3. Circular open source fashion¶

This week was about Circular open source fashion

Inspiration¶

I found some very interesting projects about circular open source fashion

The post Couture Collective¶

It's a belgian collective who is providing open source pattern for making clothes and accessories with laser cutter. Post couture

|

|

|---|---|

Atacac Pattern¶

Atacac Pattern is an open source pattern brand. You can download patterns for free, or make a donation if you want. It's a research about kinetic pattern, which changes the way patterns are designed, according the shape of the body. A lot of patterns are composed of only one piece, like the Linda shirt.

The files can be used on the CLO3D fashion design software where you can open the pattern and see the result in 3D.

Modular Rugs¶

Carawonga is a very nice project and is working with modular carpet tiles.

It's easy to build, just connecting pieces together, and it let you build your very own rug. I like the fact that regarding of where you put the different components it is possible to make different carpets from the same modules.

Project¶

My project is based on the modular losange shape. I find really interesting to create nice modular pattern that can evolve in order to get different patterns.

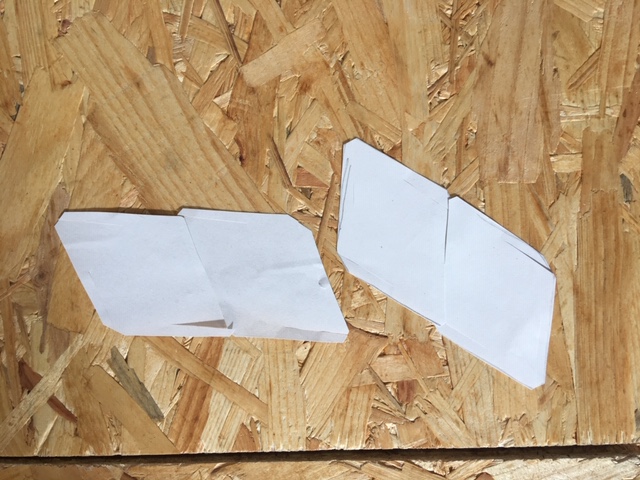

I started working on the losange shape and figured out that in ordrer to be able to create nice patterns, the losanges should have the possibility to connect together on the 2 sides.

In order to get a nice and flat result, losanges have to be made on an hexagonal base.

Once geometrical conditions defined, I started to work on the connections between the modular losanges.

I tried 3 connections possibilities

| Connection 1 | Connection 2 | Connection 3 |

|---|---|---|

|

|

|

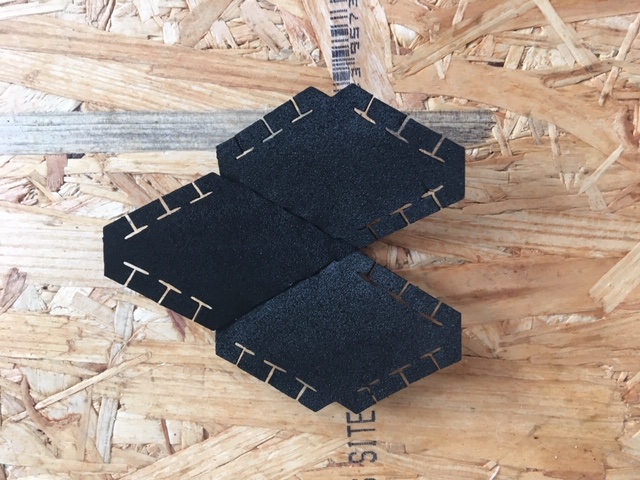

I finally went with the connection 3 because results seemed nicer and it was possible to combine in every direction.

