4. Biochromes¶

Global class by Cecilia Raspanti

For this project was requested to create a natural based colour study. Natural vegetal dyes were made and tested in animal and vegetal fibres. Personal catalogue was made with Hibiscus dye. A material catalogue was made with Burel - felted wool, collecting all the dyes tested by the group. Different inks were developed and tested on paper. Process of bacterial dye was developed in WetLab with bacteria Serratia marcescens

Assignment¶

A. Produce at least one natural dye or bacterial dye:

-

Natural dye - modifying it’s colour and mordanting it in different ways to dye at least 2 different categories of fibres

-

Bacterial dye - Explored dyeing with bacteria of different fibres and/or bacteria

B. Produce at least one botanical or bacterial ink:

-

Botanical Ink - explore different materials, recipes and understand how to adjust them based on the ingredients

-

Bacterial Ink - explore bacteria solvents and understand how to adjust or use the inks

Document your recipes, the ingredients and process and if there have been changes, document your unexpected discoveries:

-

Name your materials

-

Classify them by typology

-

Display them in a systematic order of samples

RESEARCH¶

Old natural dyes require land and time.

Modern dyes based on petrochemicals, representing many risks to human health and the environment

(i.e. dye bath contains chemicals).

"According to Forman (2016) Biotechnology presents not only a solution for application in textile production on an industrial scale but also enables its sustainable development."

"Colour and Ecological Behaviour in Textiles: a path to sustainable choices", Carolina Delgado et al, DTEX 2019 - Internacional Textile Design Conference Session #11, Sustainable Textiles, p.67 of Abstract Book

What is Colour?¶

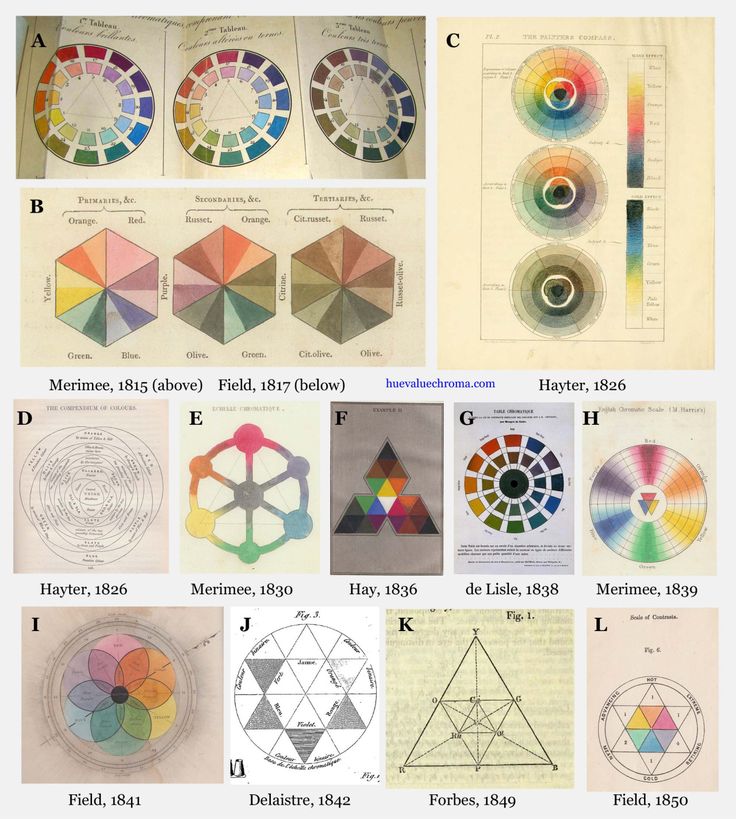

fig.1 - Exemples of Colour wheels designs of the 1800s, - David Brigs, the Dimensions of Colour

As described by Gerritsen the energy imitations imitated by mater reach the eye and are captured from the cornea to the retina and are sent to the optic nerve and are received by the cortex visual brain. (Gerritsen, 1975, pp. 45–51) The three-colour sensitivity systems of vision, for short, medium or long lengths give us the sensation of colours: blue, green and red when activated separately. When two of the colours are activated primary we get the perception of the colours called secondary: from red with the green, we get the sensation of yellow colour; from the red and blue visualization we get the sensation of magenta colour; of the green and blue visualization, we get the sensation of the colour cyan. As secondary colours become more or less activated in association, we will have the sensation of various colours, dividing the chromatic spectrum into several colourings. If all colour waves are on at the same time, we get colours neutral, ranging from white, grey to black. (Gerritsen, 1975, p. 68)

Natural Dye?¶

A Dye is a liquid that is soluble in water and put into the material. There are different types of dyes: acid, basic, direct dyes, mordant dyes VAT dyes, reactive dyes, disperse dyes, azoic dyeing, sulfur dyes, food dyes. Natural dyes are dyes derived from Organic sources (plants, animals, organisms) or Inorganic (minerals).

