10. Open Source Hardware - From Fibers to Fabric¶

Research & Ideation¶

Goal for the week: Hack Ender into a biomaterial printer.

We have used Rexflexlab 300CC-Extruder as a follow along, but we have added slight changes. We wanted to achieve the same result as shown in the video bellow.

Our goal was to build a new hardware called 3D extruder to experiment with 3D printing using biomaterials. I have to give BIG credits for this documentation to Shushanik and Marieke, both were assigned to make notes and keep structer and did a great job. If you want to see the whole process, please check Marieke'sdocumentation. This is just a short addition to hers documentation by some files

For this purpose, we needed to focus on building a hardware by combining the following machines: • 300 CC BioMaterial Extruder • 3DPrinter-Ender 3 Parallel to building the hardware , we needed to find the right bioplastic material recipes to make sure it has an ability to hold the shape!

Here below you can find our pdf with all the steps we followed

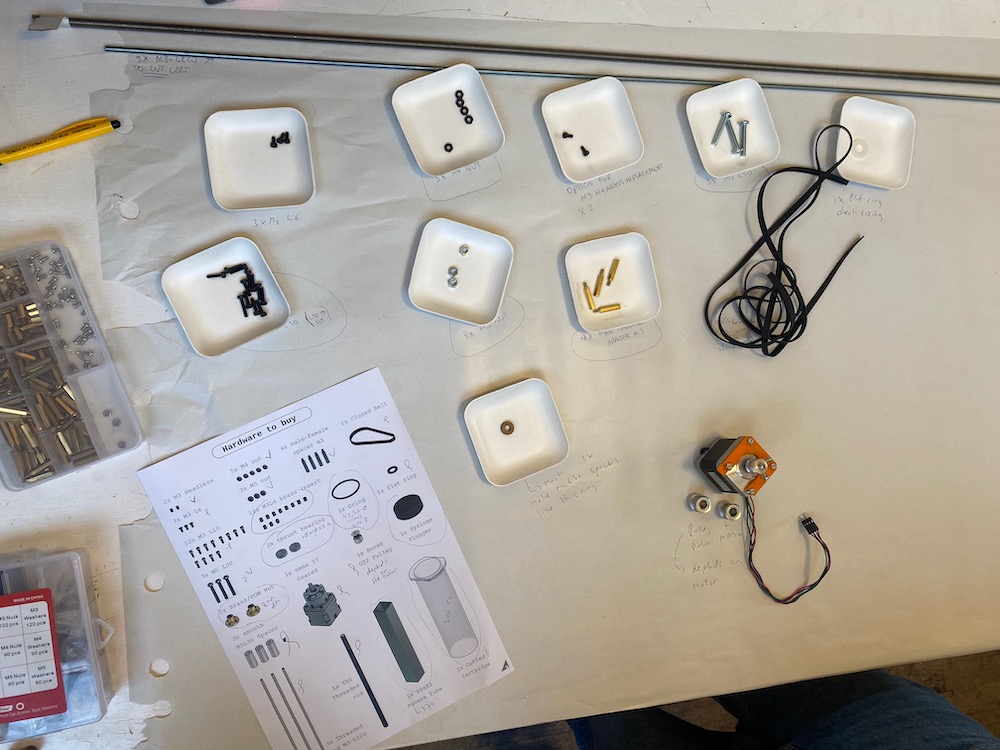

Below is a picture of our brainstorming while checking the parts we would need to build the machine, we were able to use something Textilelab Amsterdam already had, but many other elements we had to order or buy.

THE team :)

