7. Computational Couture¶

Hello, this week seem very exciting, inspiring and complex for me. It was the week I was looking forward to and here it is. Many life and work circumstances didnt allow me to follow this course harmonically which makes me upset, but I need to catch it up in a way I can.

Inspiration¶

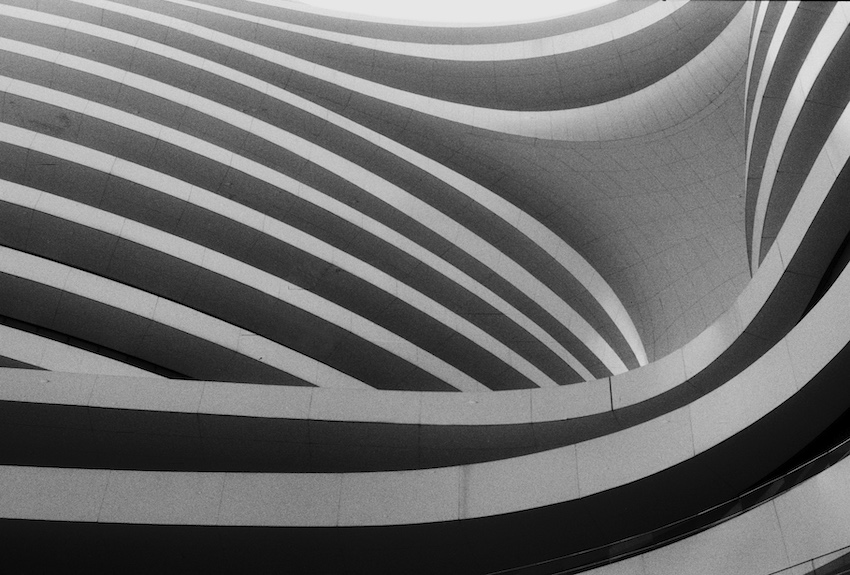

I see a lot of poetry in this course, 'techno poetry' I would say, it reminds me Zaha Hadid creations of endless curves that surround you and you lose yourself. Here is the photo I took in Beijing few years ago of Zaha Hadid's Galaxy.

