3. CIRCULAR FASHION¶

Yes, circular fashion week!

This week talks about an open alternative to the current fashion industry based on an open value chain that provides modular clothing files, with seamless assembly through interlocking connection, where the assembly, disassembly and replacement of parts is facilitated. Thus, production can be globally connected through the exchange of experiences, files and knowledge, but production is done locally. These modules further facilitate zero waste design, connecting this logic to circular economy design.

Two Slides from Zoe Romano's class defined the Open well:

Slides can be seen here

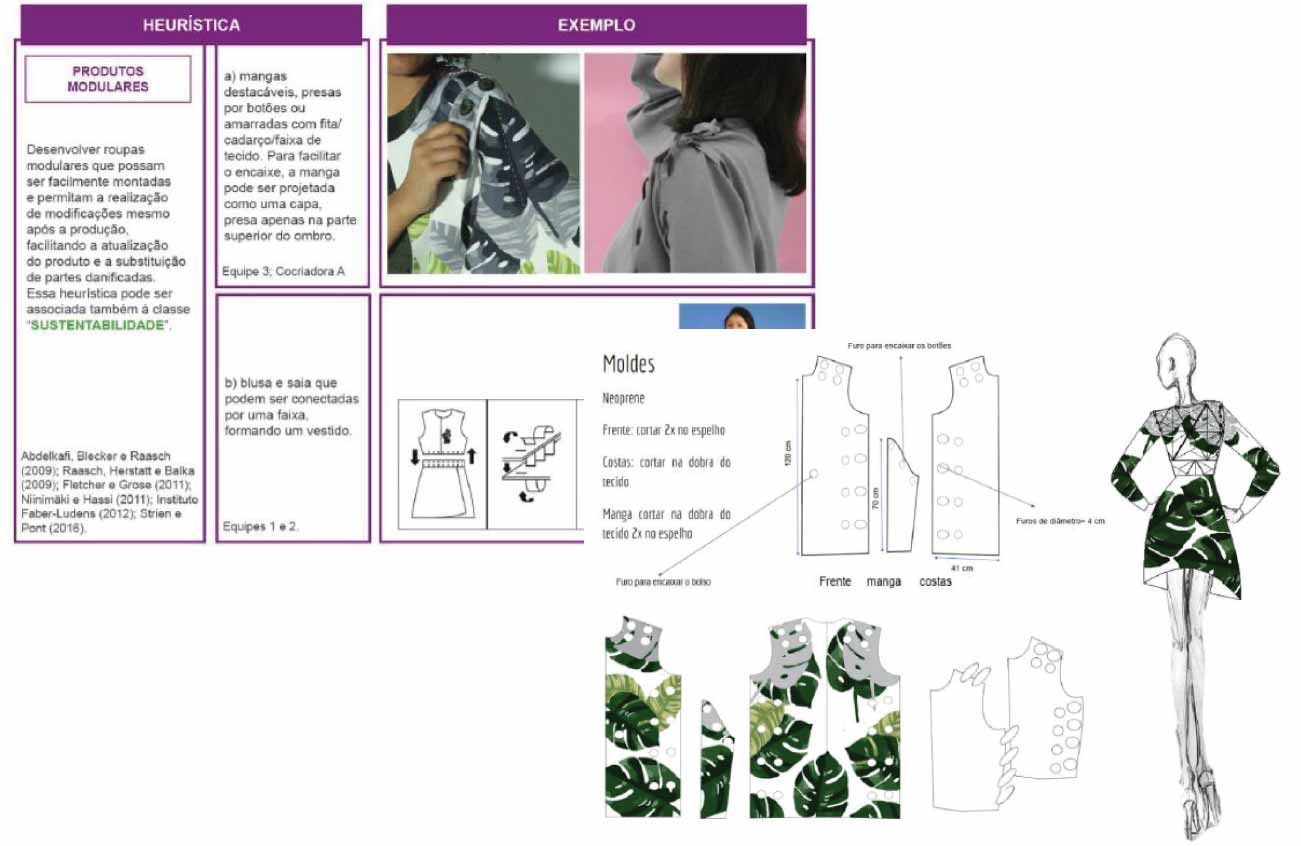

My first contact with open design was through Iana Uliana Perez's master's thesis "OPEN DESIGN IN THE PROMOTION OF DISTRIBUTED ECONOMIES: heuristics for the development of clothing" which aimed to "identify and systematize heuristics for the application of open design principles to the of more sustainable clothing, with predominant use of digital fabrication technologies” (PEREZ, 2017, own translation).

