7. Computational Couture¶

References & Inspirations¶

I was inspired by the repetitive patterns in nature if we look close enough on almost everything we can find a single module that is being repeated to form a larger shape

Islamic patterns used the same concept of repeating a single module to form the bigger picture

The Ultimaker¶

In this week we are using the Ultimaker printers you can know more about them HERE

I used Ultimaker3 & Ultimaker5, TPU & PLA filaments, white, blue and gray colors

Process & Workflow¶

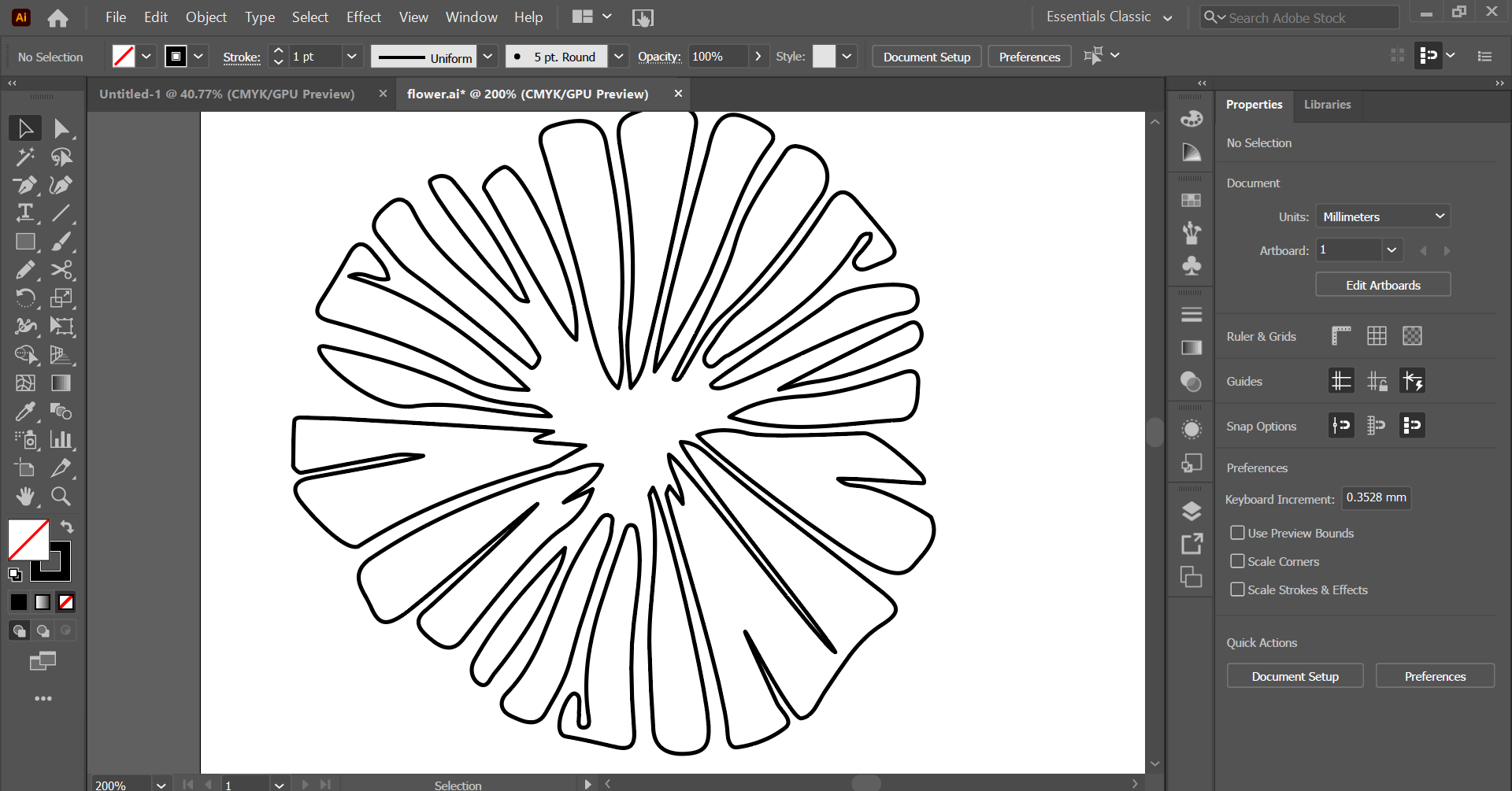

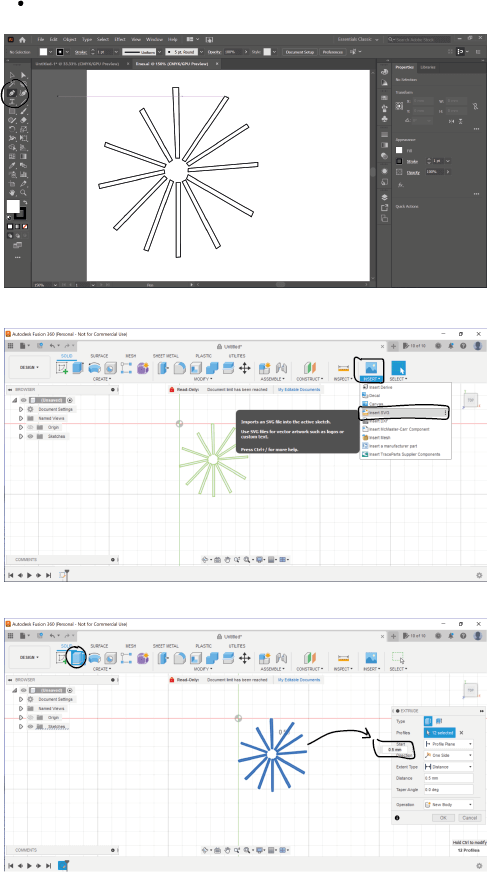

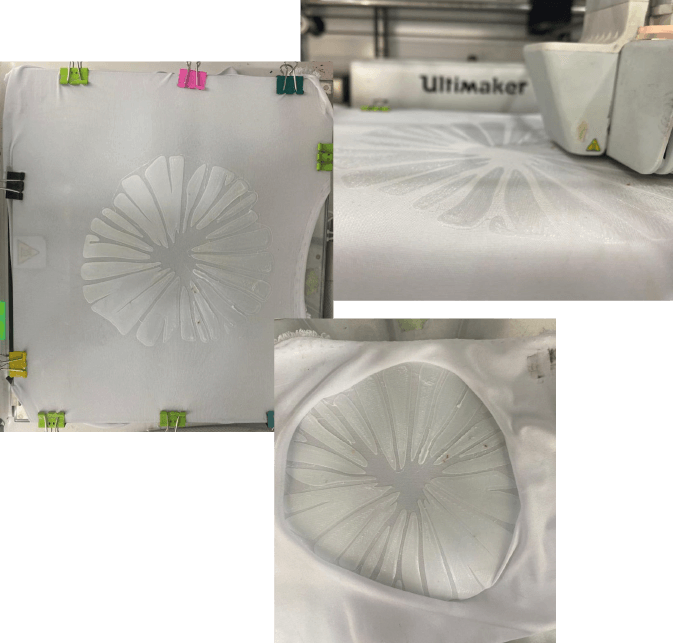

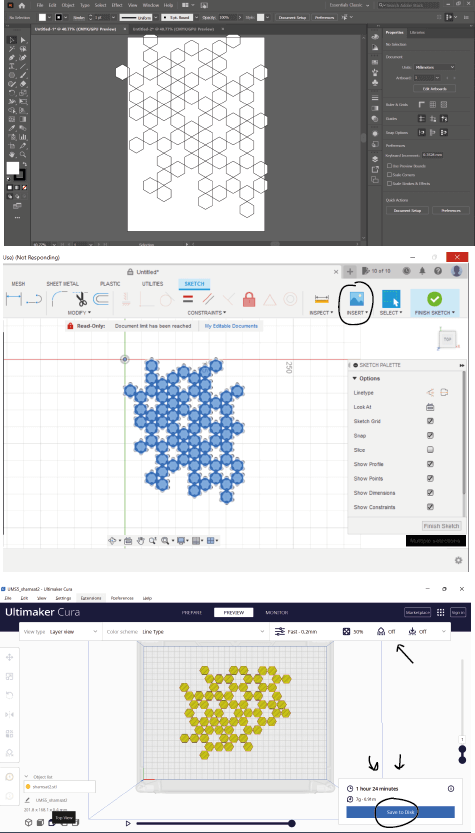

I started by sketching my flower petals on illustrator, make sure you have a closed shape and it is better if you have it as one shape not separated dotes or lines, save you sketch as SVG to open it later using fusion or rhino

