9 Textile as scaffold

Learnings

--> Technical Textile applications

--> Composites and biocomposites

--> Crystallization

--> Fabric formwork & Concrete or Plaster Casting

--> Wood + Textile Composite

To do

--> Document the concept, 3D model of the piece and document the design process

--> Make two samples with 2 out of the 5 techniques to make a prototype of a textile form: fabric formwork with casting crystalization wood-textile resin-textile leather molding or other

--> Document the process from CAD to CAMM, document how to use the CNC mill and prototype your textile composite

--> Upload your 3D model and CAMM file

--> Document the 2 processes you have followed step by side from design to machine and hands-on making, materials you used, your mistakes, failures and achievements

--> Use 3D modeling software to simulate your fabric deformation

--> For this assignment you will require to build up your tools (container for molding, vacuum bag set up, frames, matrix, recipients) and process for your workflow

Lecture takeaways & inspo

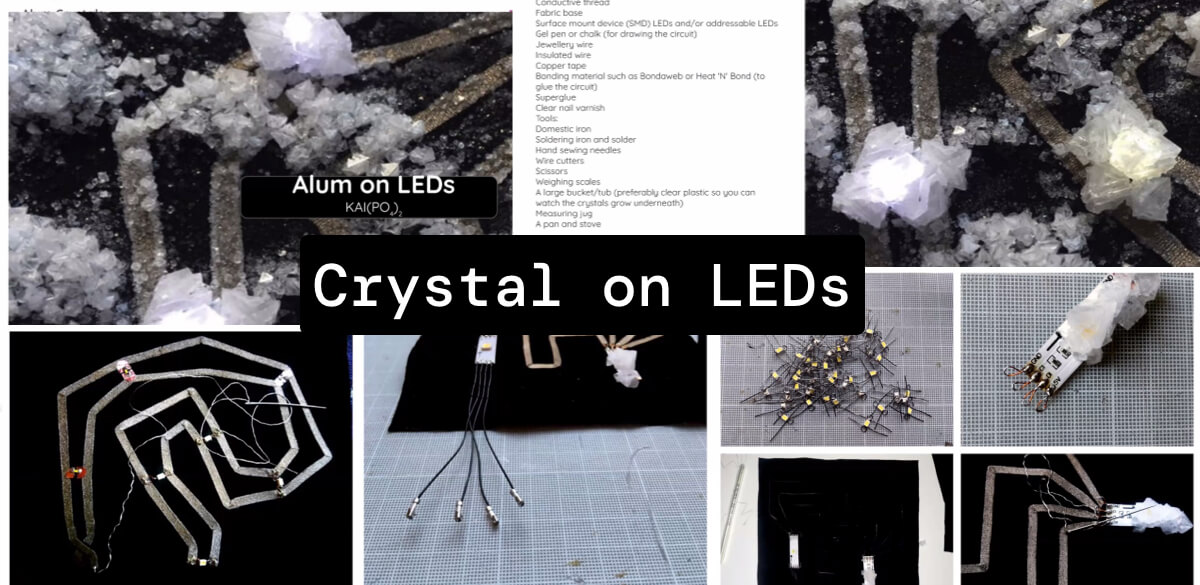

Making crystals

--> I followed the tutorial to understand how it's done and I followed the recipe, heated the water, added alum, filtered the solutions with coffee filters in long cups, placed the items without touching surfaces, and covered the cups:

--> I tried three recipes for crystals:

ALUM CRYSTALS

+ 1L water / 250gr alum / red pigment (made of curcuma, baking soda, arabic gum)