This work was very important for me to begin to understand the concepts of distributed production, open design and the possibilities for the garment focused on sustainability.

PREVIOUS WORKS¶

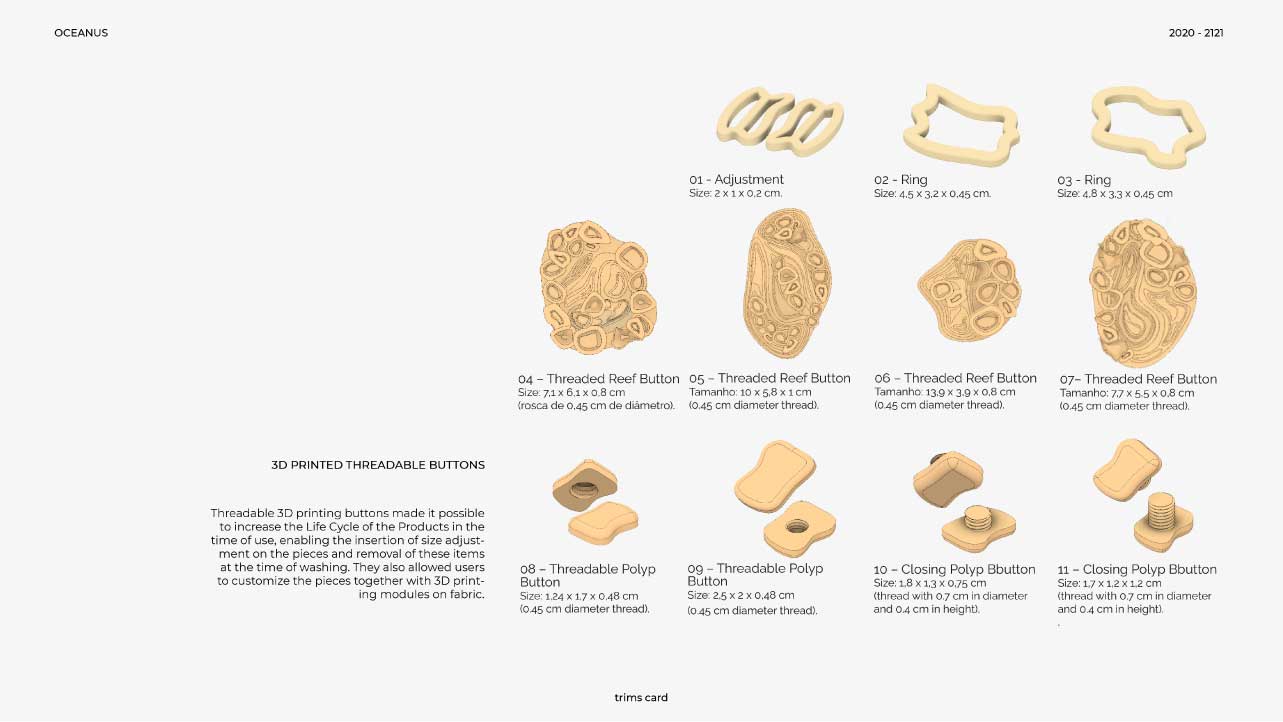

Iana ended up co-supervising my graduation thesis. In it, I also worked a little with the modularity through 3D-printed screw-on buttons, which facilitated the removal of some product parts and customization by the user.