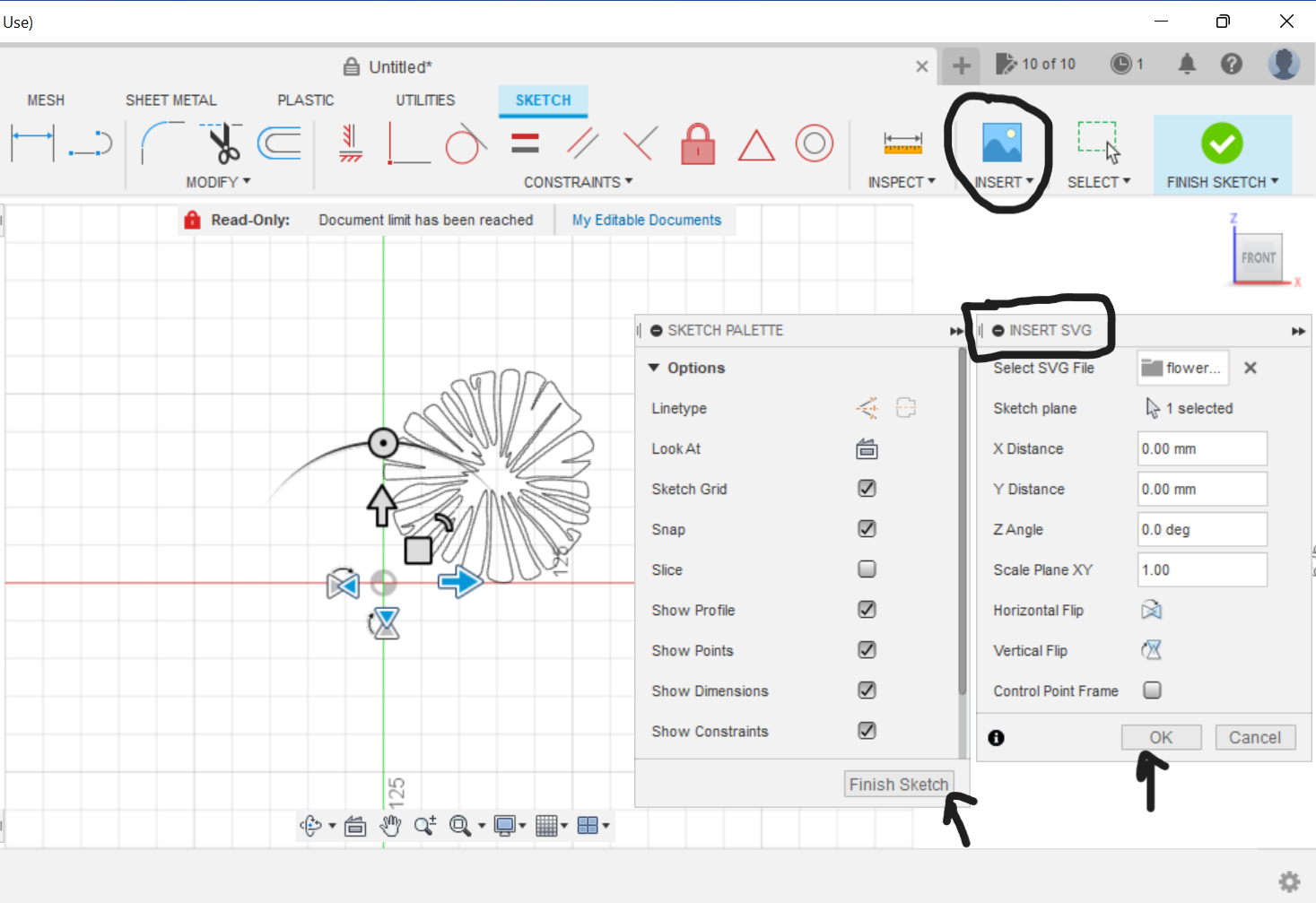

After sketching and saving I inserted my SVG file to fusion 360 - open fusion - go to insert - select insert SVG file and you will get this page - click ok and finish sketch

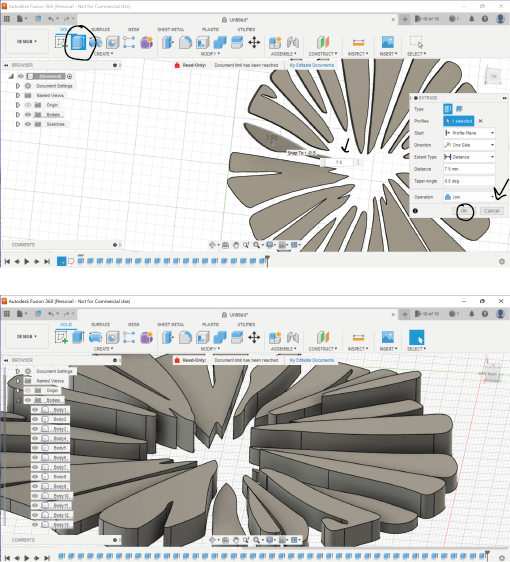

To make you 2D sketch 3D use the Extrude command shown in the picture, you can adjust the height by writing the number with Millimeters in the small box with an arrow pointing at it, I adjusted all my petals in different heights to have some sort of movement in the piece

