03 | PREVIOUS SEAWEED RESEARCH

PREVIOUS SEAWEED RESEARCH| STATE OF MY ART¶

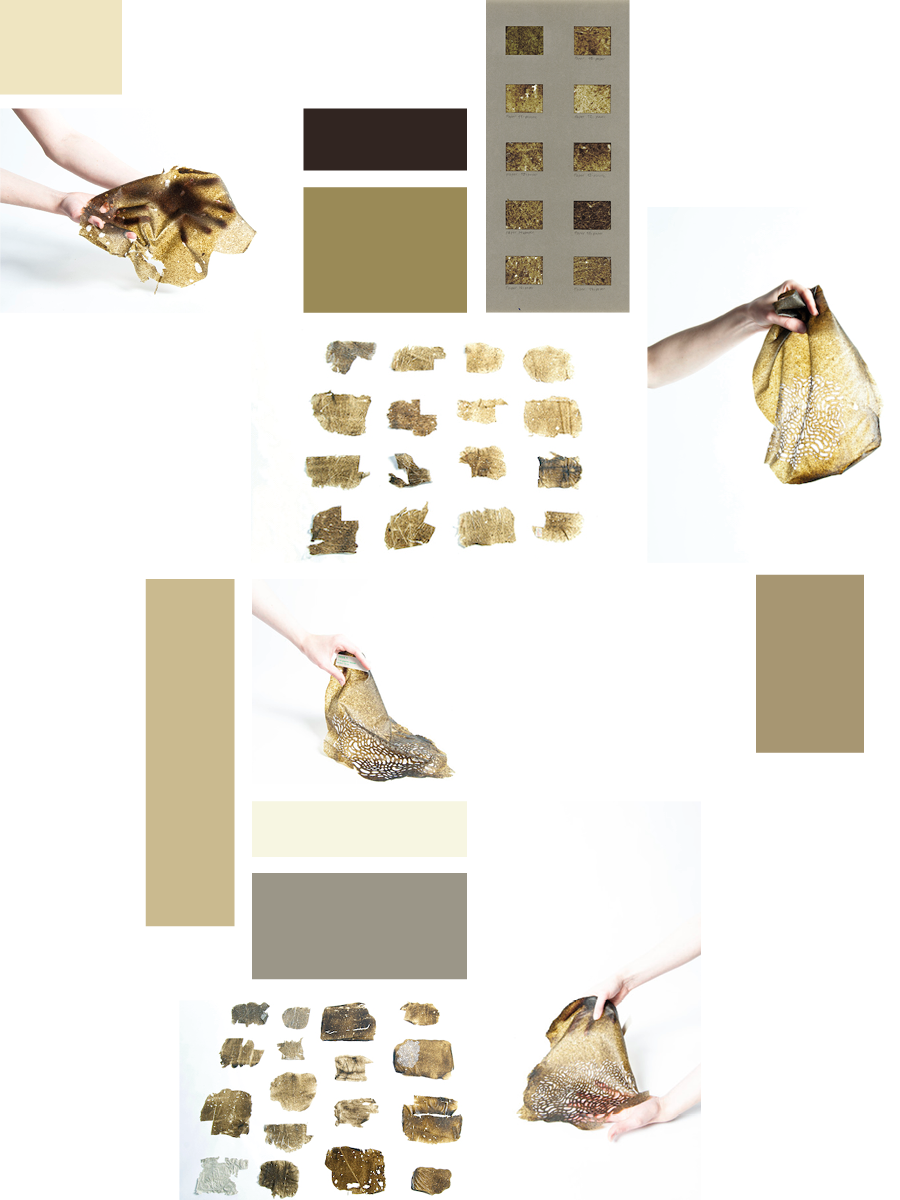

In recent years I have become very invested in working together with nature to design ecocentricly instead of humancentricly. I have both delved into this practice by myself and in collaboration and with guidance from design professor Julia Lohmann. One of the products from this interaction was a material library of waste Kombu seaweed. Obtained from the sculpture Kombu Ahtola that I helped create during my internship with Lohmann in 2020. The biomaterial is based on recipes found in The Chemarts Cookbook. I also had great sucess laser cutting in the material, creating patterns and surfaces in the material. This is a path I want to explore further both being inspired by nature in processes and aesthetics, but also by working with natural materials.