+ 1.5L water / 350gr alum

BORAX CRYSTALS

+ 1L / 80gr borax

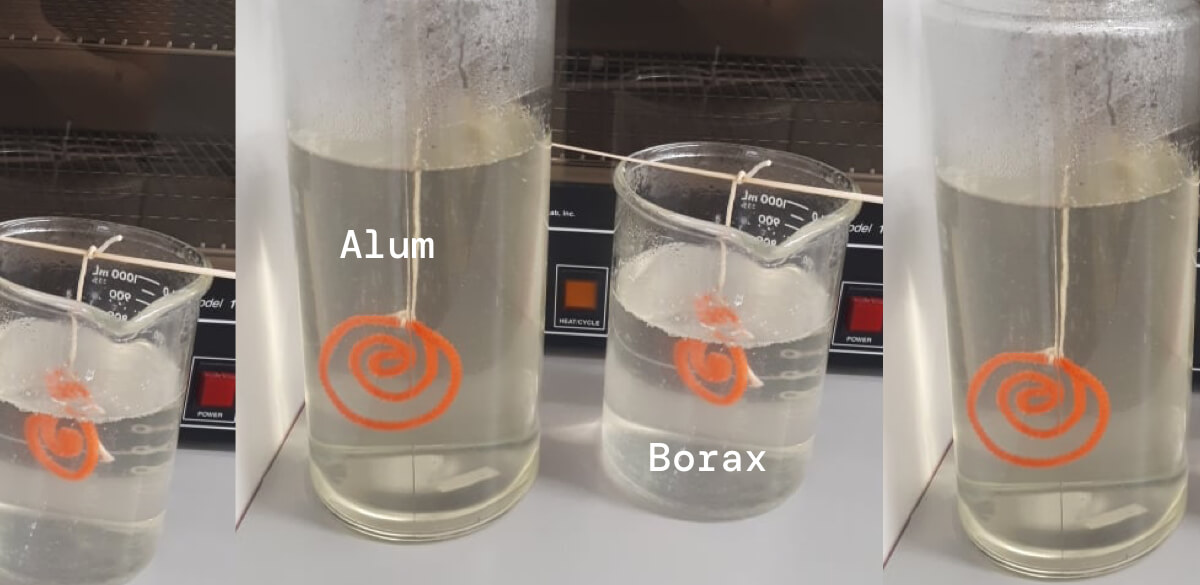

After 24 hours, the crystals did not grow, so I heated the solutions again adding more borax and alum

Only the Borax crystals worked out after 24 hours of rest:

Only the Borax crystals worked out after 24 hours of rest:

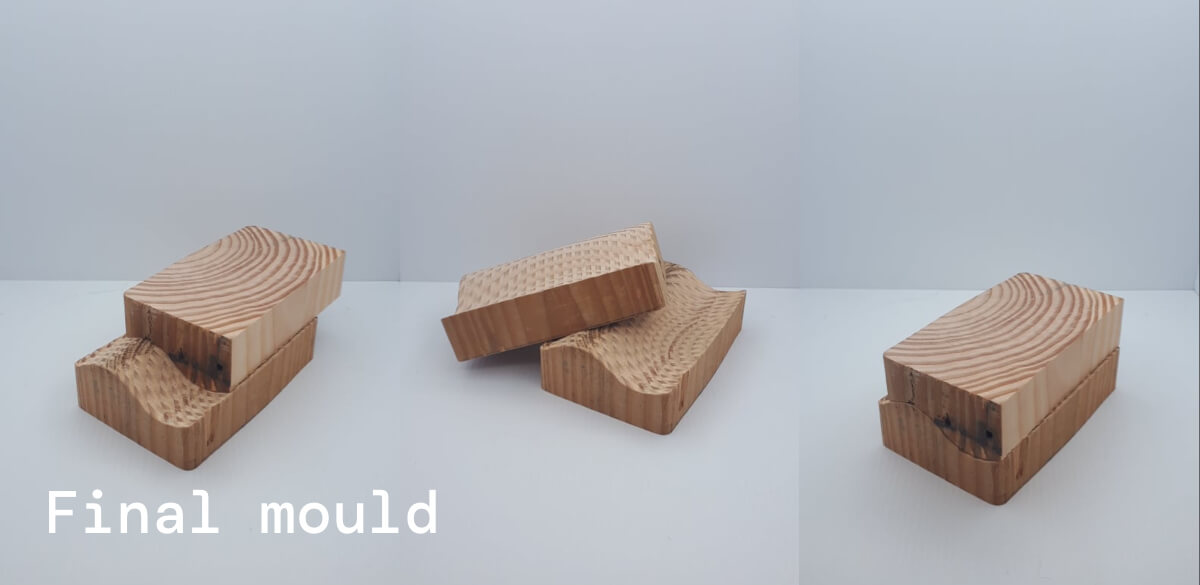

Making a mould & leather moulding

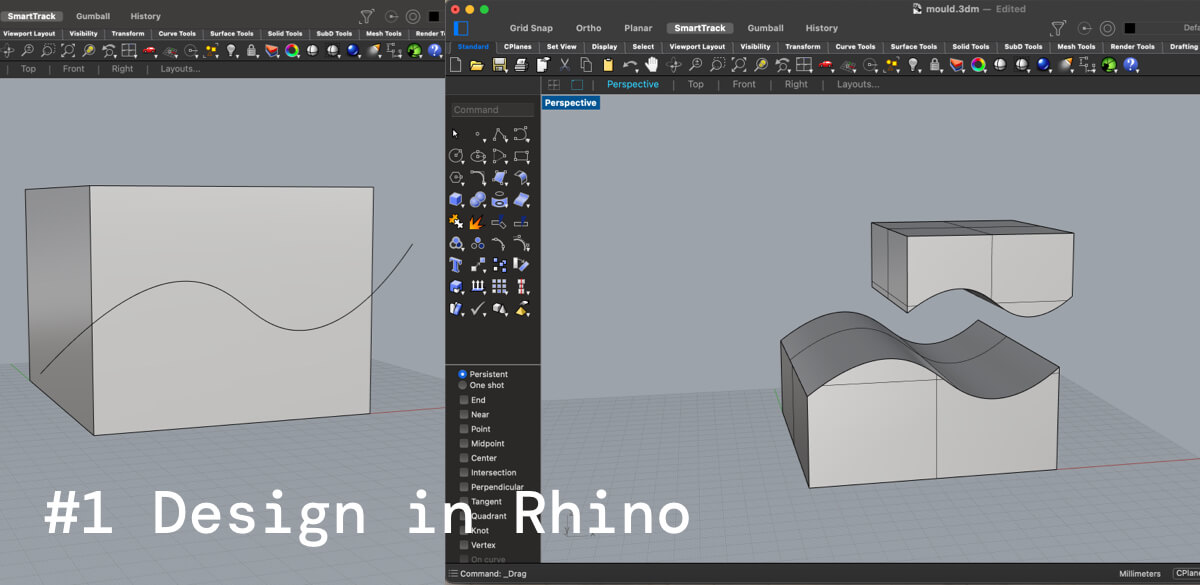

--> Designing in Rhino 3D

Create cube > create cruve > curve to surface > boolean split

Exported object in 3dm

Import in Fusion 360

Rhino files

--> Setting files in Autodesk Fusion 360

Setting up the file for the CNC

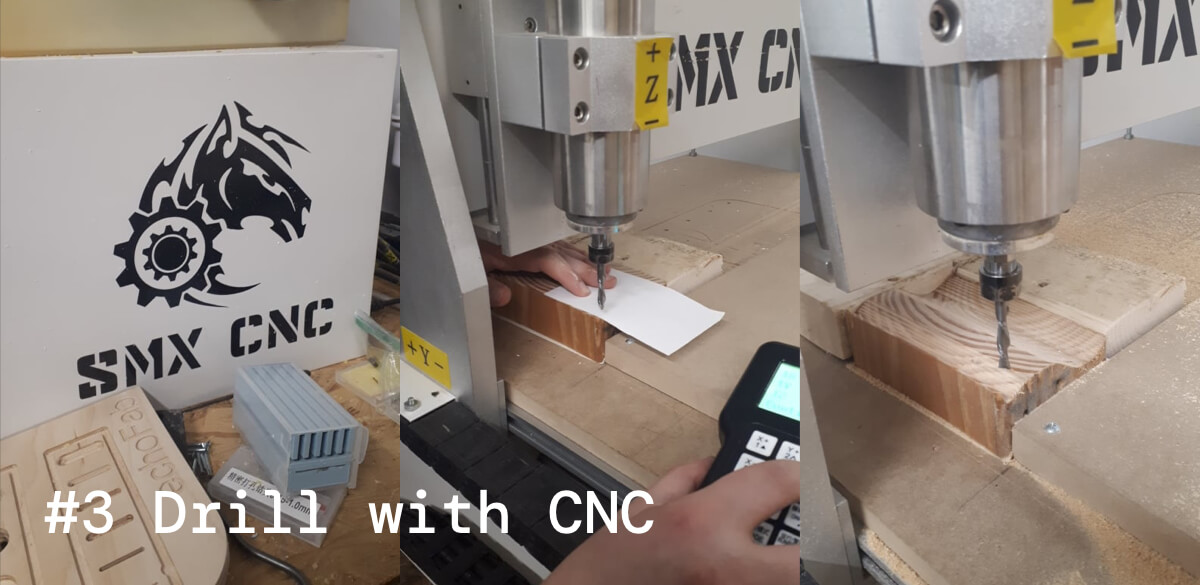

--> Cutting wood with a SMX CNC

We first used a pocket clearing setting (to substract roughly) and then a PARALLEL setting to substract smoothly

--> The leather was soaked in cold water for 30 minutes than placed in a mould, compressed for 4 days.

Useful things

--> Surzhana Radnaeva documentation

--> Marisa Satsia documentation

--> Annie Ferlatte documentation

--> François Auclair documentation