Seaweed Materials¶

FIBRES¶

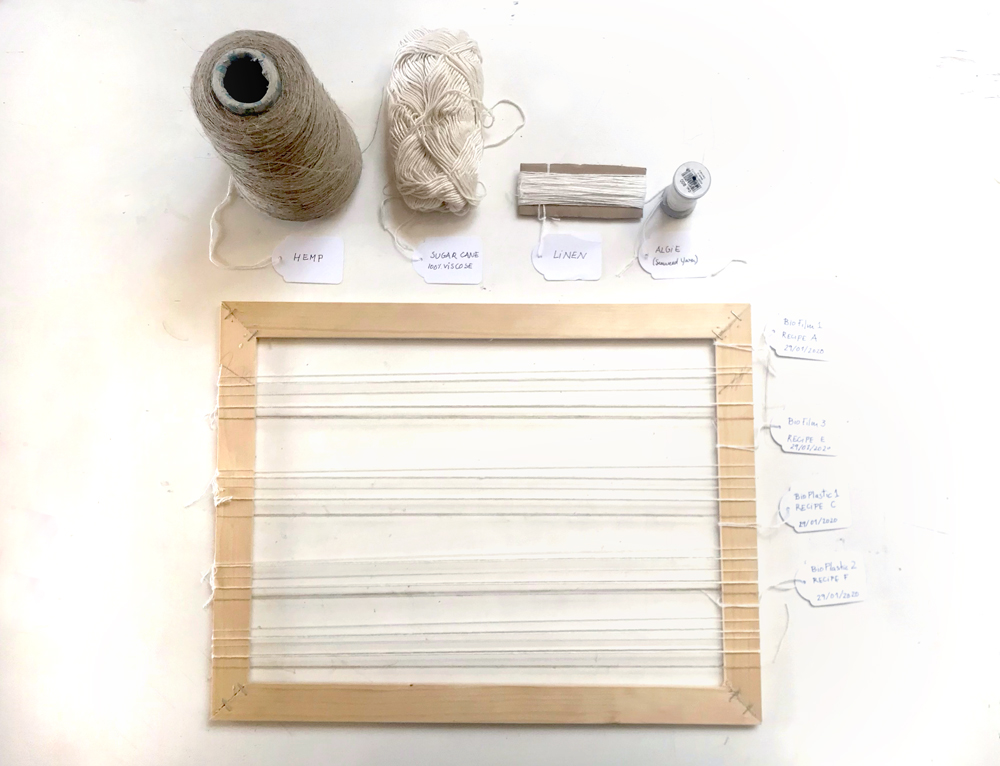

To start testing the behaviour of Bioplastic in yarn for Sustainable studies I decided to use only nature-based fibres. We had much variety of fibres already at TextileLab Amsterdam. However, we have to know them and make sure of first choices. It was relevant for this project to start with raw or not coloured fibres so that we could understand the results better. After a quick view and a first selection, we prepared a collection of 14 yarns. But without the certainty of some fibres, we start by testing them.

The Burn Test¶

How to know Animal, Vegetal or Acrylic Fibres?

- Cotton - Catches fires quite fast; the smell is very different from the wool, smelling like burned paper; the flame turns yellow.

- Wool - Strong smell of burned hair; when take off the flame stops burning; the flame slowly dies.

- Bamboo - Imflamable; flame deep yellow almost orange; smell similar to cotton; the strays will fall apart.

- Acrylic - Catch fire fast; strong light and burns longer than bamboo; the smell is chemical and the ashes are like bead crispy plastic.

Resume

The Burn test was made on 15 yarns and one cotton mesh, only one reveals wool.

Some had identification others did not.

Yarn Types:

1. Cotton mesh

2. Acrylic knitting yarn

3. Acrylic knitting yarn

4. Mohair Wool

5. Linen yarn

6. Recycled Cotton

7. Regular Cotton

8. Polyester green thread

9. Polyester white thread I

10. Polyester white thread II

11. Not identifyed yarn (?)

12. Sugar cane yarn (100% viscose)

13. Hemp yarn

14. E-Textile Merino (80% wool, 20% Inox steal)

15. Algie yarn

16. Silk Spinning Test (40% Tussah silk, 40% Bombyx morus silk, 10% Pima Cotton, 10% Linen)

Results

image

Testing the fibres, Carolina Delgado

Conclusions

The Burn test was made on 15 yarns and one cotton mesh, only the yarn 4 reveals wool.