2022 FABRICADEMY | MODULAR SEAWEED¶

Laser cut seaweed paper, based only on Kombu kelp and glycerol. This material is made out of waste Kombu from my work with Julia Lohmann.

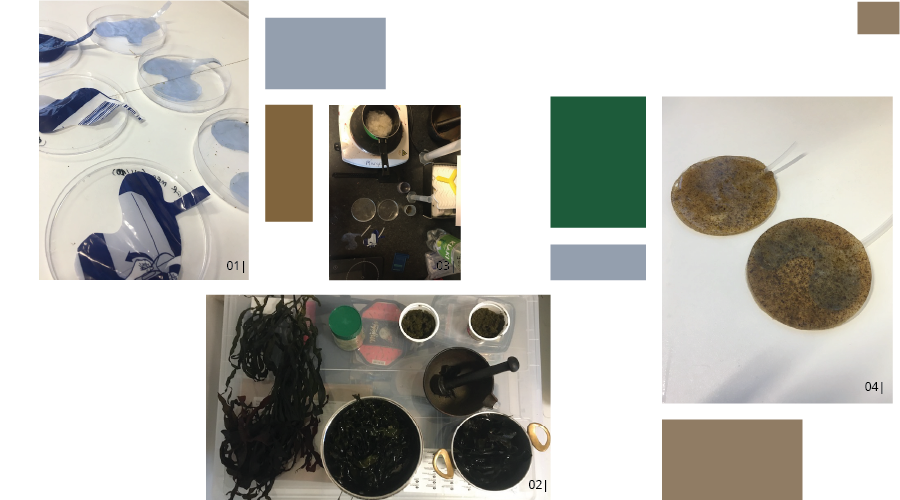

2022 FBRICADEMY | LOCAL SEAWEED AS BIOMASS¶

I went to the beach and collected some seaweed, washed it out with a bit of organic detergent and hung it to dry. I founf that depending of their state of degration the seaweed has different coulurs varying from orange, green, red and brown, some really beautiful colours. I made some samples only with the seaweed, drying it up over a mold, they became very hard and brittle, but they are very beautiful in their brittlenes. The dryed seaweed I ground up in a coffee grinder, making a very fine powder. During the process I interchangebly used the dry powder and soaked it in glycerol water.

- 01| OVERVIEW OVER MATERIAL SAMPLES, PHOTO ALBERTE BOJESEN

- 02| DRYING RINSED SEAWEED, PHOTO ALBERTE BOJESEN

- 03| DRYING RINSED SEAWEED, PHOTO ALBERTE BOJESEN

- 04| DIFFERENT COLOURS OF THE SEAWEED, PHOTO ALBERTE BOJESEN

- 05| DRYING RINSED SEAWEED, PHOTO ALBERTE BOJESEN

- 06| RINSING THE SEAWEED IN SODA ASH DILUTED WATER, PHOTO ALBERTE BOJESEN

- 07| SEAWEED PAPER IN MOULD, CRACKELED UP, PHOTO ALBERTE BOJESEN

- 06| SEAWEED WITH WHEAT FLOUR, CRACKELED UP, PHOTO ALBERTE BOJESEN

GELATIN AND AGAR¶

Gelatine based bioplastics are based on collagen derived from animal parts. In a world where we eat meat it makes sense to use the other parts of the animals that we do not eat, such as the bones, hair and intestines. Collagen Hydrolysate is derived by treating skins, bones or fish scales with an acid or alkaline process. Gelatine gel can also be made at home by boiling the animal parts, creating the gel when cooled. Gelatin can be combined with agar agar to generate a less wet hand of the final material.