INSPIRATIONS¶

For this week's assignment, I wanted to work inspired by the popular Brazilian saying, "o que os olhos não vêem o coração não sente", in english:

what the eyes don't see the heart doesn't feel

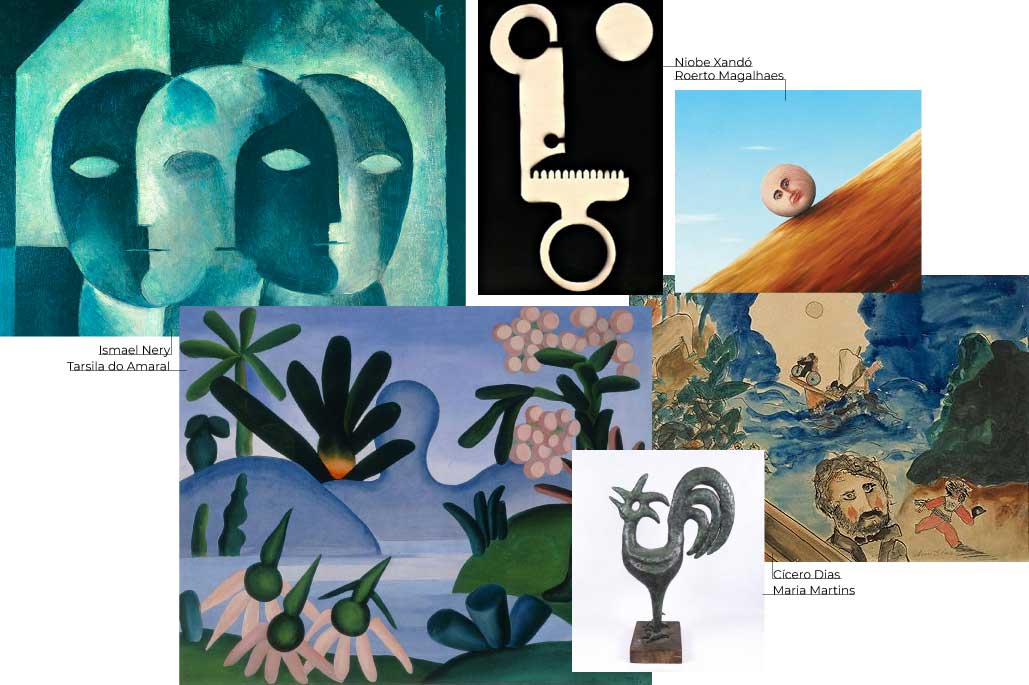

Along these lines, I also wanted to bring some references from Brazilian and Latin American surrealism, organized in this moodboard:

I am struck by the volume present in the works of Ismal nery and Tarsila do Amaral, in addition to the figurative characteristics of the artists and the ethereal character present mainly in the works of CÍcero Dias.

In addition, the modular work brought me directly to the memory of rugs and artisanal pathwork, very common in Brazilian grandmothers' homes hahahah! I wanted to bring some of these aesthetics to my work as well.