Most of the simple yarns to sew were synthetic.

The supposedly 100% cotton mesh reveals chemicals, suggesting that is made from recycled cotton with parts of polyester or other synthetic.

We did not have enough Algie yarn desired for the final project, but we opt for using plant-based yarns to test the first steps. That way we could not only compare them but also start working before our order of 2 different Algie yarns arrive.

Reference¶

BURN TEST for Wool, Cotton, Bamboo and Acrylic Yarn, 10 Rows a day

Un-twining a yarn¶

Comparing the Sugar cane yarn with the desired Algie yarn, it appeared very thick. The yarn was made by the torsion of 6 thread so the solution was to make 2 options: one maintaining the original yarn and other with only one thread.

How to untwine the yarn without a machine, Carolina Delgado

This was the faster solution I imagine. It can consume lots of time and patience but I just wanted some meters for the first tests.

Note: I've learn that it is possible to make a yarn with different threads by attaching 2 or more on one side (e.g. on the doorknob), and in a cardboard with a hole attached to a drill!

BIOPLASTICS¶

To achieve a waterproof material was chosen the Alginate base instead of Agar and gelatine. In collaboration with Lorena Trebbi, a PhD student from Rome, were made 6 recipes of Alginate at the WetLab.

Alginate Recipes, Carolina Delgado

Alginate Recipes, Carolina Delgado

Bio-Films¶

Recipe A¶

16 gr Alginate | 30gr Glycerol | 400 ml Water

Recipe B¶

16 gr Alginate | 30gr Glycerol | 200 ml Water

Recipe E¶

16 gr Alginate | 30gr Glycerol | 800 ml Water

Bio-Plastics¶

Recipe C¶

24 gr Alginate | 40gr Glycerol | 600 ml Water | 20 gr Sunflower oil

Recipe D¶

24 gr Alginate | 40gr Glycerol | 200 ml Water | 20 gr Sunflower oil

Recipe F¶

24 gr Alginate | 40gr Glycerol | 800 ml Water | 20 gr Sunflower oil

How to¶

Put all the ingredients in the blender machine and mix it and leave it overnight, so the bubbles come out. In the next day, you'll be able to use it spray sodium chloride hydrate before you put the material. Remember to apply after if you want to dry it faster and become waterproof.

From the six recipes, the ones with less water results in very thick material, difficult to apply with brush, syringe or even dip in the fibres. Therefore, they were discarded, and we tested the remain 4 (A, C, D and F).

Calcium Chloride Hydrate¶

Was made on a sprayer bottle with: 10 gr Calcium Chloride | 100 ml Water

For the bath to curate the BioYarn, I chose to use more water so that it gives more time to manage the syringe.