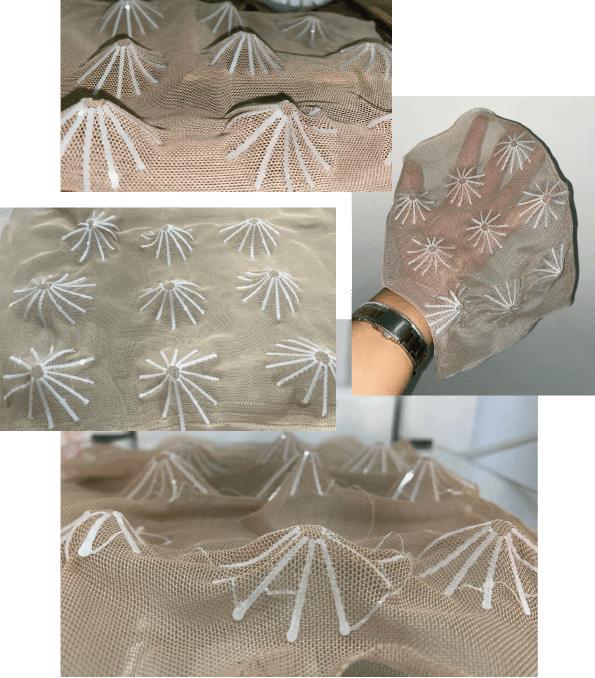

Printing on two ways stretch fabric¶

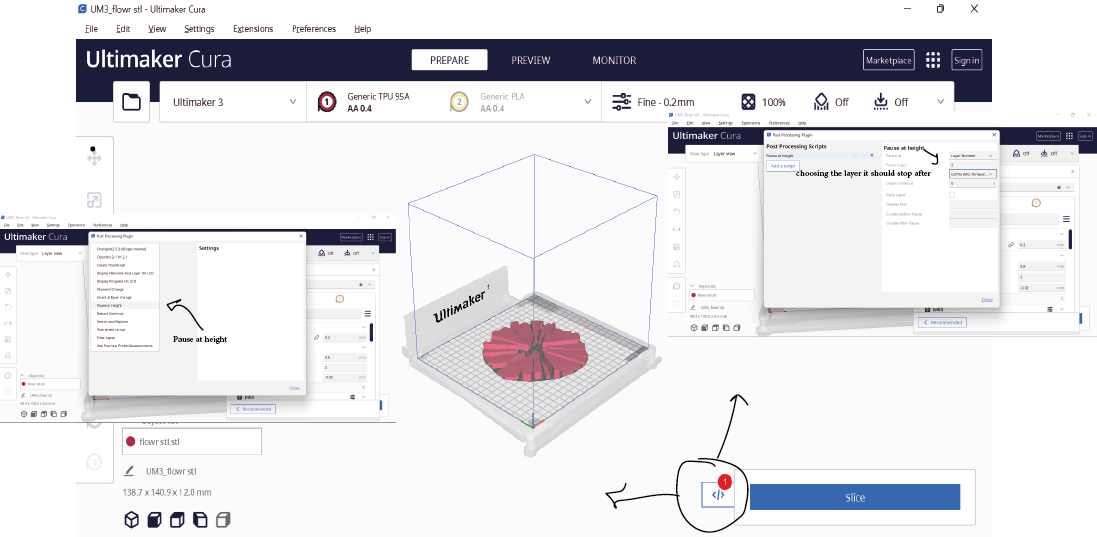

To make your print stick better on your mesh fabric try making the first layer on the bed of the printer pause the print put your fabric and continue printing, there is two ways to do that: - just press pause after the first or second layer

- change the G-code of the printer by adding a script that tells the printer when to stop

I used TPU filament to print this flower on a mesh fabric that stretch in two ways, TPU is a flexible nylon

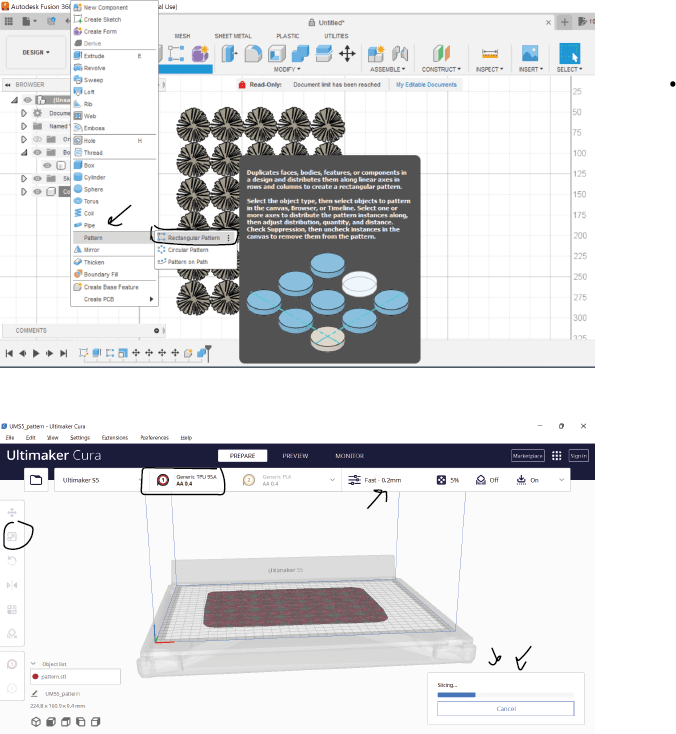

Cura settings¶

* printer ultimaker 3

* TPU filament

* infill 100%

* infill pattern lines

* build bed temp. 60

* no support

* no adhesion

* Printing Temperature: 228 °C

* Print Speed: 25.0 mm/s

* Layer height: 0.20 mm

make sure you stretch your fabric as much as you can and hold it with clips before printing to get better results