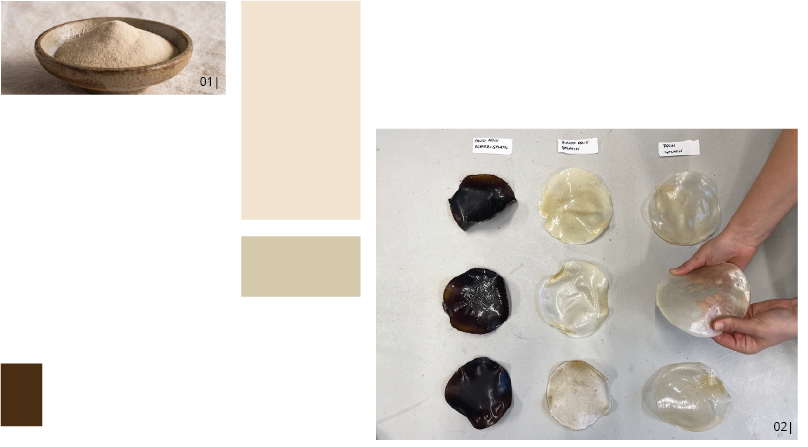

- 01| PHOTO OF GELATINE POWDER

- 02| GELATINE BIO-RESIN, PHOTO ALBERTE BOJESEN

THE ICELANDIC BIO-MATERIALS CHRONICLES: GELATINE can be seen here, code provided by Emma Shannon.

Combining gelatin, agar agar and Digitata powder creates a beautiful translucent material.

- 01| AGAR

- 02| GELATIN

- 03| GELATIN MAKING, PHOTO ALBERTE BOJESEN

- 04| FINAL SAMPLES, PHOTO ALBERTE BOJESEN

- 05| SEAWEED WITH GELATIN, PHOTO ALBERTE BOJESEN

- 06| SEAWEED WITH GELATIN AND AGAR, PHOTO ALBERTE BOJESEN

- 07| SEAWEED WITH GELATIN, PHOTO ALBERTE BOJESEN

ALGINATE¶

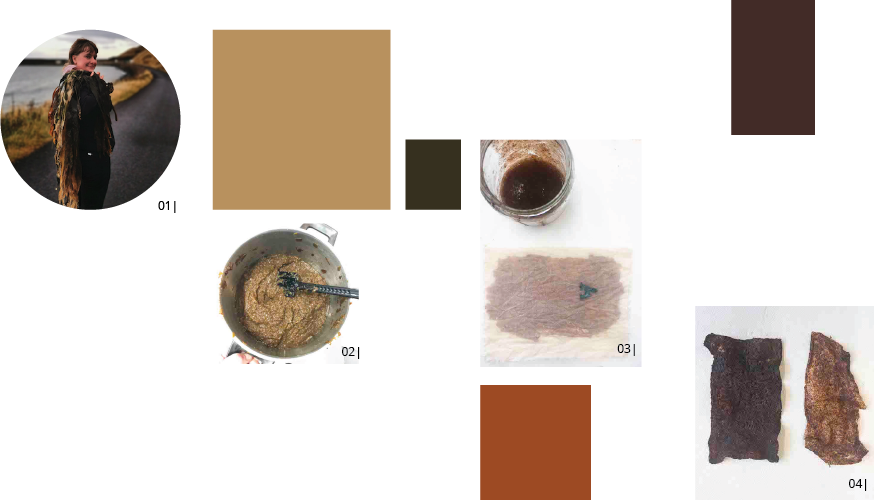

- 01| LOCAL SEAWEED DIGITATA , PHOTO EMMA SHANNON

- 02| BOILED AND MIXED DIGITATA , PHOTO ALBERTE BOJESEN

- 03| HIGHER CONCENTRATION OF GLYCEROL ALGINATE SAMPLE IN FABRIC, PHOTO ALBERTE BOJESEN

- 04| DIGITATA ALIGNATE SAMPLES, PHOTO ALBERTE BOJESEN

- 05| DIGITATA ALGINATE ON CURING IN THE MOULD, PHOTO ALBERTE BOJESEN

- 06| DIGITATA ALGINATE SAMPLES AFTER 2 WEEKS, PHOTO ALBERTE BOJESEN

STARTCH¶

Wheat and potato startch can also be used as a binder, it becomes very brittle if used with the seaweed powder, however it works very well as a coat for whole seaweed.

