8. Open Source Hardware - From Fibers to Fabric¶

This week I had to plan and build a machine or hack a machine to customize it to my needs.

I made a small Vacuum Former to form thermo plastics around 3D Objects using my oven and a hover

Research¶

I never built any machine and I never thought on doing it myself, cause I never felt like an engeneer or safe in using heavy tools without cutting my arm off or having the intelectual skills to actually make anything work :D

I was researching before that assignment on how to build your own CNC Lasercutter or Milling Machine with OpenSource Tutorials because those are super expensive but I always wanted them to have.

Now after Researching a few possibilities of DIY machines or hacks I feel a bit more certain of actually being able to make it myself. When I went to the shop to get my material for this week, I kind of went crazy about the tools and also will get a flex in the future and loose the fear of using it, so I don´t have to ask my male friends to help me out anymore.

First of all I did not have any idea what to do this week cause I couldn´t start a big project and I have no skills on how to create my very own machine without any experience in engeneering. As I dont have access to a Lasercutter or CNC Milling Machine I was getting a bit frustrated aswell. I just decided to start off with a Open Source Tutorial and rebuild something that was already existing. I think if I come to the point in future where I think that some production method is missing, I probably will come up with my own hack and find some intelligent nerd to discuss my projec :)

Machine Hacks¶

As I wanted to build something that I actually can use I ended up with 3 Machines/Hacks. The Sewing Machine Hack to make an Embroidery Machine, a DIY Direct Extruder to print flexible Filament and a Vaccuum Former Box.

Textiles

- DIY Embroidery Machine 1

- DIY Embroidery Machine 2

- DIY Embroidery Machine 3

- 3D printed simple Mini Loom

- Home Vacuum Former

__3D Printer_

CNC

- [DIY Dremel CNC] https://www.instructables.com/DIY-3D-Printed-Dremel-CNC/

Mechanicals

Arduino Projects¶

- Collection of Arduino Projects

- AR Eye Glasses

- Light Painter Robot

- Solar Mendocino Motor

- OS Turtle Robot

Supply¶

Vaccuum Former¶

I decided to make a small Vacuum Former to use in my oven. Previous DIY Vacuum Formers I found where either to big and needed more components and tools to make it.

Making the Vacuum Former¶

I pretty much just followed the Steps from that tutorial

Materials¶

2x Screenprinting Wood plates 30cm by 40cm / 0.5cm

2x Screenprinting Wood plates 12cm by 28.2cm / 0.9cm

2x > 2x Screenprinting Wood plates 12cm by 40cm / 0.9cm

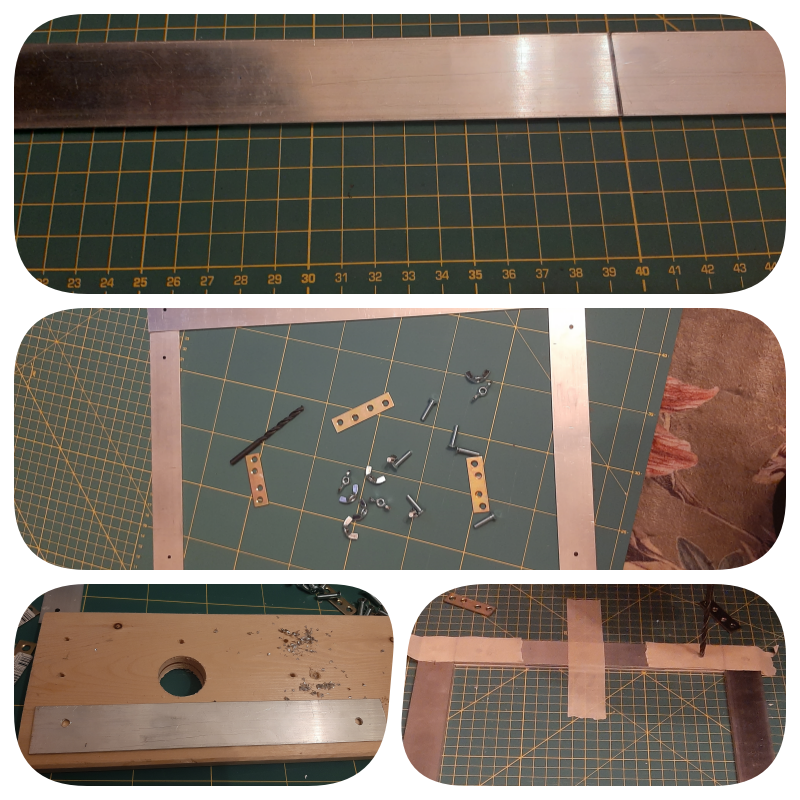

4x Aluminium flat rod

Screws/Nails for the Box

8x Butterfly Nuts and 8x Vertical Screws

4x connection plates fitting the screws

Silicon

Assembling¶

As I didn´t have a CNC Milling Machine I ordered that humanoid CNC to drill the holes