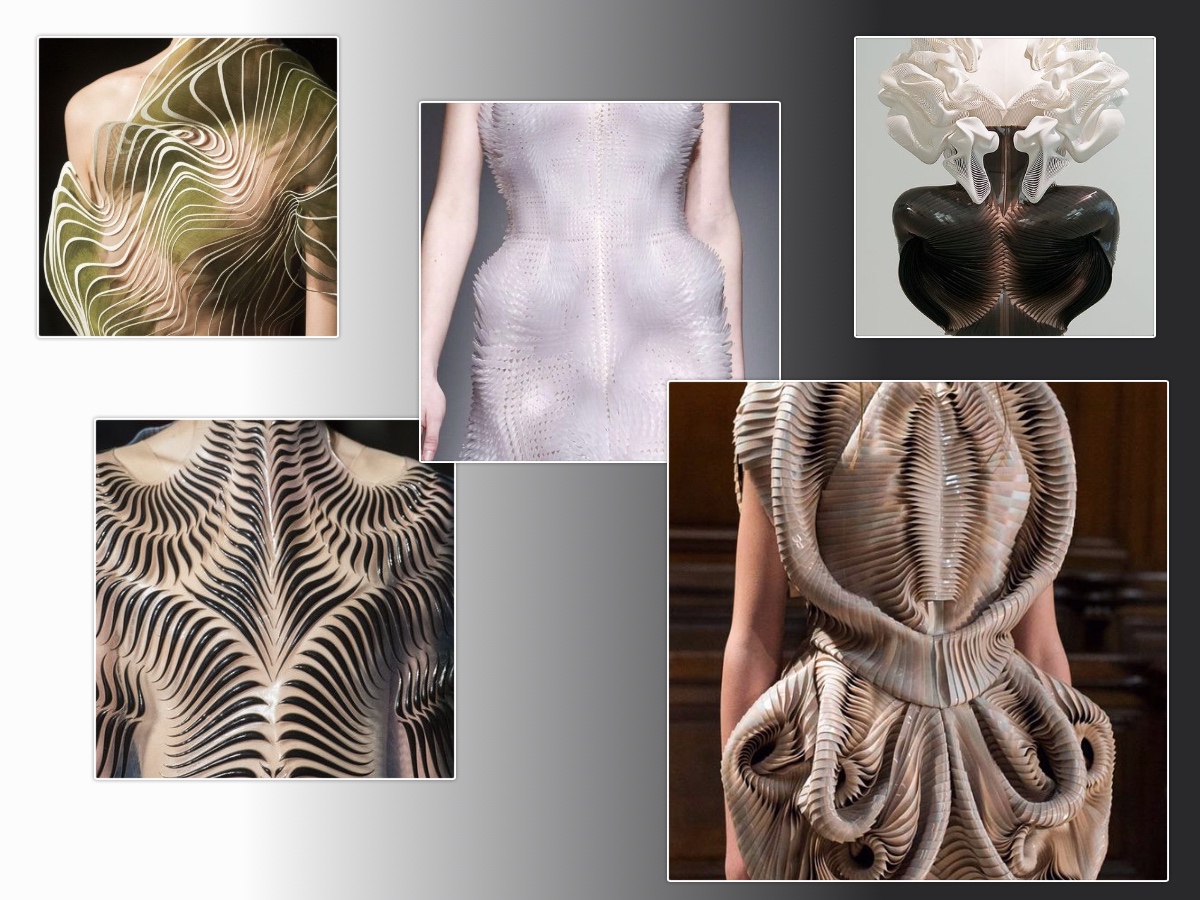

And of course Im going to show Iris Van Herpen - the best example of Computaional Couture practice.

"Since Van Herpen started her company in 2007, the Dutch designer has found that exploring the juxtaposition between the beauty of Mother Nature and the beauty born from man-made innovations to be her happy place. 3D printing has become one of her signature avenues of sartorial expression, as has the incorporation of unconventional materials. She also bends state-of-the-art techniques and technological advancements to her creative will to bring into being sculptural garments that always seem to have a sense of movement at their heart." Can read full interview here

Neri Oxman

is an American–Israeli designer and professor at the MIT Media Lab, where she leads the Mediated Matter research group. She is known for art and architecture that combine design, biology, computing, and materials engineering.(Wiki)