- 01| WHEAT FLOUR

- 02| FINAL SAMPLES WITH FLOUR, PHOTO ALBERTE BOJESEN

- 03| WHOLE SEAWEED WITH FLOUR COATING, PHOTO ALBERTE BOJESEN

- 04| SEAWEED MIXED WITH WHEAT FLOUR, PHOTO ALBERTE BOJESEN

- 05| CUT SEAWEED MIXED WITH WHEAT FLOUR, PHOTO ALBERTE BOJESEN

- 01| POTATO FLOUR

- 02| SAMPLES WITH FLOUR, PHOTO ALBERTE BOJESEN

- 03| FINAL SAMPLES WITH FLOUR, PHOTO ALBERTE BOJESEN

- 04| POTATO STRATCH GLUE IN THE MAKING, PHOTO ALBERTE BOJESEN

- 05| SOAKING SEAWEED IN THE GLUE, PHOTO ALBERTE BOJESEN

- 06| WOVEN SEAWEED BASKET WITH POTATO STARTCH COATING, PHOTO ALBERTE BOJESEN

- 07| MIXED SEAWEED WITH POTATO STRATCH AND ADDING OF MODUES, PHOTO ALBERTE BOJESEN

2022 FBRICADEMY | ALGAE BASED BIOPLASTICS¶

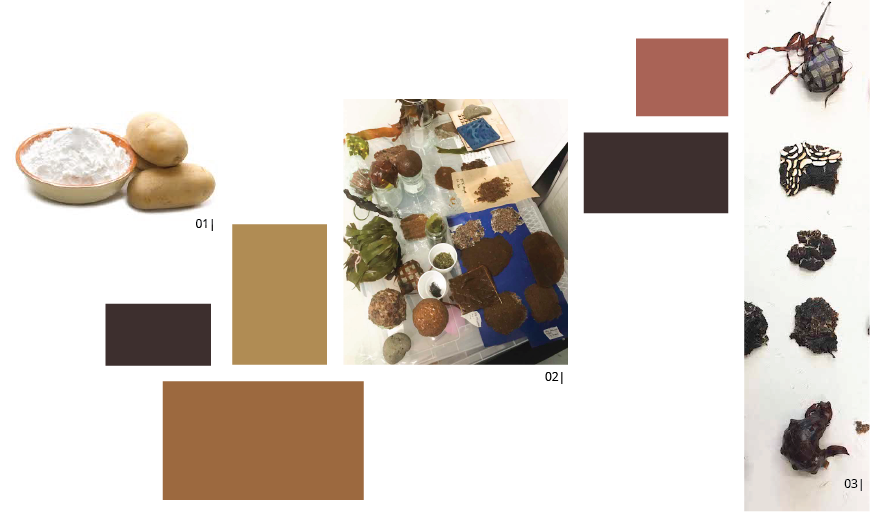

AGAR¶

Agar or Agar-agar is a gel-like polysaccharide composed of agarose and agaropectin, which is derived from the cell walls of specific red algaes, Rhodophyceae. It originates from Japan and has been used there since around 1650 and was introduced in Europe in approximately 1859. During this time it was mainly used in the food industry, and still is today.

Prepare this recipe [^1] by collecting the ingredients necessary, to be found in the list below:

- 01| PICTURE OFAGAR-AGAR

- 02| AGAR BIO-PLASTIC 2, PHOTO ALBERTE BOJESEN

THE ICELANDIC BIO-MATERIALS CHRONICLES: AGAR can be seen here, code provided by Emma Shannon.