Colorful images of these craft works can be checked in this Pinterest folder

TESTS¶

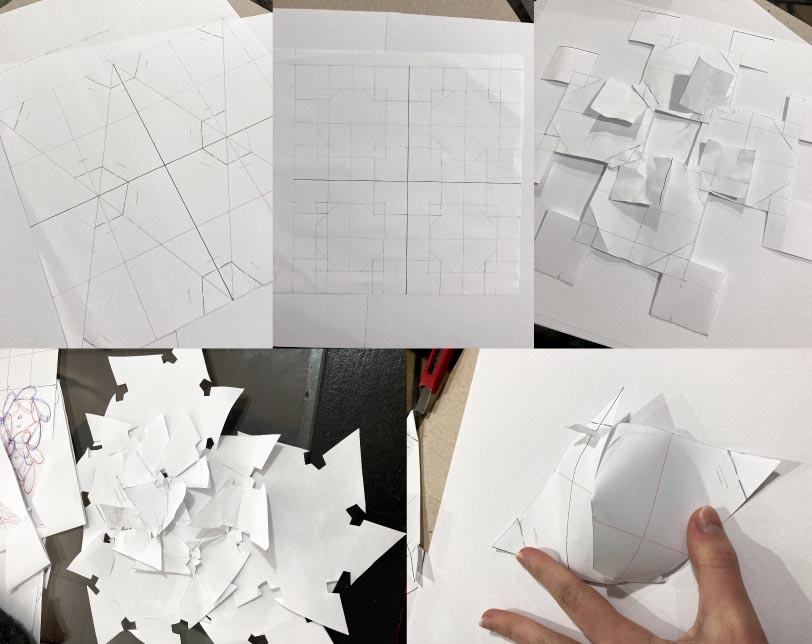

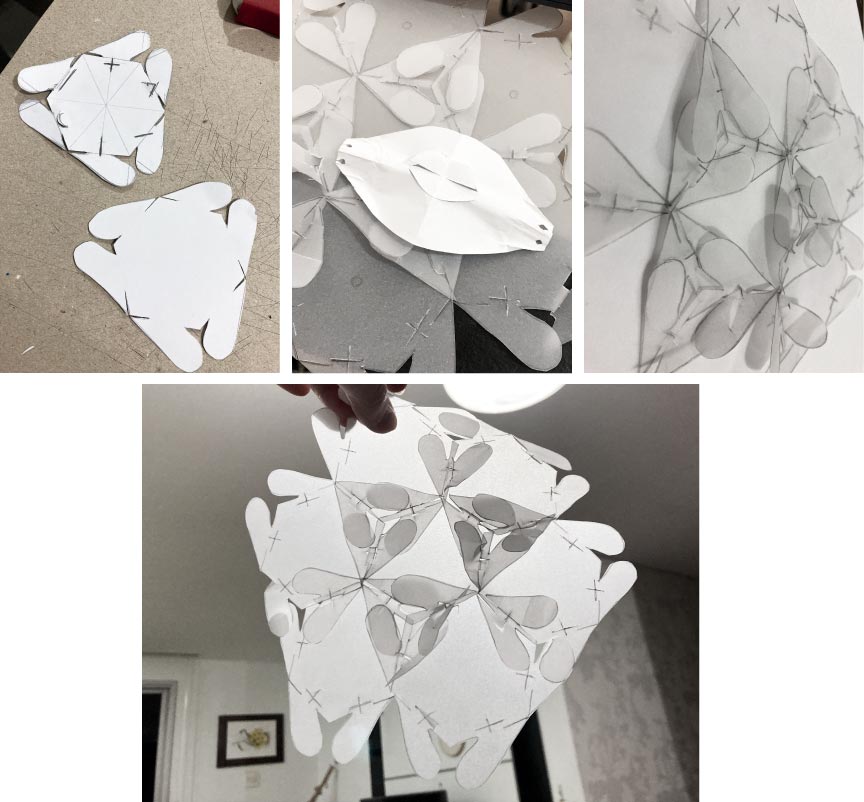

paper¶

I started by doing random tests with paper and scissors, as suggested by the teacher. As I was testing, I arrived at the module made from a hexagon where its interlocking forms a heart.

