10. Open Source Hardware - From Fibers to Fabric¶

Week 10 focused on the theme of open-source hardware, specifically exploring the process of building or modifying machines using freely available resources found on the internet. Participants had the option to create a fully mechanical machine or integrate it with an Arduino for added functionality.

During this week, we divided into three groups for different machines, I was in the group with Ségolène, Louise working on the construction of a loom, delving into the art of weaving. Additionally, participants had the opportunity to learn about knitting on a knitting machine, gaining hands-on experience with this textile technique. An exciting highlight was Pauline's introduction of her textile drawing machine, which left a strong impression due to its innovative nature.

The emphasis throughout the week was on leveraging open-source principles, encouraging participants to tap into the wealth of knowledge and designs available online to develop their own unique machines or modify existing ones. By exploring open-source hardware, participants were able to embrace creativity, innovation, and collaboration, while also learning valuable skills related to textiles and machine building.

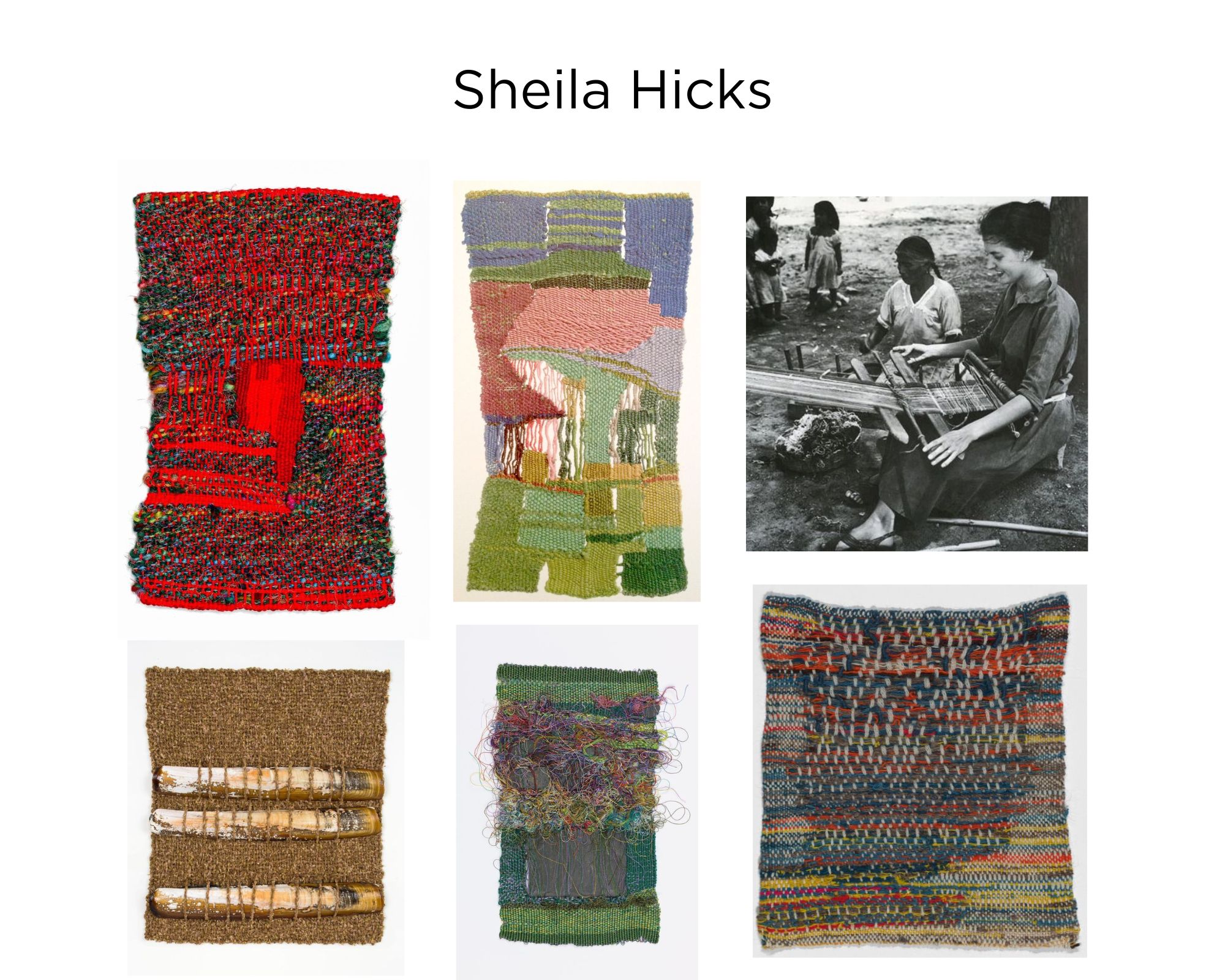

Inspiration¶

I really admire work of Sheila Hicks, she is a great artist that inspires averybody to start weaving even if they are not into it. I saw her work for the first time at Centre Pompidou in Paris in 2018 and fall in love. Her works are great source of inspiration!

Building a Weaving Loom:¶

We teamed up with Ségolène and Louise to build a loom for the week's project. After some research, we found the perfect guide on Instructables called DIY Laser Cut Rigid Heddle Loom - Part 1: Building the Loom. The guide provided clear instructions that made the process straightforward.

