6. Biofabricating¶

Biofabricating is the original way of life material fabrication.

From the theory of ARN world, preceeding proteins, nature has developed through evolution all the materials needed to sustain life. Latter in evolution history, carbohidrates and proteins where used by life to create polimers to fullfil the necessity to support diverse structures, from the lignin of trees to the feathers of a bird.

Even the oil (petroleum) is actually biofabricated. Something alive (not dinosaurs, but zooplankton and algae), made the biopolimers that latter was converted in hidrocarbons.

Humanity has been using biomaterials form the beginning of the technology. Animals, plants and other organisms have provided the materials for different applications until relativelly recent times. The century of fossil fuels and plastics somehow displaced the use of grown materials (timber, wool and plant fibers). Unfourtunatelly, greenhouse gases and plastic pollution are things that wasn't counted in the ecuation, and now they have become the most serious problem that humanity is facing.

In this week we are going to experimet with the growing and processing of bio-materials. Crafts made with this stuff are very symilar to the synthetic ones, are biodegradable and not petroleum based.

Fabrication and recipies¶

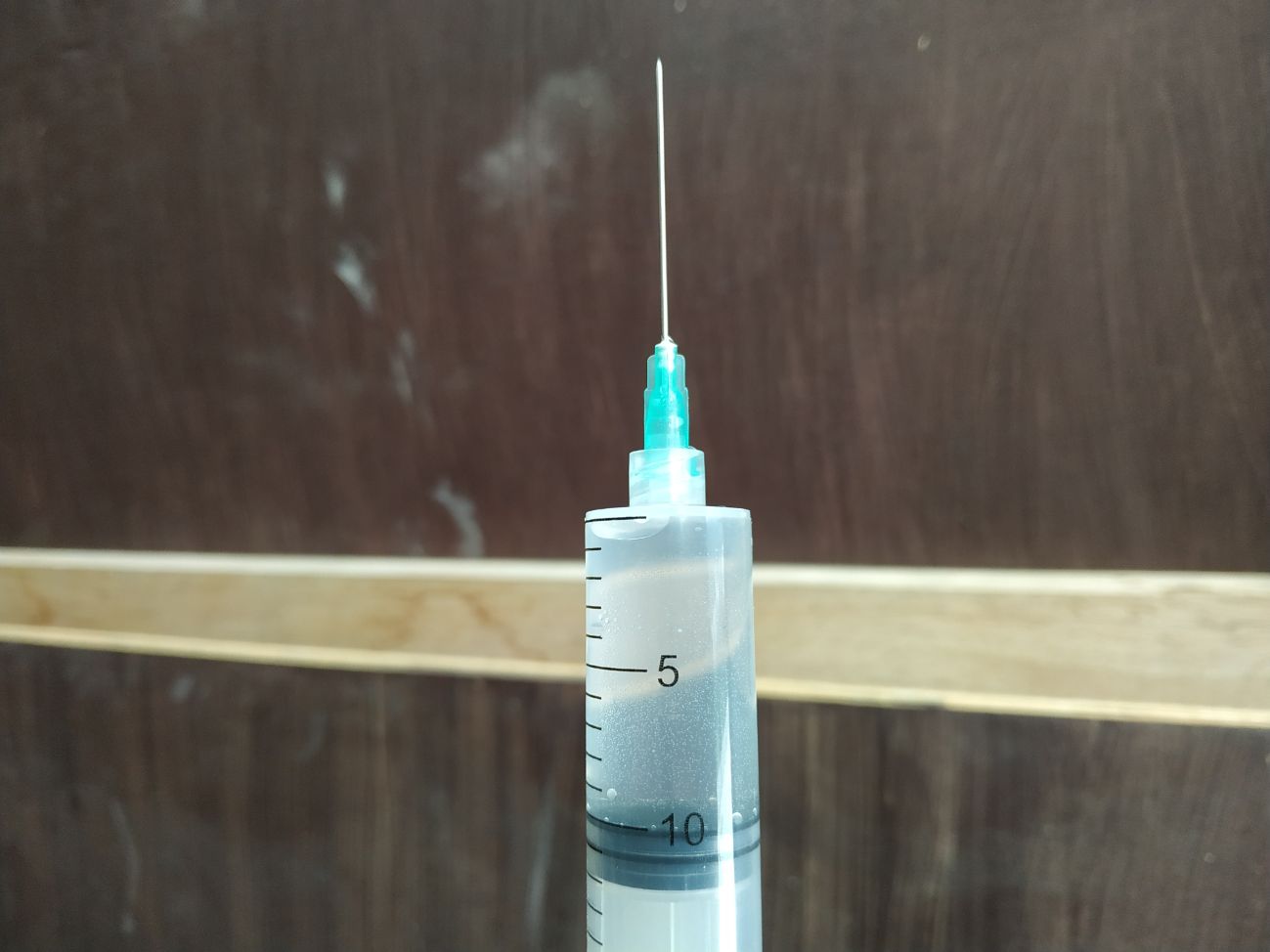

For measuremet of the quantities we can use generally weight or volume. For water, it is useful to use pipettes or sringes, because the density is relativelly constant (1gram/1cm3). For more precise quantity of matter measuremet though, it is better to use the force the substance is deforming a sensor, in other words, weighting it.

For volume, we used a sringe.

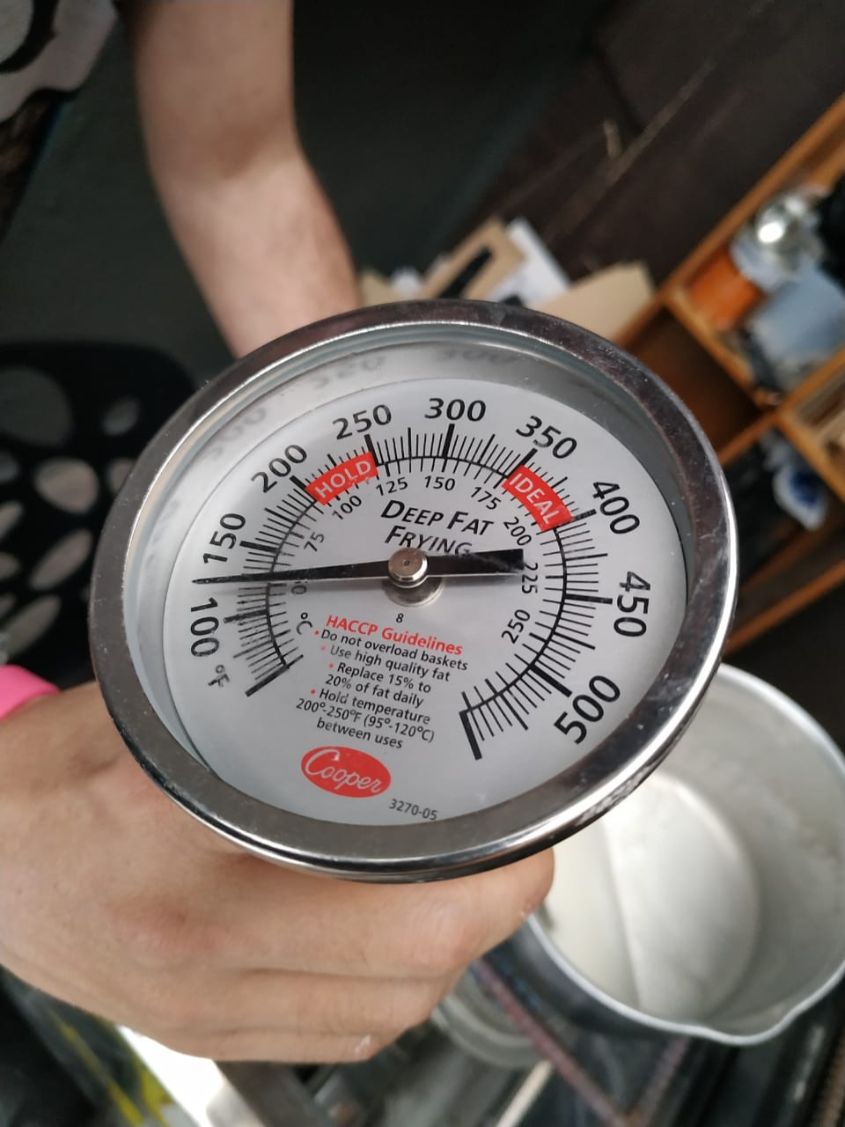

For temperature, we used an industrial thermometer. This one can meaure up to 300°C.

