04 biochromes

12th - 19th October 2021

4. Biochromes

This week we'll work with natural dyes, make inks and pigments and also dye with bacteria. I am really intrigued by the processes and the varieties of colours you can extract naturally. The methods take more time but have rewarding results.

I remember trying a few experiments at home with turmeric and black beans without following the science of the process, so this time around is more exciting.

This video was really inspiring because there are really so many colours to extract from the world around us - without the need for synthetic dyes; before synthetic chemical colours, dyes were always natural. It's also a way to reconnect with our landscape. Here they use everything from bark to berries, and fungus to flowers.

Yoshioka is a textile dyeing company which has been running since the 1800s. This documentary explores the pursuit in achieving colours - so valuable to consider the achievement of colour so that it is not taken for granted.

MURASAKI (English Subtitle) from ART TRUE FILM on Vimeo.

intro¶

We are working with 3 types of fabrics:

-

animal (animal based ie silk),

-

vegetal (plant based ie cotton)

-

cellulose man-made (viscose) fibres.

The first part of the process is to weigh the fabrics to calculate the ratio of mordant to weight of fibre "(WOF).

Mordants prepare the fibres in fabric to bind and be able to absorb dyes. From the French to bite - it prevents colour bleeding and brightens the colour you're applying.

annatto¶

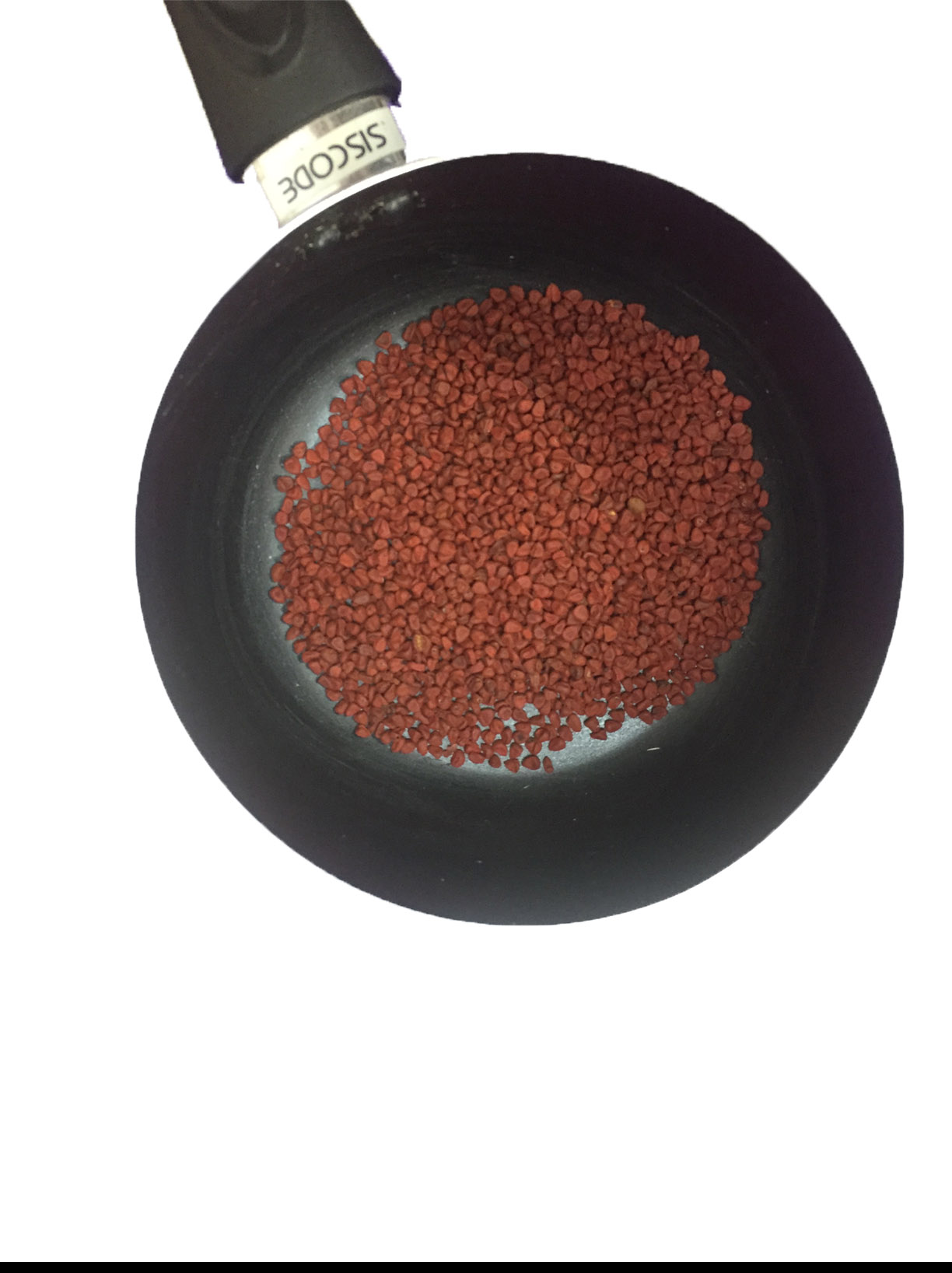

For this assignment I'm working with annatto seeds. They are typically found in the tropics from the achiote tree.

