Artistic Research¶

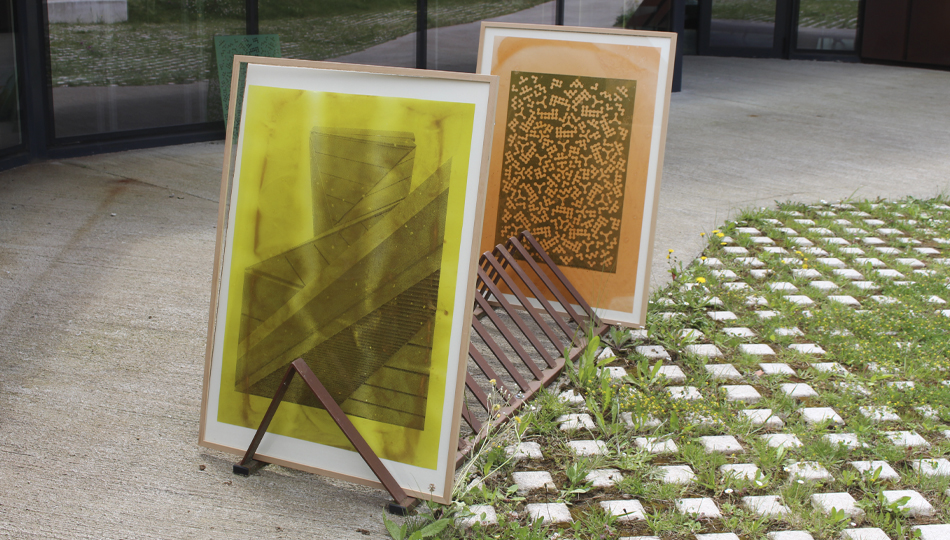

In this Heterotopic world that I have created in Fabricademy mixing various types of biofabrication, I have also combined various types of techniques, such as the explorations in the printing laboratory that we had in the node of the Basque Biodesign center.

And of course this exploration of techniques would not have been possible without the head of the printing workshop Irati Retolaza since her knowledge and desire to experiment have been crucial in taking my project to a level that I did not know it could reach.

Relief Print¶

Relief printing is a family of printing methods where a printing block, plate or matrix- which has had ink applied to its non-recessed surface- is brought into contact with paper. The non-recessed surface will leave ink on the paper, whereas the recessed areas will not.

A printing press may not be needed, as the back of the paper can be rubbed or pressed by hand with a simple tool such as a brayer or roller. In contrast, in intaglio printing, the recessed areas are printed.

Picture treatment¶

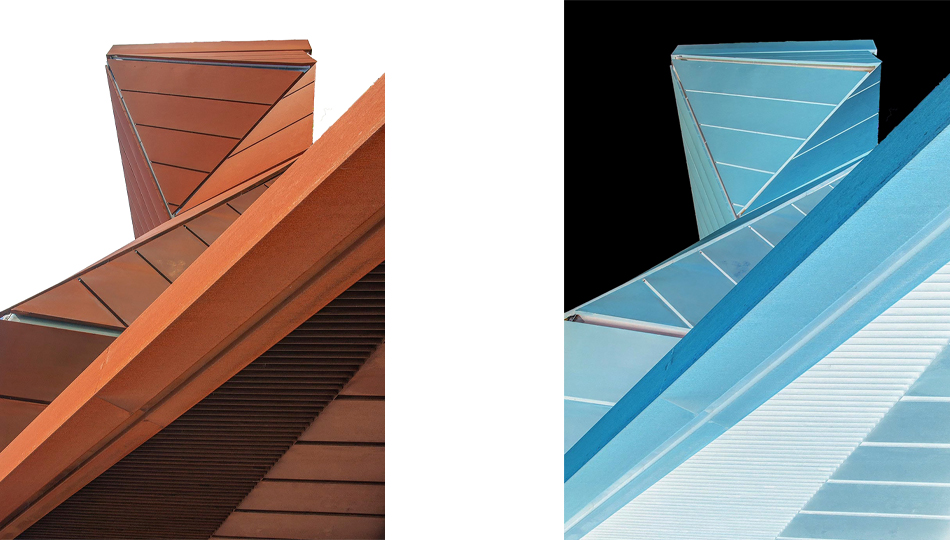

From this photo of the building of our Node in Bilbao. I moved it into Photoshop and used the Invert command to pass it into the LASER CUT program. IMAGE > ADJUSTMENTS > INVERT

