8. Computational couture¶

This week was all about Rhino a 3D modelling software and GrassHopper an algorithmic modelling for Rhino.

Architectural reference¶

As I am an architect I was really inspired by kinetics in architecure.

First try 3D print on fabric¶

For the first try I worked with a model found in Thingiverse

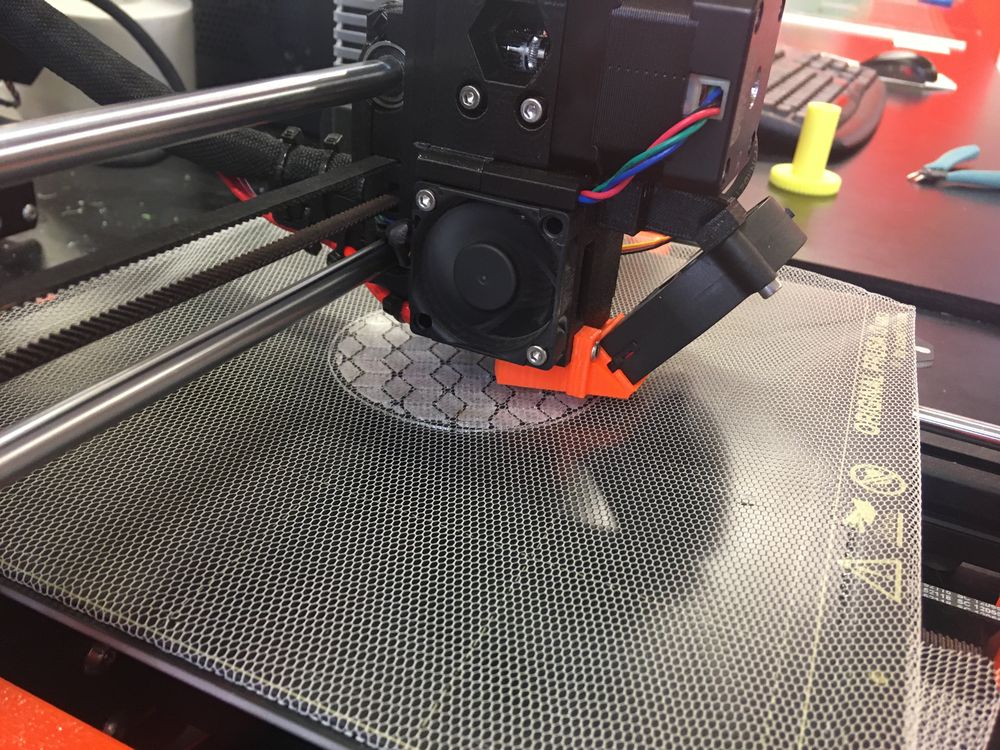

I used a transparent flex filament to make the print, and printed it on tulle. The tulle fabric was used because the print can attach between the holes.

The result was not so flexible, and during the printing the filament got stuck in the Prusa printer. (The fablab is working with Prusa I3 MK3 printers).

Finishing week 3 code¶

During week 3 I tried to use GrassHopper in order to make hexagonal patterns but didn't finished the intersection between the region and the pattern.

I started with this.

The grasshopper code allow to make losange volume in a curve.

In order to 3D print the design, I exported the Rhino file as an .obj file and opened it into the prusa slicer.

In the prusa slicer I chose the Flex filament and then cut the model in order to export the G-Code.

I then 3D printed it on fabric. Made it thinner than the previous print (thickness 3mm) and reduced the speed in order not to stuck the filament (speed 50%).

Parametric Bistable Auxetic¶

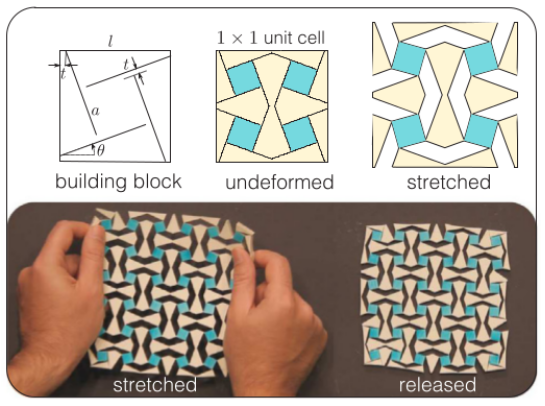

Denis Terwagne who is working at the Fablab and Nicolas De Coster made a very interesting tool during their Fabacademy called the "Bistable Pattern Generator Bistable Auxetic"

"Kirigami is simply a sheet folding in which there are cuts. When the 2D structure is stretched, it deforms in a particular way: It can expand, retract, rotate, move out of plane,...