Cassava bioplastic.¶

For this bioplastic we are going to polymerize come from the energy-rich storing carbohydrate starch. Using temperature we can open the bonds of the molecules, and when the temperature goes down, they polymerize spontaneously, with the help of the acid environment (vinegar).

The starch we use come from the species Manihot esculenta, that we need not to confuse with the unrelated yucca.

| Ingredient | mass |

|---|---|

| Cassava Starch | 60 gr |

| Water | 60 gr |

| Glycerin | 100 gr |

| Vinager | 20 gr |

Cassava content.

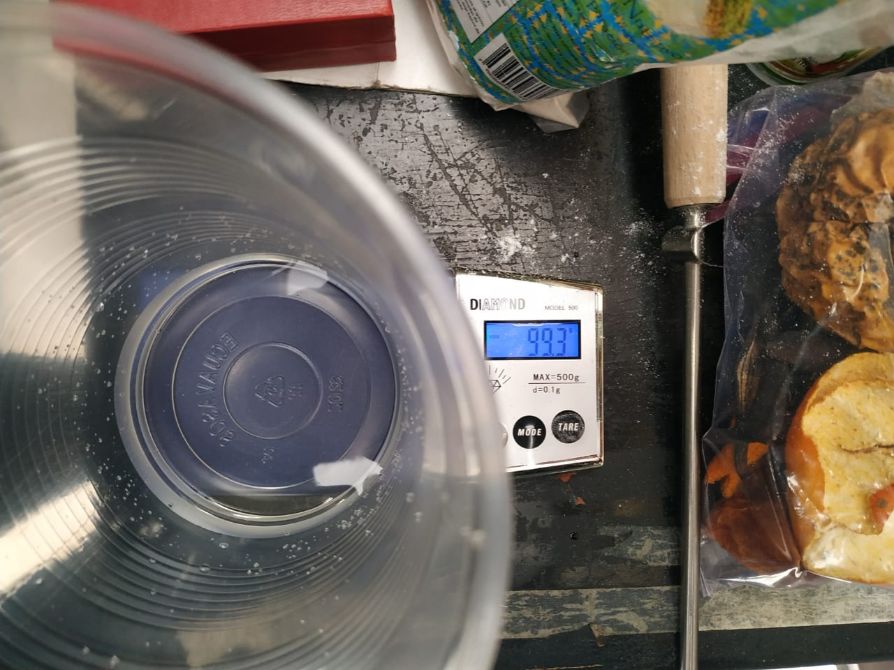

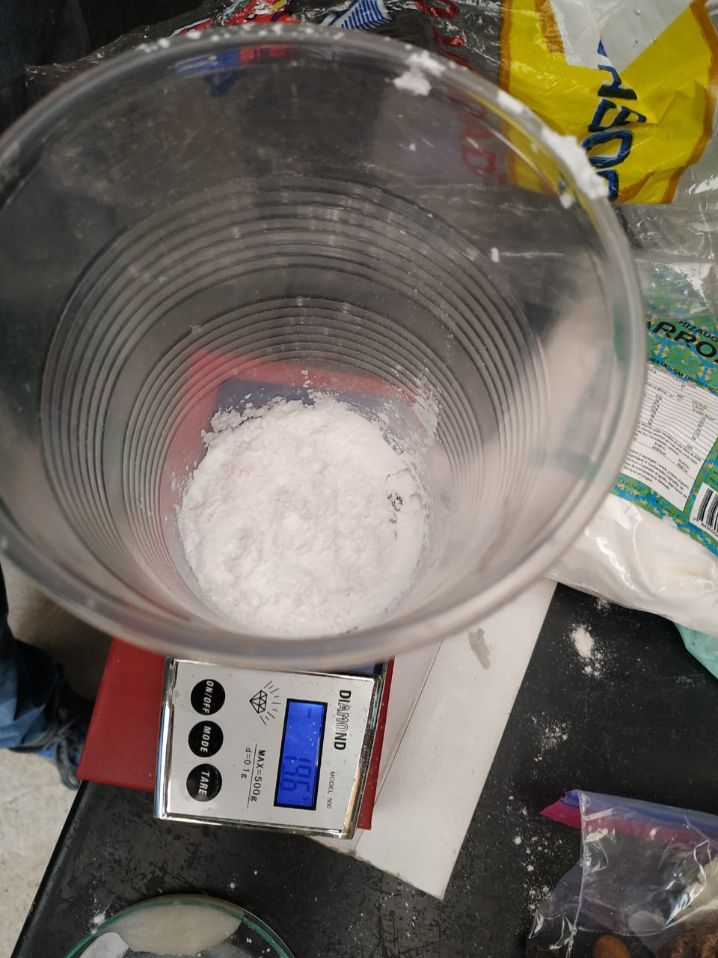

Starch weighting.

Water weight.

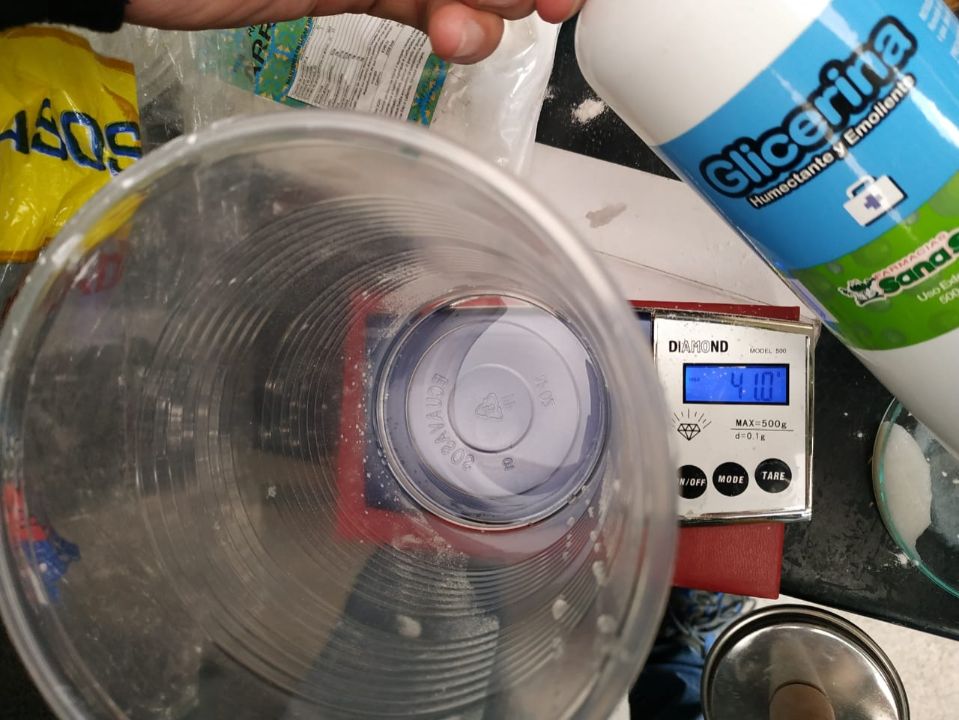

Glicerin weight.

