6. BioFabricating Materials¶

It's the week when officially I joined the team. The week that while I worked on the creation of biomaterials, I recovered from previous homework. Stressful, exciting? Yes! And I forgot to mention that with my acceptance to Fabricademy I had to give up other activities and reorganize my schedule of the day, the schedule of the week. Will I succeed? I will see it along the way :) ... but let's get back to Biomaterials. They're fantastic!

Research¶

Biomaterials are in my interest area, but is the first time then I create them.

Let begin with the research!

For the beginning I will mention about the researches done previously: the bambus.

Bamboo is the multifunctional fiber that revolutionized the textile industry, which leads to the need to conduct studies that would confirm or not the assumptions about its multiple advantages.

A group of researchers from Portugal conducted studies of 3D textile structures of different composition. Bamboo, cotton, polyester and bioactive polyester in proportions from 14 to 72%. 72% antimicrobial fiber spacing, such as bamboo, was not active against the tested micro-organisms, while flattened knitted fabrics made from the same yarn were effective against E. coli, P. aeruginosa and T. rubrum. Textiles subjected to testing are recommended for use as lining material for footwear.

In another study, bamboo raw materials obtained from the Anhui Taiping test center of the international bamboo and rattan center were tested. The outer and inner layers of bamboo were removed, and then cut into blocks of 10 mm. All the blocks were washed with ultrasound with deionized water and alcohol for 30 minutes at room temperature. To remove the impurity inside the bamboo structure, all samples were vacuum impregnated under water several times and then dried for 24 hours at 60 °C in vacuum. The obtained samples were subjected to antibacterial testing by the bacteriostatic circle method, with the purpose of observing the growth inhibition properties against Gram-negative bacteria (E. coli) and Gram-positive bacteria (B. subtilis).

Studies investigating the antimicrobial functionality of bamboo fiber were conducted on samples obtained from bleached bamboo material. The samples were incubated at 37 0C for 18 to 24 hours. A clear area of inhibition was observed for both tested microorganisms: E. coli and S. aureus.