Downloadable File of the original images

Downloadable File of the invert images

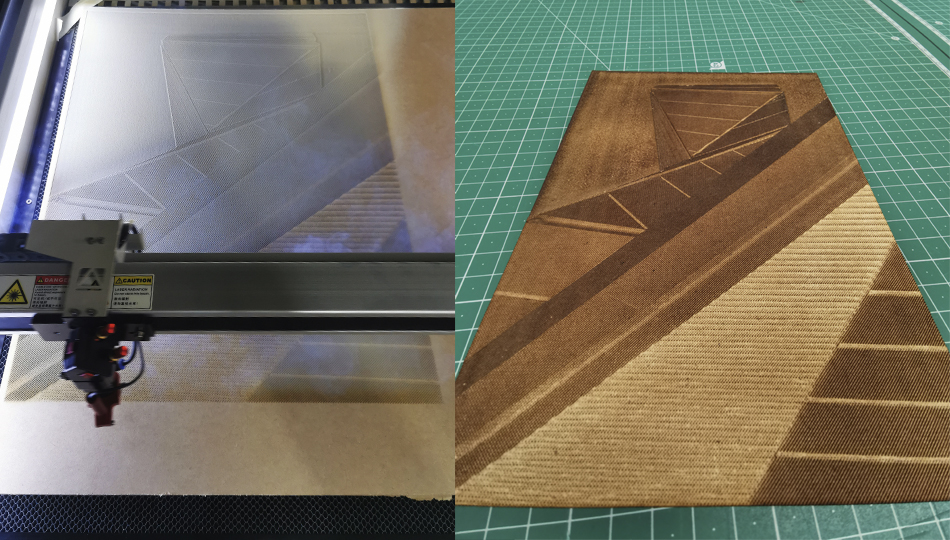

Then in the RDWorksV8 program use: HANDLE(W) > BITMAP HANDLE when you are in that window, select the size, material and imported back to the laser

Downloadable File Bitmap images

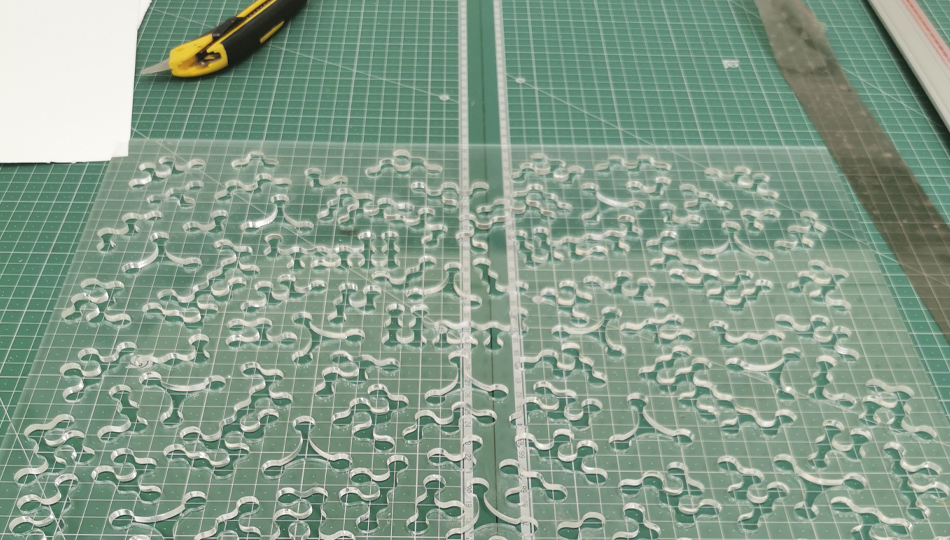

Preparing the matrix¶

I have used a 4mm thick MDF wood board

For the engraving:

Speed(mm/s): 400.00

MnPower(%)-1: 35.00

MaxPower(%)-1: 35.00

For the cut:

Speed(mm/s): 25.00

MnPower(%)-1: 70.00

MaxPower(%)-1: 75.00

Once we have the piece of engraved wood, it is ready to remove all the dust and that it does not have anything external that could affect the surface.

