8. Wearables¶

Hello! This week is the second part of the Electronics integrated into textiles/materials - Wearables! It is getting more and more frustrating that I dont have enough time to explore and dig into each subject deeply as we have such short time and it is always hard to choose and try 1 thing during the week while we see ocean of possibilities, it makes me feel lost.

Inspiration and Research¶

Ying Gao¶

I really love what Ying Gao creates, she makes a lot of different experimantal interactive projects, its very poetic and the tonality of her colors is beautiful. You can see more of her works here

Practice Hands-on¶

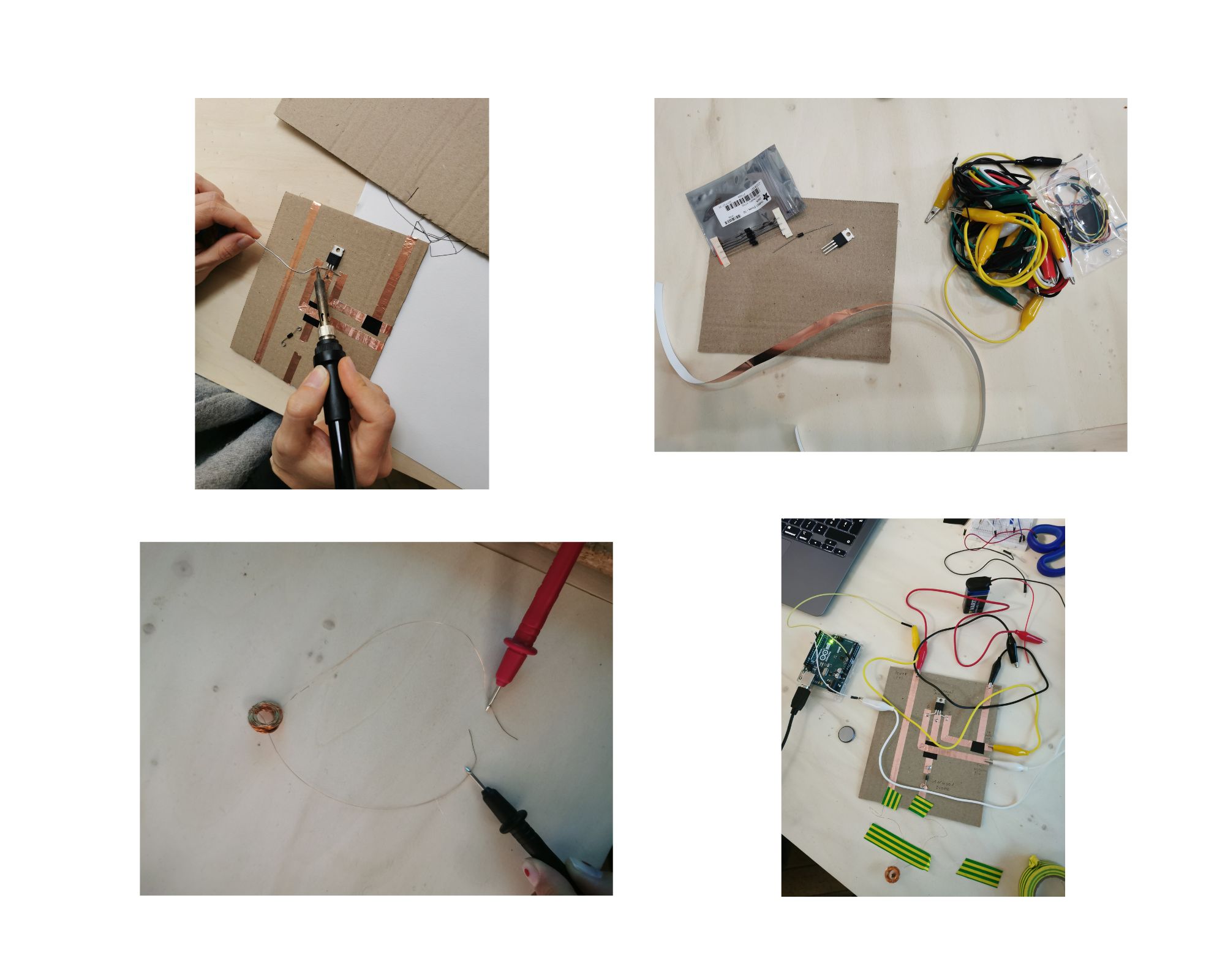

As every week we all met for a new adventure in our Textile Lab in Oullins. Following Emma's tutorial we built a board with Mosfet From the equipment we had possibilities to work on :

- Neopixels

- Thermochromic ink + heated circuit/code

- Fabric speakers + amplifier circuits/code

- Shape memory alloy + high load circuit/code

- Mini vibration motors

Some test on Electromagnet¶

When an electric current flows through a conductive wire ring, it generates a magnetic field with distinct "South" and "North" poles. Reversing the direction of the current will result in a switch of the South and North orientations. If a magnet is introduced into the ring, it will experience a noticeable attraction or repulsion depending on the direction of the current passing through the wire. This interaction causes the magnet to move or jump when the appropriate current (in the correct direction) is applied to the wire.

So we divided into groups of interest: Neopixels, Thermochromic Ink and Shape Memory Alloy.

I was in the Shape Memory Alloy with Louise and Charlotte as it seem very touching for me the moving electronic petals of fabrics, as we had a possibility to make not-alive things move and make them breathe.