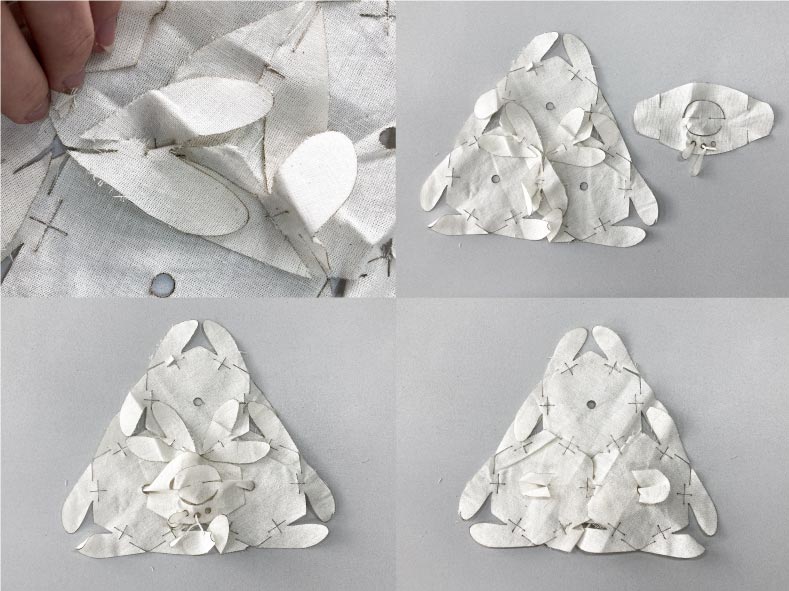

The idea is to overlay the eye-shaped module to bring volume. The Eye will also have holes to place the eyelashes (or the tears, depending on the point of view!).

