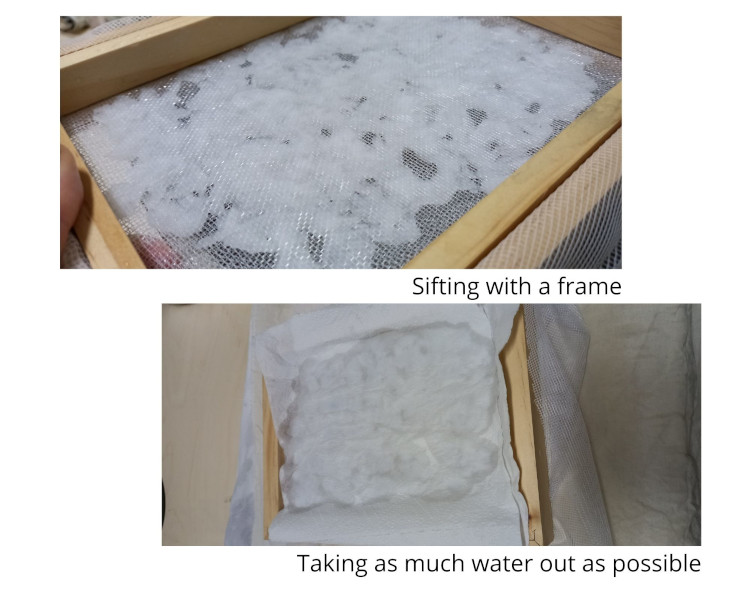

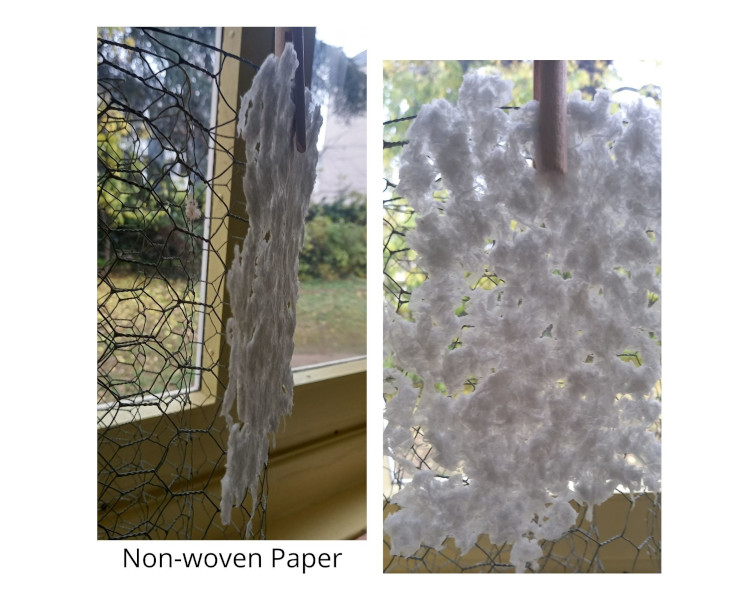

Non-woven Vliseline¶

We wanted to try to make something of this wastes from the embroidery machine, a kind of non woven vliseline. This one is not glue coated. It looks like a thick and untearable paper.

- put it in water during a night and a day. Apparently, the time of the bath doesn't change much the result, since it didn't dissolve into water.

- prepare a second bath with a spoon of glue for wallpaper

- put the paper in it and wait again a couple of hours.

- then mix it.

Denim Wastes¶

One of my idea for this week was to focus on Denim wastes. I love this fabric, but we all know that it is an ecological disaster, in particular if you consider its dying process. And we have a huge amount to deal with, so it's qite an obsession to find a way to re-use it, as much as possible.

So for this week, I thought about making paper with it.

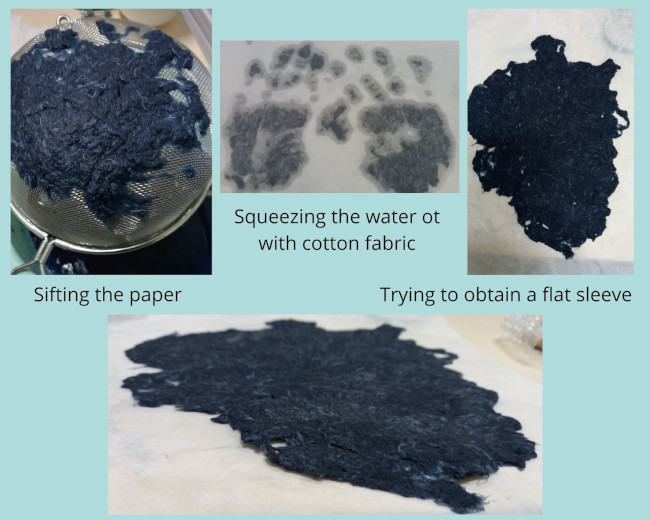

Here is the process I tried, step by step, for a 35g quantity of denim :

- Cut it in little pieces (as small as I could)

- Put it in a bath of 1 liter water, and wait for a couple of hours

- Prepare another bath with water and a spoon of wall-paper glue

- Take the denim out of the first bath and put it in the second

- Mix the Denim in a blender

First observations so far :

-

the denim was quite hard to mix, the fibers twisted around the screw propeller

-

35g of denim made an enormous quantity of fabric once mixed compared to the quantity of water. So I decided to take away half of this quantity, pressed it to squeeze the water out, and placed it all night long behind to pieces of wood, under a huge and heavy paint can. I'll explain what I did with it in the felt section !!