Organic Dyes¶

- Plant Dyes - are made from parts of plants like flowers, stems, leaves, bark, wood, algae.

- Animal Dyes - are made from insects and mollusc.

- Organism Dyes - are made from bacteria and myco (fungus).

- Minerals, earth, rocks, salt and metals.

Inorganic Dyes¶

- Minerals, earth, rocks, salt and metals.

Mordants¶

A substance to combined with a dye bath to prepare the fibres. It improves the fastening process of organic fibres. They also have an impact on the final colour. Alum - helps brighten the colours and assures a good light and wash fastness. Copper - has a greater effect on vegetable fibres than animal ones. While saddening the colours, it brings out greens and blues. Iron - often used as a modifier instead as of a mordant. Helps to darken and saddening the colours.

Modifiers¶

These are substances applied after the dye bath to extend the number of shades. The same modifier in combination with different mordants will produce different colours as well. With some dyes, the colour change is dramatic, with others is subtle and soft. Some modifiers change the Ph of the water, others act as a stronger mordant. Can be divided into 4 typologies of modifiers: Acidic, Alkaline, Copper and Iron Modifies.

Natural Ink?¶

An Ink is a dense liquid, also soluble in water and is put into the material. Is composed by vehicle, binder and additive.

Vehicle¶

Is the liquid in which the pigment is suspended. * Water – for liquid ink. * Ethanol – for marker ink - the substance that acts like a glue. * OIL / GEL – for printing ink - the substance that stabilizes, intensify, thickens the ink.

Binder¶

- Arabic gum - the substance that acts as a glue between the dyestuff and the liquid.

Additive¶

- Salt, vinegar or metals - the substance that helps to stabilise, intensifying, modifying, preserving or thickening the ink.

Bacteria Dye?¶

A Bacteria Dye is made from single-celled organisms, present in almost everywhere on earth, from the bottom of the sea to inside animals. Some common Bacteria Dye with safety level 1 are:

- Vogegella indigofera - colours blue.

- Janthinobacterium lividum - colours purple.

- Serratia marcescens – colours pink, red, orange and yellow

DYE & INK¶

Different fibres were prepared. Aldo the projects were collaborative, each chooses a dying material to work on. All the samples will be shared but this way we could achieve many more materials and shades of colours. In the other hand, each one has to use the dye in 9 different natural vegetal and animal fibres. After, will be tested modifiers so that we get a range of 3 samples for the same fibre and dye. The expected result is to assemble an individual catalogue of 27 shades - 9 fibres x (1 dye + 2 modifiers) A collaborative work assembling all materials and shades as a full-colour weel.

Personal work:

- Study on Hibiscus flower Dye on different fibres.

- Test on natural Ink.

- A small catalogue of Burel samples of collective dyes.

Process - Hibiscus Dye¶

- Preparing the fibres - Start by weighting your dry fibres (WOF). Wash and scour your fibres. Mordant your fibres with one of the mordants - we used Alum. Make sure you separate Animal fibres from Vegetal ones (Animal Fibres: Wash the fibres gently with lukewarm water and a little bit of soap. Vegetable Fibres: Boil the fibres for an hour in water and sodium carbonate (soda ash) ±2 spoons for 4-litre water) We used different sources of fabric and yarn forms: Vegetal fibres (Cotton, Sugar Cane, Algae, Hemp, Linen, Recycled Cotton) Animal fibres (Regular Wool, Burel felted Wool, Silk/Mohair and Silk).

- Make skeins of the yarns (4 x around the arm).

- Preparing the dye bath - 100 gr of Hibiscus flowers into +/- 2Lt water at 220ª and after boil turn to 80ºC.

- Submerge the materials and keep them for 30 min. Turn off and keep in the bath all night for darker reds (if you want lighter shades of pink take them after 30min).

- The Ph of the Dye was measure - Ph3.

- Materials were rinsed with lukewarm water.

- Materials were divided in 3. 1/3 part of the material stay to dry.

- On the 2/3 part was chosen to modify the Ph for more Alcaline with rinse water with soda (very small quantity - put on the water and test the Ph). Put more water if is too acid. We achieved Ph6/7. Note - is difficult to see the exact Ph because it changes very fast.

- Submerge the materials for 5 min. Then take them to dry.

- For the 3/3 part of the material, we made a water and soda bath with Ph9/10.