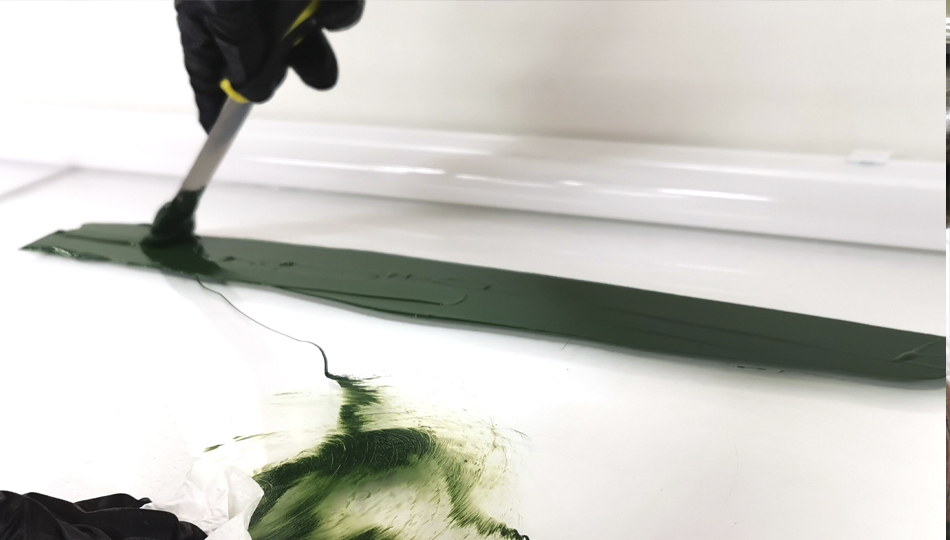

Preparing inks¶

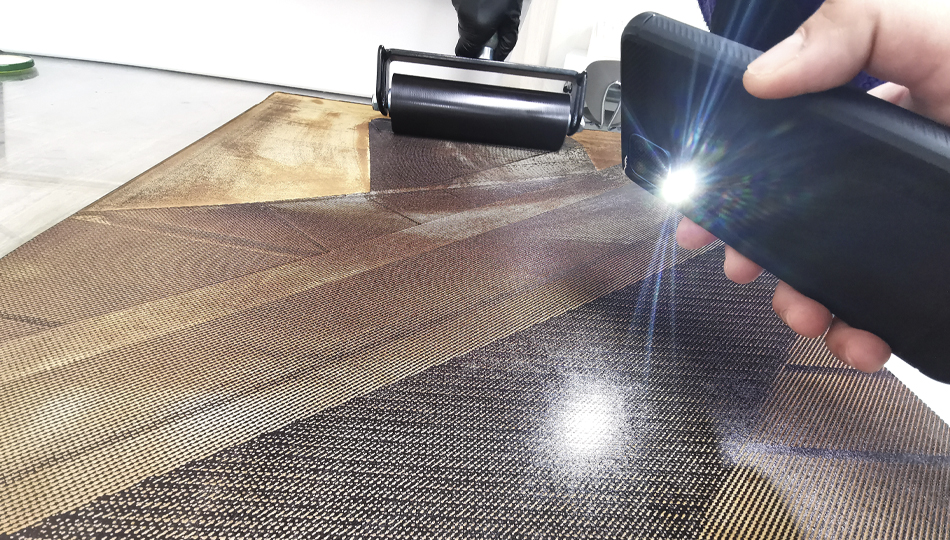

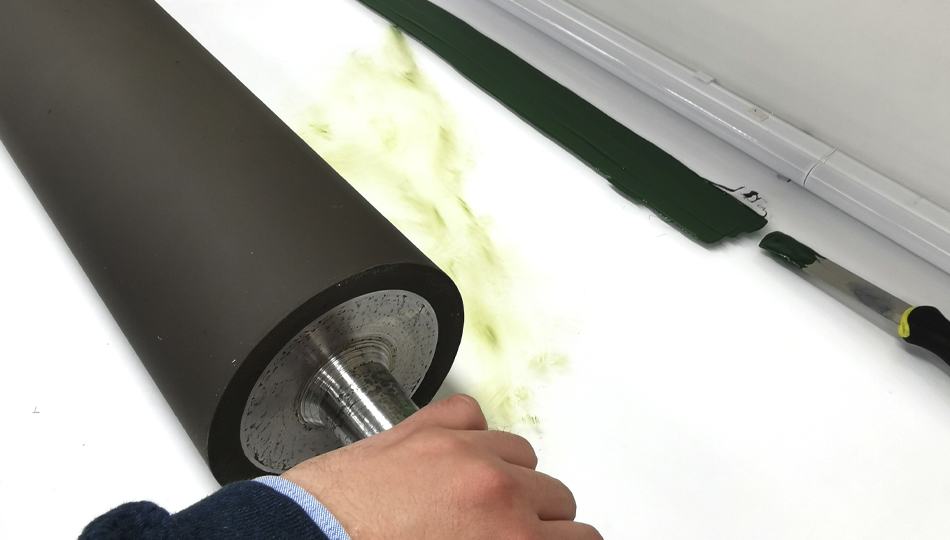

You will need a leather roller, Novavit® BCS BIO INTENSIVE is a modern series of highly pigmented basic colors for sheetfed offset. It is based on renewable raw materials and is semi-fresh., printing sponges.