Work From The Icelandic Node, Fabricademy, 2022.

ALGINATE¶

Sodium alginate is another polysaccharide of alginic acid and gum derived from the cell walls of brown algae. Working with alginate for fabricating bio-plastics is different from working with the gelatine of the agar, where you add heat to dissolve and jellify the powders. For sodium alginate you do not need heat but a curing solution of sodium chloride hydrate and water. The Alginate is first mixed in a water glycerol solution with a mechanical mixer, left overnight to set and then placed on a surface sprayed with the sodium chloride hydrate solution, thereafter the alginate solution is sprayed with the same solution to cure and solidify. The amount of curing time affects how cured the material becomes. Thereafter the alginate material should be rinsed in water.

Prepare this recipe [^1] by collecting the ingredients necessary, to be found in the list below:

- 01| PICTURE OF SODIUM ALGINATE

- 02| ALGINATE BIO-MATERIAL SAMPLES, PHOTO ALBERTE BOJESEN

THE ICELANDIC BIO-MATERIALS CHRONICLES: ALGINATE can be seen here, code provided by Emma Shannon.

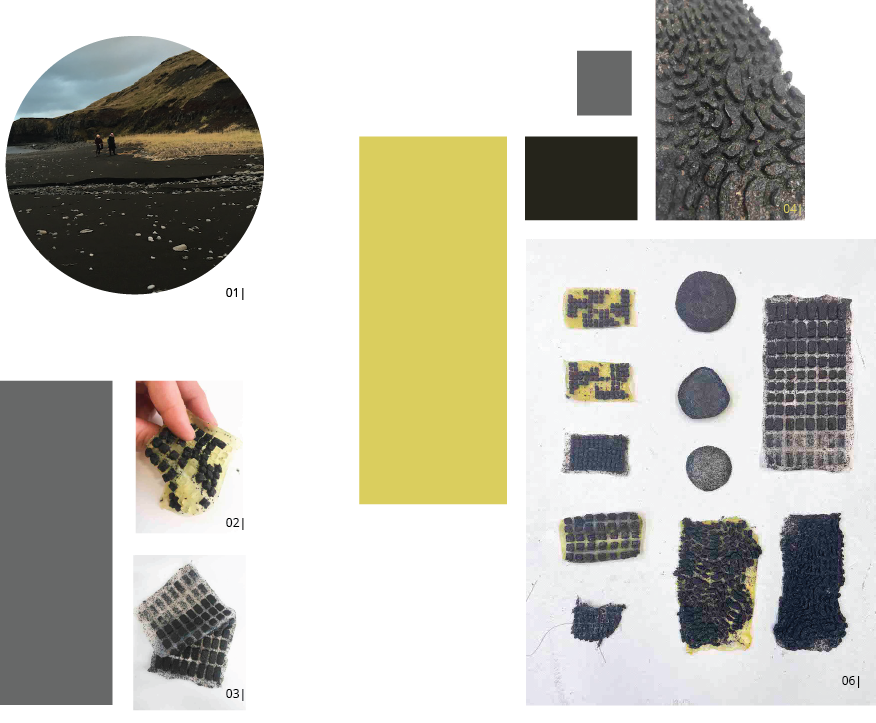

Here in Iceland we have the most beautiful black sand beaches due to the volcanic activity around the island. One of the first things I was told when I came here was that there is a white-sand beach here, the Natuhólsvík Geothermal beach, where the sand is imported from Morocco. That just sounded so comical to me, that we import sand to have the "correct" colour on the beach, it goes against all my local-focused and ecocentric values, especially when the black sand is so beautiful. Therefore I wanted to see how this sand functioned as a filling material in order to harness its dark beauty.