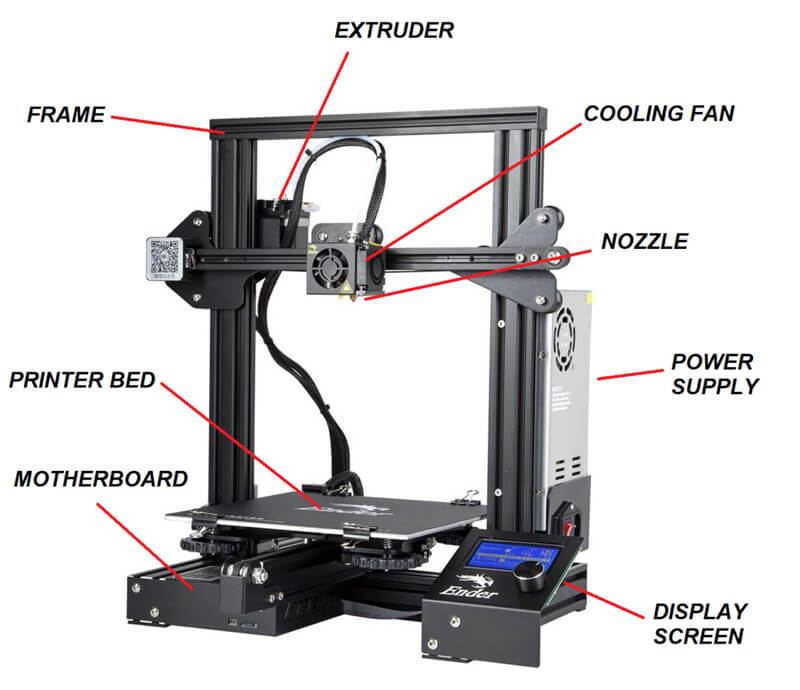

What is 3D printing?¶

It is a process that involves creating three-dimensional objects by using a printer that works with solid filaments. These filaments are melted, extruded, and then solidify to form the desired object. The process is similar to how an inkjet printer operates, but instead of printing on paper, it builds the object layer by layer.

To create a 3D printed object, you start with a 3D computer-aided design (CAD) drawing. The printer takes this digital model and breaks it down into multiple 2D cross-sectional slices. These slices are then printed one on top of the other, gradually building up the object from the bottom upward.

The printer works automatically, depositing layers of molten material onto a build plate. Each layer fuses with the previous layer to create a solid object. The molten material can be made of various materials, such as plastic, metal, or even food ingredients, depending on the type of 3D printer and its capabilities.

The printing process can take anywhere from a few minutes to several hours, depending on the complexity and size of the object being printed. The result is a physical object that closely matches the design specified in the 3D CAD drawing.

Overall, 3D printing allows for the creation of intricate and customized objects with relative ease, making it a versatile technology used in various industries, including manufacturing, prototyping, and even artistic applications.

Filaments¶

3D printers commonly use thermoplastics, which are plastics that can be melted and solidified repeatedly. The most frequently used thermoplastics in 3D printing are ABS (acrylonitrile butadiene styrene), PLA (polylactic acid), and PETG (polyethylene terephthalate glycol).

ABS is a composite material combining a hard, tough plastic (acrylonitrile) with a synthetic rubber (butadiene styrene). It is known for its strength and is used in various applications such as car interiors, refrigerator components, and computer parts. ABS is suitable for 3D printing because it remains solid at room temperature and melts at a moderate temperature (over 100°C or 220°F). It is not biodegradable but can be recycled.

PLA is easier to use than ABS and is recyclable and biodegradable. It is made from plant-based materials derived from crops like corn. Over time, PLA can be broken down by microorganisms into carbon emissions. However, PLA is softer and less durable compared to ABS.

PETG is a material that offers a balance between the strength of ABS and ease of use. It is relatively easy to shape and recycle but is not biodegradable.

While plastic is commonly used, it is possible to print objects using other molten materials that harden quickly. This opens up the potential for experimenting with different materials in 3D printing beyond traditional thermoplastics.