- Submerge the materials for 1 min. Note: because the bath is very alkaline and the Dyed material was very acid the colour changes very fast. To achieve a better result submerge one fibre at a time and take it of. Then take them to dry.

- Document all samples.

Youtube

Cecilia showing how to make skeins, Carolina Delgado

Preparing fibres: Animal fibres pot | Vegetal fibres pot | separated after, Carolina Delgado

Preparing Dye Bath | Submerged materials | Remove materials, Carolina Delgado

Separate materials to dry | Verified Ph of the Bath, Idem

Materials Dyed | after 1ºmodifier | testing Ph modifier | after 2ºmodifier, Idem

Teamwork, Idem

Material shades: Burel, Idem

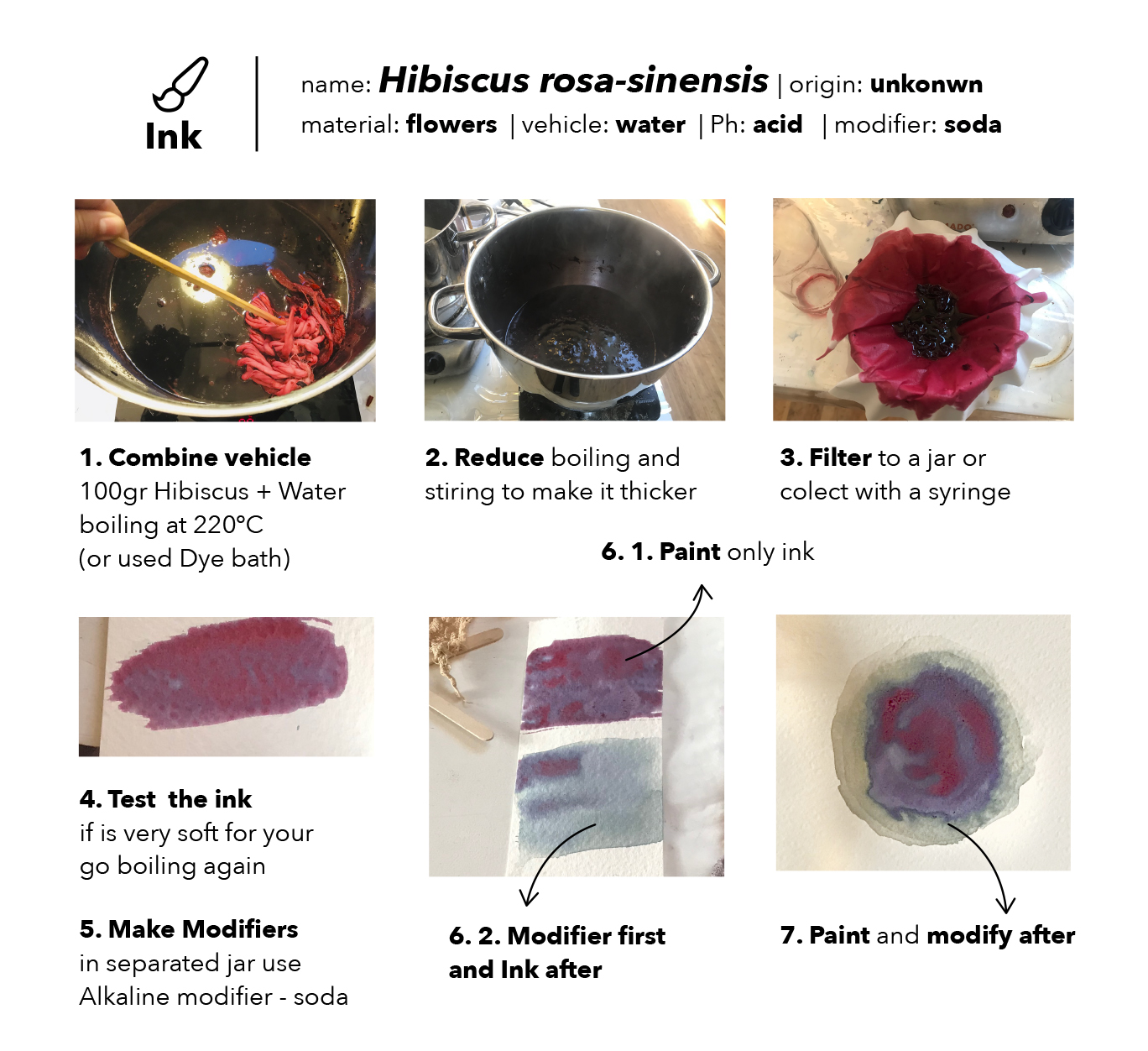

Process - Hibiscus Ink¶

- Keep the liquid of the Dyeing bath made before (point 3 from above) on the pan.