The seeds smell amazing.. like a kind of tomato berry..

Annatto is used as a food colouring in food production as well as dyeing.

According to healthline.com an estimated 70% of natural food colors are created from annatto. It has been used over centuries in South and Central America for art, as a cosmetic, and to treat medical conditions. The color comes from compounds called carotenoids, which are pigments that are found in the seed’s outer layer and many other fruits and vegetables, such as carrots and tomatoes. Annatto seeds have antimicrobial properties and are also used in sunscreen and as insect repellants. Compared with artificial food colorings, annatto offers antioxidants and is non-toxic which must be why it is used so widely.

I found this article which explores dyeing PET fabric with annatto. They conclude that the synthetic fibres require temperatures over 100°C. The original link for the article is here

scouring¶

Scouring is the cleaning and stripping away of chemicals and oils from fabrics, opening the fibres so they are ready for dyeing. In general, scouring is a given for all processes. We do this with Sodium Carbonate aka Na₂CO₃·10H₂O - it's an odourless, water-soluble salt extracted from the ashes of plants grown in sodium-rich soil.

Adding tannin with the soda for cellulose fabrics will make the scouring process more effective

To scour you need to heat up, boil and stir the fibres for at least 20mins.

mordanting¶

Mordanting is the prepping of fibres for colour absorption..

In this case we're mordanting with Alum and Iron because Copper is more dangerous to work with.

Alum requires 12% of the WOF to be added (and dissolved in water)

Iron requires less than 1% of the WOF to be added

Adding tannin to the mordants help open the vegetal fibres in this case we use Creme of tartar which will also soften them.