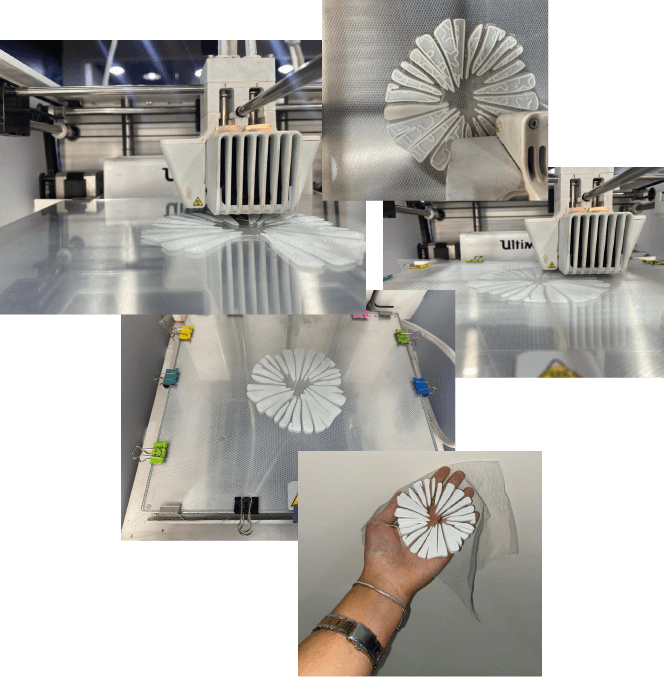

Even though this flower was printed using TPU it

came out very rigid because of the layers, the more

layers you add the more rigid your piece will become

Going through the prosses again to make a different design, I reduced my flower into an abstract lines, made a pattern to experiment how fabric will react and change shape according to the print

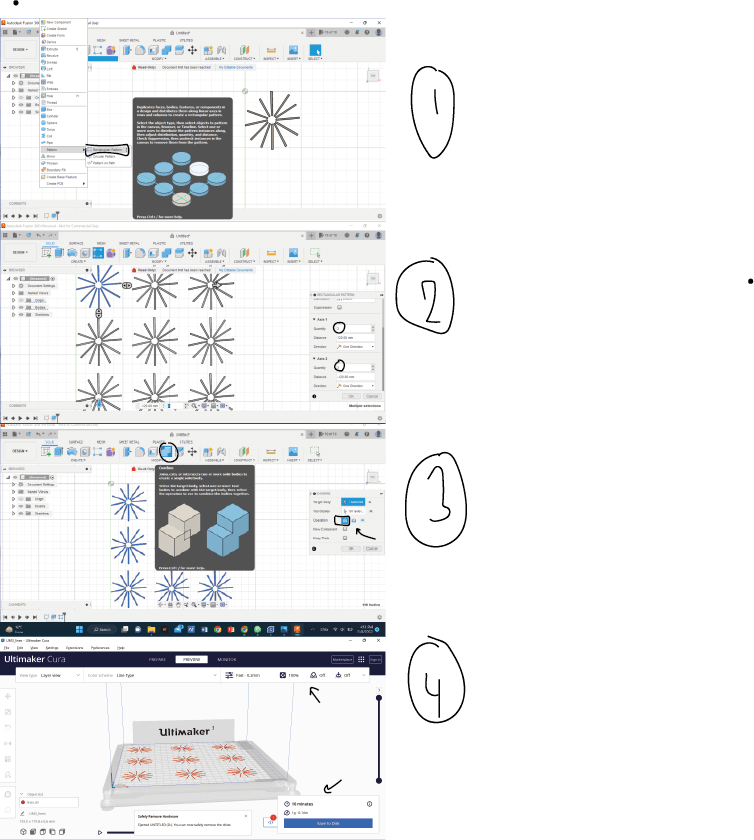

By following the steps shown below you can create a pattern for any 3D shape in Fusion 360 - 1) under modify you can find pattern, I selected rectangular pattern - 2) select the body you want to repeat, choose how many shapes you want - 3) select your pattern and click combine to make them all one component and save as an STL file, right click on the component click save as mesh - go to Cura change the setting as shown in the first design save to USB and print