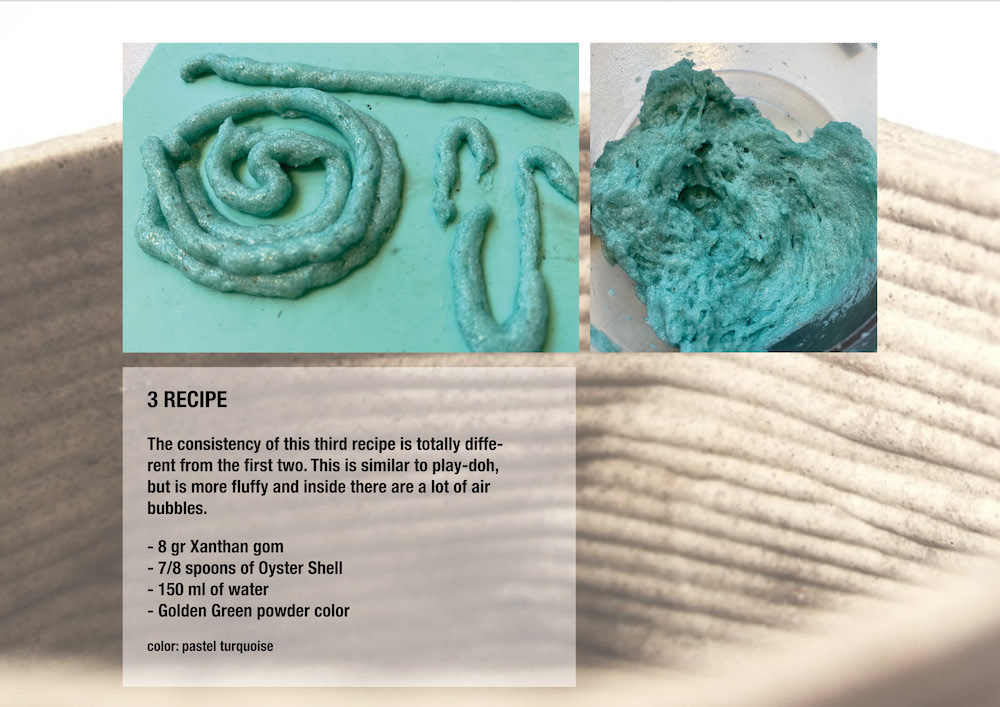

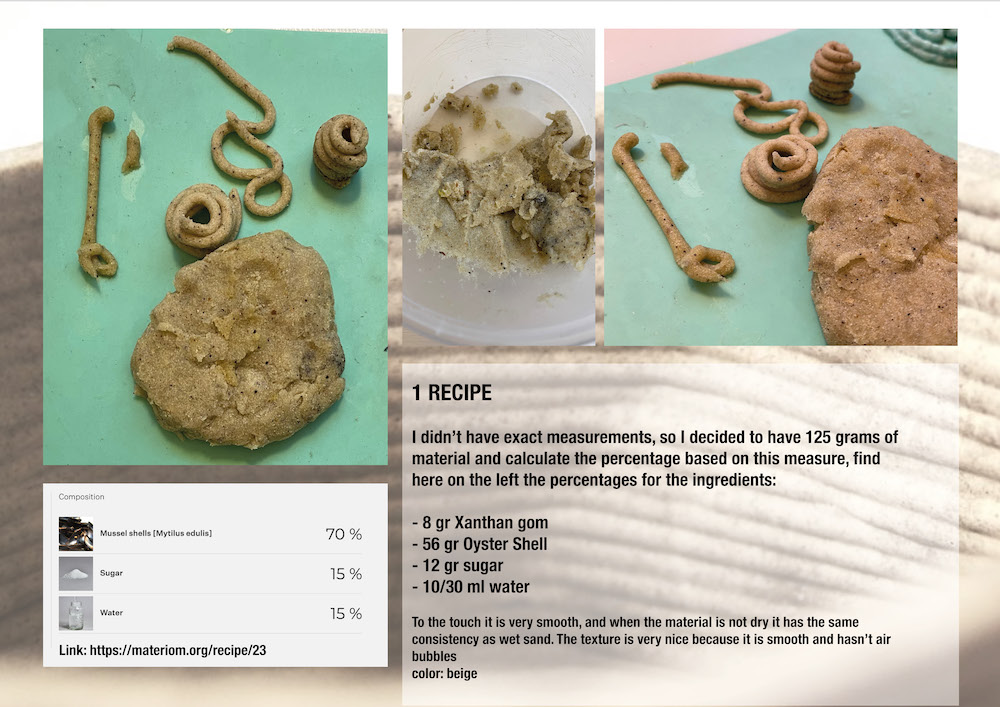

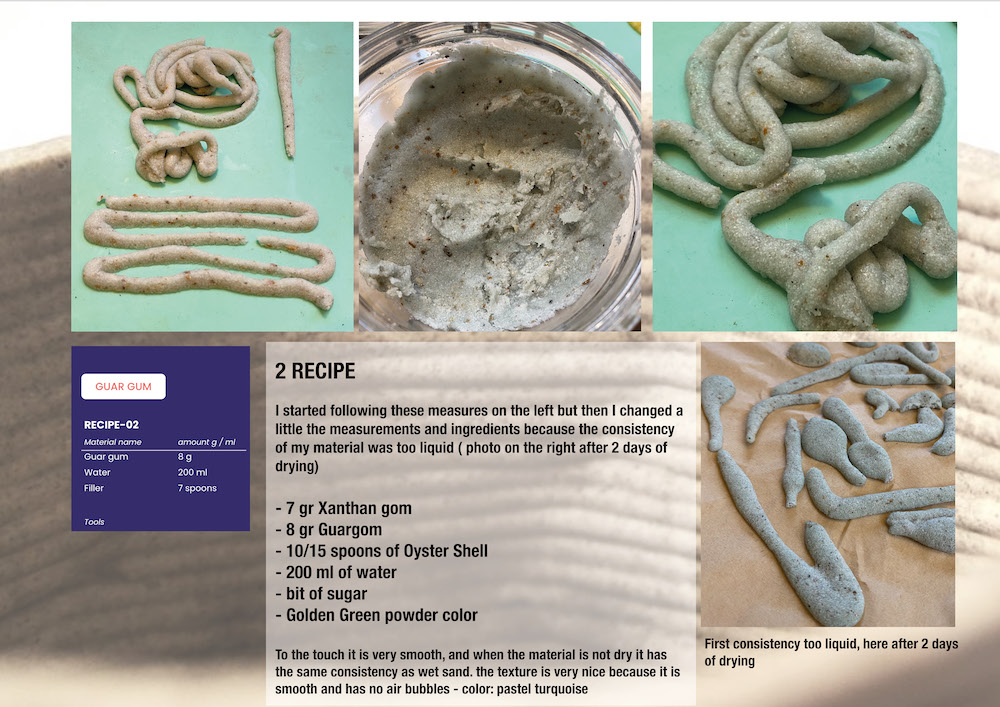

I gave support to building the hardware but especially I focused my attention on the development of our bio-material. It was not easy to find a good balance of texture for my bio material. After some research on the web, I'll put some interesting links below, I realized that it might be a good idea to use xantham gum, which would give a solid consistency and moldable texture to the material.

- Oyster Shell | Alginate Composite 3D print

- Eggshell paste for 3d printing

- Mussel shell - sucrose composite

Testing Biomaterials :)