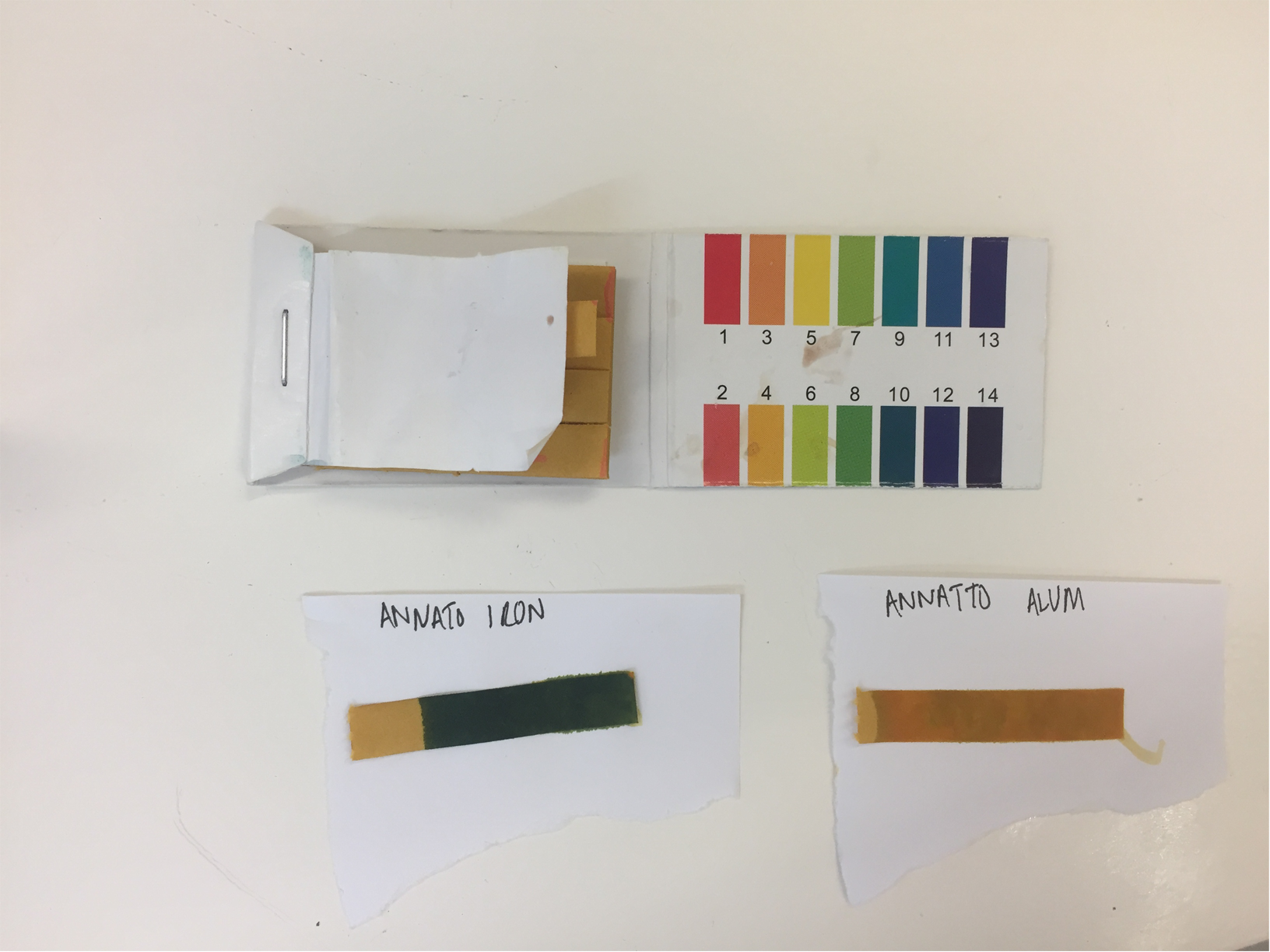

You can see the difference in colour from the picture: the right side has been mordanted with iron and makes a darker colour as it is alkaline; the left has been mordanted with alum which is more acidic.

dyeing¶

So to make the dye.. :

- Soak the seeds over night in some cold water

- Removed the seeds the next day, and put them in a fabric bundle for future use (of course if you leave them in the water and want to use them in the rest of the process, the colour will be richer..)

- Gently simmer for 1 hour

- Add 1 or 2 tsp of soda bicarbonate to simmering pot

- Strain off liquid

- Allow to cooooool

Annatto produces the dye compound bixin and gives a range of shades from yellow to reddish orange.

50g will dye double it's weight in fabric. To achieve a rich, dark colour use approx 5:1 (weight of seeds to weight of dry fabric)

modifying¶

Adding acids or alkalines to the liquid dyes will change the colour of the dyes:

I measured the pH of the 2 dye baths left over: annatto with iron and annatto with alum and this is how they measured...

So are you can see from this picture, the alum is acidic and the iron is alkaline. Therefore, it is more logical to add acid to acidic dye to enhance the acidity and colour:

Here you can see how bright the vinegar and soda made the original colour

pigments¶

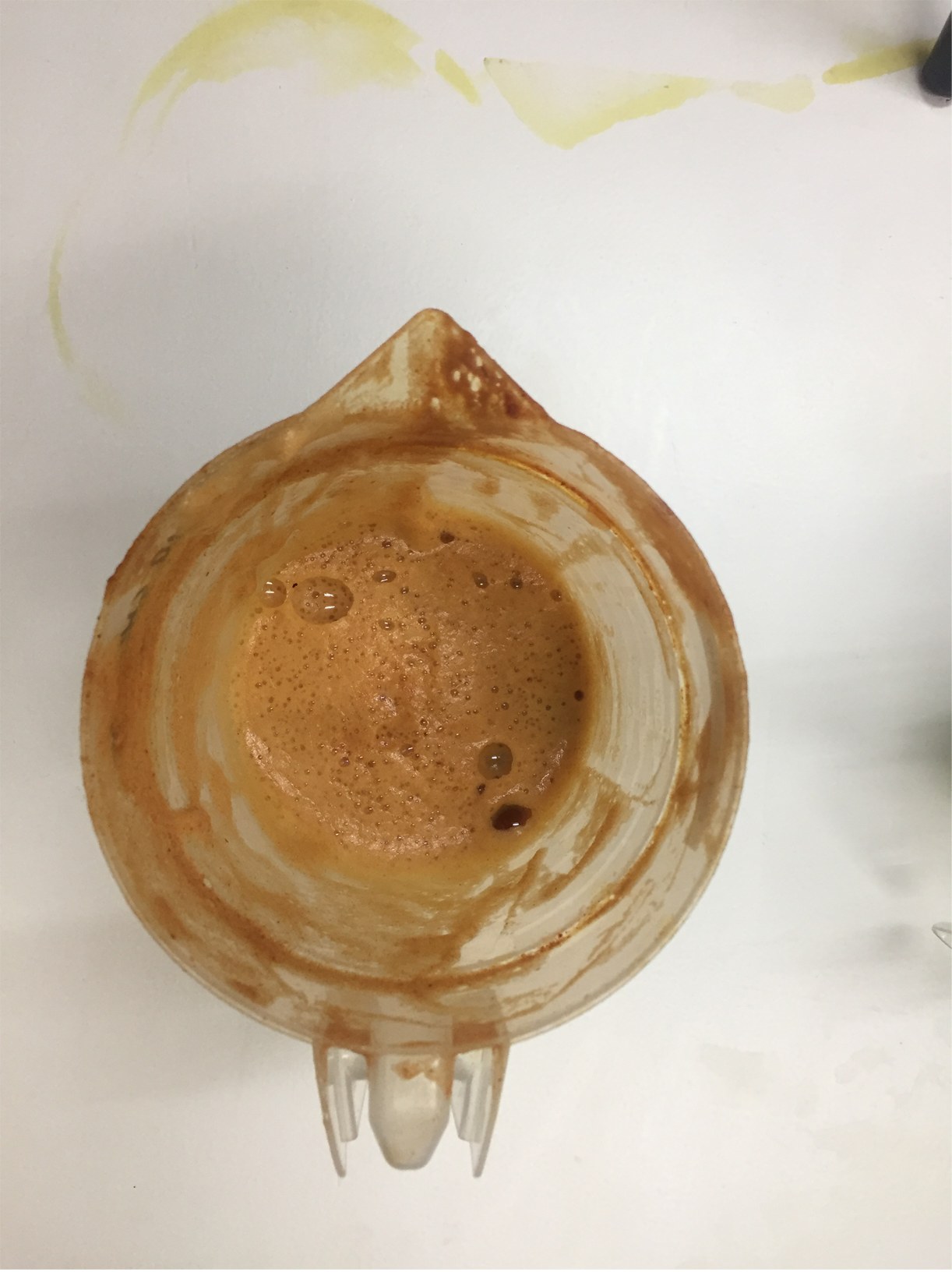

To extract the pigment colours you need to seperate the liquid dye by making a chemical reaction. Here's the recipe:

- 16g alum

- 8g sodium bicarbonate

Dissolve both chemicals seperately in warm water. Then add the dissolved liquid slowly to the jug of dye. This will cause the seperation reaction: the liquid will froth in the process so use a bowl to catch the mess! Stir the jug gently but consistently as this reaction is happening, pushing the foam down as it reduces.

Stir the jug gently but consistently as this reaction is happening, pushing the foam down as it reduces.

When the foam has reduced to the maximum, it will be ready for pouring and you should be able to see the seperation because the denser and more colour rich liquid will be on the bottom.