Cura settings¶

* printer ultimaker 3

* extruder1 TPU filament

* infill 100%

* infill pattern grids

* build bed temp. 60

* no support

* no adhesion

* Printing Temperature: 228 °C

* Print Speed: 25.0 mm/s

* Layer height: 0.20 mm

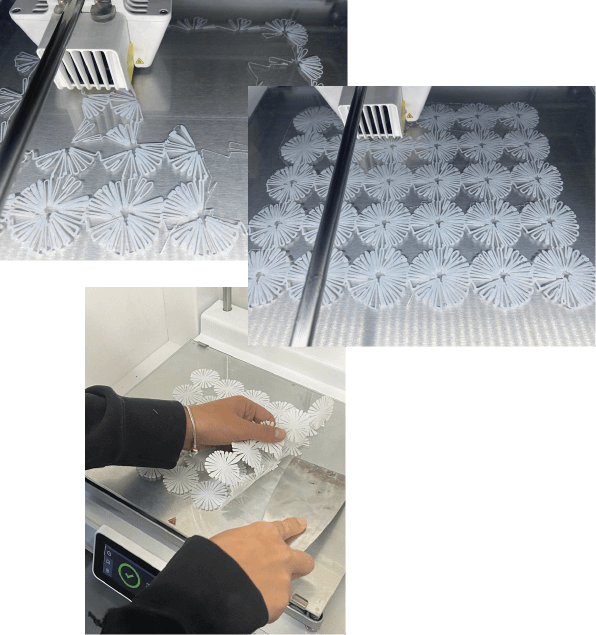

Printing¶

Results¶

Printing on one ways stretch fabric¶

With this kind of fabric there is no need to have a pre print on the bed of the printer you can directly start on the fabric, you can spot the difference in the way the fabric reacted to the print in this one and in the two ways stretch fabric, this one reacts less

Printing Textile¶

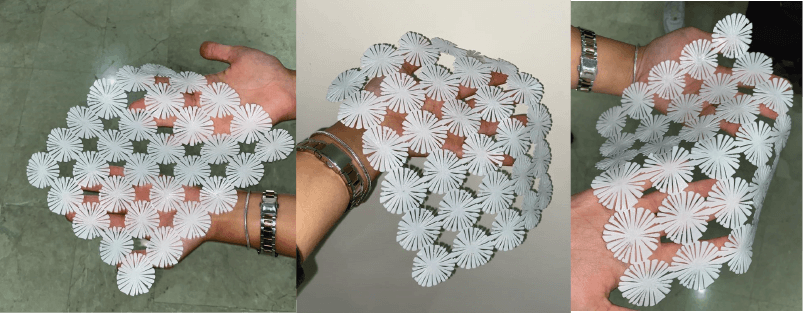

We can use 3D printing not just to print on fabric but to make textiles from scratch, I used my flower design to make this one - make sure your design is completely closed and make a pattern with the same steps I mentioned earlier

-

keep the shapes close to each other it ok if they overlapped a bit but they need to be touching each other

-

select all (Ctrl+A), choose combine and save the component as an STL

- open cure drag and drop your file change settings as desired and save it to a USB to print

Cura settings¶

* printer ultimaker 5

* extruder1 TPU filament

* infill 100%

* infill pattern lines

* build bed temp. 60

* no support

* no adhesion

* Printing Temperature: 228 °C

* Print Speed: 25.0 mm/s

* Layer height: 0.20 mm

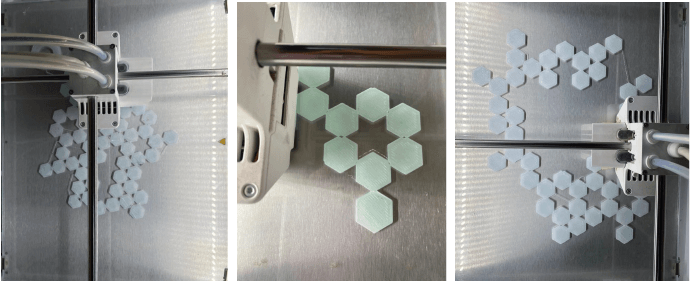

Printing¶

Results¶

This material was flexible, a little bit fragile,

not stretchy at all, this pattern can make a very

nice cardigan or blouse

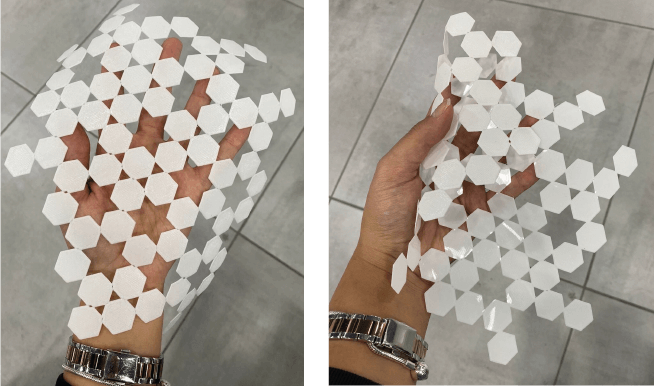

Islamic pattern design¶

Following the same steps with a different design - sketching - saving as SVG or DXF - inserting in fusion - extruding - saving as STL - open in Cura - change settings - save to USB - print