We have discovered that the fourth day is the best time to print, but when it is not possible to do so at that time, it can be moistened and gently sponged with water.

With the roller perfectly impregnated with ink, you pass it over the way of engraving first horizontally and then in the other direction. To check that the entire surface is well impregnated, it is good to use a beam of light, we have used the mobile flashlight but you can use any lamp.

Press¶

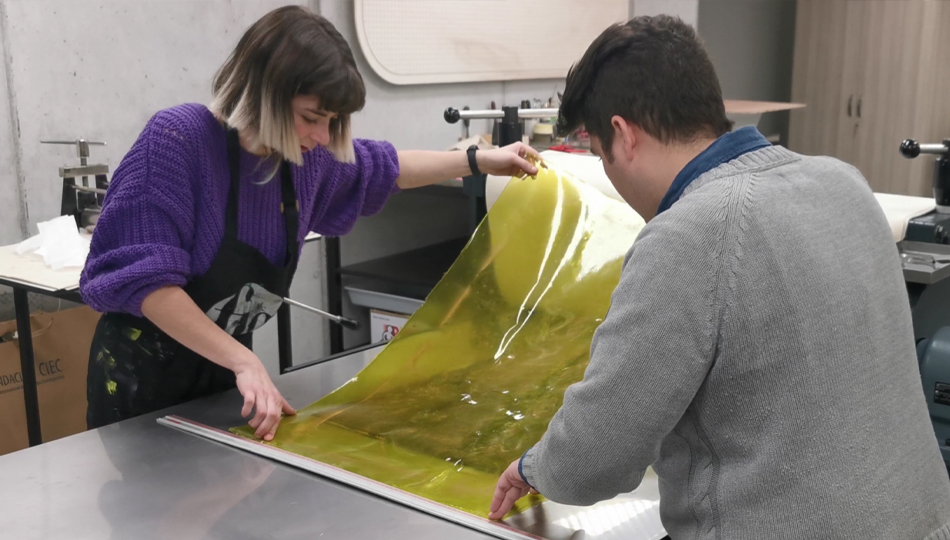

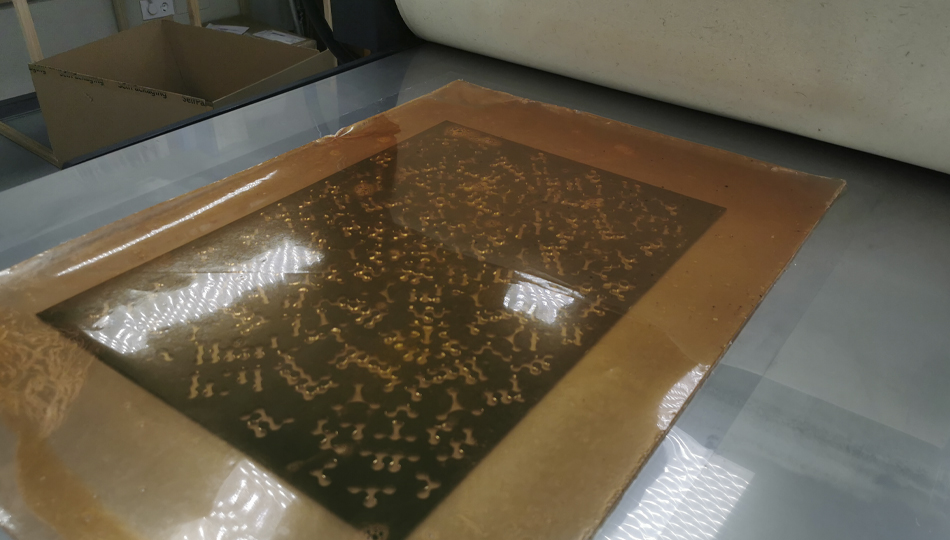

After we have the engraving ready we put it in position on the etching press.