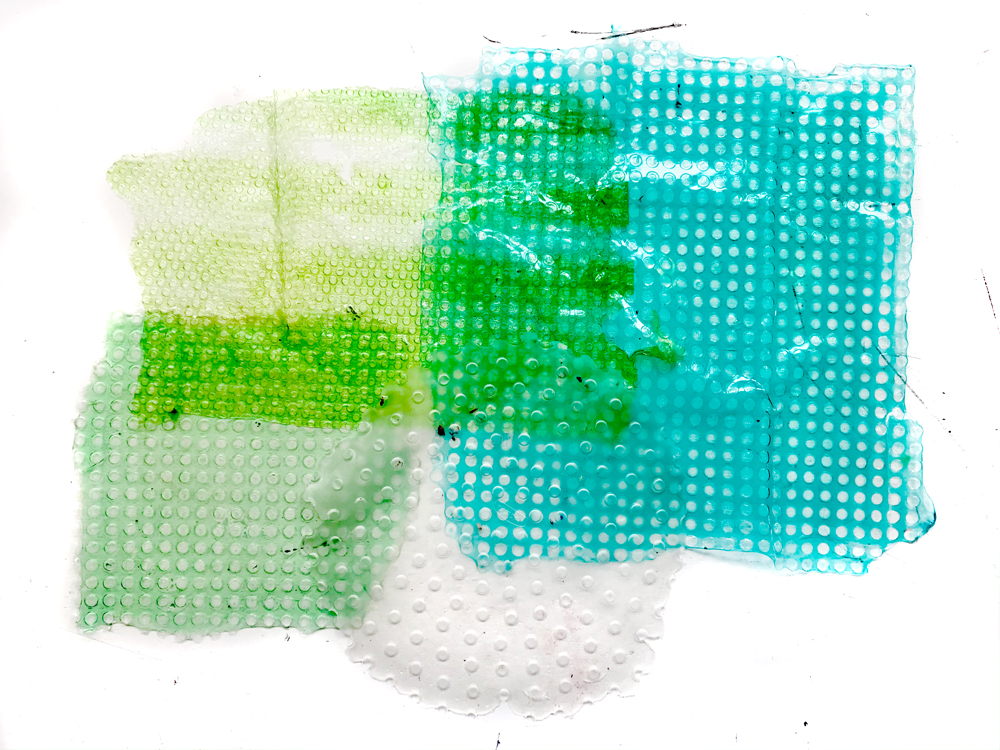

Alginate Biofilms, Carolina Delgado

Alginate Biofilms, Carolina Delgado

Test 1 - Brush¶

Yarns on frame, Carolina Delgado

For the first test were used 5 samples from 4 fibres. They were stretched in a frame and brushed with different Alginate bioplastics recipes. The fibres after brushed automatically became loose so some of them had to be tied again. For the same reason, it as put a stick of wood so that the yarns were more stretched.

Then they were sprayed with calcium chloride solution.

After dry, they were removed. Some small pieces of plastic are attached to the fibres and the parts that were touching the frame didn't receive bioplastic.

Results

Yarns brushed with Alginate, Carolina Delgado

Conclusions

The yarn that behaves more similar to Algie yarn was linen (note: it was yarn and not a thread). Good for use in knots tests.

The fibres appear not to absorb enough bioplastic to became covered and waterproof.

Test 2 - Dip in¶

There still was enough Algie thread to this test so it was only used this one. Were cut thread of 2 mt, dipped in the recipes of Alginate with food colours (to easy identification). Then passed by a calcium chloride hydrate bath and then in another water bath. They stay over a plastic fabric for drying on air.

Results

Algie Yarn diped in Alginate, Carolina Delgado

Conclusions

All the yarns became more rigid. They absorb more Alginate material so they became more thief and I supose waterproof (to test).

Recipe of bioFilm 3 was the easier to work with. It is hard to dip in the yarn, so the better way is to put it all in and remove separate (the stretch as possible) and slowly dip in the calcium chloride bath. Then it was washed to be sure that the calcium chloride excesses were removed and stop curing.

BioPlastic 1 result was very curly hard to work after dried.

Note: need a dip in machine to make the coating the threats.

Netting¶

Weaving Net (NL)¶

My first trial was with a Sugar Cane threat (the one collected from the yarn). This one was chosen for its similarity to the Algie yarn, as the Linen, but also, because (Surprise!) it is from a Portuguese company with I recognise for it quality wools and yarns.