SMA | Shape Memory Alloy¶¶

In order to work with Shape Memory and electricity, you can use a special wire called flexinol. This wire is known as an actuator because it can contract (shrink) by about 10% when it gets heated above a certain temperature. It took some time for us to understand how it works, but we finally figured it out. Just like a heating element, the flexinol wire needs a circuit driver to provide enough power.

When using flexinol, you need to decide on the shape you want it to have initially. Make sure the wire remembers this shape by heating it to about 400°C while it's in that desired shape. To check if it's working correctly, you can put it in a glass of hot water. It should go back to its original shape if everything is working properly.

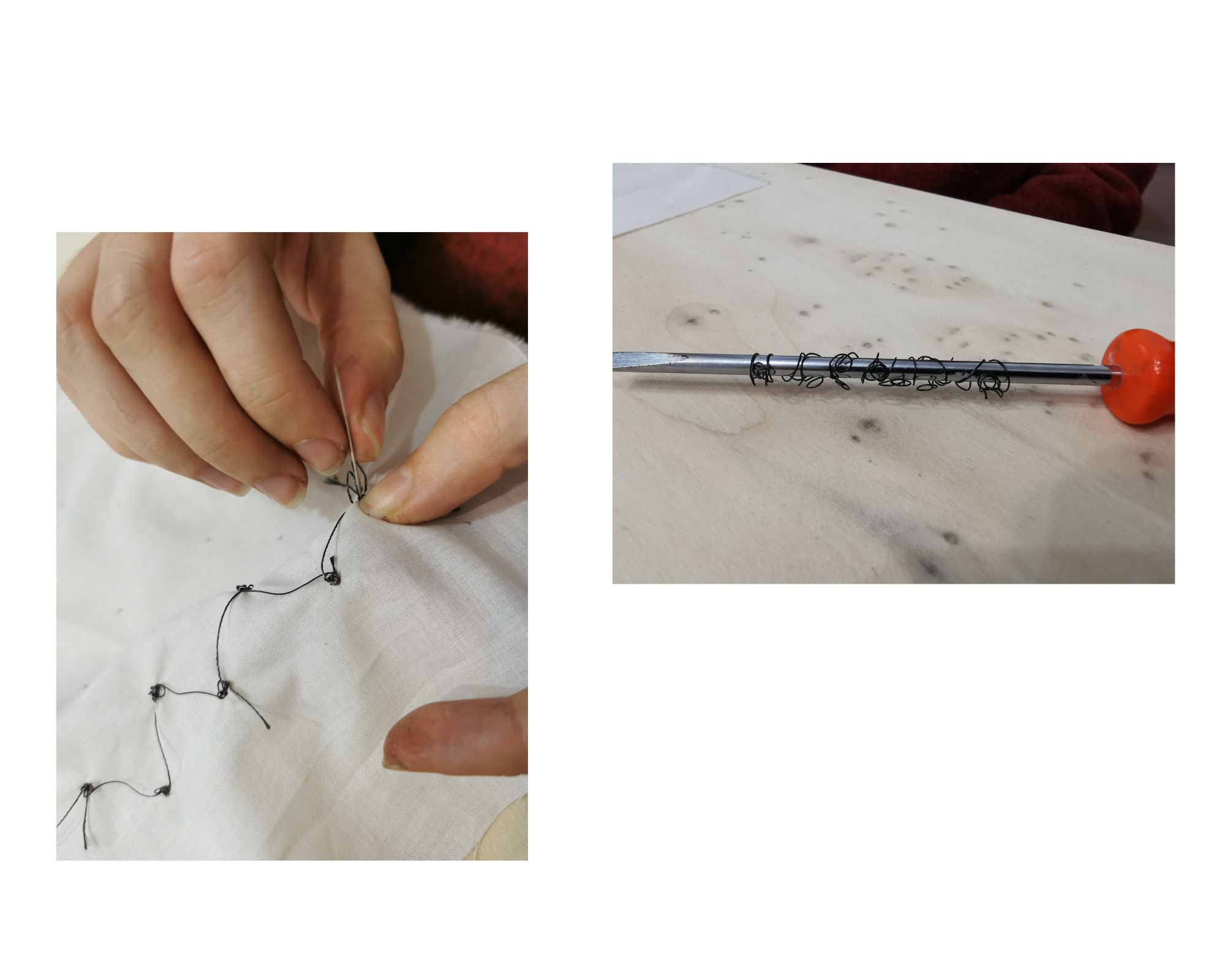

We decided to explore the use of Canadian smock for our actuator experiment. To achieve this, we incorporated flexinol wire into a wave pattern, replacing the knots. When heated, the fabric would fold into the characteristic smock shape. We prepared the flexinol wire in a coiled or spring shape, enabling it to contract when heated. Below, you can observe an example of the initial fold of the smock (powered by a 9V battery).

So here its working! :)

Using this step-by-step Crane tutorial I created a flapping hand Hi-Hand

process of the "Hi-Hand"¶

I was inspired by this Flapping Crane and came to the idea of a rising hand. I prepared the flexinol - which means "trained" it with fire, the same process like for previous Canadian Smock. The result was not amazaing as I wanted as I needed to put the flexinol in the fingers as well in order for it to raise fully. So here are the images and video.

Here is a small video:

It was a great week of learning new magical tool. Thank you for your attention!