- Turn the heat to 200ºC and boil to evaporate most of the water.

- Collect to a jar part of the Dye and test it. Ours was too liquid so we boiled more time: 1h

- Use the link on a dish and try modifiers after painting soda+water, or prepare the paper with the modifier and use the ink on top.

- Future Note: for better results make a reduction more time till you get a thick liquid.

- Document tests.

Hibiscus Ink, Idem

Results¶

BACTERIAL DYE¶

Bacteria as “coloring machines”, Natsai Audrey

Process - Bacteria Dye¶

Welcome to the WetLab¶

Make a relax moment before you start!, Carolina Delgado

Meet your new friends¶

Bacterias colaborators, Carolina Delgado

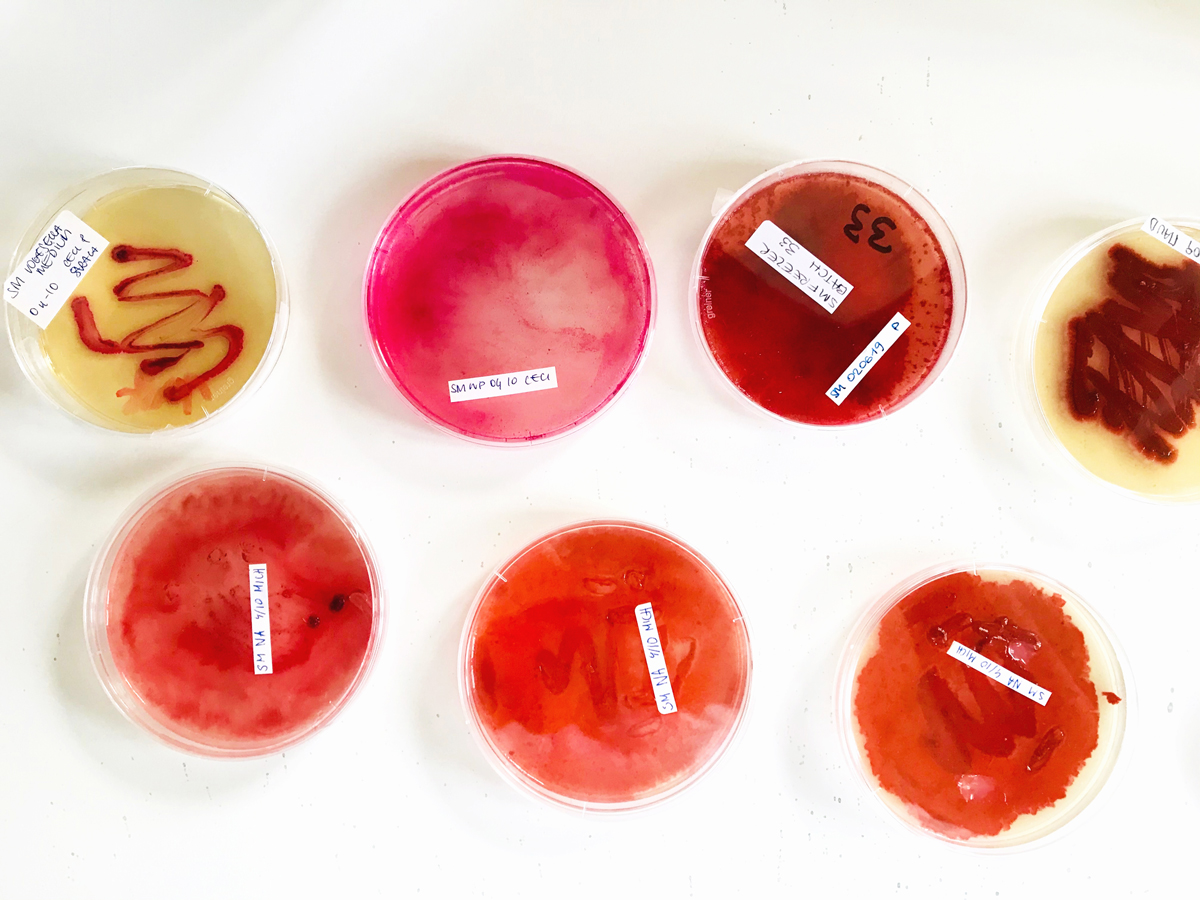

Tests on Bacteria Serratia - Serratia marcescens - on the WetLab

Bacteria Dye Process, Carolina Delgado

- At the Wet Lab take all the precautions to not contaminate the bacteria as well as yourself. Disinfect your hands when entering and leaving the room (ethanol or alcohol gel). Tie the hair and dress a white jacket. Don't eat or drink in the lab.