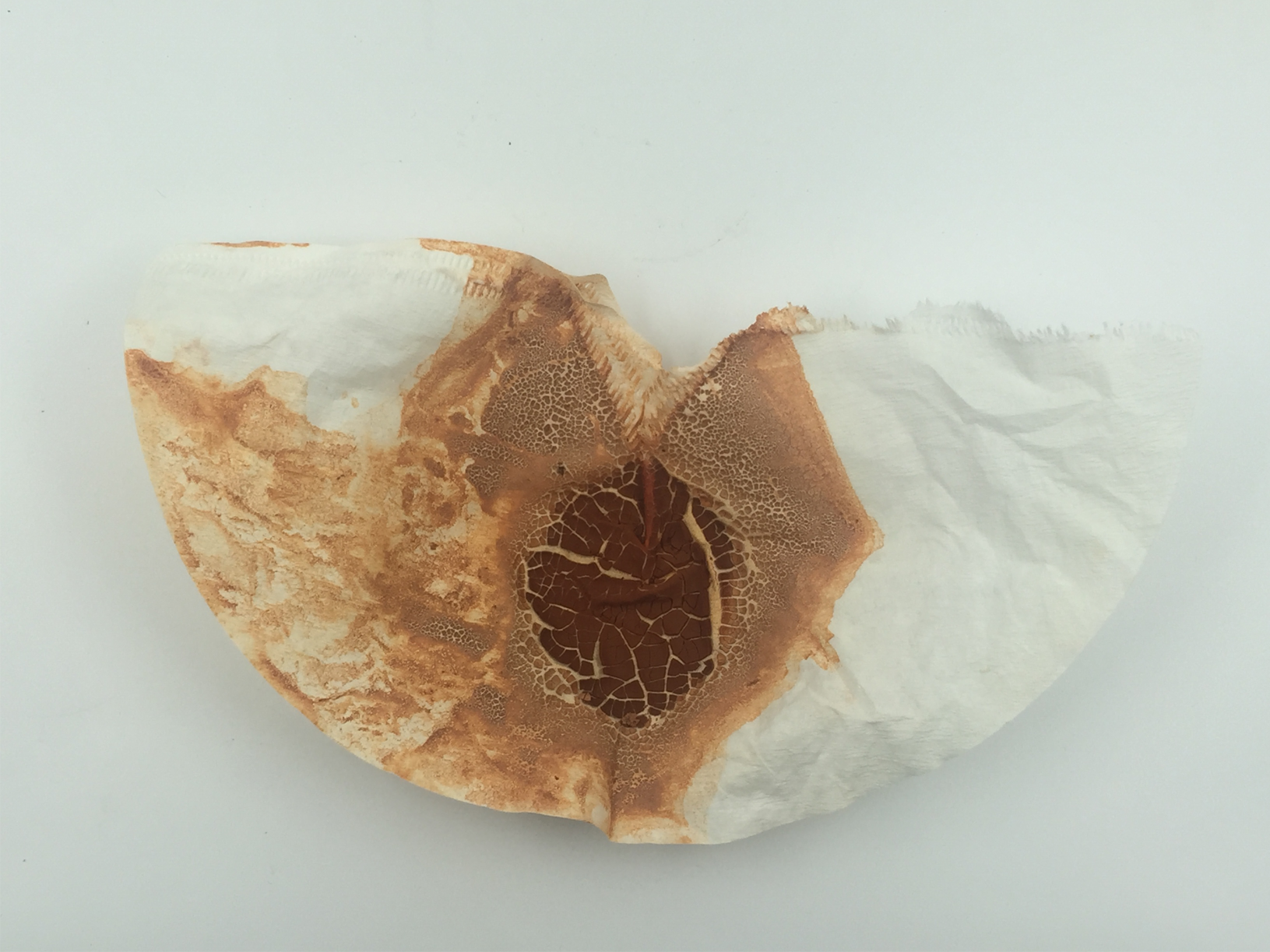

- Prepare a cone of filter paper (we're using coffee filters) open over a small sieve and over an empty dish or jug.

- Pour the liquid into the filter paper gently, giving it time to absorb.

- Depending on your container underneath, you might need a couple of different filters .. but pour until there is nothing left and all the colour is poured into the filter.

- Leave to dry over night

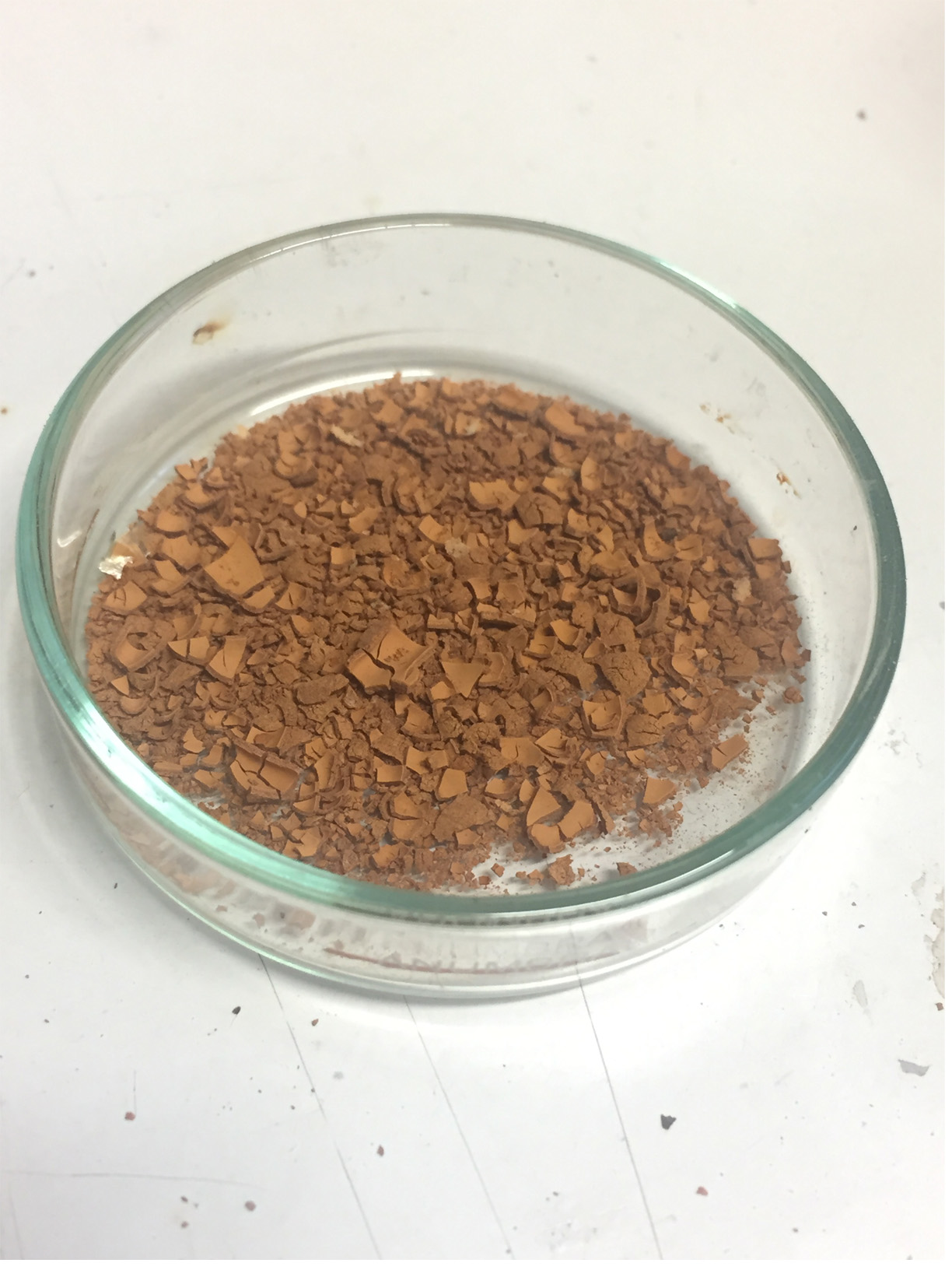

This is what I found!