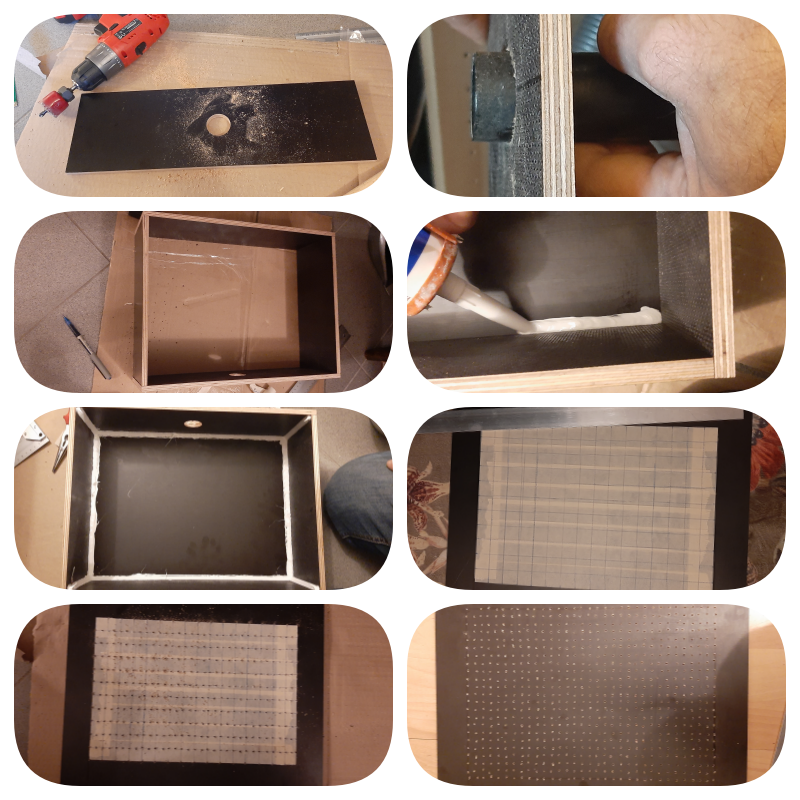

Making the Vacuum Box

Drill a hole on one side panel to fit the hover hose

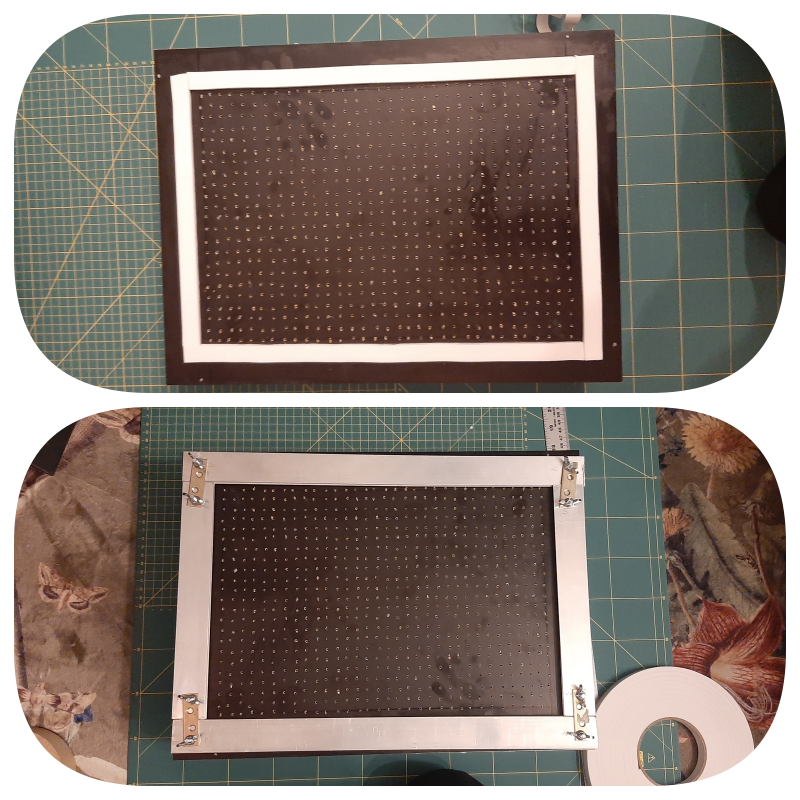

Making the Frame

Final Box with Frame

Orbiter 3D Printer direct Dual Extruder¶

I didn´t start that project yet, cause it came out if I order the components I will have to wait till end of january to recieve them. Until then I probably get a ready made extruder to use my filaflex.

- [About the Orbiter] (https://hackaday.com/2020/11/05/a-featherweight-direct-drive-extruder-in-a-class-of-its-own/)

Bill of Materials¶

Those are the links for the components

- 1 x Wantai 36HS2418 round Nema 14 stepper

- 3 x Wantai 36HS2418 round stepper bulk by

- 1 x Dual drive gear extruder kit for 1.75mm filament - 12mm outer / 8mm inner diameter

- 2 x Mini bearings MR148-ZZ

- 3 x Mini bearings MR95ZZ

- 1 x Full metal heat break

- 1 x Thumbscrew assembly

- 1 x Insert M3 L4mm nut - 2 x M3 screw L = 14mm - 1x M3 L= 22mm shaft for the latch - 5mm carbon fiber rod

Useful links¶

Links from the Lecture¶

This week VARVARA & Mar Creative Studios hold the Lecture about Open Source Hardware and Machine Hacking. They showed a lot of DIY Machines. A lot of complex useful ones, but also fun interactive arty machines, including their own :) Check the Link!

- Giant Knit Nancy ```