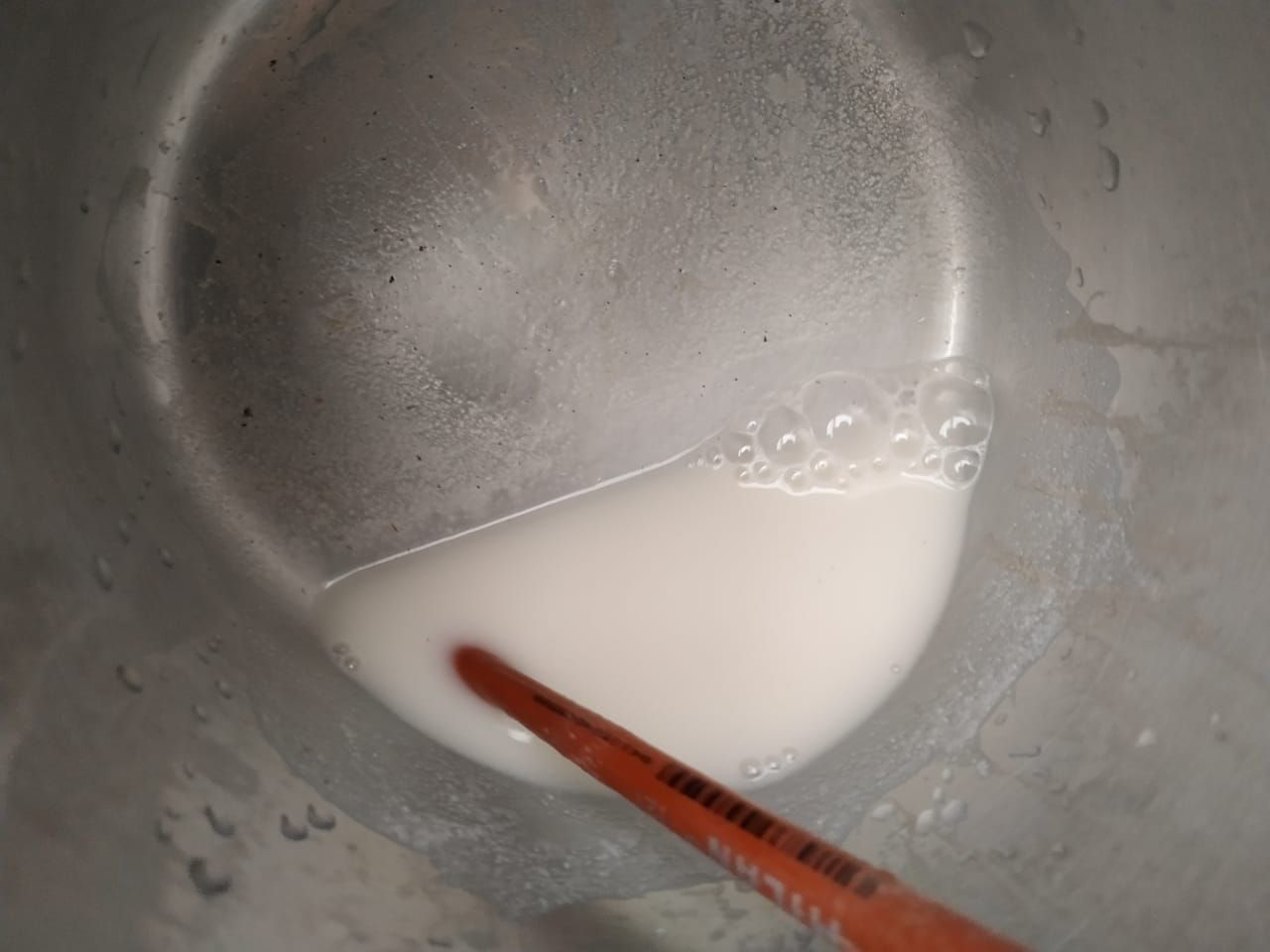

Starch heating and temperature.

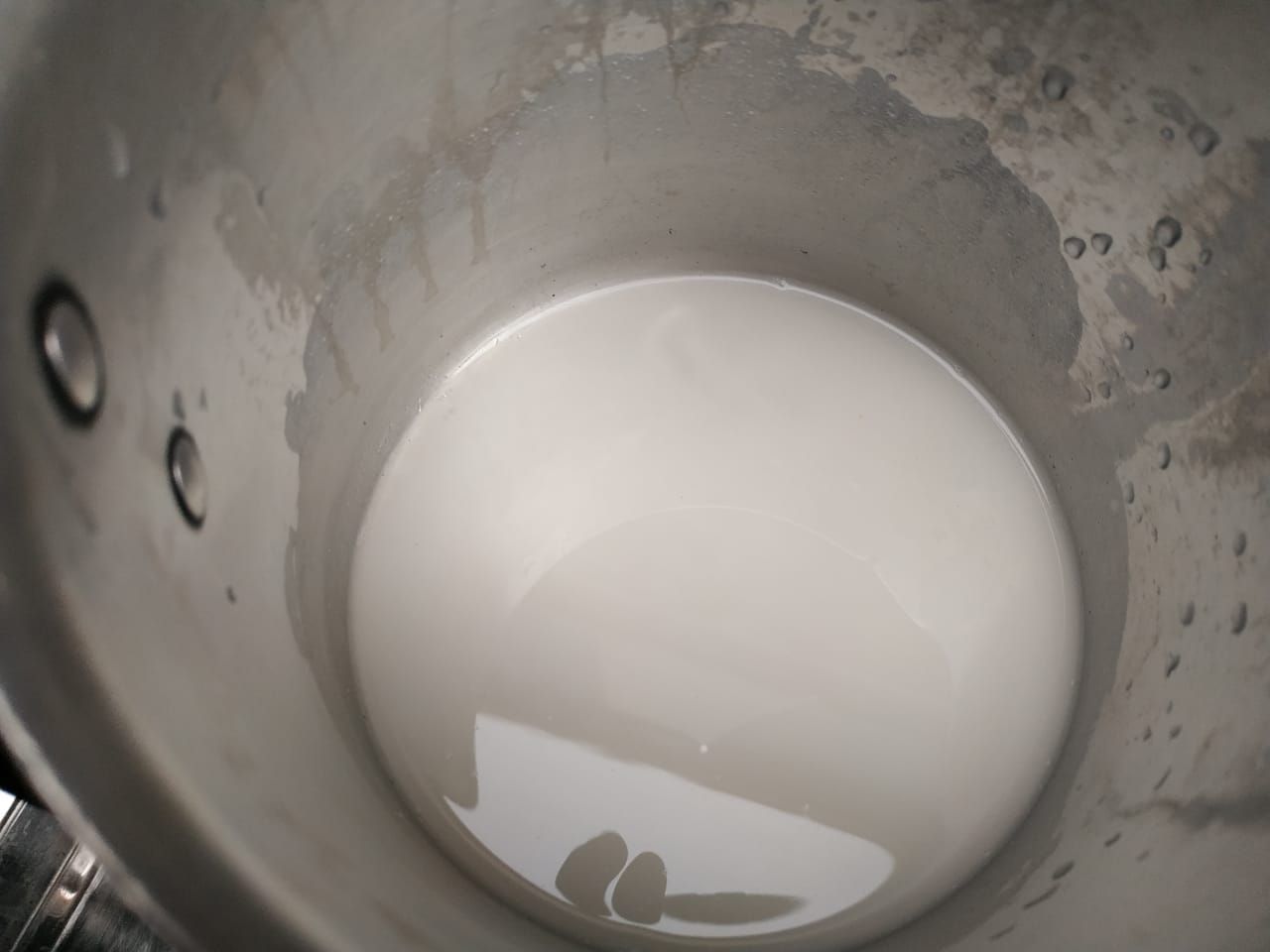

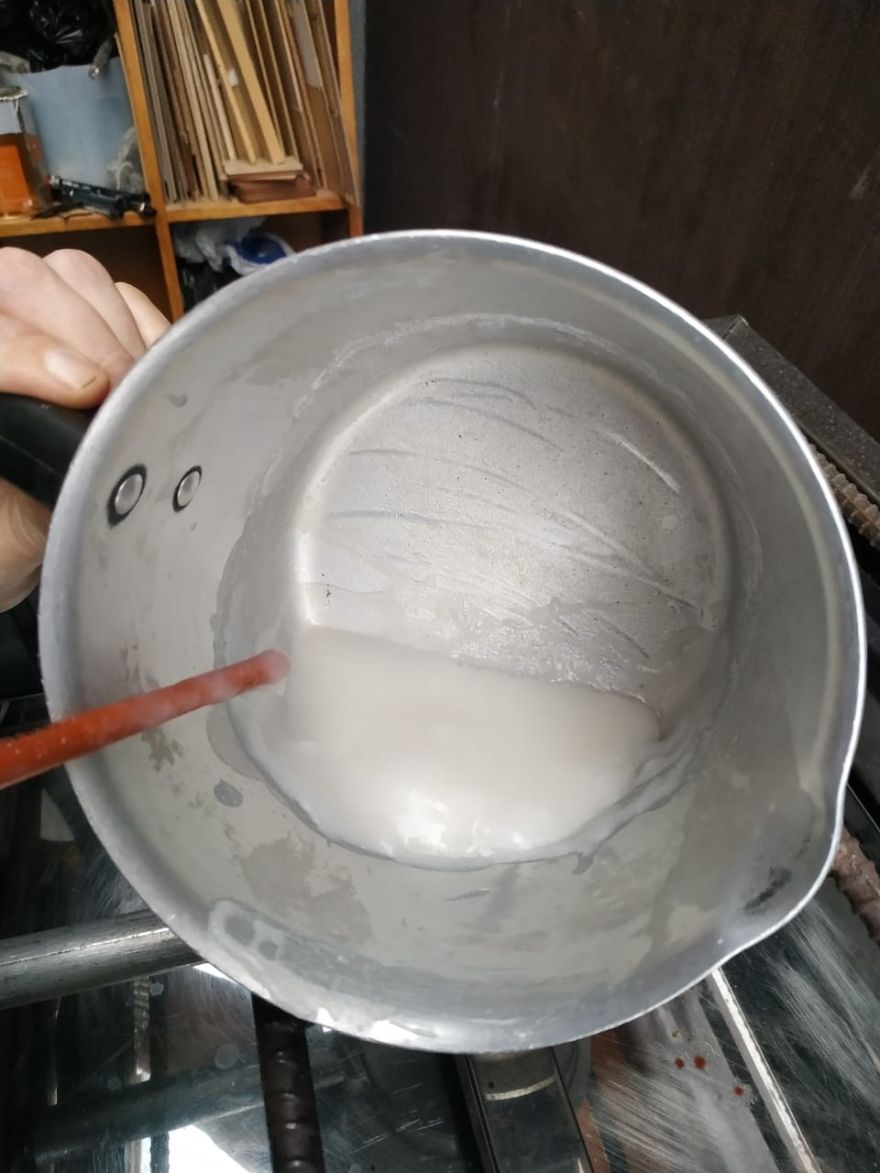

Starch disolved.