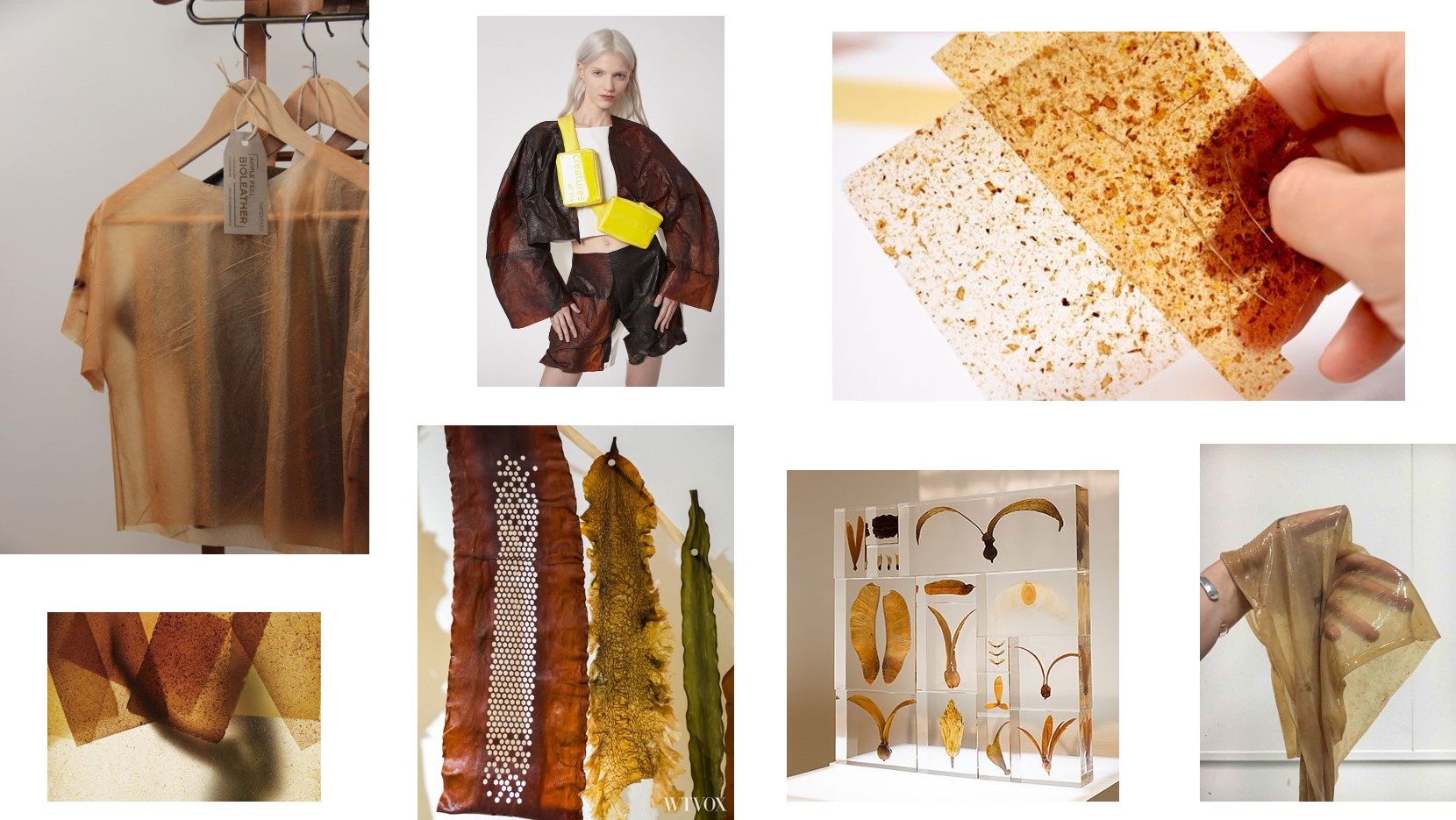

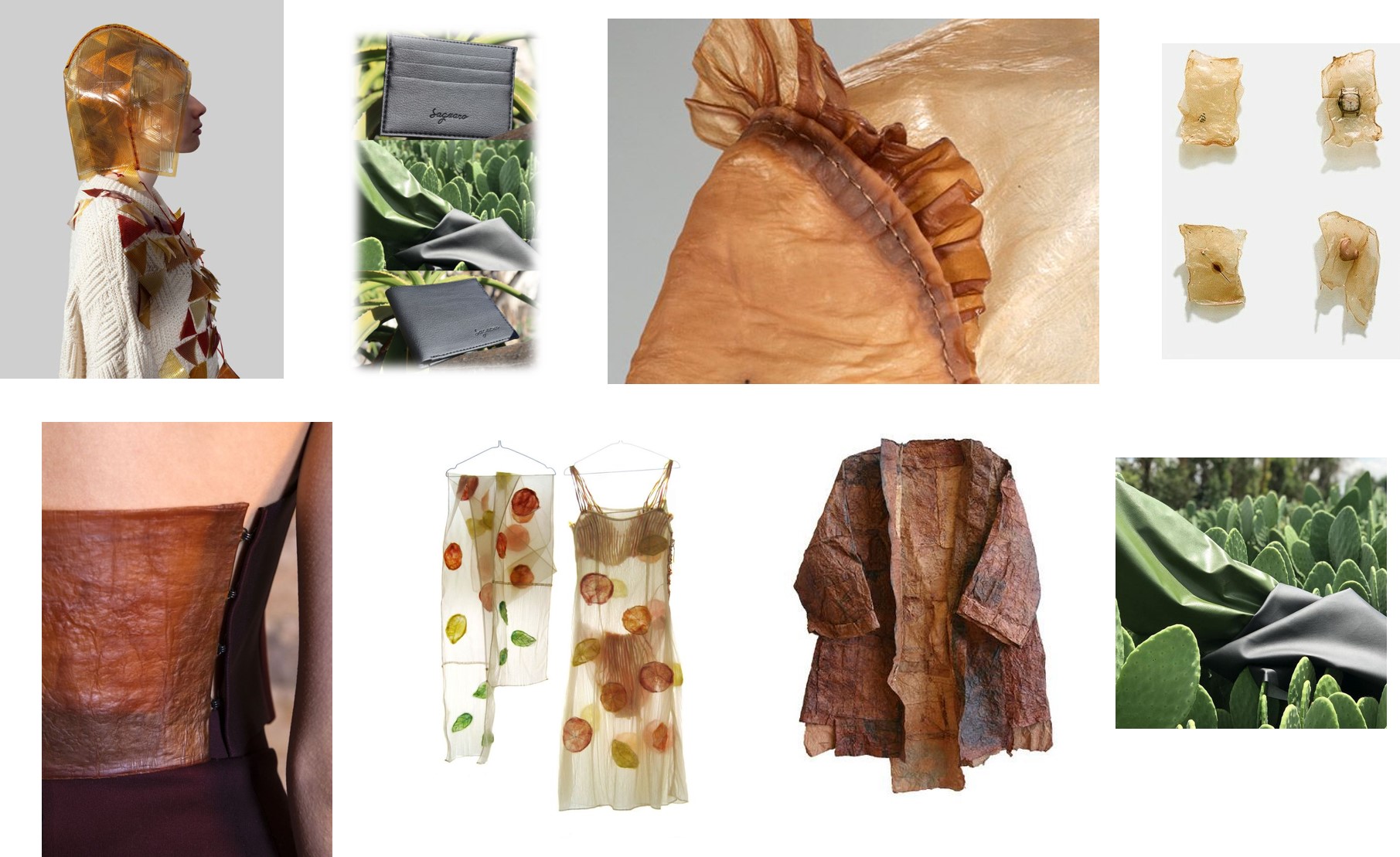

Because in Republic of Moldova we don't have raw material for create bambus textiles, I continued theoretical reasearches from what and how can the biomaterials be created at our local level. My Internet searches took me to Pinterest. In Republic of Moldova we don't have specialist in this domain, so all we have to do is to get inspiration from specialists abroad.

Biomaterials from diverse raw materials have been created around the world. The most common are used: banana peels, orange peels, cactus, egg peels, apple peels, seaweed etc.

References & Inspiration¶

For more inspiration I browse other participant’s pages of Fabricademy 2021-2022: Isabel Alert; Annah Sangosanya; Julie Merlino;Marie Desforges and Thomas Laetitia.

... and more inspiration from Pinterest

Overview material research outcomes¶

As a conclusion I will mention the advantages of BioFabricating Materials:

-

biofabrics are considered sustainable;

-

they are eliminating harmful chemicals and reducing water usage;

-

they reduced energy use and carbon emissions;

-

they are actively reducing waste.

Process and workflow¶

With some ideas together as a team, we experimented and created BioMaterials!

The tools and ingredients needed for this week ... that's what can be found in any kitchen.

Other necessary materials and ingredients will be mentioned during the description of each recipe.

I. Bio foam - mixture in witch the main element is soap. Prepare this recipe - bio foam - by collecting the ingredients necessary, to be found in the list below::

* gelatin powder - 48 gr

* glycerine - 8 gr (brittle);

* water - 240 ml

* table spoon soap

* cinnamon

* pigments

* spoon, tongs, wisk;

* stove;

* pots, jars;

* scale;

* molds, textiles, textures, etc

* Warm water in a pot.

* Warm water in a pot on the stove (water can be plain or already dyed).

* Add the Glycerine.

* Add the Gelatine.

* Mix gently the ingredients until a smooth mix.

* Boil for 15-20 min at 80-86ºC max whisking constantly.

* Prepare Molds.

* If you are paling to use multiple colors, prepare them in jars.

* Once it becomes thicker like a syrup, mix your colours on the jars and gently cast in moulds.

* Let it dry on a ventilate and dry room.

A small part of the process in the video that follows.

