Motivation¶

Waste issues derived from shoe production¶

The use of multiple materials and adhesives in current production methods difficults post-consumer recycling.85% of the shoes that are disposed in Europe end up in a landfill. Less than 5% are recycled. And it takes 1000 years for a pair of shoes to degrade. (Source)

3D printing opportunities for sustainable production¶

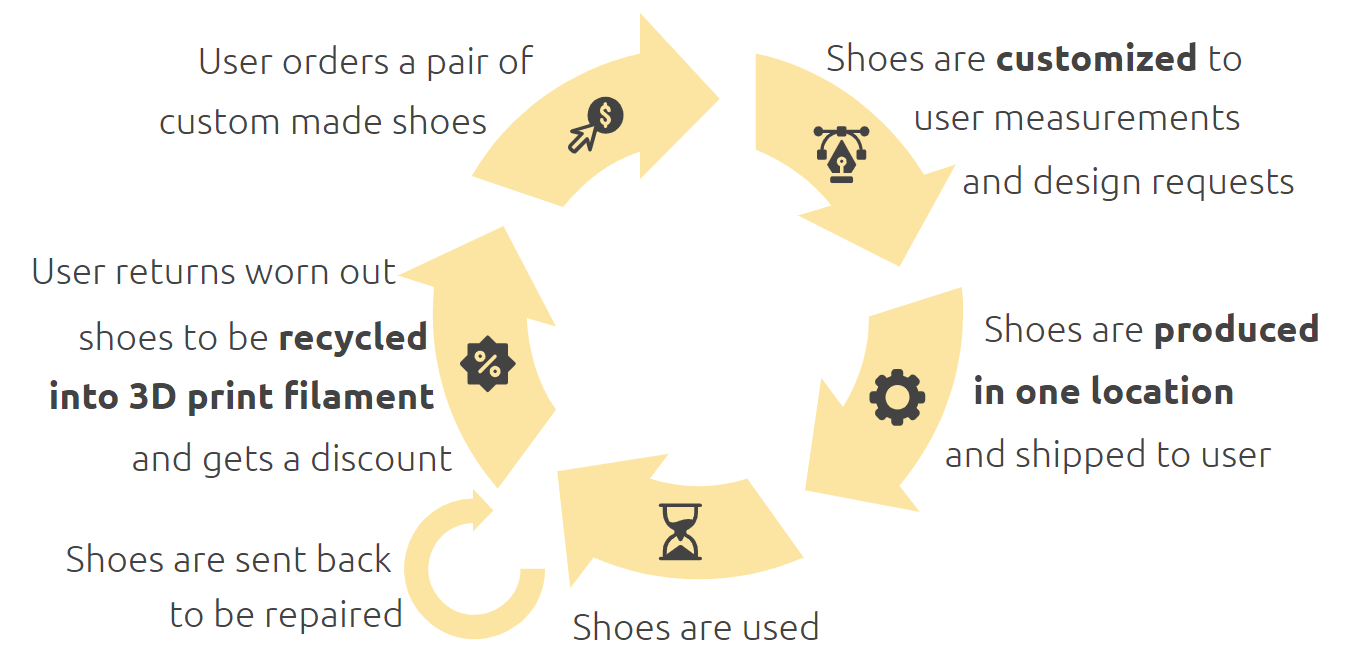

3D printing allows for distributed manufacturing, which means products can be made with localized sourcing and manufacturing tools. Besides that, since it is an additive technology, it only uses the amount of material needed, generating negligible waste. This, combined with the use of the correct materials, allow for a circular business model in which material can be reincorporated to the manufacturing process retaining its high value.

Aesthetic gap on existing 3D printed shoes¶

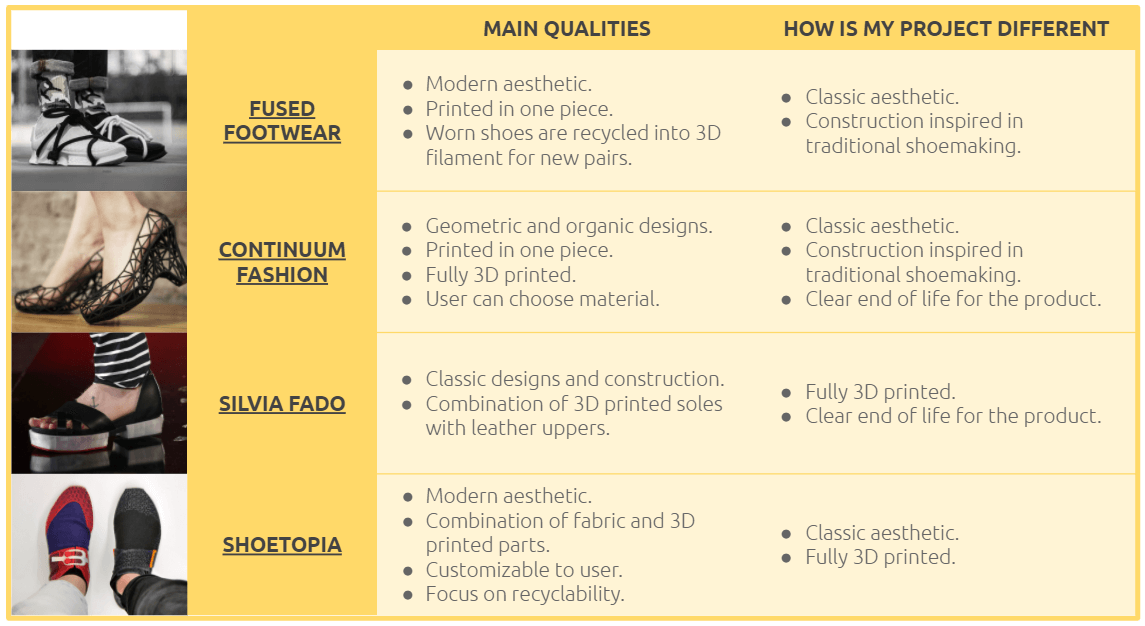

Most of 3D printed shoes that can be found nowadays stand out because of their futuristic design. On top of that, most of them don't have a focus on circularity and customization.