Cura settings¶

* printer ultimaker 5

* extruder1 TPU filament

* infill 100%

* infill pattern lines

* build bed temp. 60

* no support

* no adhesion

* Printing Temperature: 228 °C

* Print Speed: 25.0 mm/s

* Layer height: 0.20 mm

Printing¶

Results¶

This material as will is flexible, a little bit fragile,

not stretchy at all, and it can make a very

nice cardigan or blouse, or even table cloth

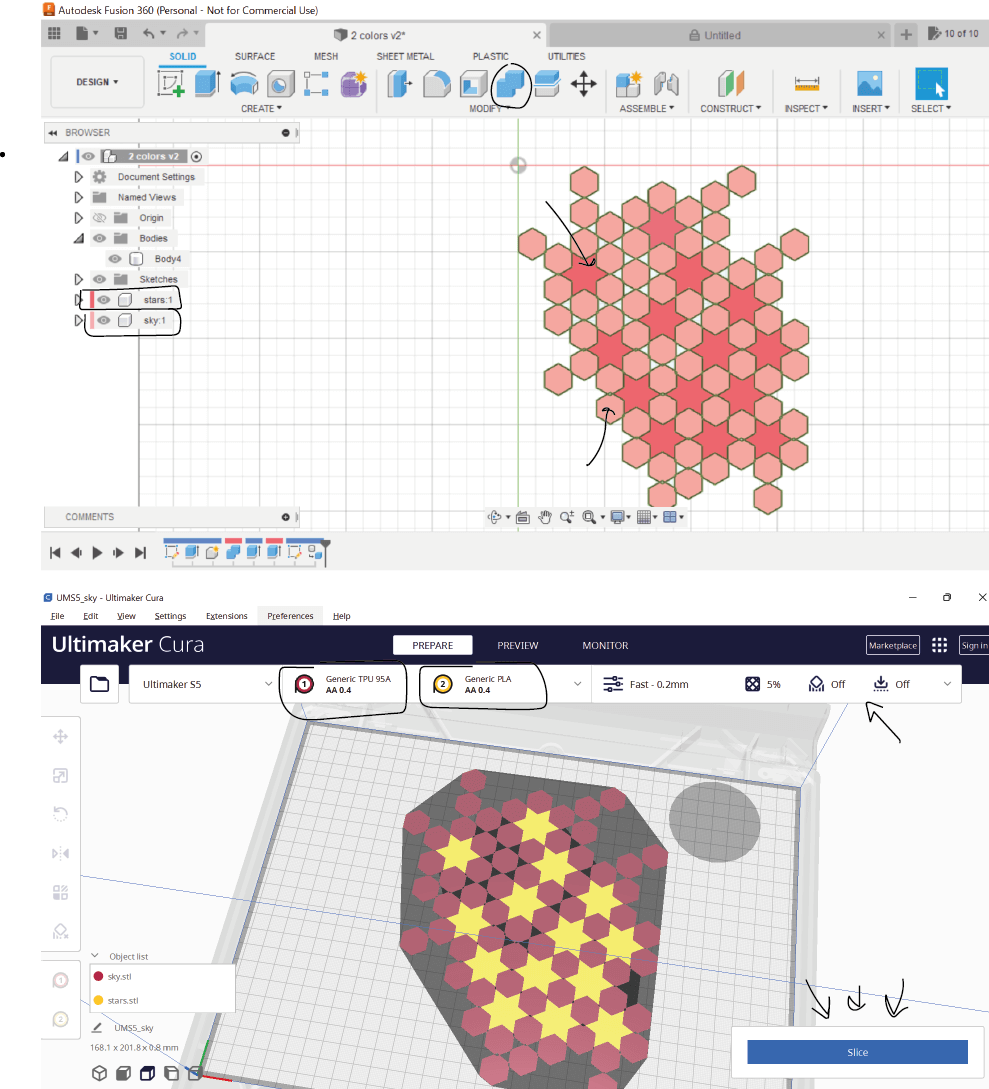

Adding colors¶

Here I tried using two different materials with two different colors to print this one, I used PLA and TPU, PLA is a rigid plastic material and TPU is a fixable nylon based material

How I made the design

I used the same design from the Islamic patterns I did before but I save it as two different components - first select the shapes you want in a different color and use the combine command to make them a component

-

select the rest and make component 2

-

save them as two separated STL files without moving anything in the original file

-

drag and drop both files in Cura together make sure they are aligned

You will need to change a little bit on Cura settings before printing make sure you enabled both nozzles and picked the right material ( the one you are printing with ), slice and save