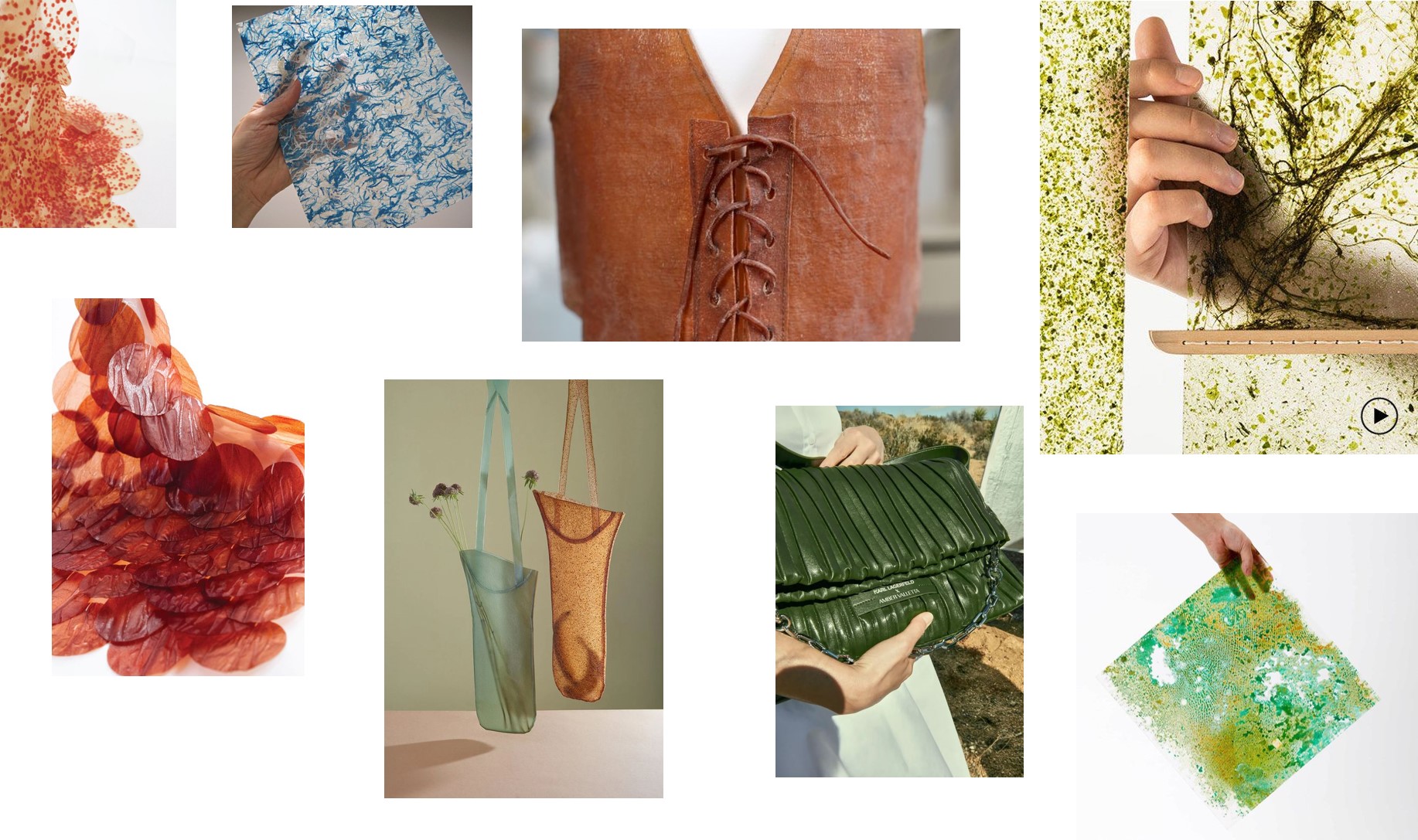

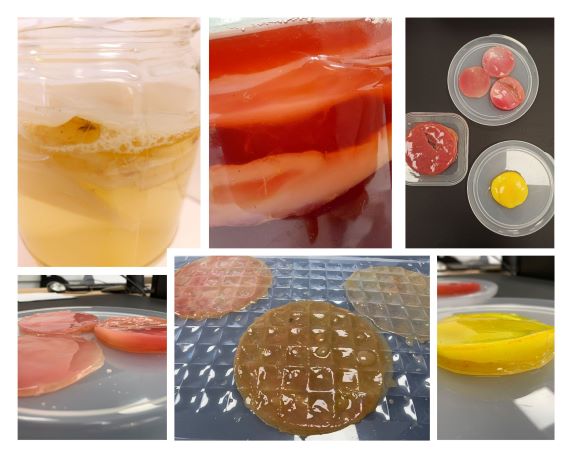

II. Agar. Prepare this recipe - agar - by collecting the ingredients necessary, to be found in the list below::

* agar-agar powder - 4 gr

* water - 100 ml

* glycerine - 0 gr (brittle);

- 5 gr (semi-flexible);

- 14 gr (flexible).

* pigments - zero

- little;

- mediu.

* flowers, peels, etc.

* cinnamon

* spoon, tongs, wisk;

* stove;

* pots, jars;

* scale;

* molds, textiles, textures, etc.

* Warm water in a pot

* Add the Glycerine

* Add the Agar or Agar

* Mix gently at 60 ºC so that Agar is dissolved with the Glycerine.

* Simmer more for 80ºC.

* Prepare Molds.