Starch temperature 125 degrees Celsius.

Starch getting thick.

Starch on petri.

Starch weight.

Water weight.

Glicerine weight.

Cassave starch.

Temperature.

Cassave bioplastic in Petry dish.

Gelatin yeast foam¶

The material is going to be made with two components, gelatin bioplastic and yeast, as a carbon dioxide generator to provide the gas phase.

The ingredients are shown in the following table:

| Ingredient | mass |

|---|---|

| Yeast | 30 gr |

| Gelatin | 60 gr |

| water | 150 gr |

| Glicerin | 60 gr |

Yeast activation¶

We are going to use the yeast as a bubble generator through the carbon dioxide by-product of the methabolism of the yeast.

Yeast is a eukaryotic unicellular organism. They are dormant until the conditions are right. That means the right temperature, food availability (carbon source), and humidity. For baking, this technique is used for bread rising, as the yeast produces bubbles of carbon dioxide. We used this property to induce a foam-like texture in the hot gelatin. Under the right conditions, the yeast needs some time to go under mitosis. At room temperature, it takes approx. 15 minutes. after the addition of water at 37 degrees (Celsius). It is important to note that the yeast is rich in protein and other nutrients, and it is possible to use it to grow fungi.

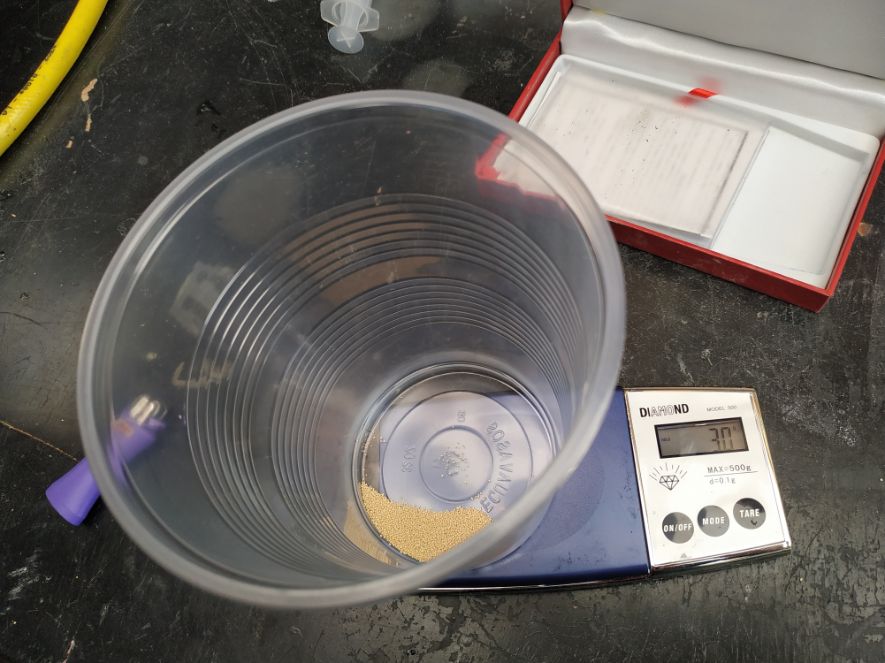

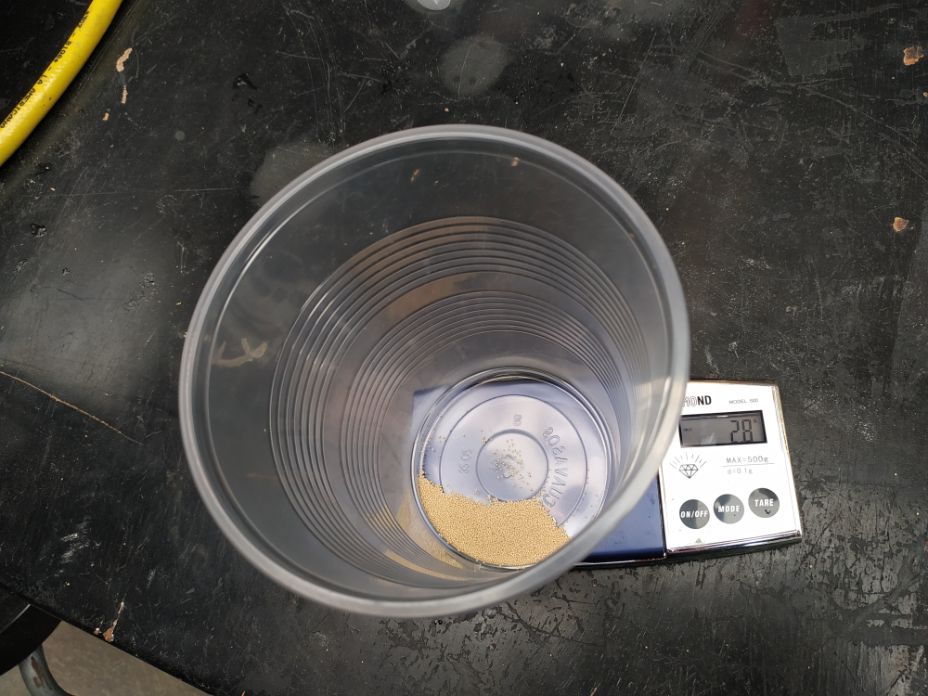

Yeast weighting.