Cura settings¶

* printer ultimaker 5

* extruder1 TPU filament

* extruder2 PLA filament

* infill 50% for both

* infill pattern zig zag for both

* build bed temp. 60 for both

* no support

* no adhesion

* Printing Temperature: TPU 228 °C PLA 210 °C

* Print Speed: 25.0 mm/s 65.0 mm/s

* Layer height: 0.20 mm for both

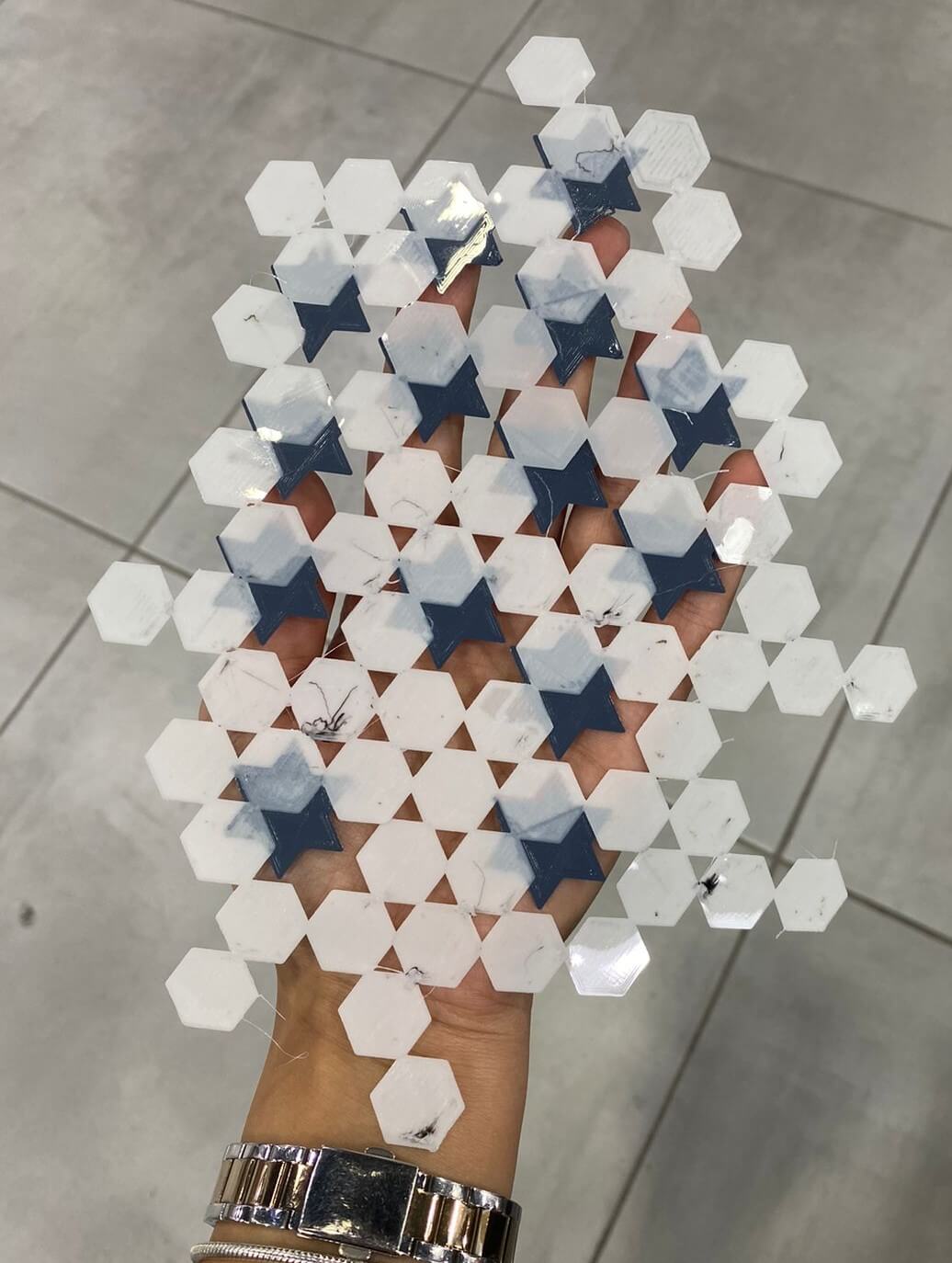

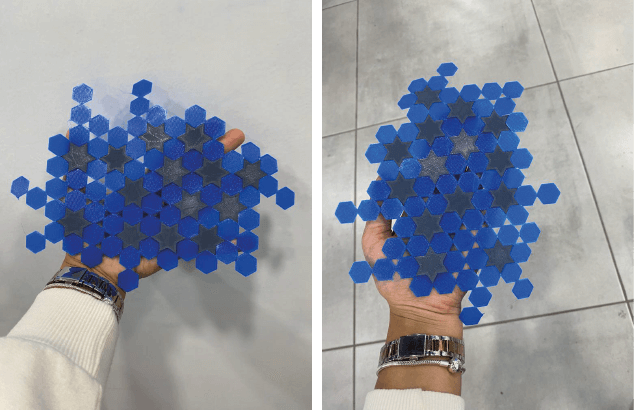

Printing¶

Results¶

The first one I did failed, maybe because something moved in Cura while slicing or preparing the settings so I tried again

This material as will is flexible, but the stars inside

are rigid they were printed using PLA, it is a little

bit fragile as will, not stretchy at all, and it can

make a very nice tapestry or table cloth

I loved the outcomes of this week very much the designs looked so much better when printed and came to life, this can actually