We position the biomaterial on top of the engraving

Then, before passing it through the press, we put a protective felt on all the layers.

Before passing it through the press, it is important to check the pressure of the press as it can damage the biomaterial and the engraved wood. But after that check everything is ready to go through the press and develop the lithograph.

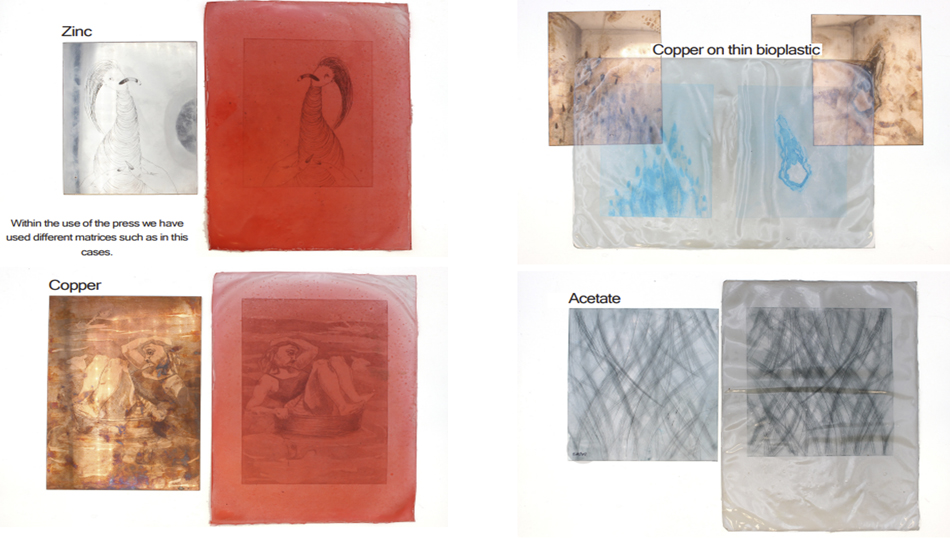

Different matrix¶

To give a new use to the mold where I made the silicone figures, I thought that I could add texture to the bioplastic, also as both repel the ink a little, they could give me different shapes and give richness to the print.

Downloadable File of the Matrix

You will need a rubber roller, Novavit® BCS BIO INTENSIVE is a modern series of highly pigmented basic colors for sheetfed offset. We add a transparent base to camouflage with the bioplatic.

To add the ink to the glass slab or smooth stone, pick up a small amount with a brayer and beging to roll out.

Continue to add ink and roll out in small quantities. when the ink is roller out, the surface is smooth and velvery, and the ink makes a “tacky” sound, it is readyto transfer.

this is the same process as the previous one, what changes is the matrix, so it is to place the matrix in its place, then use the registration marks to place the image well positioned, and then put a 200 micron acetate to protect the felt.

One very important thing that we have to take into account in order not to damage the matrix or the bioplastic is to have the pressure of the press correctly measured.

When you have checked everything you have put the felt and you can pass it through the press.

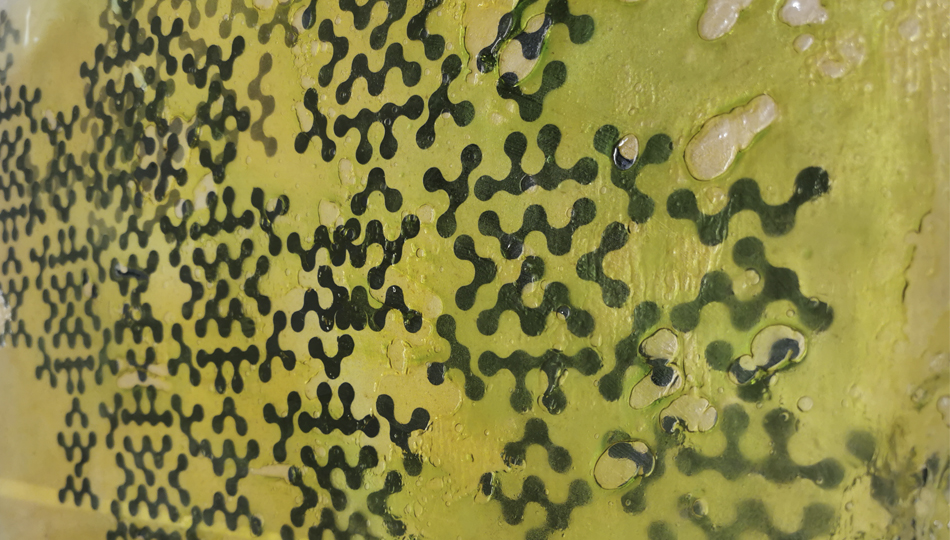

Very interesting the forms that helped it to form, because the greasy inks were repelled with the materials.