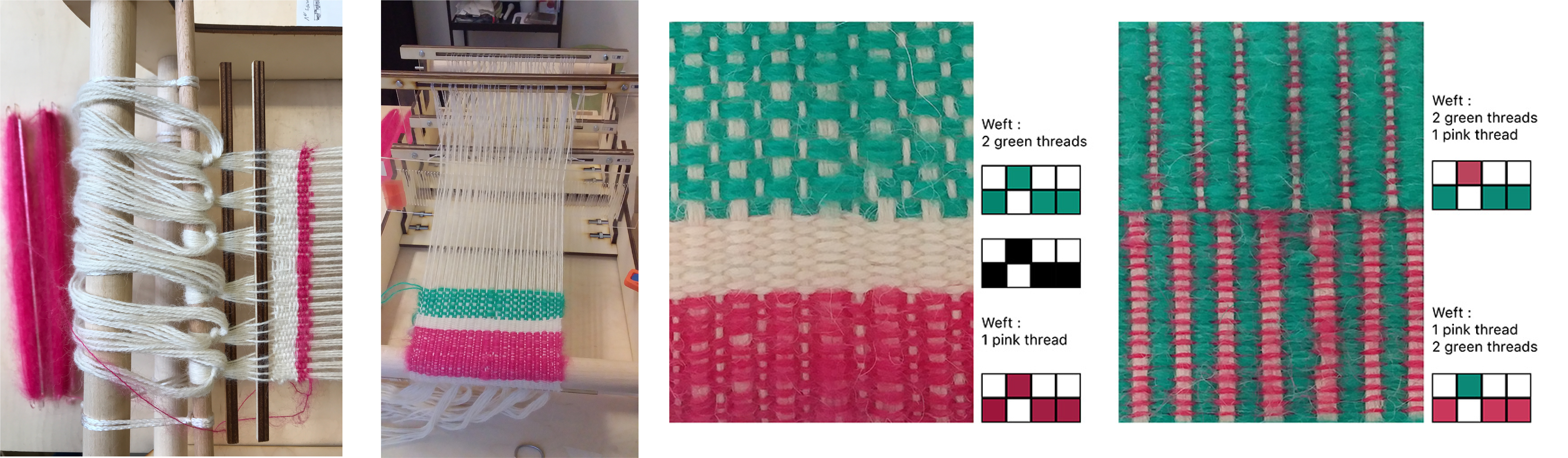

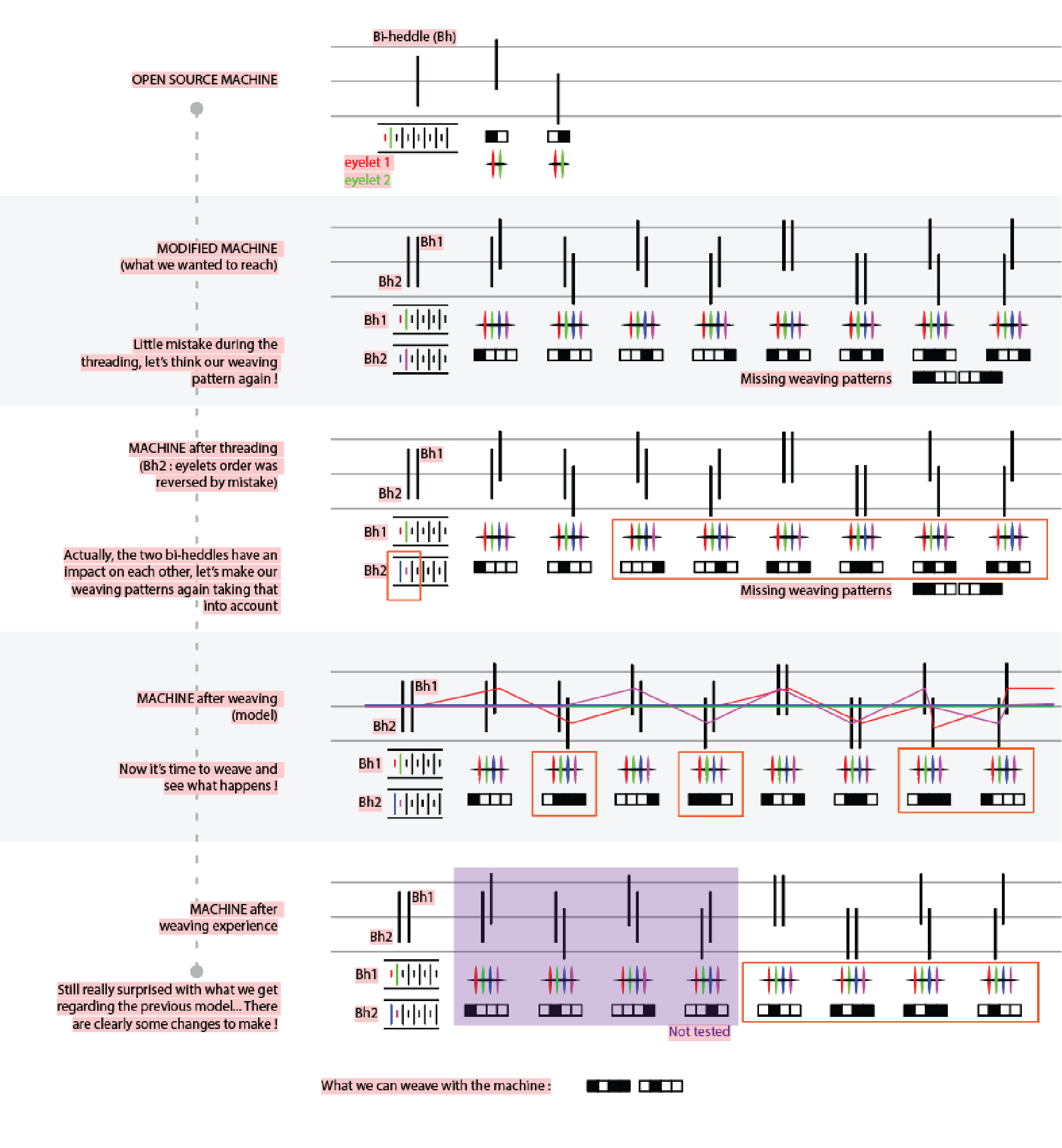

The loom we chose had a rigid heddle, but we wanted to make it more versatile. Instead of using a single heddle, we decided to create a bi-heddle, which essentially combines two heddles into one. This allowed us to weave different patterns and designs. To make things even more interesting, we replaced the rigid bi-heddle with eyelets made from threads. This change made it easier to adjust the weaving density. We also needed to make a comb, which we laser-cut once we decided on the warp thread.

Here are the steps we followed:

We checked the materials needed and made a shopping list. We modified the files from the Instructables guide to include a second bi-heddle. We used a laser cutter to create the necessary pieces. We prepared the additional components by drilling holes and adding cords, following the instructions in the guide. We assembled all the parts together. We set up the warp by adding the vertical threads. We laser-cut the comb, an essential tool for managing the warp threads. Finally, it was time to test the loom and start weaving! Building the loom allowed us to delve into the art of weaving and have fun creating our own textile designs.