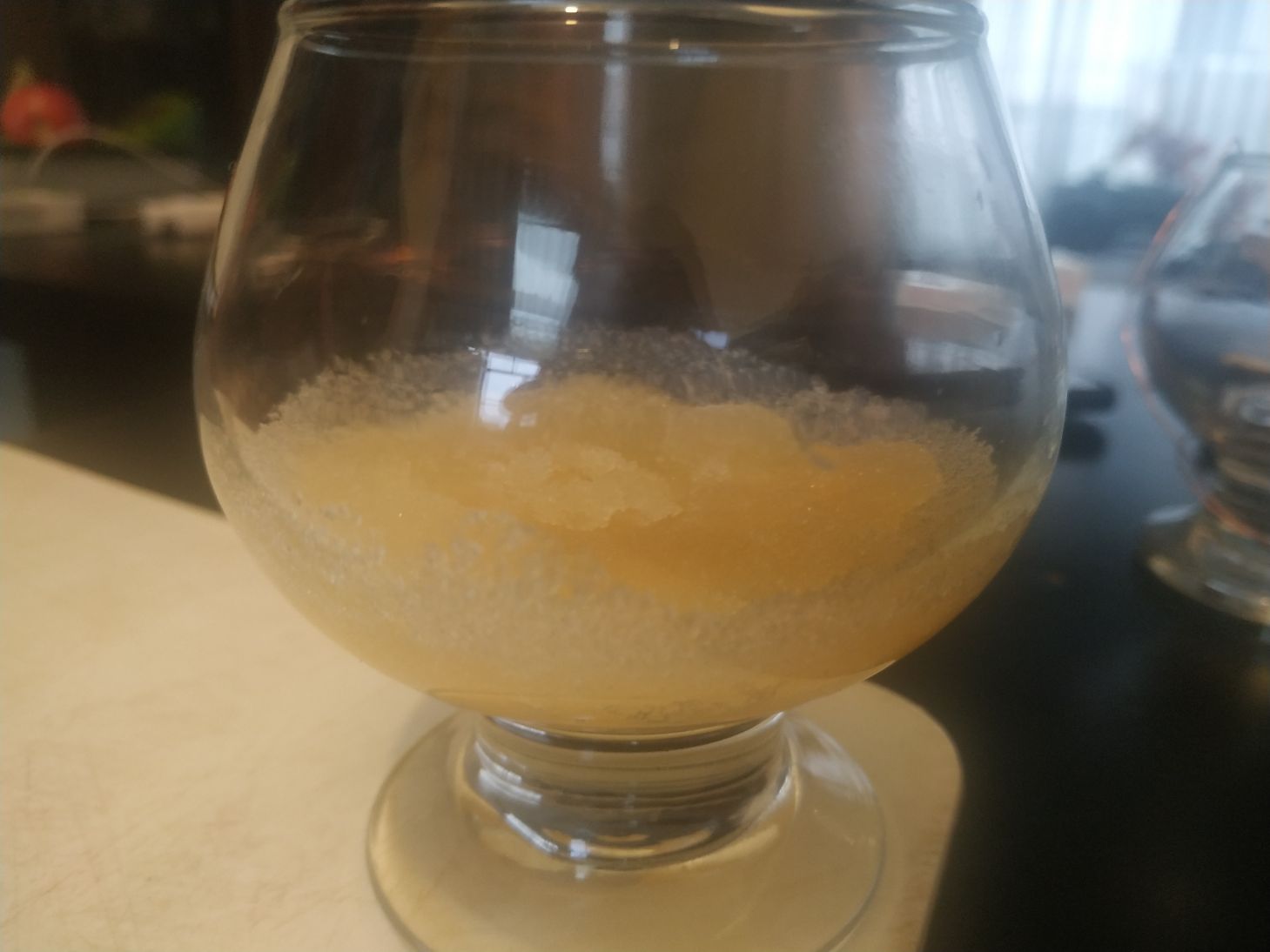

Yeast hydratation (water at around 37 degrees Celsius). We can prime the cells sparkling fluor and sugar to the mixture. Then we wait for 15-30 minutes. We will notice the bubbles.

Gelatin bioplastics¶

Gelatin is a natural polymer. All we have to add is a plasticizer (Glicerin), so the matrix is not so rigid (brittle).

Gelatin preboiled weighting.

Gelatin bioplastic base¶

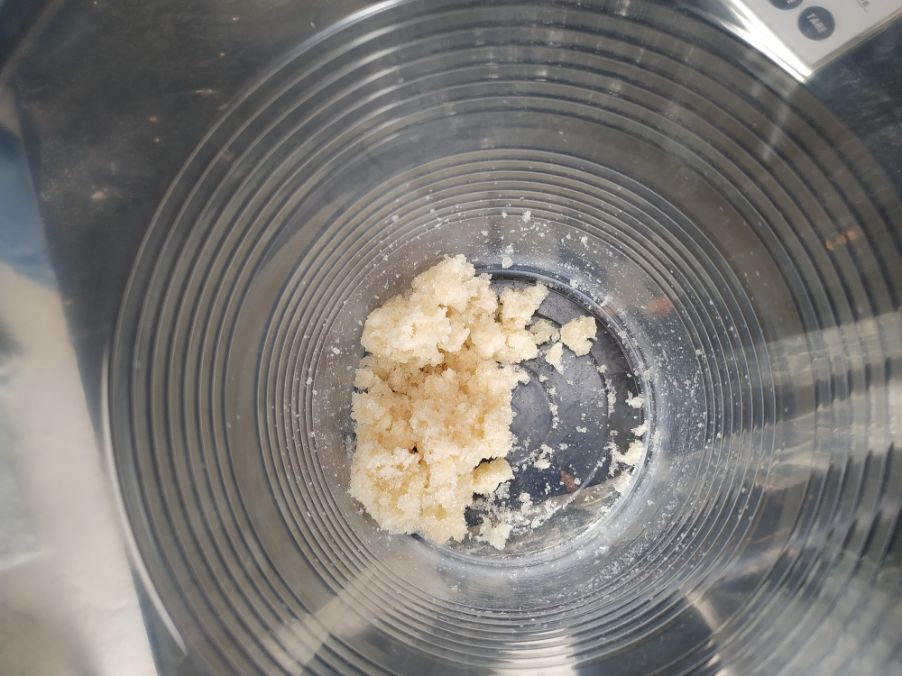

Gelatin hydratarion.

Gelatin pre-boiling.

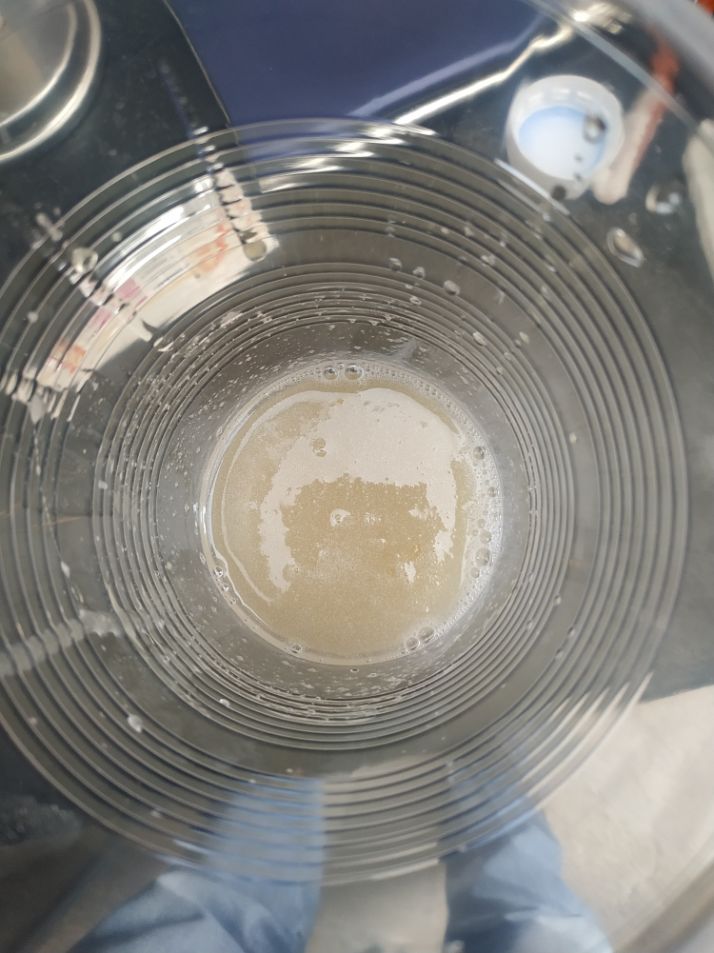

Gelatin boiled.

After the two ingredients are ready, we mix them thouroughly and pour the mixture in a mold.