- 01| LOCAL BLACK SAND BEACH, PHOTO ALBERTE BOJESEN

- 02| SAND SHADE 3 AND LUPIN ALGINATE SQUARE RELIEF, PHOTO ALBERTE BOJESEN

- 03| SAND SHADE 3, 2, 1 ALGINATE, PHOTO ALBERTE BOJESEN

- 04| SAND SHADE 3 ORGANIC RELIEF, PHOTO ALBERTE BOJESEN

- 05| SAND ALGINATE SAMPLES, PHOTO ALBERTE BOJESEN

- 06| GIPH OF ORGANIC RELIEF SAND SHADE 3, PHOTO ALBERTE BOJESEN

- 07| GIPH OF SQUARED RELIEF SAMPLES, PHOTO ALBERTE BOJESEN

- 08| GIPH OF RECTANGULAR RELIEF SAND SHADE 3,2,1, PHOTO ALBERTE BOJESEN

- 09| GIPH OF ORGANIC RELIEF SAND SHADE 3 WITH LUPIN BACKING, PHOTO ALBERTE BOJESEN

- 10| BLACK SAND ALGINATE SAMPLES AFTER 2 WEEKS, PHOTO ALBERTE BOJESEN

2022 FBRICADEMY | SEAWEED AND BIO COLOURING¶

I also used the waste dyebaths to colour the cut-offs of my seaweed from WEEK 03, I realised I could re-make a new material, as the seaweed paper is dissolved in the water. So the waste was put in the waste baths and absorbed the dyed water. I tryed this with cochenille, red onion, madder, rubarb and lupin, where the cochenille was by far the most effective, mainly because the pink colour is wery visible trhough the green of the seqaweed.