You can download files here

Here is the list of materials needed:¶

6mm MDF - 600mm x 400mm

3mm perspex or MDF - 300mm x 150mm

1mm MDF or thick card - 50mm x 170mm

4 x 25mm Dowling cut into 300mm lengths

2 x 9mm Dowling - cut to 280mm lengths

8 x Machine Thread to Wood Thread Dowel Screws - M8 x 75mm

4 x M8 Wingnuts

4 x M8 Hex Nuts

8 x M8 Washers

4 x 40mm M6 Bolts

4 x M6 Hex nuts

4 x 20mm M4 Bots

4 x M4 Nuts

2mm Nylon cord

6 x flat head drawing pins or thumbtacks

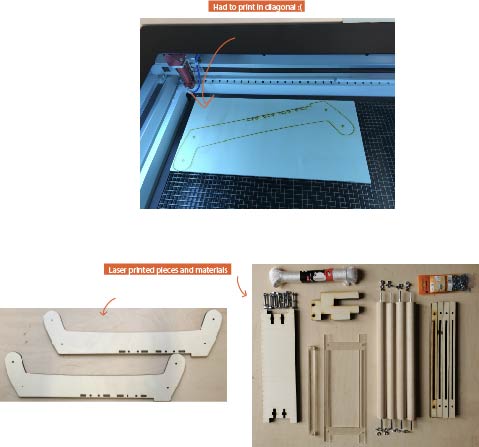

Laser cutting¶

For the construction of the loom, we primarily used 6 mm wood PLA for most parts. The comb, shuttles, and the two bi-heddles were made from 3 mm plexiglass.

For the construction of the loom, we primarily used 6 mm wood PLA for most parts. The comb, shuttles, and the two bi-heddles were made from 3 mm plexiglass.

However, we encountered an issue while printing the larger part of the loom. In Inkscape Software, the shape didn't appear as expected, so we had to print it diagonally. Unfortunately, this resulted in some waste material, but it was the only way to obtain the complete shape.

We utilized a Rayjet r400 laser cutting machine for the fabrication process.

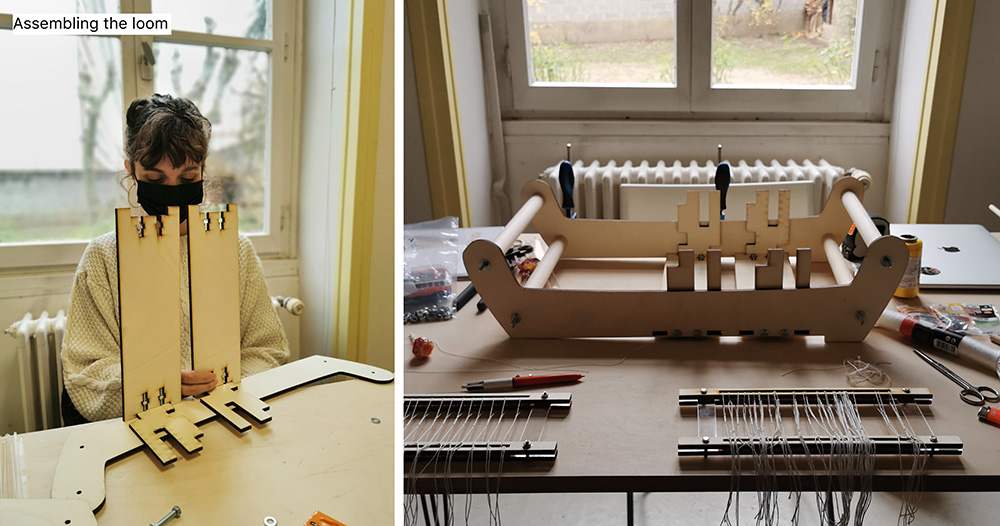

Building the loom¶

This part was a lot of fun

Testing Weaving¶

It worked! Even though it didnt make all the patterns that were expected, but it made two types of patterns, which is good as well.

And here is a great schema by Louise of the plan and turn-out.

Its been a great week of discoveries and new knowledge. Thank you!

Here are some more info from Lara Campos:

Lara Campos final project documentation with weaving loom and spinning machine

Files and instructions of the Loom by Lara Campos