ScreenPrinting¶

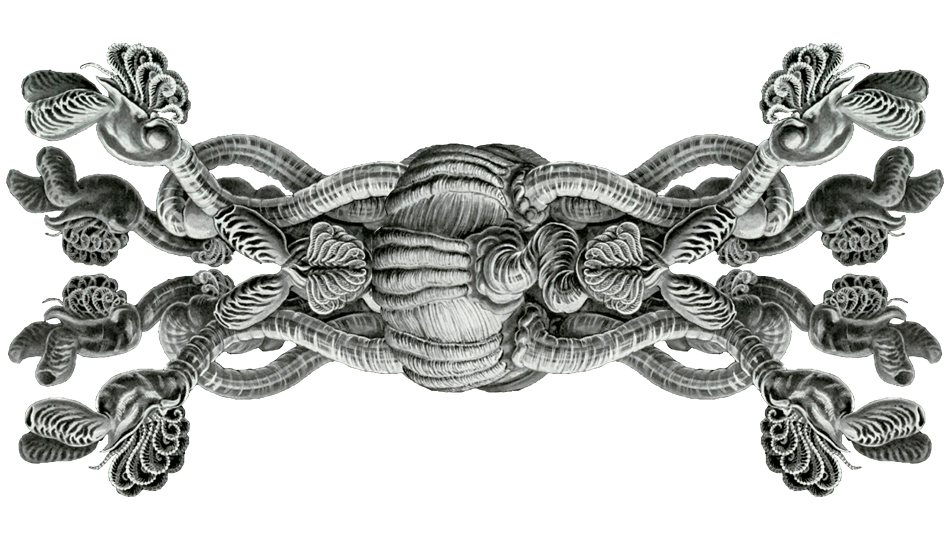

My skills as a graphic designer have helped me to experiment in this field since I have been in screen printing workshops and I know what I needed to print and what the ink could give me. Going through an experimentation in “In Crescendo” where I started silk-screening the biomaterial with conventional inks and screens with several threads where I wanted to know how long it could give me definition, then when I saw the variety of definition I was already experimenting with the ink and then I was adding bio-inks , to then change the acramine for bioplastic and although there is still a lot of experimentation left to do, I can draw a conclusion and that is that a world with inks without microplastics is possible, inks that we can make at home.

In addition, it could have a very important utility in art and advertising since, for example, in events and congresses these inks could be used to screen print and when finished, the fabric could be washed and used as the beginning, thus recycling the materials.

Downloadable File of the photolith

I have created a collage of several Ernst Haeckel illustrations to create a photolithograph. To create it, I converted it into a bitmap with a suitable dither for the screens I was going to use.

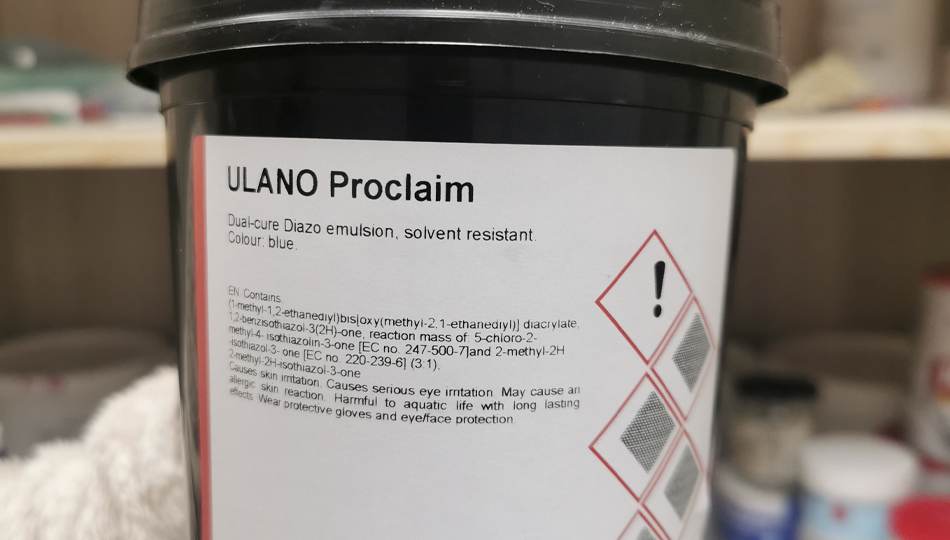

Fill the scoop-coater. Starting from the bottom of the screen on the back, tilt the scoop coater-up with the emoulsion touches the screen. Pull the scoop coater-up with firm pressure to deposit a thin flim of the emulsion oon the screen