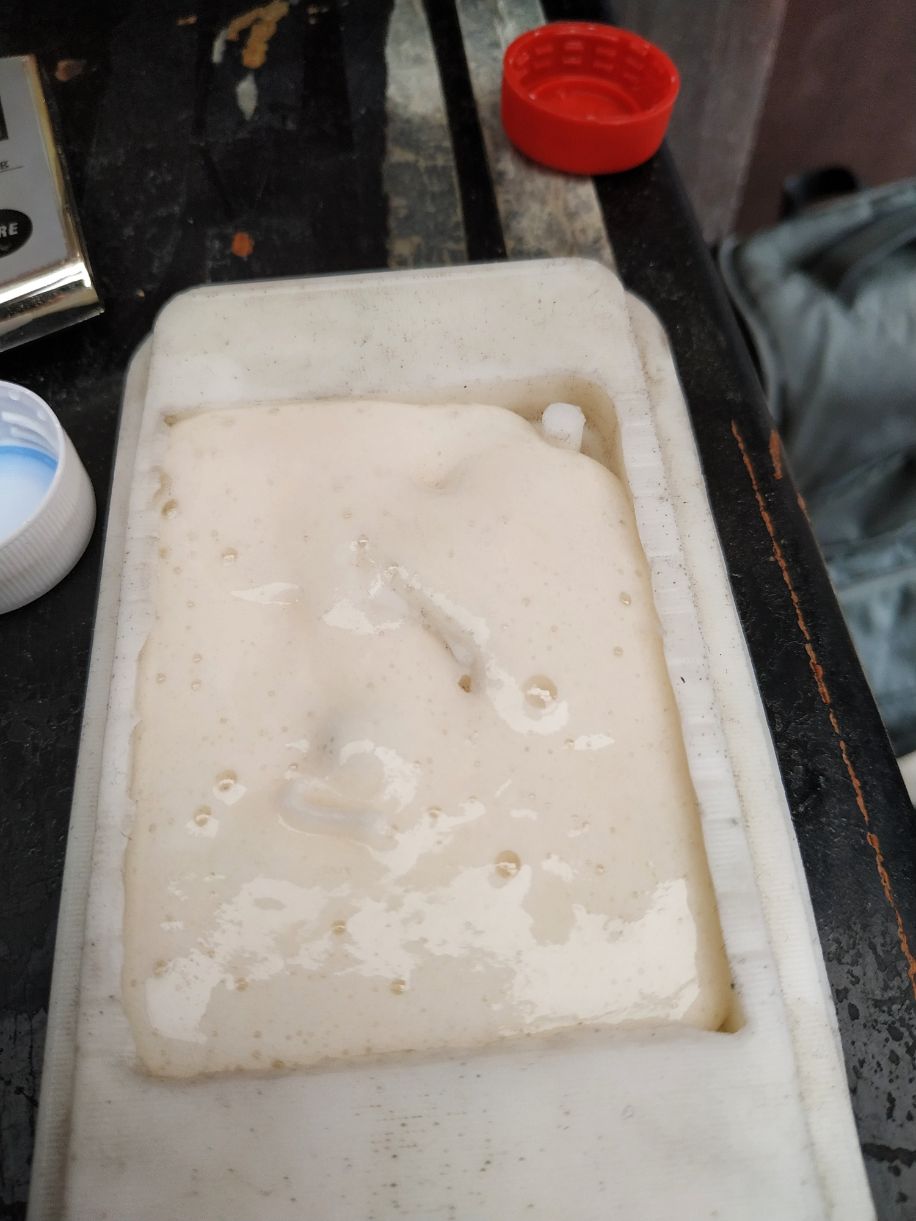

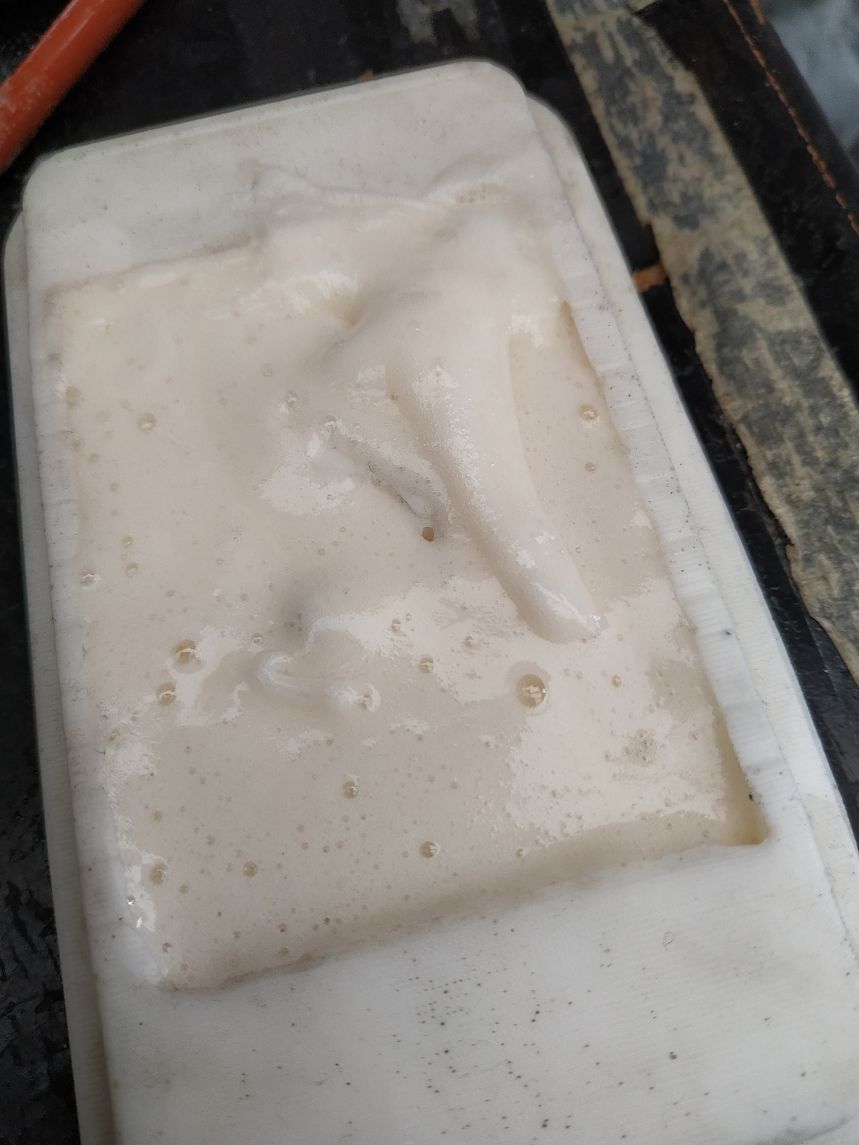

Gelatin on mold.

Gelatin on mold.

Gelatin membranes¶

The first thing we do is prepare the gelatin (5gr.) with water. This porcess is called hydratarion, and is important for the proteins to get unfolded. Add water and wait in steps for half an hour, little by little, focusing in adding the less ammount of water possible.

Water bath: Then we proceed to place the container (glass) in water.

Then we take it to boil. The temperature could rise over 40 degrees Celsius.

I tryied the first test with an improvised support. It is not pretty, but served as a proof of work test.

