Blue-Green Horizons: Redefining Alginate Bioplastics with Spirulina Dyes¶

Blue-Green Horizons: Redefining Alginate Bioplastics with Spirulina Dyes

Article selected for publication on Springer Materials Circular Economy in Vol. 6, Article 7 (2024) after double peer review.

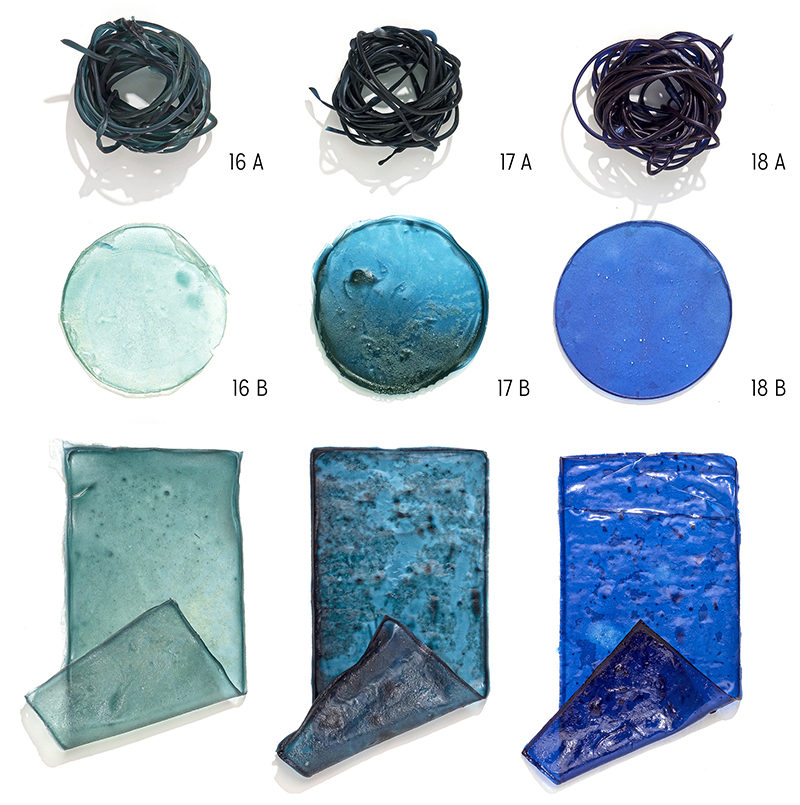

Graphical Abstract, Alginate bioplastics with Spirulina Dyes, photos by Luís Silva Campos

Article - Original Research Paper¶

DOI: 10.1007/s42824-023-00099-1

Materials Circular Economy (2024) 6:7, SPRINGER PDF

License CC BY 4.0

It was a collaboration with Fabricademy, and with my supervisors Gabriela Forman, PhD, from Lisbon School of Architecture, Universidade de Lisboa, Portugal and Arlete Apolinário, PhD, from IFIMUP - Institute of Physics for Advanced Materials, Nanotechnology and Photonics, Faculty of Sciences, University of Porto, Portugal.

To cite this article:¶

Delgado, C., Forman, G. & Apolinário, A. Blue-Green Horizons: Redefining Alginate Bioplastics with Spirulina Dyes. Mater Circ Econ 6, 7 (2024). https://doi.org/10.1007/s42824-023-00099-1

Abstract¶

This study introduces a novel, eco-friendly approach for the extraction and application of Spirulina (Sp.) pigments in alginate bioplastics, representing a significant advancement over traditional dyeing methods. The research explores a zero waste model process in a Fab Lab setting, involving three stages, liquid dye preparation, fibre dyeing, and bioplastic dyeing, with a focus on utilizing all by-products sustainably. In the liquid dye preparation phase, vibrant blue-green pigments were successfully extracted from Spirulina powder. The colour depth depended on the Spirulina concentration and the precipitation method used, with pH playing a critical role in achieving a range of green–blue hues. The fibre dyeing phase tested Spirulina dyes on various natural fibres, examining the impact of alum mordant pre-treatment on colour absorption and stability. Optimal dyeing results were obtained with a 1:1 ratio of Spirulina-filtered powder suspension to alum acid precipitation solution at a pH of 4. The techniques optimized were then applied to alginate bioplastics, including bio-yarns and bio-films, yielding a wide spectrum from green to blue. Bio-yarns showed better colour retention compared to bio-films, possibly due to residual alum. However, challenges in long-term colour stability and structural integrity against environmental factors like oxidation and humidity were observed. The study contributes valuable insights into the application of natural dyes in bioplastics, particularly in achieving blue and green shades with a Spirulina zero waste model. This work is significant for future sustainable material science research and emphasizes the importance of balancing aesthetic, functional, and environmental factors in circular design.

Keywords¶

Spirulina dye, Alginate bioplastics, Design through practice, Fab Lab, Circular design

Acknowledges¶

C. Delgado acknowledges FCT - Fundação para a Ciência e a Tecnologia, I.P., under the Strategic Project with the references UIDB/04008/2020 and UIDP/04008/2020, and PhD Research Scholarship FCT 2021.04708.BD.

A. Apolinário acknowledges FCT (Fundação para a Ciência e a Tecnologia), contract DL57/2016 (Ref. DL 57/2016/CP1454/CT0017) with DOI 10.54499/DL57/2016/CP1454/CT0017 (https://doi.org/10.54499/DL57/2016/CP1454/CT0017) and projects H2FlexiPEC’s (ref. 2022.07332.PTDC) - DOI 10.54499/2022.07332.PTDC (https://doi.org/10.54499/2022.07332.PTDC), CERN/FIS-TEC/0003/2021, UIDB/04968/2020, UIDB/04968/2021, and LA/P/0095/2020.

The authors gratefully acknowledge TextileLab Amsterdam/Fabricademy collaboration and Luis Silva Campos for the sample photos.