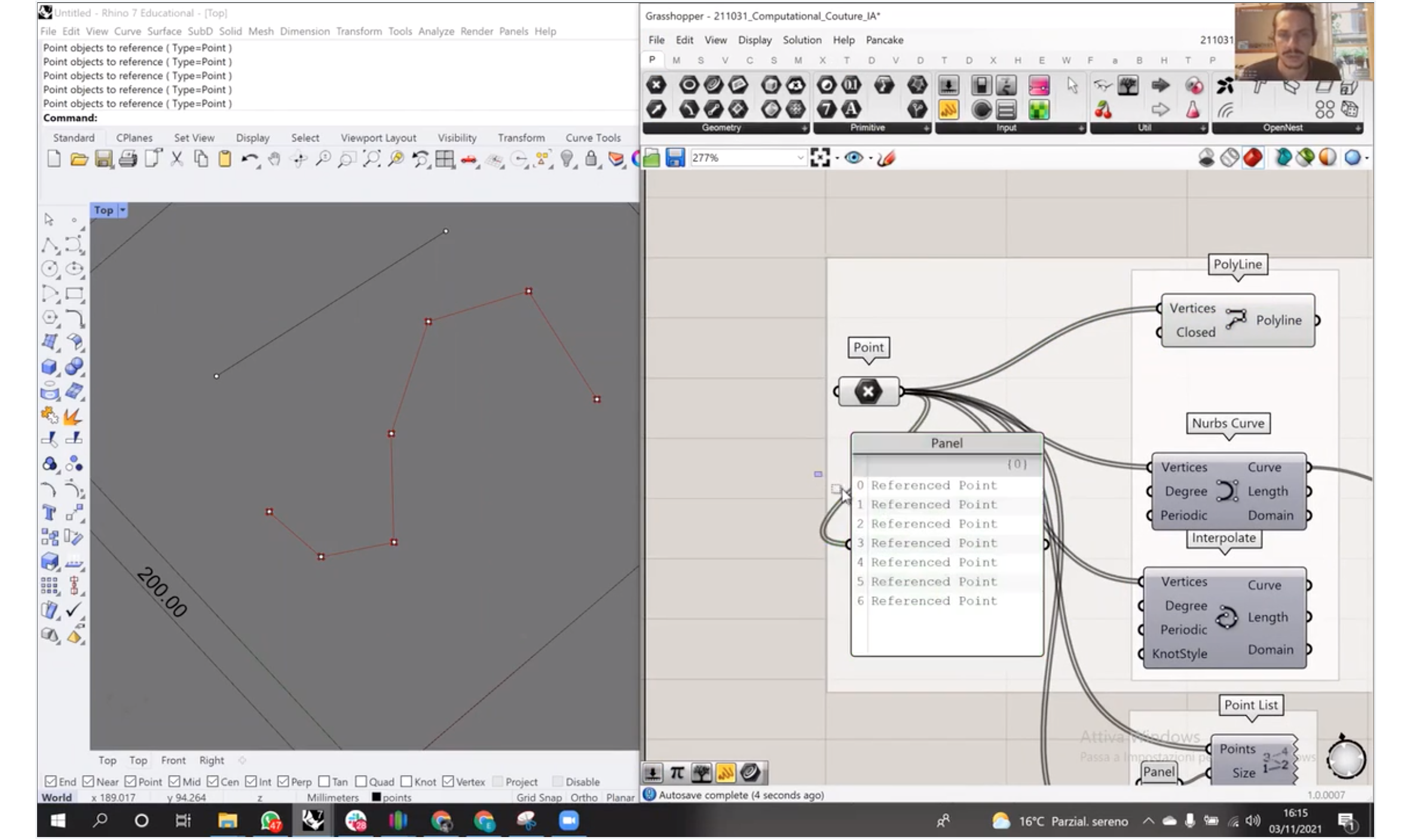

Tutorials and studing of Grasshopper¶

To be honest this week is really out of my comfort zone, a big challenge for me and also very frustrating as I cant learn it properly and take my time, will dive into it deeply later on I hope. I'm leaving here all the tutorials that can access easily.