Carefully analyzing these bistable auxetic mechanical metamaterials, we found that there is a beautiful logic behind this puzzle.

They are made of

- a building block, the smallest part that is required to build the final structure by rotating, mirroring and translating it.

- a unit cell made of several rotated, mirored and translated building blocks.

- the final structure, made of multiple translated unit cells (along a squared or triangular latice).

In the figures below, here are 2 parametric designs that we would like to make. For these 2 building blocks, there are 4 parameters: l, the length of the building block, t the hinge gap, a the size of the cut, theta the cut angle.""

Equations¶

Here's the equations used to simulate the Auxetic Pattern. Thanks Nicolas Decoster for the equations ;)

Variable values

Cell size = W

Distance = T

Angle = θ

t=T/W

teta = t*sinθ + (t-1)*cosθ + t

x = -teta*W*cosθ

y = w(t-teta*sin*θ)

Points coordinates

[(0,T);(x,y)]

[(W-T,0);(w-y,x)]

[(W,W-T);(W-x,W-y)]

[(T,W);(y,W-x)]

I used Grasshopper to code this and to be able to make a variable pattern.

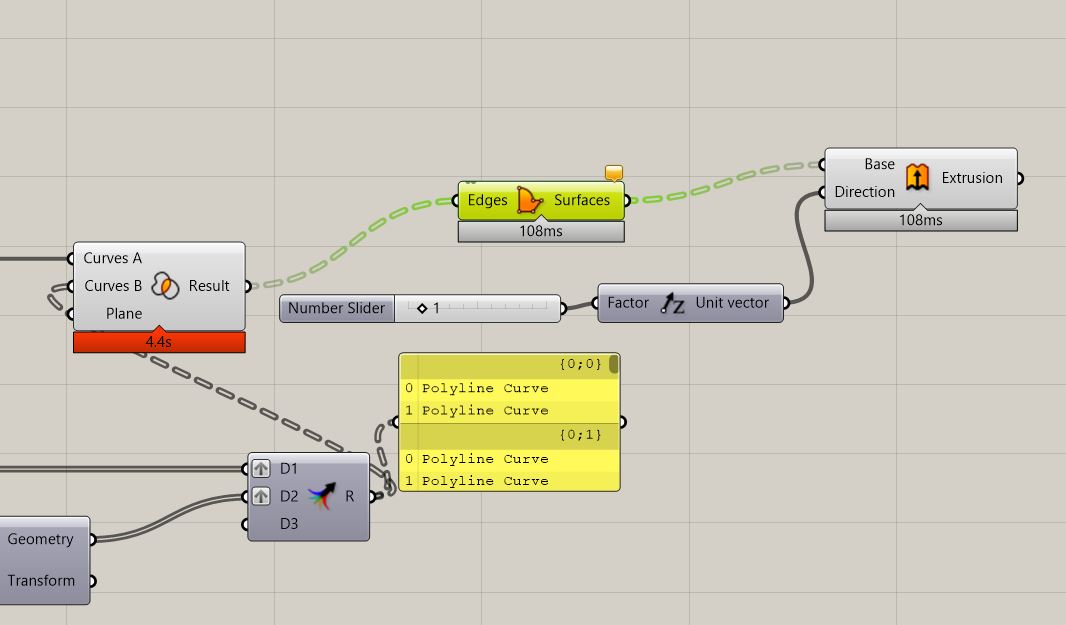

Grasshopper code¶

I put into grasshopper the previous equations.

The result is parametric, 4 values can be modified : - W : cell size - T : hinge gap - θ : Angle - N : Number of cells

This code allows to parametrize the cells and to cut the generated pattern along a curve.

Test on fabrics¶

I tested the cuts on differents fabric types, and cut with the laser cutter.