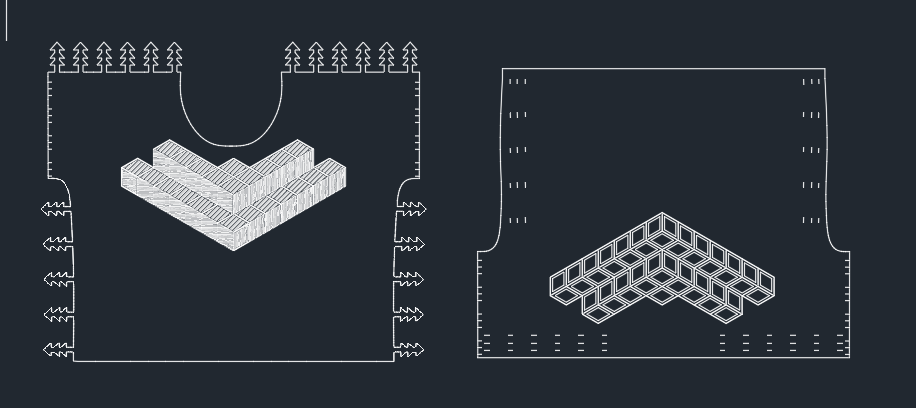

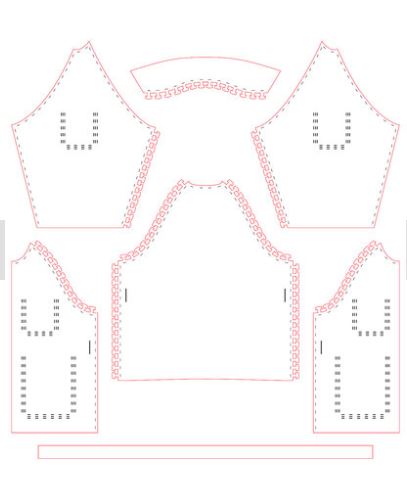

After that I decided to make a t-shirt from the Linda open source Pattern from Atacac. I divided the pattern in four pieces, front left, front right, back left and back right to be able to cut the pieces with the laser cutter machine.

To make the connections between pieces, I went with the same connection that the one from the modular losange.

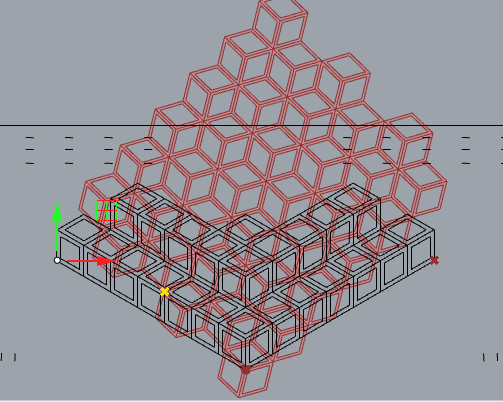

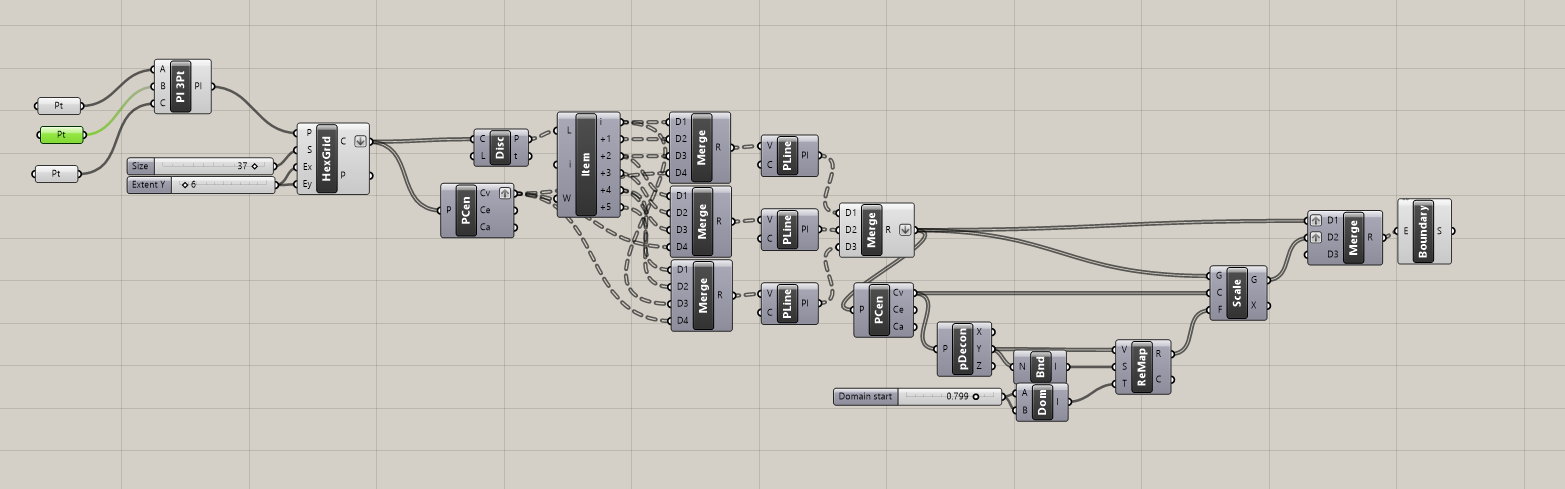

I worked first in Rhino 3D modelling software, trying to make insides modular pattern with the Grasshopper plugin, a graphical algorithm editor . I ended up with a pretty good result but wasn't able to put the pattern in the shape I wanted to (updated in week 8).