* Prepare your colours in jars.

* Once it becomes thicker like a syrup, mix your colours on the jars and gently cast in moulds.

* Let it dry on a ventilate and dry room

What I managed to film from the trial ... in the video what follows.

III. Gelatine. Prepare this recipe - gelatine - by collecting the ingredients necessary, to be found in the list below:

* gelatine powder - 48 gr

* water - 250 ml

* glycerine - 0 gr (brittle);

- 24 gr (semi-flexible);

- 48 gr (flexible).

* pigments

* flowers, peels, etc.

* cinnamon

* spoon, tongs, wisk;

* stove

* pots, jars;

* scale;

* molds, textiles, textures, etc

* Warm water in a pot on the stove

* Add the Glycerine

* Add the Gelatine

* Mix gently the ingredients until a smooth mix

* Boil for 15-20 min at 80-86ºC max whisking constantly.

* Prepare Molds.

* If you are paling to use multiple colors, prepare them in jars.

* Once it becomes thicker like a syrup, mix your colours on the jars and gently cast in moulds.

* Let it dry on a ventilate and dry room

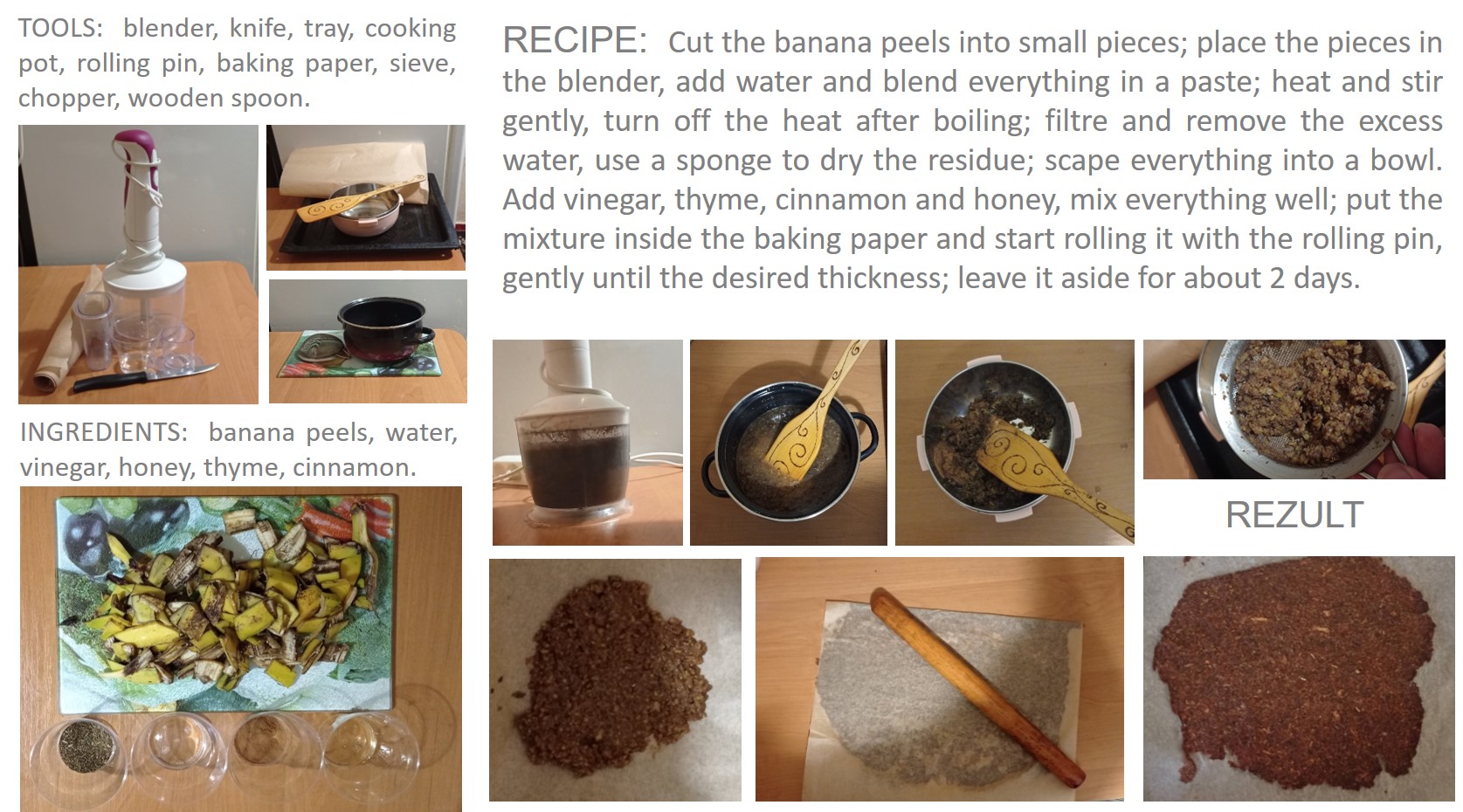

IV. Banana leather. Prepare this recipe - banana leather - by collecting the ingredients necessary, to be found in the list below:

* banana peels - 70 gr;

* water - 250 ml;

* vinegar - 25 gr;

* honey - 5 gr;

* thyme - 1 gr;

* cinnamon - 1,5 gr.

* blender;

* spoon, tongs, wisk;

* cooking pot;

* wooden roller and baking paper;

* sieve, etc

* Cut the banana peels intro small pleces;

* Place the pleces intro the blender, add water and blend everthing intro a paste;

* Heat and stir gently, turn off the heat after boiling;

* Filter and remove the excess water, use a sponge to dry the residue;

* Scape everything intro a bowl. Add vinegar, thyme, cinnamon and honey, mix everything well;

* Put the mixture inside the baking paper and start rolling it with the wooden roller gently until the desired thickness;

* Leave it aside for about 2 days;

V. Kombucha fermentation. The ingredients necessary, to be found in the list below:

* tea - 7 gr

* sugar - 70 ml

* water - 1 l

* glass bowl;

* spoon;

* sun rays, etc.

* The Kombucha development started from June from a small Kombucha scoby.

* Along the way it was devided into several parts.

* 24H before the Kombucha was taken out and put to dry we prepared hibiscus and sweet turmeric tea.

What the kombucha looks like after it has dried up in the urning picture.