research¶

I was really inspired when I read about Dian-Jen Lin's design research studio Post Carbon Lab. The concept is designing garments with photosynthetic and pollution filtering properties. Incorporating bacteria with these qualities will counteract the carbon emissions created by the fashion industry. Their aim is to create multiple fabrics with these qualities.

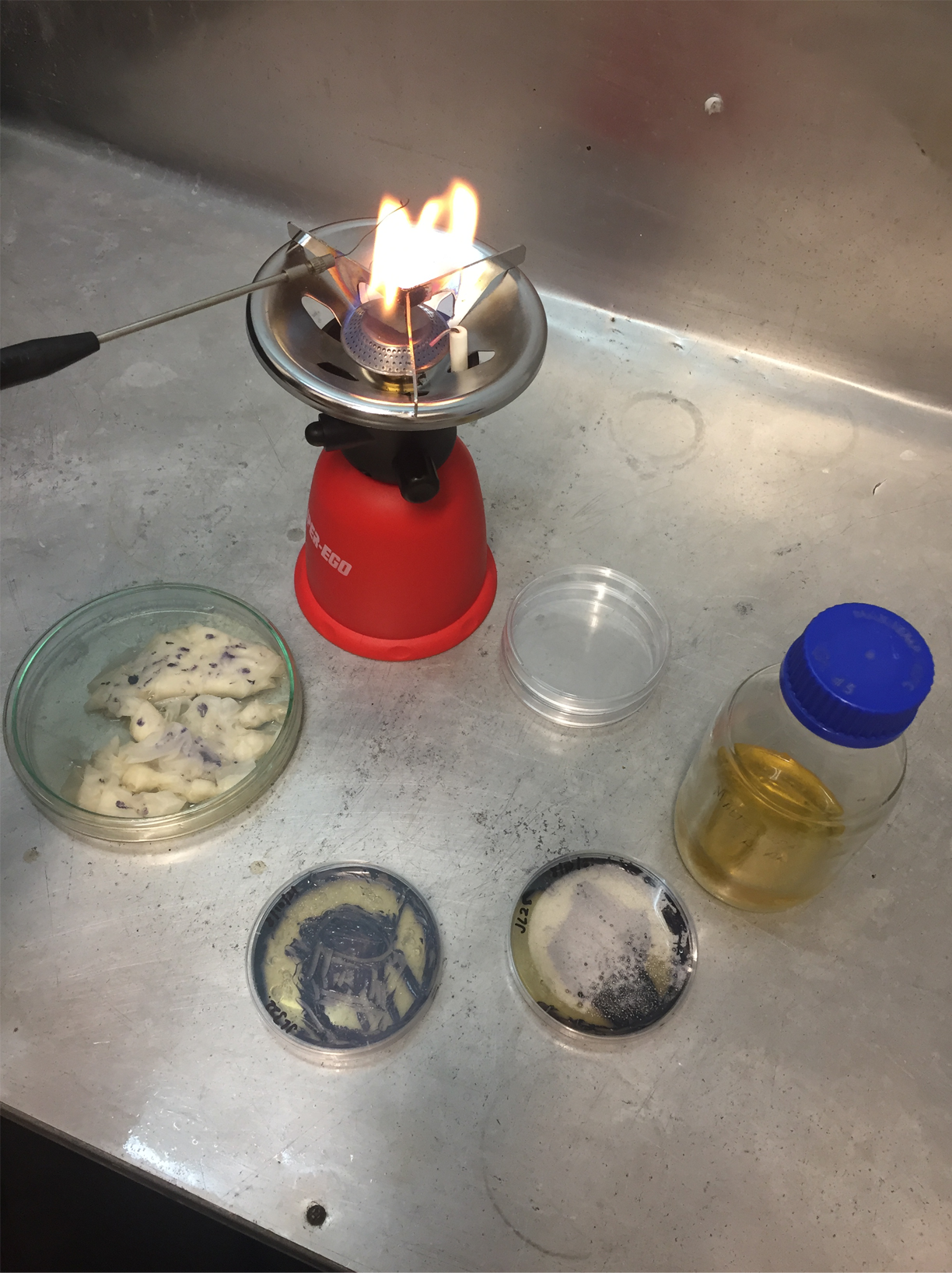

bacterial dyes¶

To experiment with bacterial dyes we're working with LB Broth & Nutrient agar. We will fold bacteria using a shibori technique so that the bacteria will grow organically within the folded fabrics; the folds will reveal a pattern whereas they would usually grow in a cluster. Bacteria will grow in the negative space of the dye.