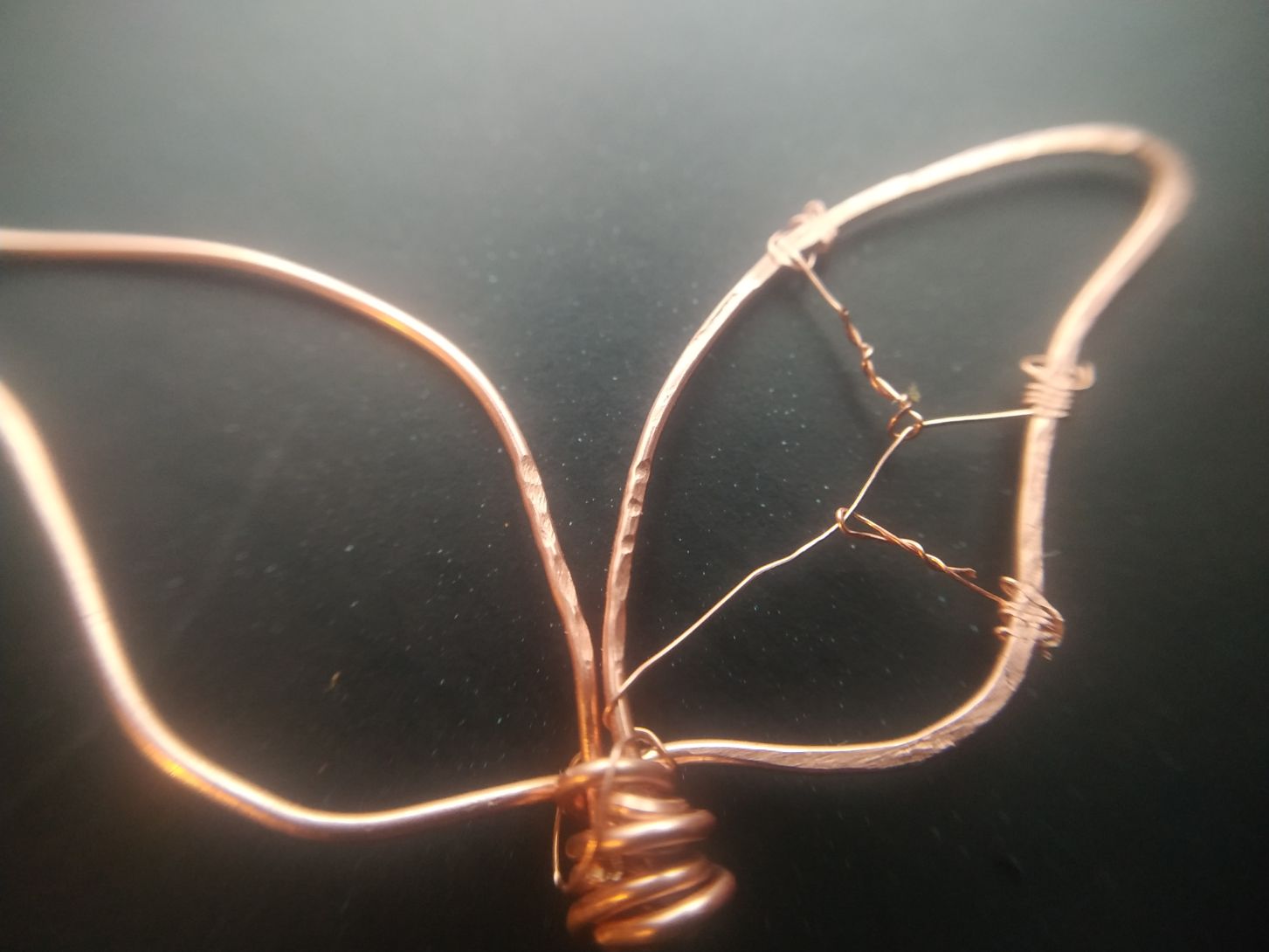

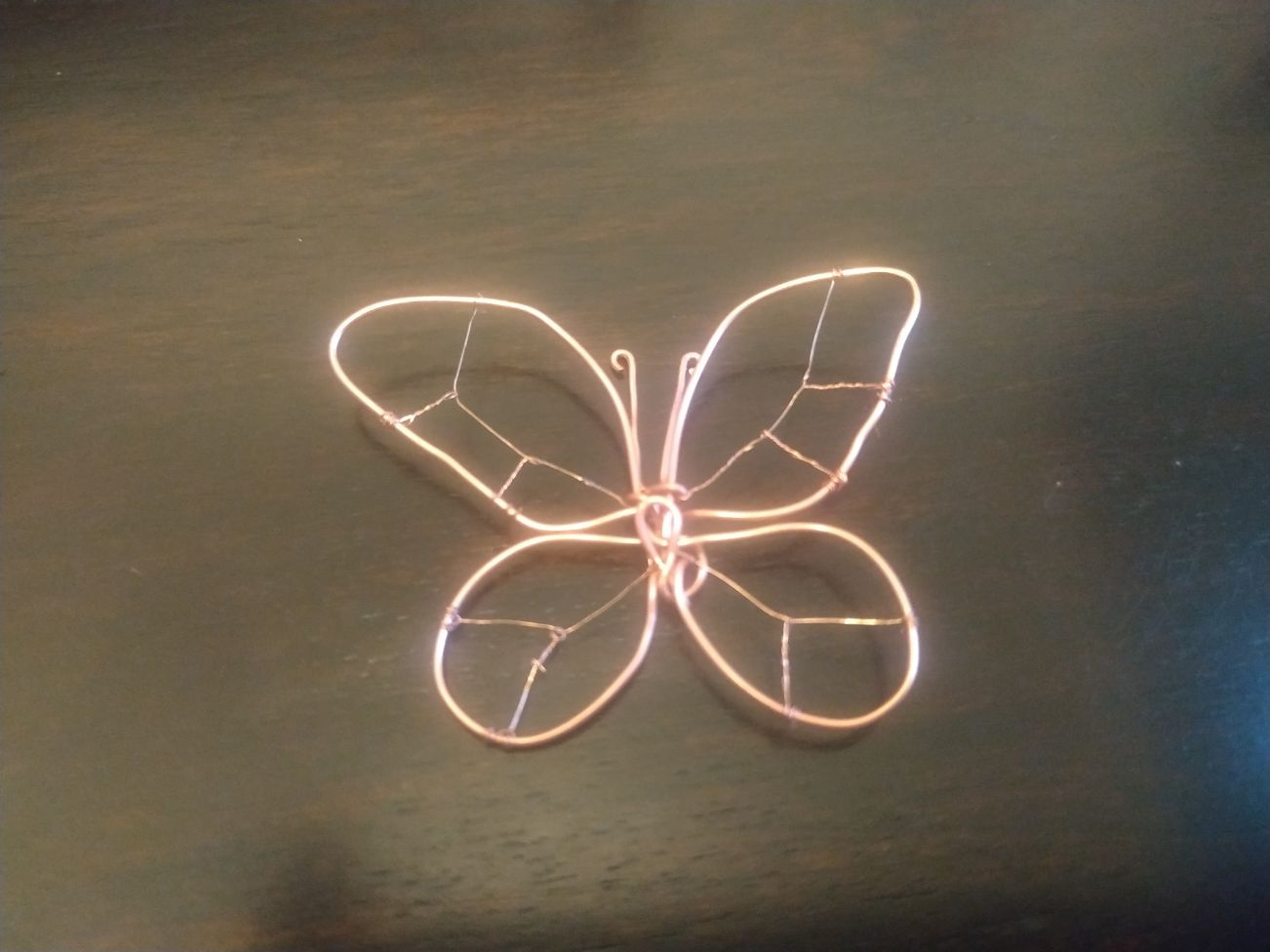

Using two kind of gauges of copper wire, the support (frame) was made, in a shape of a butterfly.

Here is the shape completed.

The frame is then dipped on the hot gelatin, and lifted in a vertical way, allowing it to make a bubble like membrane supported by the sides of the frame. It will solidify at room temperature.

Here we can see the membrane solidified.

And here a close up.

Once it is solidified, the membrane could be painted with a water-based tint. Here I used accuarelle (water color).

Glutamate crystals¶

I am going to experimet with a crystal generating substance Sodium Glutamate, used in cooking and safe to handle. The solvent is going to water, also very safe.

Here we can see the substance, with tinny crystals (as retailed).

As a textile base, I used a cotton tissue.

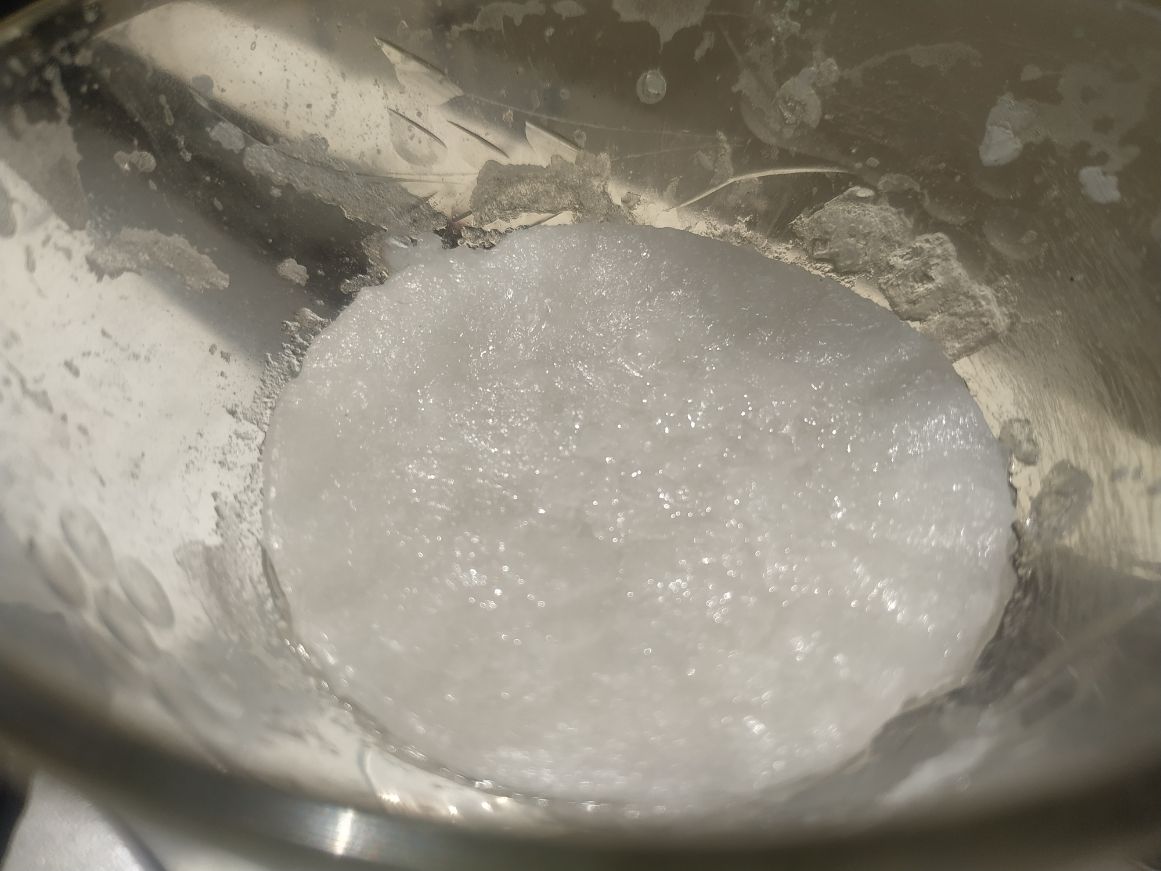

The glutamate is disolved in water. The higher the concentration, the evaporation and crystal forming is going to start earlier.

Then, the tissue is soaked in the solution.

After a couple of days, the crystals begin to form.

I placed the piece near to a window, so it could get some sun's radiation with could help with the evaporation and crystal formation.