fabric¶

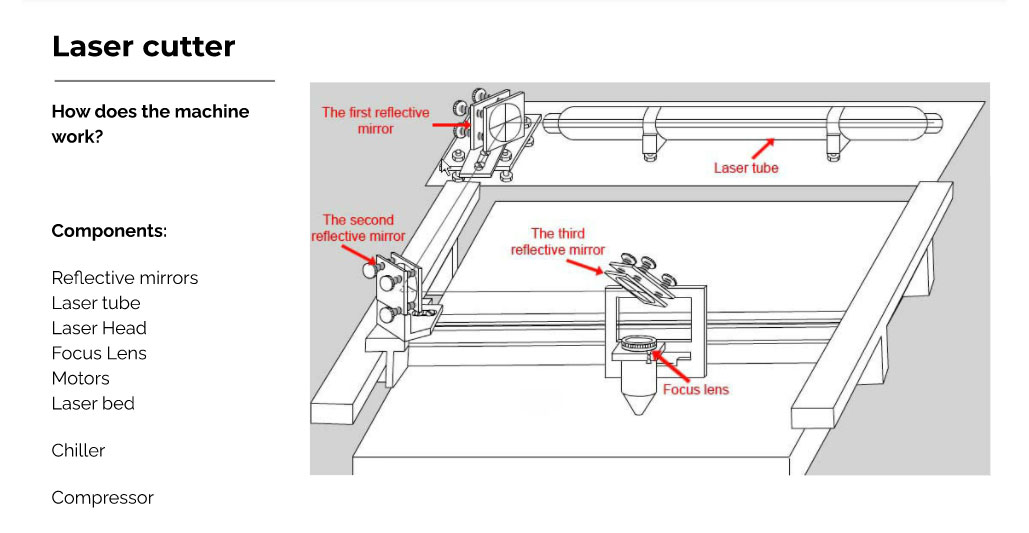

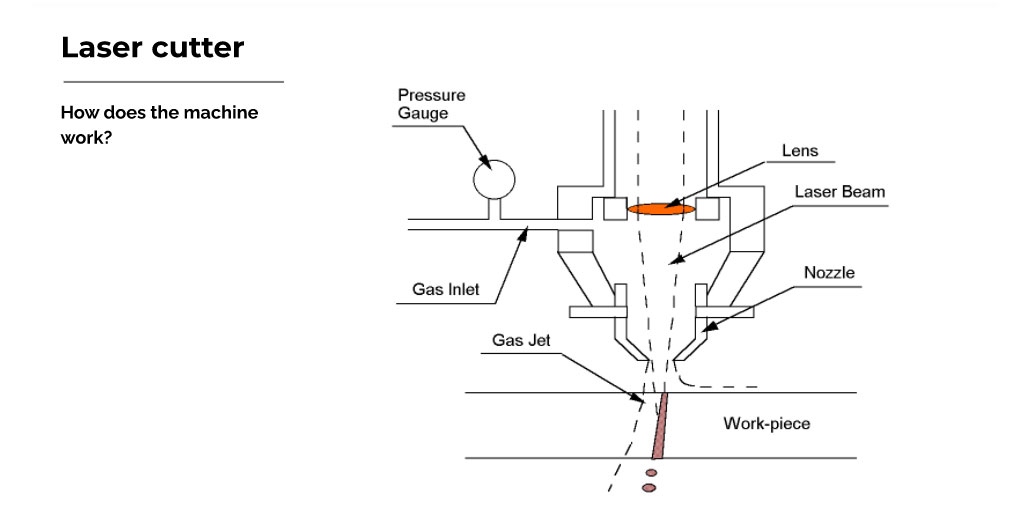

laser cutter¶

how laser cutter works by Zoe Romano's Slides

I already had some experience with cutting fabrics on the laser cutting machine because I needed to establish some cutting parameters for my graduation final project. From my tests, the process that worked the most was cutting the fabric under a glass plate (as our material support grid is wide), with the machine's vent off. As this process is dangerous as it can heat up the machine, we need to be very careful, keep an eye on the machine and make the cuts little by little.

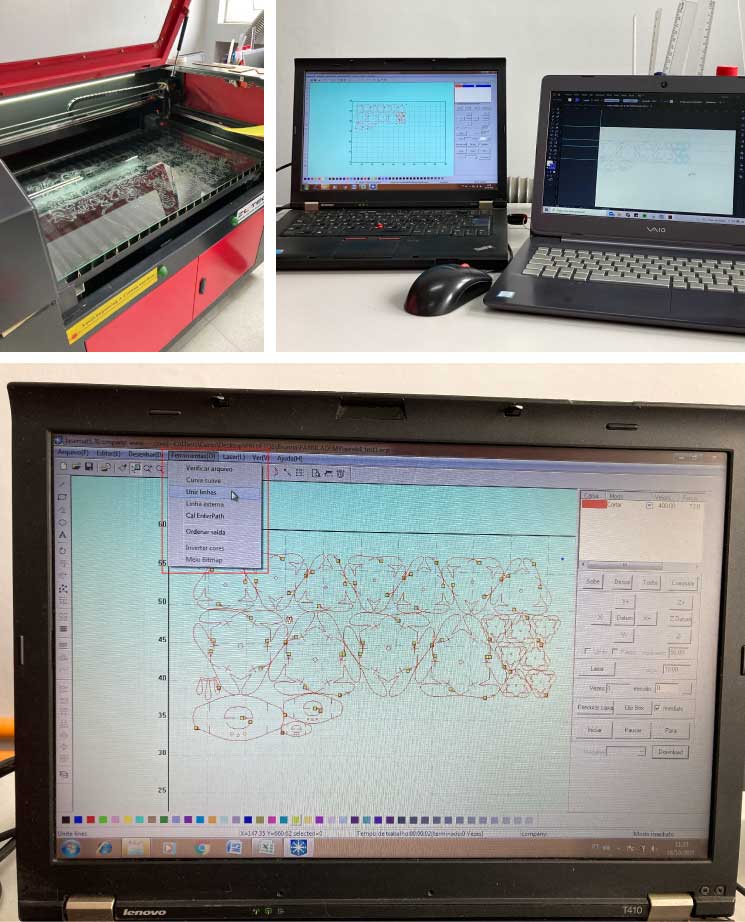

I decided to test 3 different sizes.

Important: to make laser cuts, it is necessary to join the lines of the modules when importing them into the cutting program.