Nutrient agar is an algae based bacteria and we mix it with glycerine - an elasticizer used in cosmetics and sweet products. It also encourages bacteria growth because of its sweetness. This substance is a gel consistency

Process

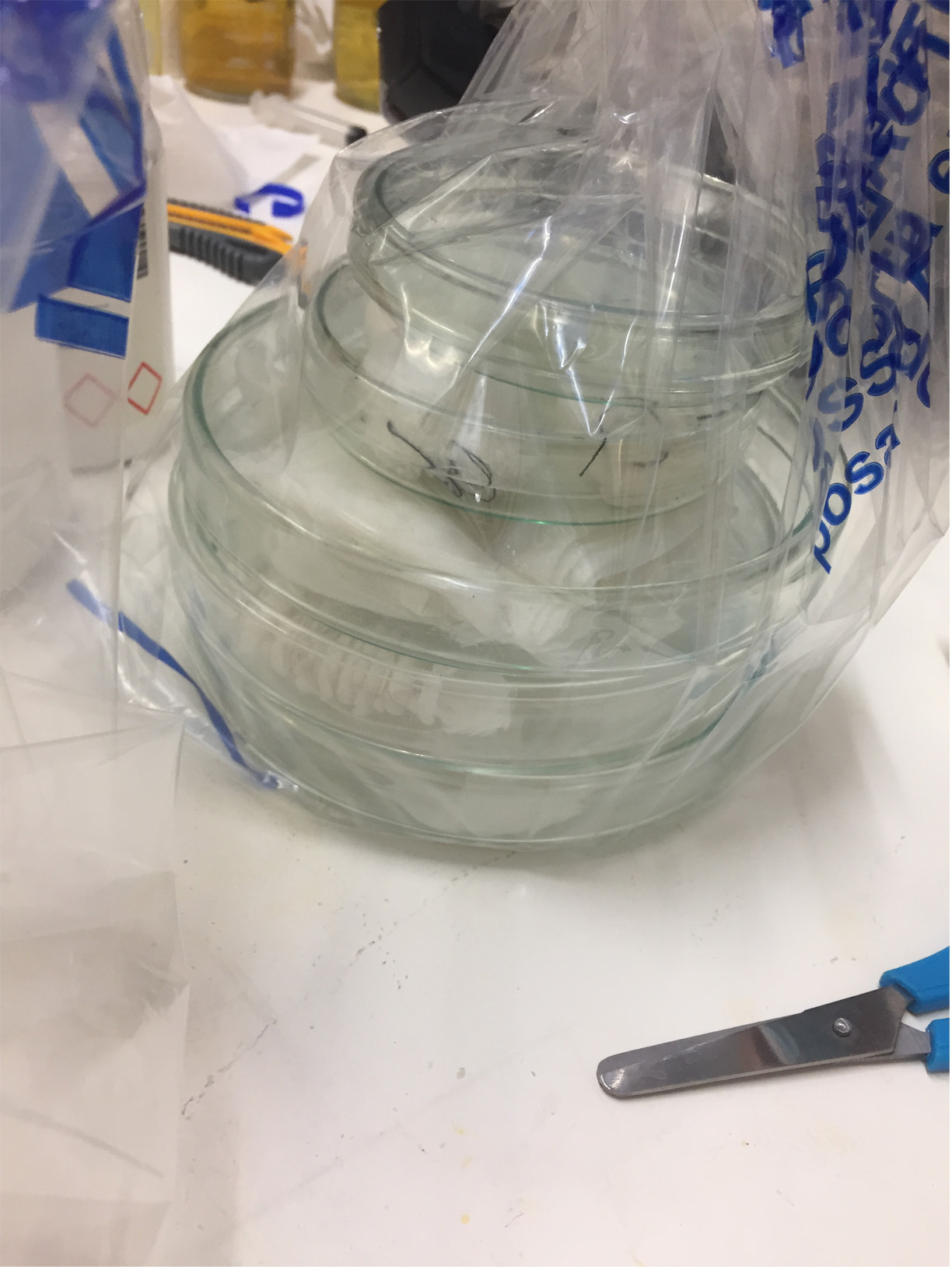

To sterilise the fabrics, first we put them in a pressure cooker vertically with the petri dish lids closed

Before removing them sterilize the whole work space around the bunsen burner with alcohol, and sterilise your hands.

Before removing them sterilize the whole work space around the bunsen burner with alcohol, and sterilise your hands.

| water | LB broth | glycerine |

|---|---|---|

| 250ml | 6.75g | 0.5g |

250ml water - 6.75g Nutrient broth - 0.5g Glycerine

- Open the bottle of LB Broth tilted over the flame to keep it sterilised.