- Tutorial 1

- Tutorial 2

- Tutorial 3

- Tutorial 4 from 2020-21 can find here

- Tutorial 5

- Tutorial 6

- Printing with Clay

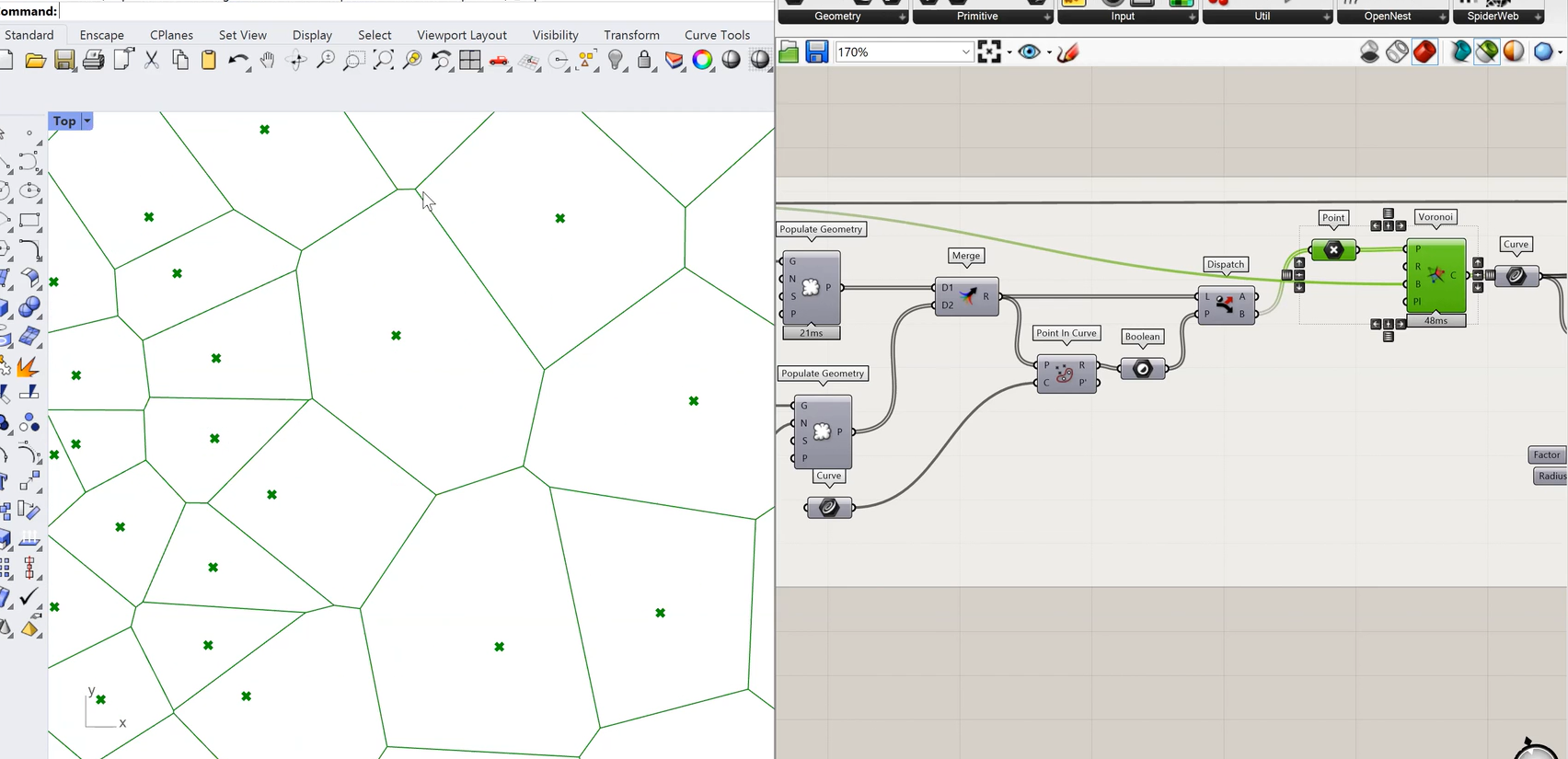

Some Voronoi tests following the Grashopper tutorial¶

When applied in Grasshopper, an algorithmic design plugin for Rhino, the Voronoi algorithm calculates the distances between the input points and creates a network of lines or segments that outline the boundaries between these regions. These resulting Voronoi cells exhibit unique geometric characteristics and can be incorporated into 3D models for printing.

I am not sure that I would be able to repeat it again.

And some tests of 3d printing¶

Some tests at Le Textile Lab by Diane and Lauriane¶

To be honest this week was the most challenging one for me, the Rhino and Grasshoppers logic I didnt implement yet into my comfort work tools yet.

Files¶

For the spiral 3D printing I used PLA Polyactic Acid with 200°C and heating bed at 50°C