-

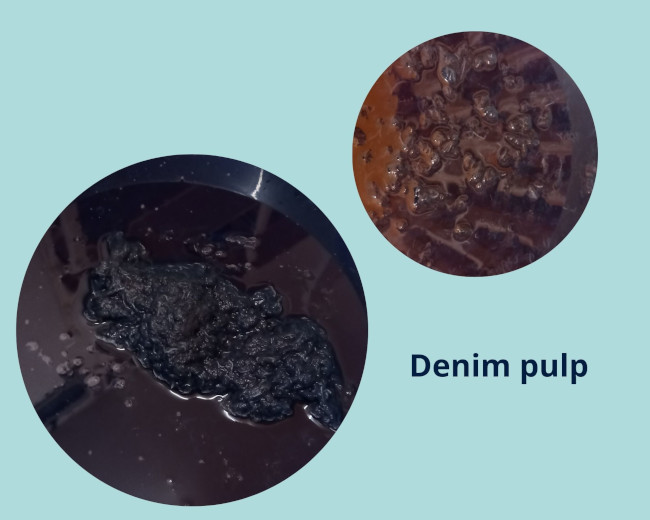

I let the mixed Denim in the second bath almost 24 hours, and mixed it a second time, so it became a sort of "Denim's pulp" :

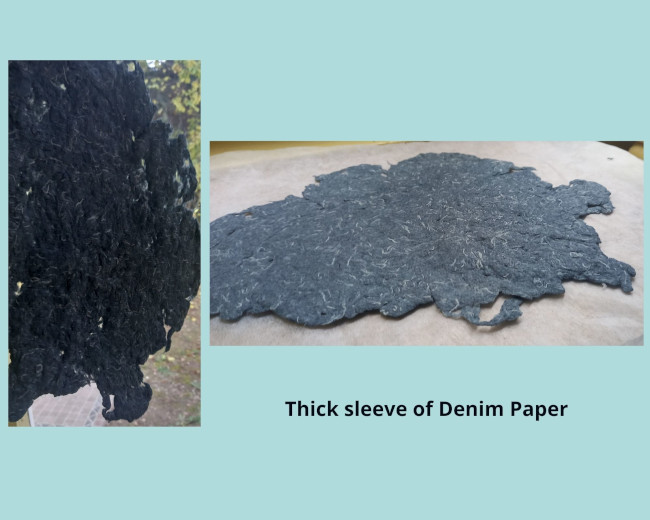

As I took out the denim of the bath, the pulp was really thick, and I couldn't manage to hav a thin niform sleeve of paper.

It seems like felt and is quite solid. I think I could try to varnish it next time, maybe with the pin resine !

Somehow I'm quite satisfied of the result, I like the light blue denim colour and the whithe threads that are more apparent.

Felt with Denim¶

The question is : What I am gonna do with this waste of denim waste ????

At first, I thought about doing a composite with the little pieces of dry denim. In fact, it has really well dried, but remained totally dislocated, so I needed something to agglomerate, like cement or any other bio material. I didn't have enough time to try everything but I'm really motivated to try this !

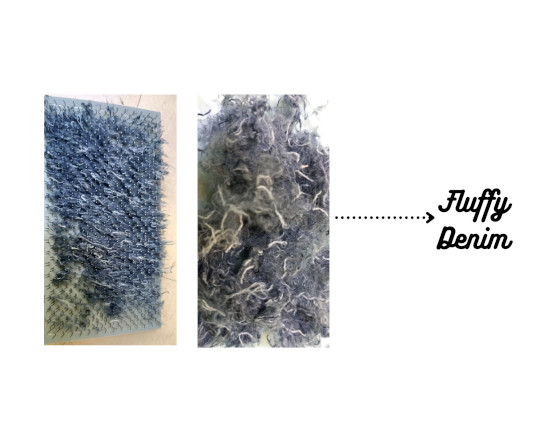

Then I saw those beautiful wools, and thought about trying to make some kind of thick felt. Diane had brought her card brush, and I began to try to card my denim, to see what happened :

Obtaining this "fluffy" fabric, I thought it would be interesting to melt it with the wool and see what happens.