We have used a ULANO PROCLAIM emulsion preparation whose high resistance to solvents provides superior results with solvent-based or conventional UV inks.

Using an insolator for screen printing, which in the lower part has to dry the screens that on some occasion I have also used to dry biomaterials.

Transparecies are placed on the glass and the screen is positioned on top. A “blender” cord placed over the screen frame helps create a tight suction. The exposed screen is rinsed in the backlit washout booth.

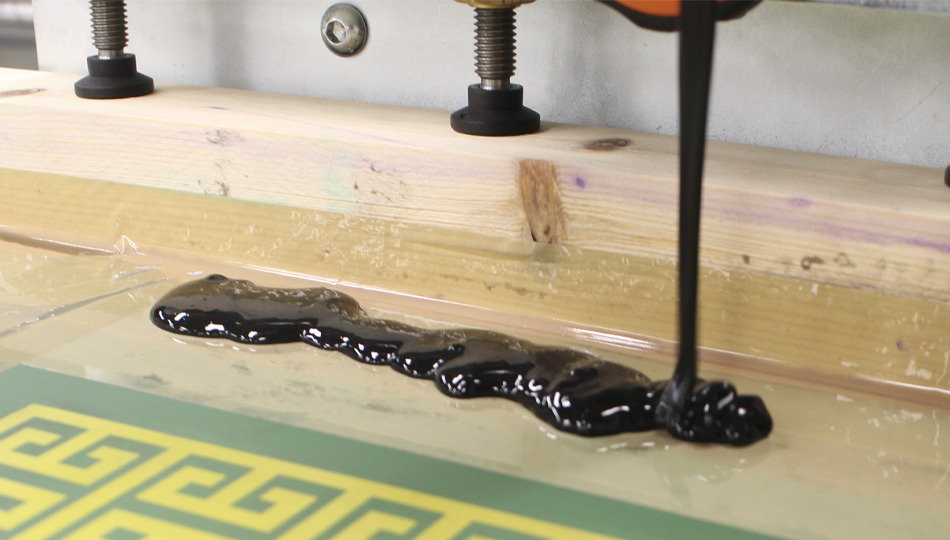

Place the screen on a stable surface, where you can make some registration marks and check that everything is in the place you want. Places the ink on one part of the screen and spreads the ink evenly across the screen.

