Products¶

With all the ways of experimentation where I have been able to have a great variety of very diverse materials where I have also used many techniques, I have tried sewing and gluing it, they have always been well received and it is a quite resistant material that has been able to give me a great variety of possibilities where they could be used in haute couture and textile design, as well as accessories design and to add to more conventional designs.

Cosmetics¶

Biomanufacturing gives us the opportunity to create a world full of possibilities and ways to create km0 products and be completely transparent as we know exactly where our ingredients come from.

Beta-carotene and other carotenoids in carrots have an antioxidant, immune-stimulating and anti-aging effect. Carrot extracts or carrot essential oil are very often used in cosmetics. That’s why I can’t resist using it in my project and add more layers within this Heterotopic world.

Bag¶

Downloadable File of the bag to lasercut

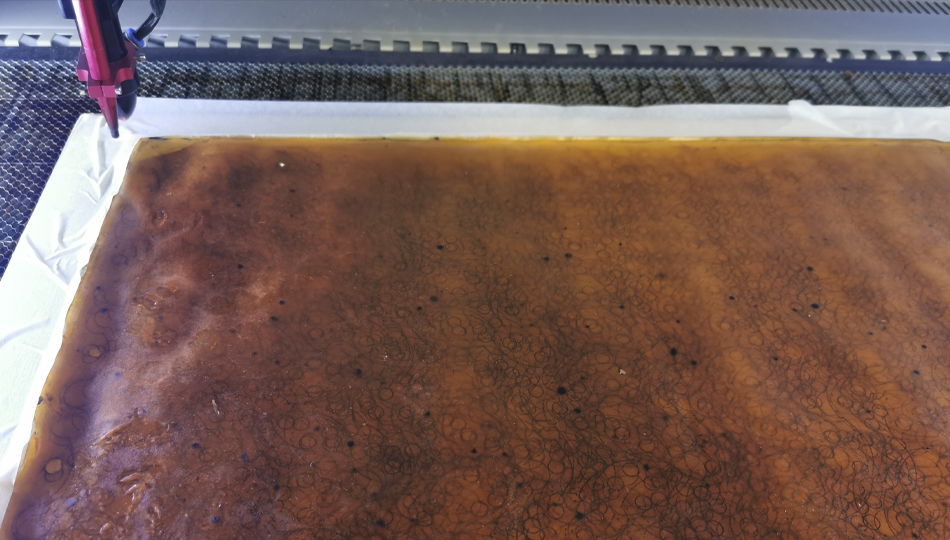

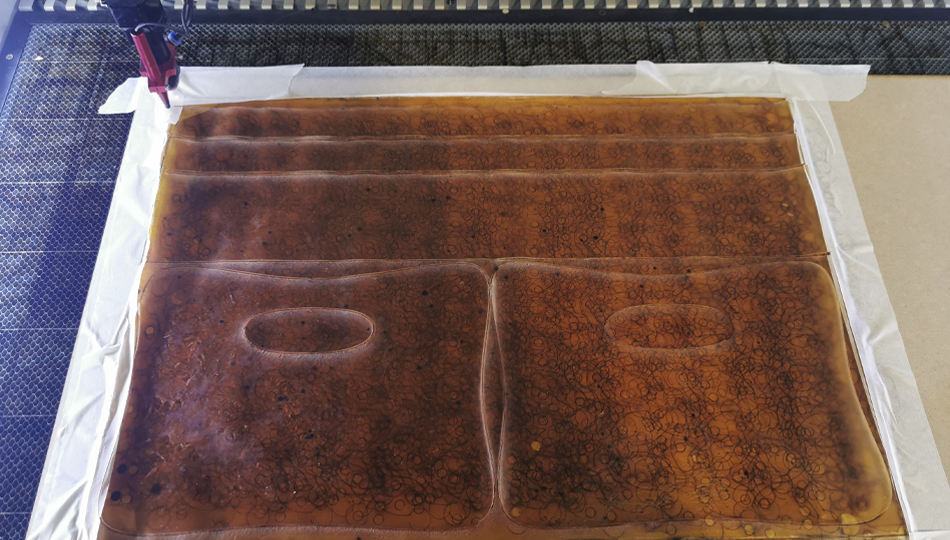

Using the same cutting parameters of the modules and the experience of cutting a lot of modules, I followed all the rules that I had imposed on myself, I decided to cut it first before silk-screening it.

Utilizing as much of the biomaterial surface as possible position the cut design so there is zero waste.

Use the entire surface for the base, sides and reinforcements of the bag.

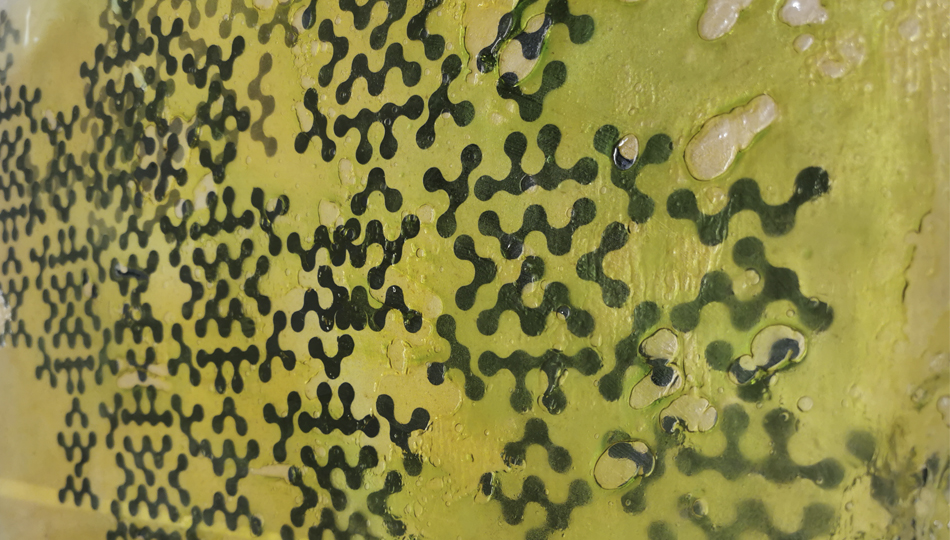

The next step was to screen print the bag so it is ready to sew.