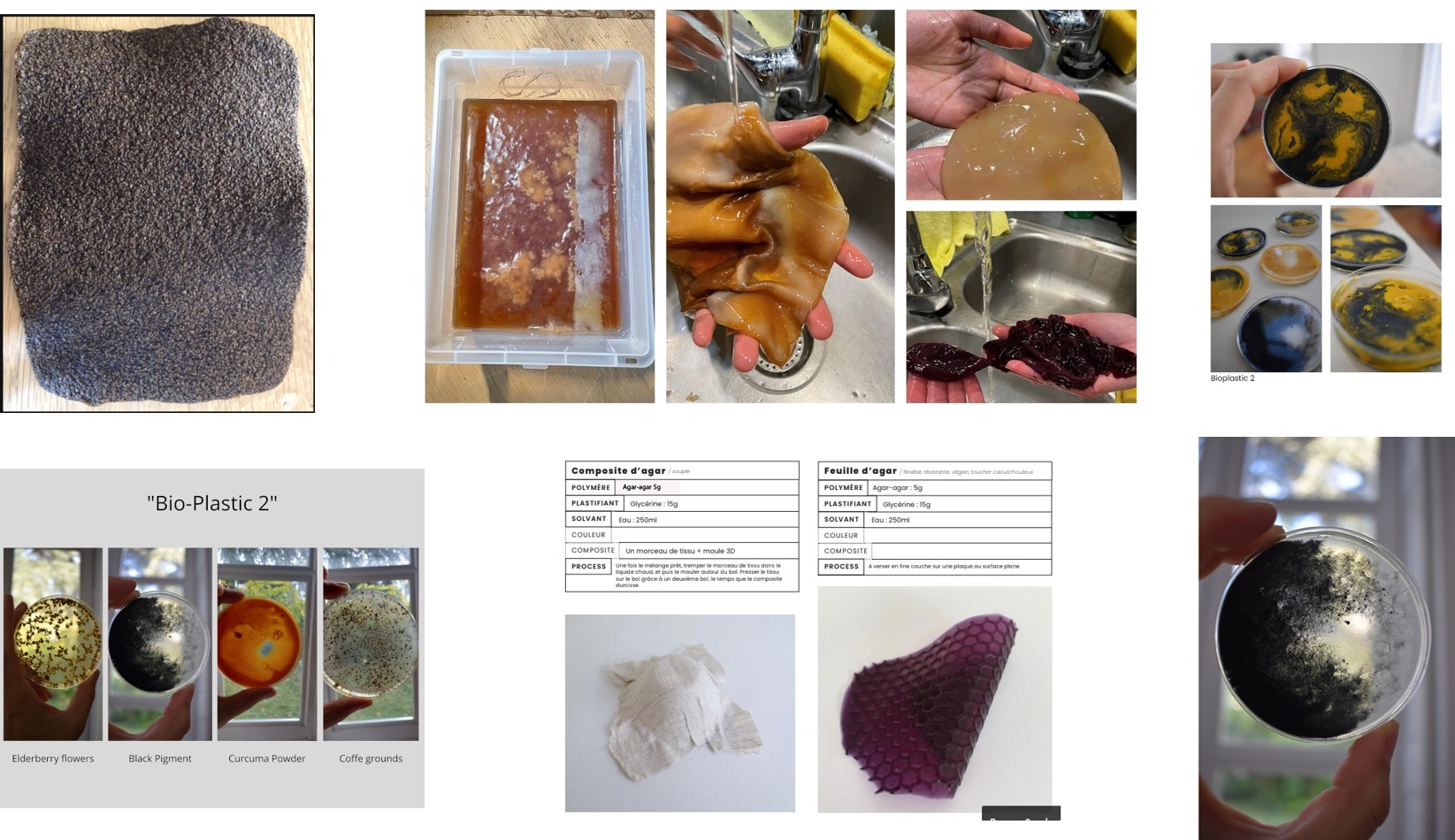

Documenting and comparing experiments¶

| Material pic | Material name | polymer | plastifier | filler | emulsifier |

|---|---|---|---|---|---|

|

bio-foam | gelatine powder 48 gr | glycerine 8 ml | green soap a drop | egg shells |

|

bio-material agar | agar-agar powder 4 gr | glycerine 0 ml | water 100 ml | green pigment 0 gr |

|

bio-material agar green | agar-agar powder 4 gr | glycerine 5 ml | water 100 ml | green pigment 2 gr |

|

bio-material agar GREEN | agar-agar powder 4 gr | glycerine 14 ml | water 100 ml | green pigment 15 gr |

|

bio-onion skins | gelatine powder 48 gr | glycerine 24 ml | water 250 ml | onion skins |

|

bio-flower petals 1 | gelatine powder 48 gr | glycerine 24 ml | water 250 ml | flower petals |

|

bio-flower petals 2 | gelatine powder 48 gr | glycerine 24 ml | water 250 ml | flower petals |

|

bio-coffee | gelatine powder 48 gr | glycerine 24 ml | water 250 ml | coffee |

|

bio-foil | agar-agar powder 3 gr gelatine powder 29gr | glycerine 15 ml | water 400 ml | tea leaves |

|

bio-silicone | gelatine powder 48 gr | glycerine 24 ml | water 240 ml | orange pgment 1 gr |

|

red bio-plastic | agar-agar powder 4 gr | glycerine 12 ml | water 250 ml | red pigment 3 gr |

|

bio-resine | gelatine powder 48 gr | glycerine 8 ml | water 240 ml | coffee |

|

bio-green soap | gelatine powder 48 gr | glycerine 24 gr | water 250 ml | green soap a drop |

|

bio-banana | banana peels | vinegar 25 ml | water 250 ml | honey 5 gr |

|

bio-kombucha 1 | tea 7 gr | sugar 70 gr | water 1 l | sun |

|

bio-kombucha 2 | tea 7 gr | sugar 70 gr | water 1 l | sun |

All samples created SubT resistant, their rigidity / flexibility is determined by the ratio of bio-polymer and plasticizer, have a neutral smell, except bio-banana, which has an intense smell of cinnamon.

Details for some of the examples created are presented in the following video.

INDIVIDUAL WORK¶

I like to eat bananas, also, my family like them... so we had many banana peels that now can be transformed in biomaterials. Thus I repeted individually the recipe and I obtain other sample. I repeated the same recipe from group work.

After it dried, I gave it The Shape of a rectangle. The Bio-banana made by me you can see it in the picture and video that follows.

In future, certainly I will go over this experiment and than I would have enough samples, I will create an accessory or bag, or probably a cloth 😃

RESULTS¶

As a result of this week is the creation of an biomaterials library. Being a captivating theme, definitely the library would be completed with new samples in future.