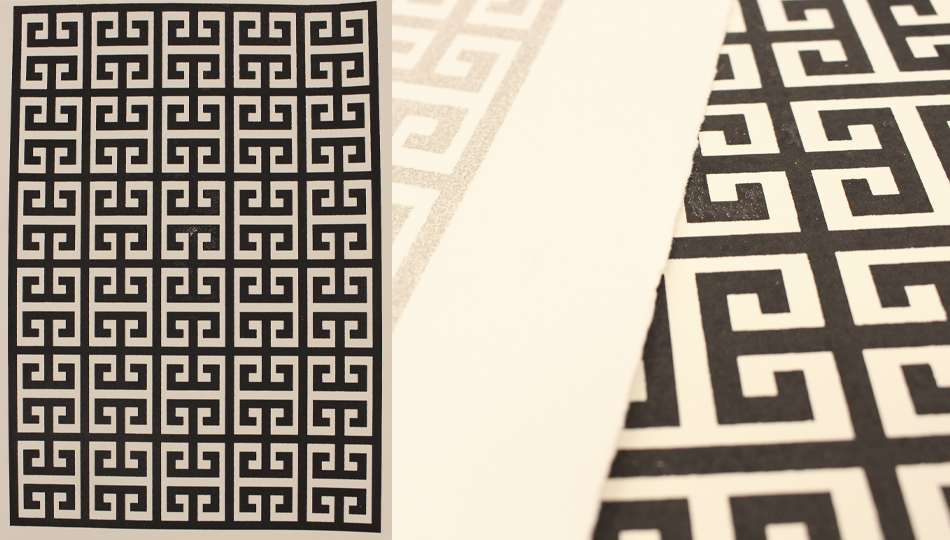

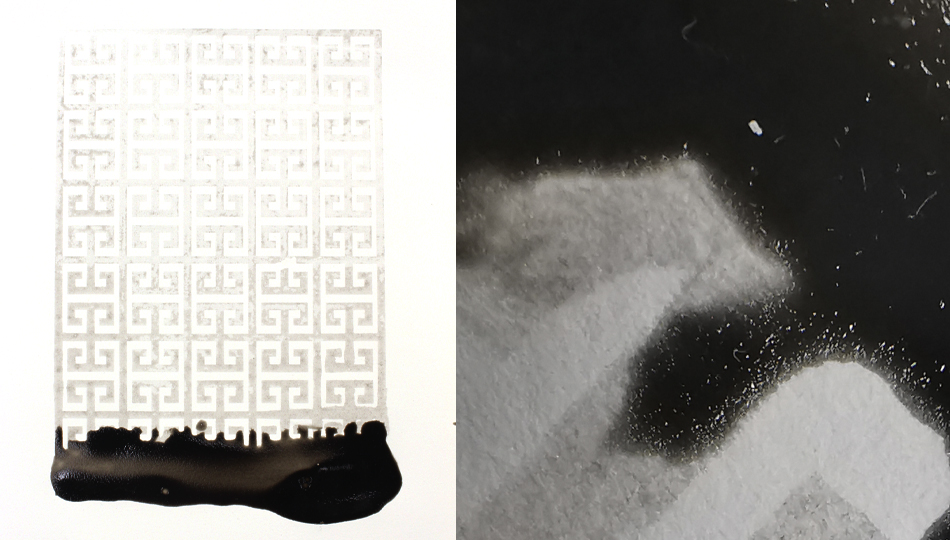

After several attempts we have seen that the impressions should always be made in the roughest part of the biomaterial and in the smoothest and brightest part the image is quite clear and defined. Just because I wanted definition in the stamping I used conventional acramines. But my goal is also to eliminate these inks and to be able to use bioinks also for more defined images.

For this silkscreen, I used a 77 thread count. Which gives me an acceptable definition could still give me even more definition. For this silkscreen, I used a 120 thread count. Which gave me great definition and detail. I recommend using this type of screen because it has very good results.

Proportions¶

For my second experimentation with screen printing, it has been the implementation of naturally extracted pigments and adding them to a commercially sold organic transparent base that considerably reduces microplastics. The proportions fot the mix was 80% transparent base acramine and 20% dryed carrot pigment

We have set up the tables in a classroom to work more efficiently and quickly, because we did not know how these inks would work on the screens, but they dried very slowly, which allowed us to finish all the meters of fabric without washing the screen, which is not enough. frequent and as a tip we already know that at least Biotinta has served as a retardant.

Although it is very good that the ink does not dry on the screen quickly, that means that the fabric does not dry either, so it takes 3 weeks to dry, a commercial ink takes about 1 hour to dry. It is not a bad thing but it is something to take into account when working and arranging the space.

Proportions of BIOINK

Carrot pigment75ml

Water 25ml

Squid ink 36gr

water 25ml

Graphite 2gr

water 100ml

with graphite it is important to know that it repels water, so don't worry if it looks weird at first, then with glycerin and gelatin it mixes well, but it solidifies almost instantly so be careful.

This is an experimentation where I was able to incorporate Bioplastic as ink for screen printing, on fabric, paper and bioplastic itself. As an important note is that following the recipe that I showed you I was able to create a smooth and concise layer that crossed the screen and could be reflected on any surface. At the moment with this ink you can only use the screen 2 times before washing as it dries almost immediately and clogs the screen.

The texture we are looking for is that of Greek yogurt that is creamy and viscous. At the time of cooking the mixture, once you see that everything is united and ready, lower the heat to the minimum possible and continue until it begins to have the texture without cooling.

With this ink it is important NOT to refill the ink screen before stamping, but once you add the ink to the screen you stamp directly on the surface.

On any surface it works very well, add a very thin layer of bioplastic. This is achieved by using a silkscreen of 43 thread count.

To make the ink last a little longer and not clog the screen, you can add a little heat with a hair dryer or heat gun. But so far we have achieved 2 and a half prints.

f we put the ink still very liquid this could happen, where it runs down the screen and spreads over the surface.