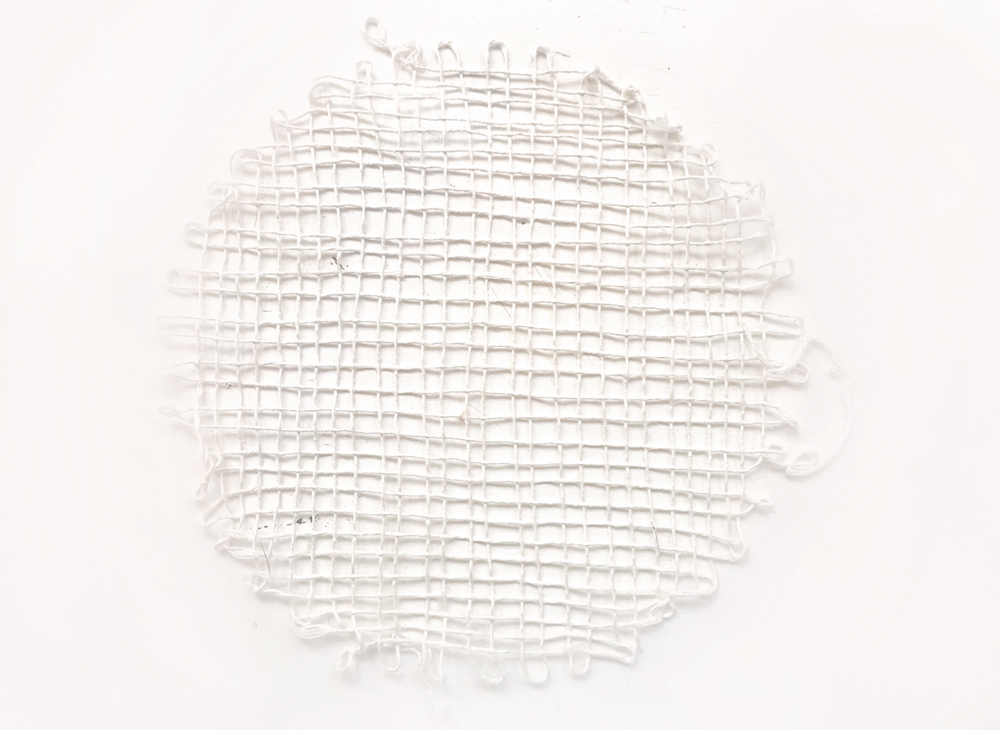

A net was made over a 29,5cm round knitting loom. The horizontal and vertical threats were intersected alternated. I did not use knots as a usual net because I wanted to test the glue effect of the Alginate as a result.

SugarCane and Alginate net, Carolina Delgado

SugarCane and Alginate net, Carolina Delgado

Knitting, Crochet and cardboard Weave (PT)¶

Another interesting thing to test was the elasticity of the loose knitting, so I used 5mm needles.

Crochet - Other 2 small samples were made with 2,5 and 5mm crochet needles.

Cardboard was cut with marks of 5mm to create another small net (smaller than the one made on the knitting.

Was left to dry during the weekend.

Note: The pins and nails that I used became rusty, therefore for the final 3D Loom the screws have to be water resitant.

Linen and Alginate - Weaving, kniting and crochet, Carolina Delgado

Linen and Alginate - Weaving, kniting and crochet, Carolina Delgado

Linen Orb with Alginate (PT)¶

The orb was made with a round knitting loom to create concentrical lines of the orb and then intertwined a circular orb beginning from the centre. Using a brush, was applied the Alginate bioplastic (?) on both sides and sprayed with the 10% Calcium Chloride Hydrate. Was less to dry on room for the weekend.

Linen Orb with Alginate, Carolina Delgado

Spider Web Concept¶

Spider Web groceries bag, Carolina Delgado

Spider Web groceries bag, Carolina Delgado

BIOYARNS¶

Extruding Alginate BioYarn with a syringe.¶

Fabricademy Bootcamp 2019, with Anastasia Pistofidou. ICELAND, Tækniskólinn Technical College, Reykjavìk.

Extruding Alginate BioYarn with a syringe, Carolina Delgado

I tested here in the TextileLab Amsterdam with the syringe (without the fine point) and the conclusion was that the calcium clroride hydrate must be half of the concentration to give time for the manual pumping the syringe.

- A syringe with Alginate BioFilm or BioPlastic

- Pot with calcium chloride hydrate (only 5%)

- Tap water to wash the calcium chloride.

Samples of Bioyarns (NL)¶

I made different tests on bioyarns using a syringe and a calcium chloride bath (with less %) so I could have time to press the bioplastic out of the syringe (hard work!). All the Alginate materials were coloured using food colours so that it was easier to identify each one of them. Also made a collection of samples of each one to compare the difference in yarns and in Petri dishes and Lego silicon moulds.

Alginate BioYarns and Knitting, Carolina Delgado

Alginate BioYarns and Knitting, Carolina Delgado