- 01| ONION DYE

- 02| MADDER DYE

- 03| RHUUBARB DYE

- 04| COCHENILE DYE

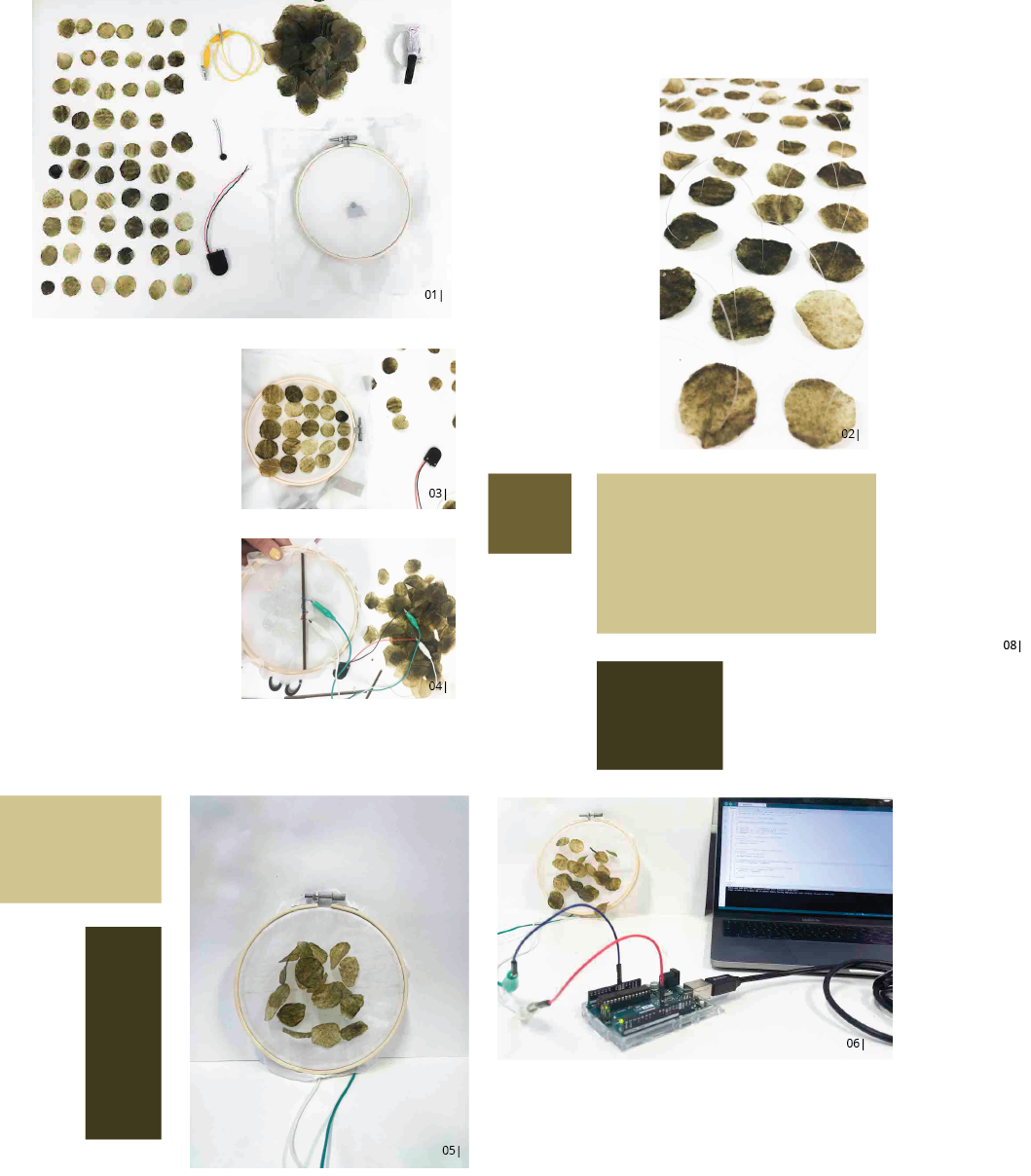

2022 FBRICADEMY | SEAWEED AND ELECTRONIC ACTUATORS¶

VIBRATION¶

- 01 | TOOL SET, PHOTO ALBERTE BOJESEN

- 02 | SEQUINS, PHOTO ALBERTE BOJESEN

- 03 | SEQUENCE OF SEQUINS, PHOTO ALBERTE BOJESEN

- 04 | BACK SIDE THE MOTOR SECURED BY PLYWOOD, PHOTO ALBERTE BOJESEN

- 05 | SECOND SAMPLE ON POLYESTER, PHOTO ALBERTE BOJESEN

- 06 | CONNECTION TO ARDUINO, PHOTO ALBERTE BOJESEN

- 07 | SEQUINS ON SEAWEED BACKING, PHOTO ALBERTE BOJESEN

- 08 | FIRST SAMPLE ON POLYESTER, BLINK SEQUENCE, PHOTO ALBERTE BOJESEN

- 09 | SSECOND SAMPLE ON POLYESTER, FADE SEQUENCE, THIS SAMPLE WORKED BETTER DUE TO THE LENGTH OF THE MONOFILAMENT, PHOTO ALBERTE BOJESEN

- 10 | SECOND SAMPLE INTERACTION, PHOTO ALBERTE BOJESEN

INFLATABLES¶

- 01 | PREPARING THE POCKETS IN THE DIFFERENT PLASTICS, PHOTO ALBERTE BOJESEN, 2020

- 02 | THE SEAWEED STATES, DRY, POWDERED, GLYCERIN SOAKED, , PHOTO ALBERTE BOJESEN, 2020

- 03 | MAKING THE GELATINE SOLUTION, PHOTO ALBERTE BOJESEN, 2020

- 04 | GELATNE INFLATABLES, PHOTO ALBERTE BOJESEN, 2020

- 05 | REMOVING THE PLASTIC, SAMPLE 03, PHOTO ALBERTE BOJESEN, 2020

- 06 | INFLATING THE SEAWEED INFLATABLE, SAMPLE 02, PHOTO ALBERTE BOJESEN, 2020

- 07 | INFLATING THE SEAWEED INFLATABLE, SAMPLE 04, PHOTO ALBERTE BOJESEN, 2020

2020 | SEAWEED MARERIAL LIBRARY¶

After my internship with Julia Lohmann I created a material library of seaweed paper.

JÄTE, 2020, photographed by ALBERTE BOJESEN