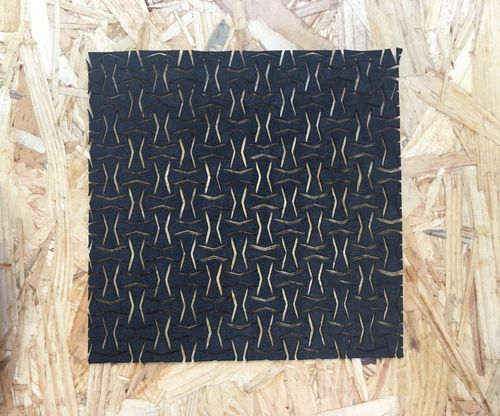

First I tried with Neoprene, which is already a stretch fabric

The fabrics got very stretchable and almost looked like lace.

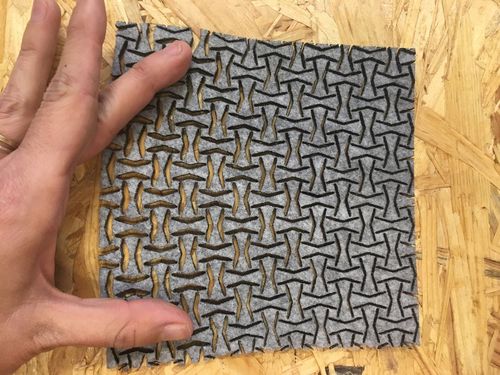

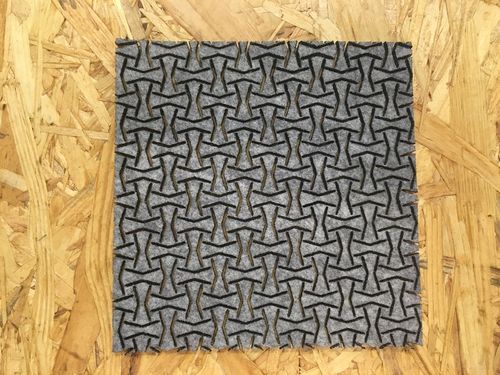

Second try was with felt fabric, not stretch and thicker than Neoprene.

The laser cut was visible, the fabric was stretchable in two directions.

Auxetic 3D¶

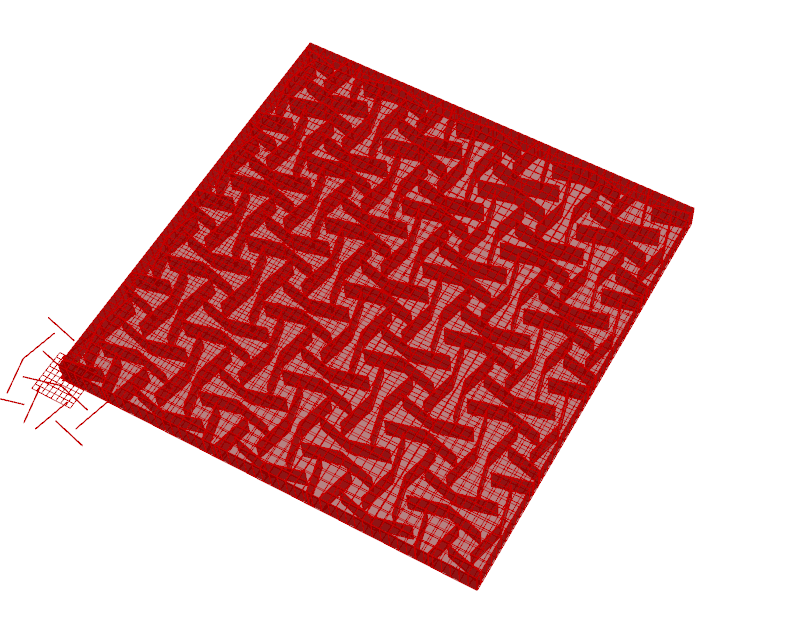

I tried to use the Auxetic code generator to make 3D patterns in order to print it with 3D printer,

The lines cut should become holes in the volume.

I wasn't able to make the holes, only get the cut 3D mesh.

With this 3D pattern, I've made a mold used on week 11.