How would the fibers melt together ???

My first trial wasn't fully satisfying, mainly because I didn't put enough wool, and lacked one important and final step, which is to shock the felt by beating it strongly and during nearly half an hour to fix it !!!

So I obtained a thin felt, with holes and not uniform, not really what I expected ...but somehow, the inclusion of denim agglomerate quite well in the wool

So I looked for tutorials and asked Capucine who has worked a lot with wool during her studies.

Here is the second process I went through :

Between two sleeves of bubble wrap:

- make a first layer of wool, spreading horizontally with little quantities

- make a second layer, processing the same way, but vertically

- then another third layer, horizontally as well (the whole layer is quite thick, you need to put enough wool )

- then spray a solution of hot water with Soap ("Savon de Marseille or black soap)

- roll the wool and massage it, making the water spread everywhere

Make it several time and take the time to massage the wool, it is sooo nice !!!

- rince it under cold clear water

- shock the wool by beating it, and repeat this step during mostly half an hour to fix the fabric and make it strong.

(Sorry, I made a video but lost it by mistake ...)

Then I put the felt on chicken wire :

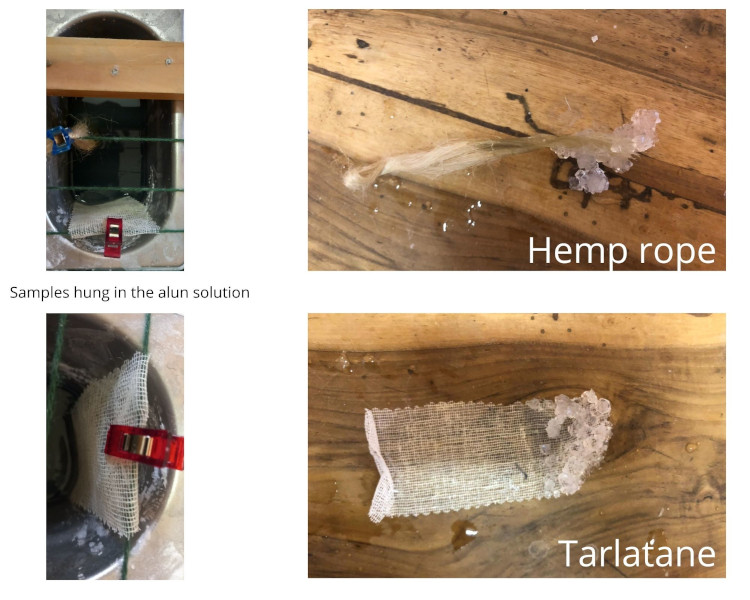

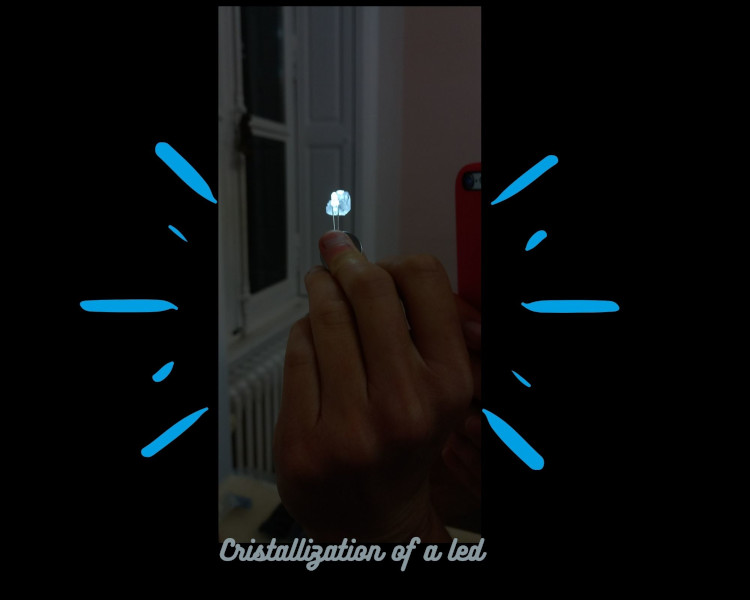

Cristallization¶

Growing material by cristallization is absolutely fabulous. Everyone can try at home, quite easily, and I can't wait to test it on my own to prepare some shiny stuff for Christmas ✨✨✨

As we had so much things to experiment, I didn't prepare the solution myself, but could try to immerse my samples, and observe the different results obtained by the girls who lead the experimentations.

So, for the process, you can follow this great tutorial

Here are the results with my samples :

look a this beauty 😍😍😍

Crochet Lesson¶

...And last but not least, I learnt doing crochet with Louise, sooooo nice !!! Thank you @LouiseMassacrier 🙏🙏🙏

Useful Links¶

-

Growing Materials : Cristallization

- Growing Materials : Kombucha