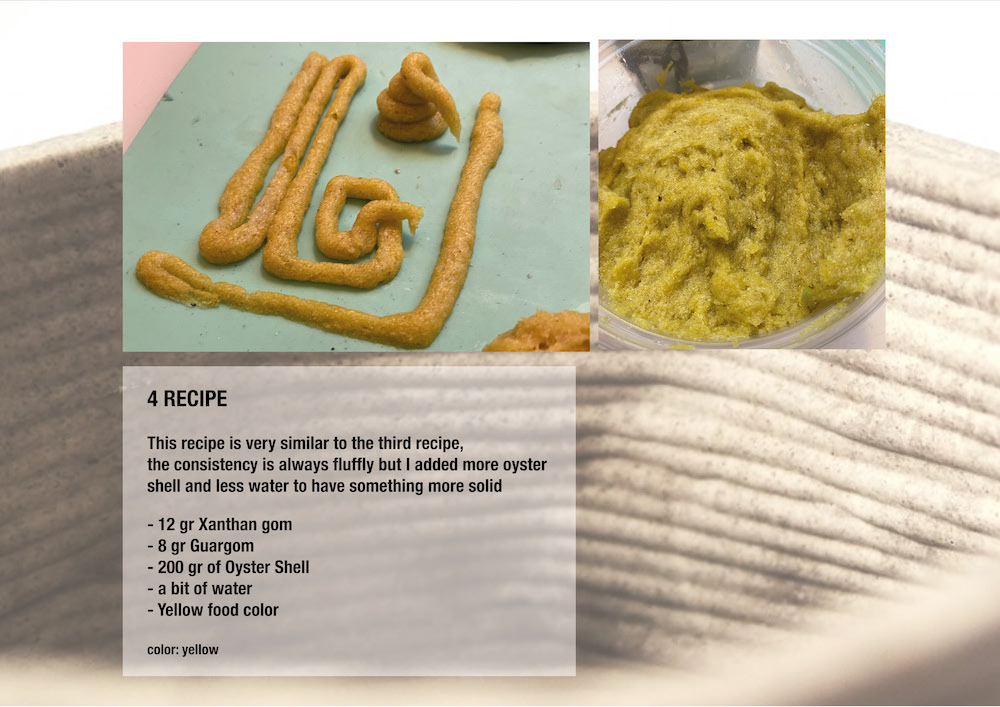

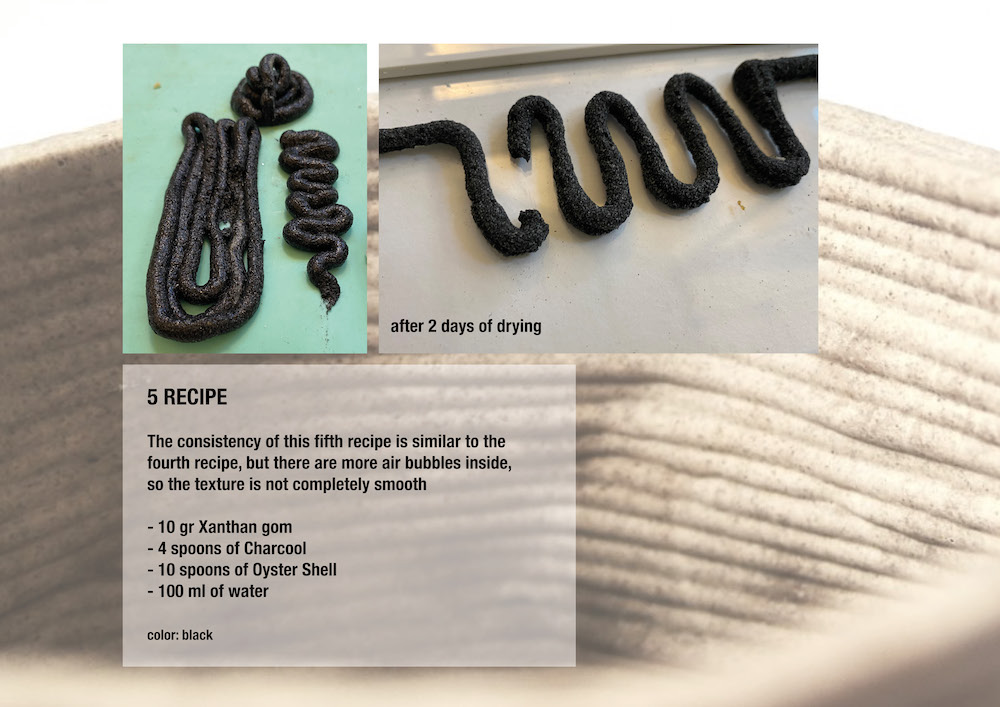

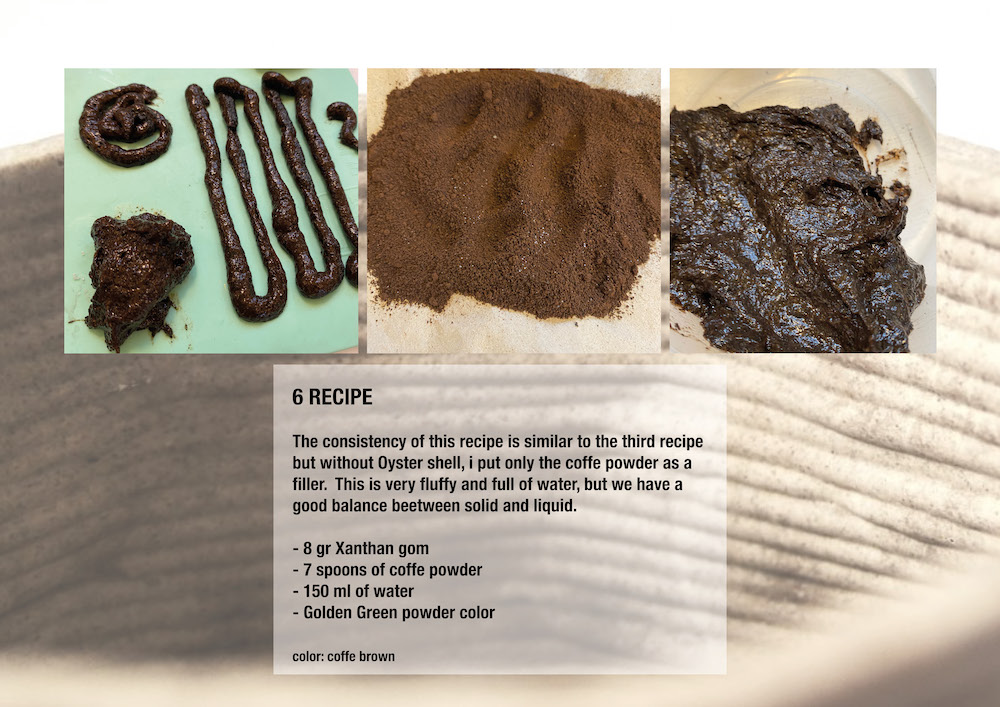

Below are some recipes I have made during the week.

I got the best result with recipe number 2, the consistency was very firm and when dry very strong and solid.

Here is a little video of us testing the plunger that should push the material down the bottle.