- Have the trays positioned by the burner, open them carefully and pour the solution in.

- Pour enough to cover the fabric and enough that the fabric sits in the liquid a little but but don't overpour.

- Hold the lid of the liquid over the flame to sterilise it again and replace the lid.

The method is very similar when working with the Nutrient Agar:

Before removing them sterilize the whole work space around the bunsen burner with alcohol, and sterilise your hands.

| water | nutrient agar | glycerine |

|---|---|---|

| 250ml | 5g | 0.5g |

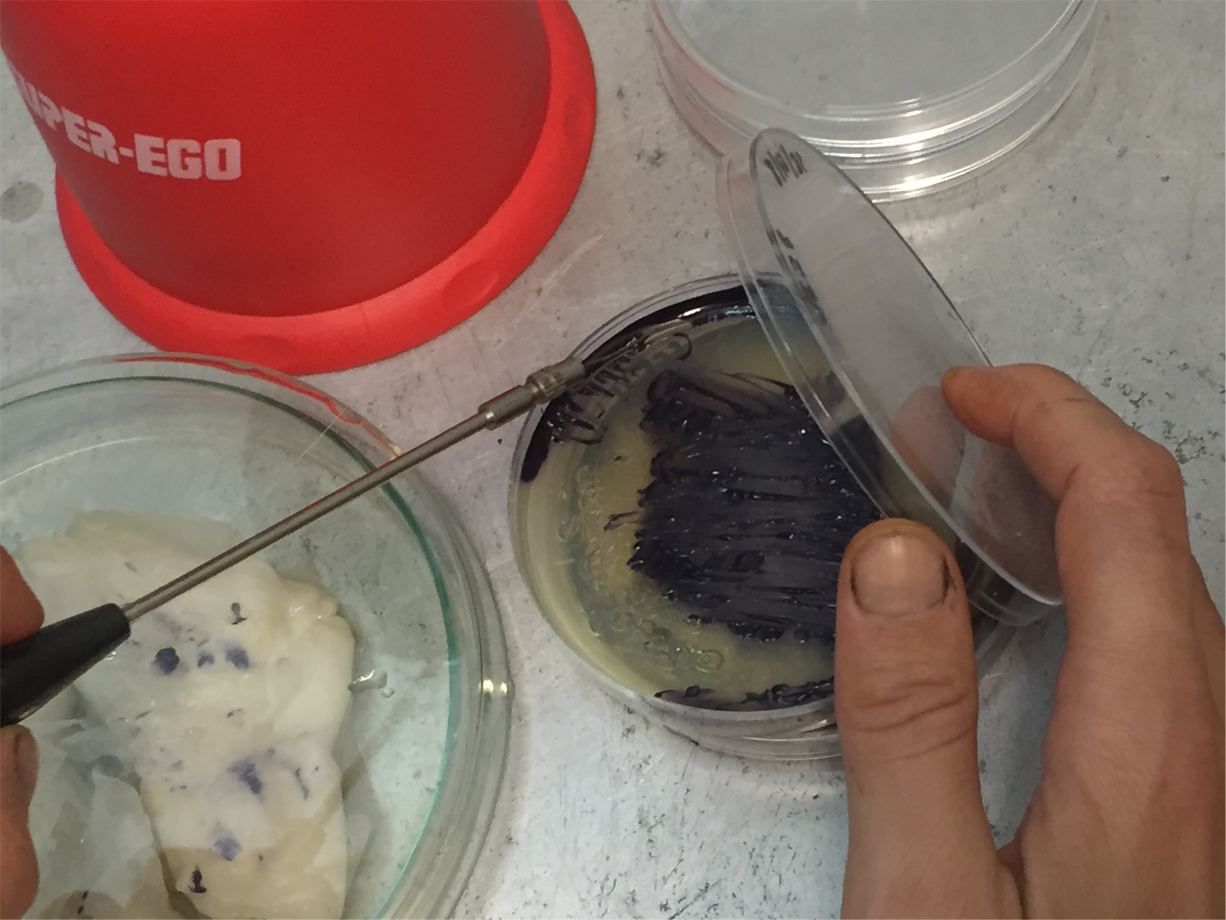

- Heat an innoculation loop over the bunsen burner over the bunsen burner until it glows red

- Open the petri dish of Nutrient Agar on a surface by the bunsen burner

- Put the heated loop into the clear area of the substance which will sizzle when it touches the surface as it cools.

-

Wipe the loop gently over the bacterial surface (purple in colour) to collect the substance on the loop

-

Close the petri dish as soon as this is done to minimise contamination

- Open the petri dish containing the fabric and lightly press the contaminated loop into the fabric in different areas

- Repeat the process to cover the fabric in as much bacterial marks as desired for the bacteria to grow more

- Incubate for 2 days

- Pressure cook the petri dishes to kill the bacteria

- Remove and unpick the sample, wash for drying