Due to the detail of the design that I wanted to print, I used a mixture of transparent-based acramine with a dark biomass, to be able to use a 77-thread screen and 120-thread for each side , to have greater definition.

To start the new process, it is best to be organized and put everything as in gastronomy in “Mise en place” order and cleanliness is very important in all processes since that way you are faster and you can focus more on the task at hand in front.

Use a double-needle seam, very common in leather goods sewing.

For the sides and to add reinforcement to the bag, I have used the modules, which allows you to add a strap and use it as a shoulder bag and have more variety.

Here you can appreciate the seams and the printing, with a backlight.

Jacket¶

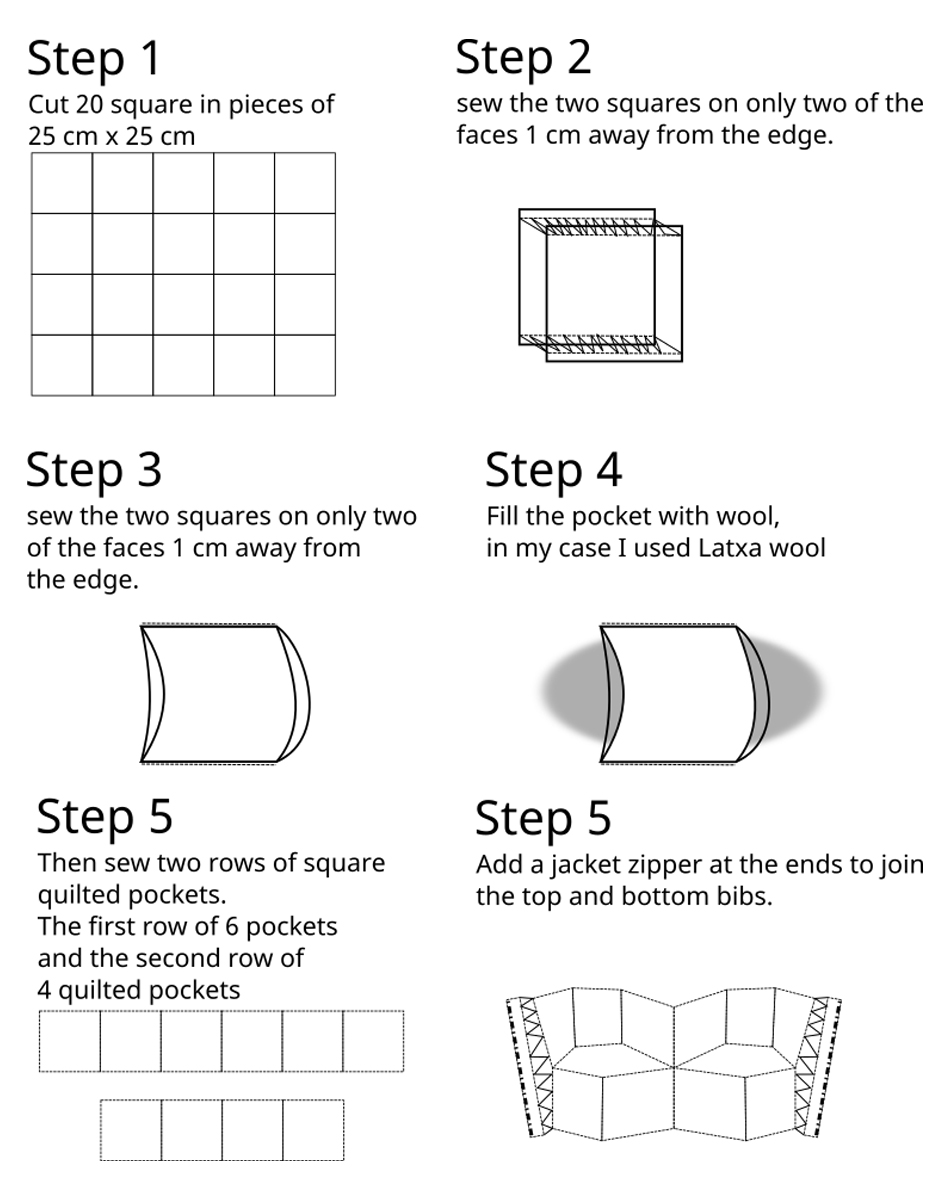

I wanted this jacket to be easily reproducible and also zero waste, so what I did is that after silk-screening the biopolymer I added another layer of biomaterial so it would give me contrast and reinforce the parts that had imperfections.

I then cut 25 x 25 cm squares and each panel had a total of 4 squares.

To proceed to sew together the 4 pocket-shaped squares.

When all the panels are sewn, the next step is to turn them over and bring the inside out.

Then I weighed 75 gr of Wool, in this case I used Latxa wool since it is a waste here in the Basque Country

You now can fill all the panels and prepare it to the next step.

To join the panels and make room for the arms in the upper part, I used 6 filled panels and 4 panels in the lower part, which gives a total of 10 panels, which was all the material I had.

Then I put a zipper attached to two 50 cm x 5 cm panels that helped me join it to the other panels and thus build the jacket.