As much as I know it's best to cut fabrics with at least a percentage of synthetic fibers for finishing, I tested it on raw cotton fabric first.

| fabric | velocity | force | force in the curve |

|---|---|---|---|

| cotton | 400 | 13 | 13 |

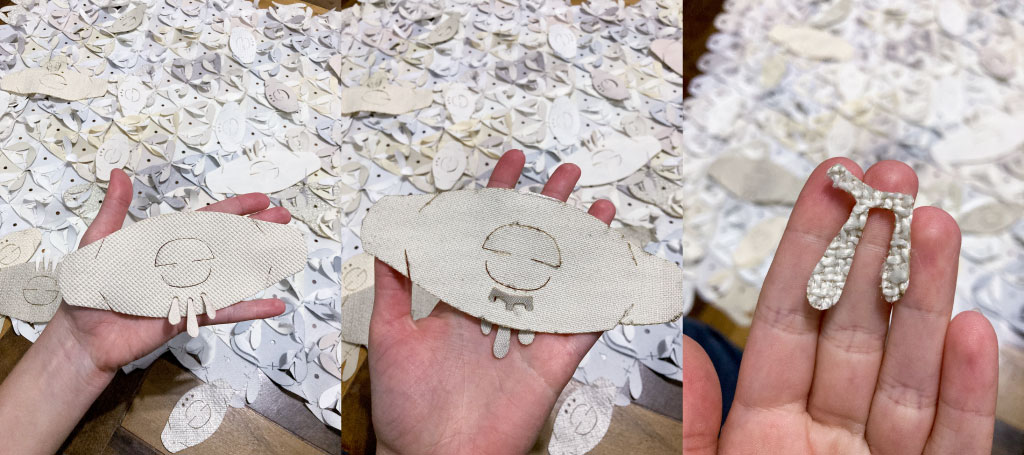

The smallest models didn't work very well. I also realized that it would be interesting to improve the fitting tips of the eye module.

The video of my tests:

FINAL MODULES¶

If the volume of surrealism is brought by the interventions with the eye module, the figurative in the hexagonal module with its heart interconnections, the patchwork here is brought by the mixture of fabrics, mixed with the ethereal in its white colors.

These fabrics are samples of interior design that would otherwise be discarded, which I have easy access to as my mother works in an architectural office.

All have at least a percentage of synthetic fibers, and most are 100% polyester. Some have little structure and will be interwoven for cutting.

final result¶

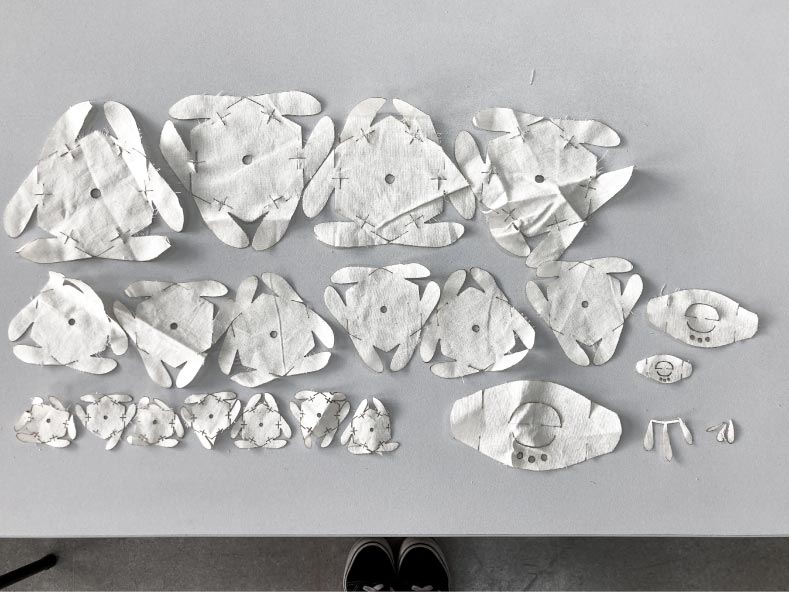

Unfortunately, when I went to cut my final molds, our lab's laser cutting machine was undergoing maintenance and I couldn't use it, so I had to send it to a company to cut, so I don't have records of the cutting process, only the assembly process. .

I started by separating the fabric modules with similar weights, to facilitate their distribution along my banner.

Then, I first joined the hexagonal-shaped modules. This process took a long time because there are several modules!

Afterwards, I added the tears/eyelashes to the eyes. Some heavier fabrics lost a tear/lash leg, but I used them anyway.