- Sterilize the silk fabric in Pressure Cook. Prepare pieces and fold it as you want. Stitch it with some points to maintain the folds.

- Prepare the growing medium. Measure the nutrient on a digital balance using a folded paper. Follow the recipe described in the jar. – We prepared 4 different types of food mixing ingredients with tap water (better filter first):

- LB Broth (LB) - Lisogenia or Luria-Bertani – 20gr to 1Lt water > liquid form

- Nutrient Agar (NA) – (25 gr to 1Lt water) we made 12gr to ½ Lt water - gel form

- Plate Count Agar (PCA) - 7gr to ¼ Lt - liquid form

- Veggie Agar (VA) - (62,2 gr to 1Lt) we made 15gr to ¼ Lt water - gel form

- Peanut butter (WP) - 1/2 teaspoon for (don’t use the oil part) to 375ml - liquid form

- Sterilize the textiles, Petri dishes and growing medium in the pressure cooker.

- Sterilize working is with ethanol and camping gas - keep a bubble when you are working

- Take the Petri dishes and pour growing medium - no talking, no moving or breath out over the working area.

- Place sterilized textile in dish.

- Innoculate the dish with Bacteria – harvest with the inoculation loop (sterilized on flame) and put on the dish.

- Identity the dish with the name of bacteria, growing medium, date and our name.

- Close the petri dish with Parafilm.

- Put the Petri dishes on the incubator at 24-26ºC and wait days…

- Kill the bacteria using the pressure cooker.

YouTube

Preparing food Petri dishes for inoculation of Serratia marcescens, filmed by Beatriz Sandini

Results¶

Recommendations¶

Videos¶

Youtube

Fashion has a pollution problem -can biology fix it? Natsai Audrey Chieza

Youtube

Making colour from bacteria, Karin Fleck, TEDxCanggu

Process by Cecília R.¶

HOW TO DYE:

- Start by weighting your dry fibres (WOF)

- Wash and scour your fibres

- Mordant your fibres with one of the mordants

- Prepare the dye bath based on the WOF: make enough dye to submerge completely the fibres

- Measure the PH or your dye

- Rinse with lukewarm water

- Choose between mordanting again, colour change by mordanting or by modifying the PH of your rinse water.

TOOLS & INGREDIENTS:

- StovePots

- Scale

- Mixing spoons

- Water Dye

- Alum

- Copper & iron liquor

- Washing powder Vinegar

- Soda

- Sodium carbonate

- Silk, Cotton, Linen etc.

SAFETY: Always be careful when handling alum, copper or iron liquor and other mordanting or scouring material. Wearing gloves and a lab coat is safer if you are not used to working with natural dyes. NO FOOD OR DRINKS AROUND!

How to prepare the Fibres: Animal Fibres: Wash the fibres gently with lukewarm water and a little bit of soap. Keep in mind that too much friction and heat will felt the wool, while it will damage the silk fibres making them dull and brittle. Also, sudden temperature changes are not recommended with animal fibres. Vegetable Fibres: Boil the fibres for an hour in water and sodium carbonate (soda ash) ±2 spoons for 4-litre water. This process will remove the oil and waxes that are naturally present in the fibres. It’s good to repeat this process twice or to start by washing the fibres at a high temperature in the washing machine.

HOW TO COLLABORATE WITH BACTERIA:

- Place the textiles in an autoclave bag for 121 degrees

- Mix growing medium

- Sterilize the textiles, Petri dishes and growing medium in the pressure cooker

- Sterilize working area with ethanol and the camping gas

- Tag your Petri dishes and pour growing medium

- Place sterilized textile in the dish

- Inoculate the dish with bacteria

TOOLS & INGREDIENTS:

* 500 ml glass bottle with cap that fits into the pressure cooker

* Nutrient broth NR1 (sigma aldrich)

* Nutrient Agar

* Pipette

Glycerine

Water

* Pressure cooker

* Electric stove

* Petri dishes

* Inoculation loop

* Camping gas + lighter

* Parafilm tape

Silk, Cotton, Linen etc.

SAFETY: Always be careful when handling bacteria and other biological material. Wearing gloves and a lab coat is safer if you are not used to working in a bio lab. Clean your hands after with ethanol and soap. NO FOOD OR DRINKS AROUND!

Links¶

References¶

- Forman, G. A. da C. S. (2016). - The importance of biotechnology in the textile industry

- Gerritsen, F. (1975). Theory and Practice of Color: A color theory based on laws of perception. London: Studio Vista.