I finally worked with Autocad, because it's the software I am more accustomed to.

I made the pattern and then sent it (or try to send) to the laser cutter. I don't know why but my dxf files were not working on the laser cutter interface (Coreldraw) (I think it's because I worked with a student version of Autocad) so I tried different things and ended up opening the file in Fusion360, exporting the DXF in illustrator and exporting the SVG files. Finally it worked...

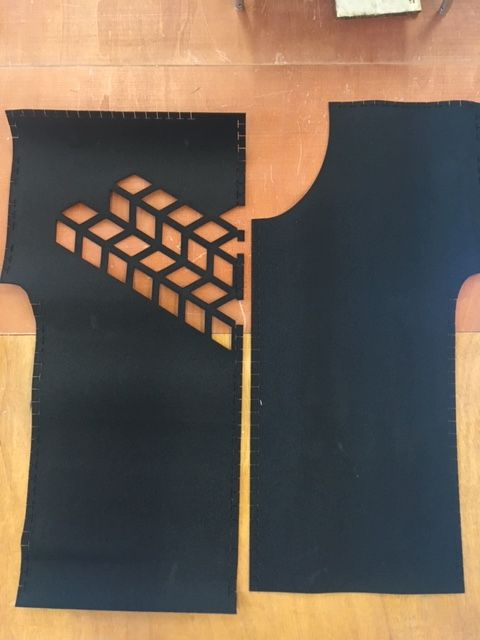

I cut the neoprene fabrics in stock in the fablab (Thickness = 1mm) pieces on the laser cutter Epilog Laser MINI 24 60W (600 x 300 mm), with the following parameters speed : 30% and power 80%.

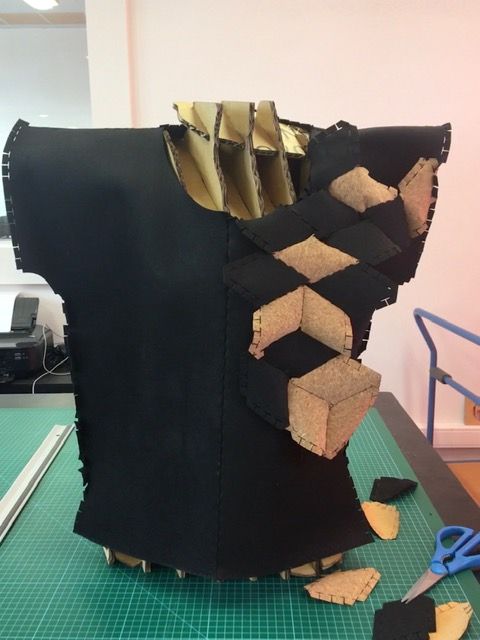

Once the big pattern pieces were cut they were pretty easy (maybe too easy) to connect together.

The connections on the sides were not super strong, so when the shirt was moved some connections tended to break. This made very difficult the last stitches as the garment cannot be reversed once all the connections are made. The connections on the front and back on the other sides are very strong because there is no tension there.

|

|

|---|---|

After the big pieces, I cut some small modular losanges. My initial project was to make sleeves with the modular losanges. It was difficult to get a nice result. I think the neoprene fabric was a little too thick and made the connections not smooth enough.

The modules can also be inserted on the side seems between the front and back pieces, giving the possibility to the garment to change size base on the same pattern.

I finally worked on a collar which can be pluged on the neck and according to the desire result, on the sleeve, side, or front.

Final result

It's working but sides connections are too fragile. I think it should be interesting to work on the connections in order to make stronger ones. We can see that the front and back seams are really neat but on the side the connections are breaking too easily. Maybe a pattern with connections on a tenseless area would work.

Maybe the modular losange could be smaller in order to drape easily, or to try with a other material.

A version that I made had stronger connections but wasn't compatible with the losange.

The files on Oscircular

Code Example¶

How to make a table

//

| titre 1 | titre 2 |

| --- | --- |

| element01 | element01 |

}