With all the hex modules connected and my eyes ready, I arranged the eyes randomly on the flag, connecting the outer legs of the eyes to the central holes of the hexes. The end result was like this:

The video of the process:

ARQUIVES¶

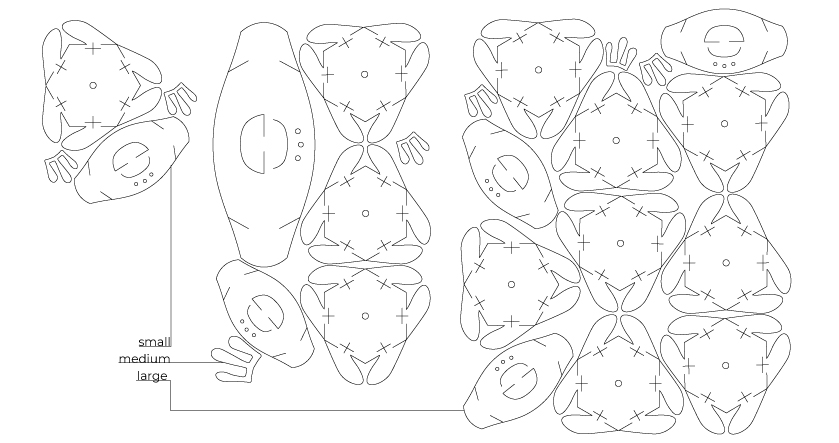

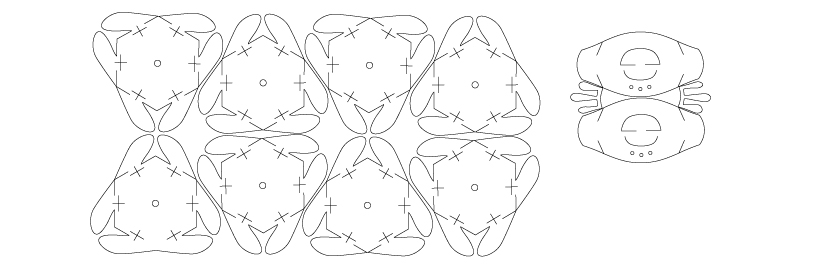

The modules are arranged according to the size of my fabrics, which were large (approximately 27 x 21cm), medium (approximately 23 x 14cm) and small (approximately 12 x 10cm).

In the image we can see that the distribution of the modules did not favor zero waste, that's because I wanted to fit the eyes together with the cuts of the intersecting modules of the heart to make it easier, since I had many different tissues. I confess that it wasn't my priority either, since I was already working with reused fabrics.

Anyway, the modules can be better fitted and the eyes can be cut separately (depending on the number of eyes desired), as in the example below:

ATTENTION: be careful when importing the document on your computer, make sure that the file is in 1:1 scale, in mm unit.

The files are available here or in Os Circular Fashion weebsite.

REFERENCES¶

PEREZ, Iana Uliana. Open design in promoting distributed economies: heuristics for clothing development. 371 p. Dissertation (Master’s) Postgraduate Course in Design, Human Sciences Sector, Federal University of Paraná, Curitiba, 2018. (Free translation)

RAMOS, Brunna Gonçalves. Fab Lab and its potential for Teaching and 4.0 practice in Fashion Design for Sustainability. 142 p. Completion of course work (Fashion Design) – Center for Education, Communication and Arts, State University of Londrina, Londrina, 2021. (Free translation)

VIRAVA, Thiago Gil de Oliveira. A gap for surrealism: perceptions of the surrealist movement in Brazil between the 1920s and 1940s. 255p. Dissertation (Master’s) School of Communication and Arts, University of São Paulo, São Paulo, 2021. (Free translation)

Fabricademy week 3 - CIRCULAR OPEN SOURCE FASHION

Personal Pinterest folder - patchwork

Surrealism in Brazil - in portuguese

Never Cut these materials on the laser cutter