I experimeted with a little food color, and the crystal takes the color really well.

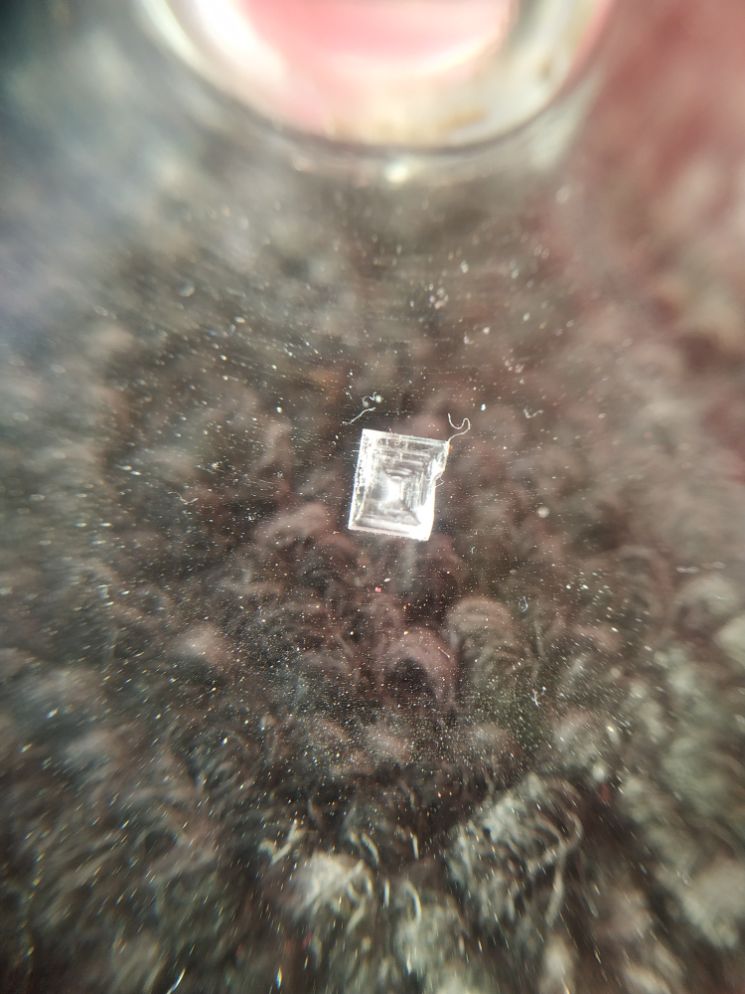

A close-up with a macro lens of the crystal.

Kombucha scubby¶

Kombucha is an ecosystem wich basic species are yeast and bacetria. It is and was used as a beverage, usually discarting the yeast part (called Scubby). It is made mainly of cellulose.

For Kombucha culture, we need a mature ecosystem. The yeast form a biofilm and interacts with atmospheric oxigen. Also, isolates the liquid creating an anaerobic environment ideal for the bacteria.

In a mature ecosystem, the acidity of the liquid is low. This is due to the acetic acid product of the alcohol methabolism of the bacteria.

The longer the ecosystem incubates, the more sugar is convereted to alcohol, acetic acid and microbial cellulose. We can see that in the thickness of the scubby.

We can see that the biofilm can grow very thin and also very thick. Knowing the rate of grow, we could accually control this feature.

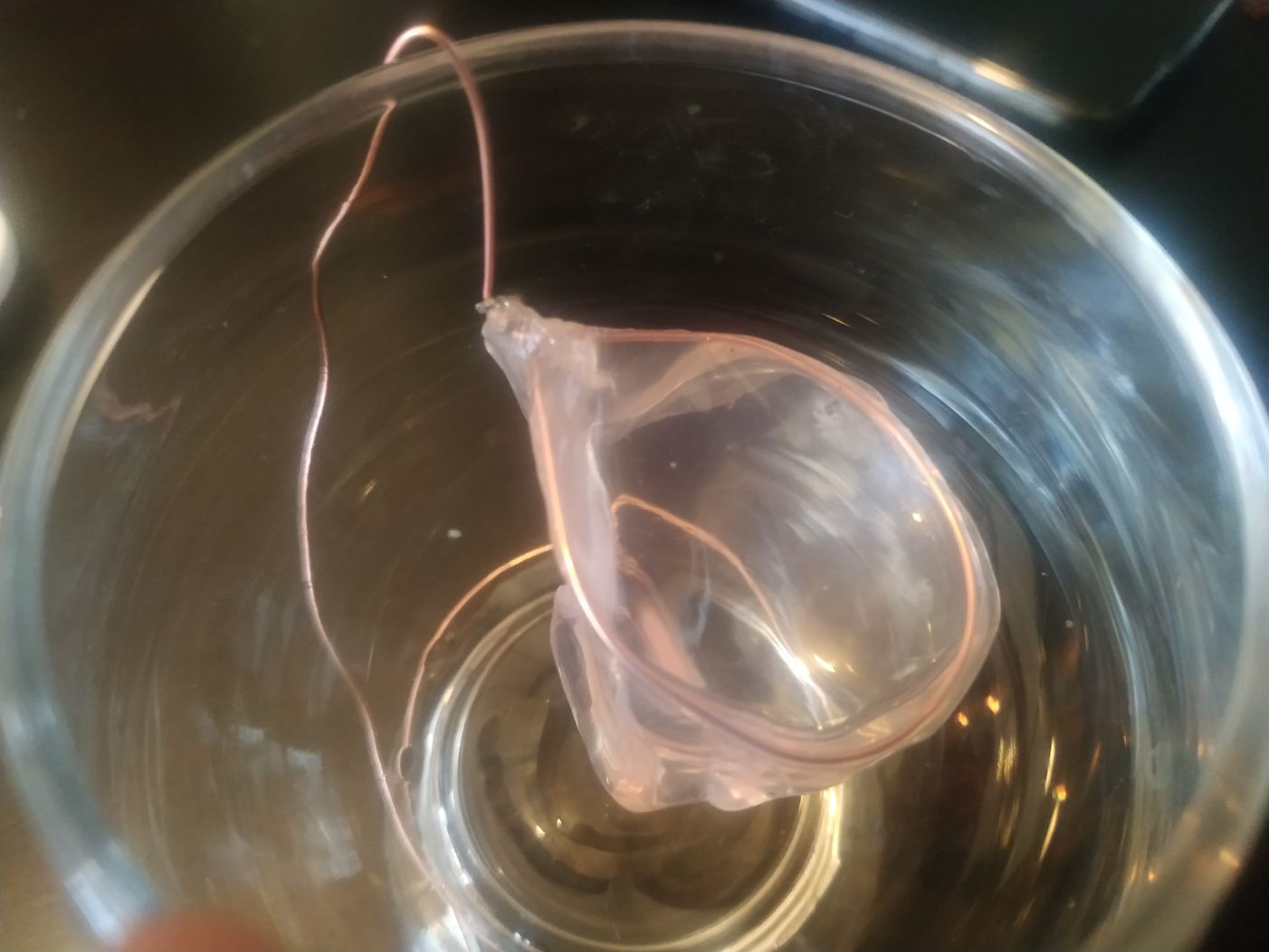

I placed some thin sample of the scubby on a copper frame, as I did before with the gelatin, to test the membrane.

Once it dryed, it was very resistant, although very thin. I noticed that a little ammount (a drop or less) of glycerin works well as a plasticizer.

That could even allow bending without breaking.

The media is realy easy to prepare. Just infuse some tea (y used two different kind, and made no diference in the scubby consistance), add sugar as a carbon source (I used saccarose, kitchen sugar) in a proportion of 3 tablespoons for each cup. It is important to add the sugar while the solution still hot, to avoid contamination.

The inoculation of the medium is done usig the scubby (yeast) or the liquid (liquor). Both yeast and bacteria liquor have cells of one another type on them, so they will regenerate the complete ecosystem. Just do the inoculation in a room-temperature media, as the organisms might die if placed in a too warm environment.

For the next batch, I used a little bigger container. As in any bioreactor, when you scale it, you get the exponential third problems, so it is better to scale with care. The culure was succesful an free of contamination, fortunatelly. Here we can see the scubby growing in the surface after two days of inoculation.

This is an aerobic dependant ecosystem. Air is important, but flies and other bugs like the scubby. So the use of a cloth as a filter is necesary to avoid contamination.

After the drying and conditioning process, we can obtain a material symilar to paper, but very resistant to tension forces.

Here we can see a thin and a thick samples. The one on the right is treated with a drop of glicerin.